Automotive Lidar Sensor Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440952 | Date : Feb, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Automotive Lidar Sensor Market Size

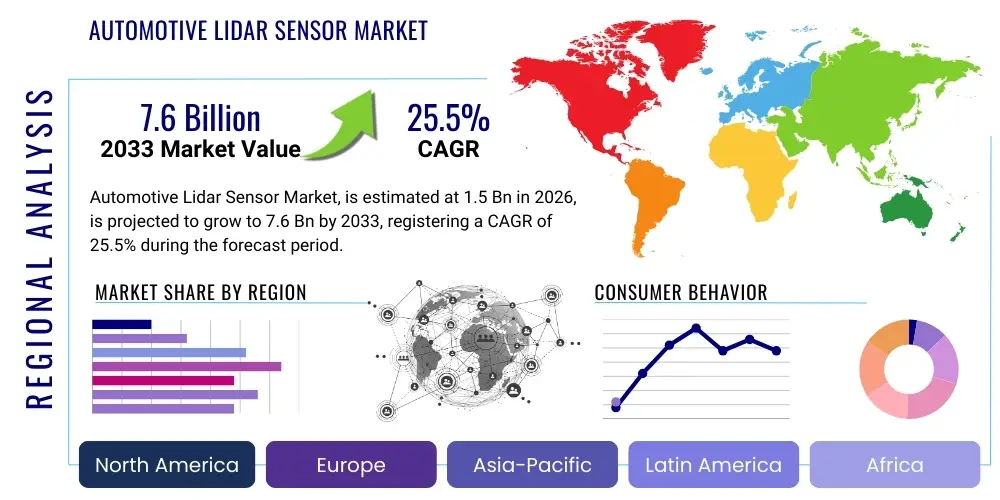

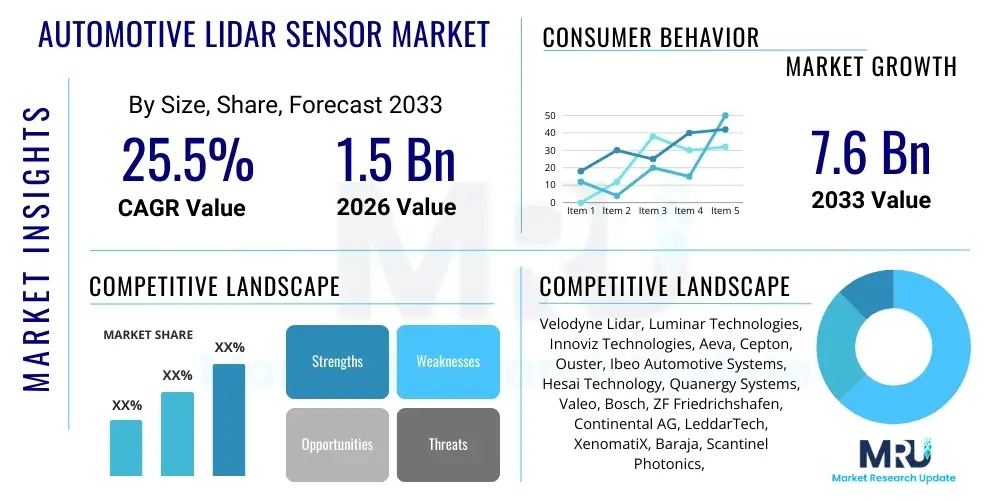

The Automotive Lidar Sensor Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 25.5% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 7.6 Billion by the end of the forecast period in 2033.

Automotive Lidar Sensor Market introduction

The Automotive Lidar Sensor Market encompasses the design, production, and deployment of Light Detection and Ranging (Lidar) technology specifically for use in vehicular applications, primarily focusing on Advanced Driver Assistance Systems (ADAS) and full autonomy (Level 3 to Level 5). Lidar sensors emit pulsed laser light and measure the time-of-flight (ToF) of the returned signals, creating high-resolution, three-dimensional point clouds of the surrounding environment. This comprehensive environmental mapping capability is crucial for accurate object detection, tracking, classification, and simultaneous localization and mapping (SLAM), offering a superior geometric understanding compared to traditional radar or camera systems, especially in variable lighting conditions.

Major applications of Lidar sensors include collision avoidance systems, adaptive cruise control, lane keeping assistance, automatic emergency braking, and, most critically, enabling safe, redundant sensor fusion stacks necessary for Level 4 and Level 5 autonomous driving. These sensors function as a core perception layer, providing the crucial depth and range information required for complex decision-making algorithms within the vehicle’s central processing unit. The ongoing shift from mechanical scanning Lidar to solid-state Lidar architectures, such as MEMS-based and Flash Lidar, is driving down costs and improving ruggedness, making mass adoption in consumer vehicles increasingly feasible. This technological maturation is rapidly transitioning Lidar from a niche technology used primarily in high-end testing vehicles to an essential component of the standard sensor suite across various vehicle classes.

Key benefits derived from integrating Lidar into vehicles include unparalleled precision in distance measurement, robustness against atmospheric interference like glare or shadows, and the ability to operate effectively regardless of ambient illumination. The primary driving factors fueling this market expansion are stringent governmental safety regulations promoting ADAS adoption globally, sustained high investments by automotive OEMs and Tier 1 suppliers into autonomous driving R&D, and significant technological breakthroughs leading to smaller, more reliable, and cost-effective Lidar units. Furthermore, consumer demand for enhanced safety features and the competitive push towards achieving fully autonomous vehicle capabilities are compelling manufacturers to expedite Lidar integration across their product lines.

Automotive Lidar Sensor Market Executive Summary

The global Automotive Lidar Sensor Market is characterized by intense technological competition and strategic vertical integration among component providers, software developers, and automotive manufacturers. Current business trends heavily favor the development and commercialization of solid-state Lidar solutions, which promise superior reliability, reduced maintenance needs, and manufacturing scalability necessary for high-volume automotive production. A critical trend involves strategic partnerships, mergers, and acquisitions, particularly where established automotive giants collaborate with Lidar startups to secure crucial technology access and influence standardization efforts. The focus is shifting from achieving maximum range to ensuring reliability, manufacturability, and performance validation under diverse operational environments, including adverse weather conditions and varying road types. Supply chain resilience, given the semiconductor component dependency, remains a pivotal business concern influencing investment decisions and capacity planning.

Regionally, North America and Europe currently represent the largest revenue share due to early adoption of advanced ADAS features, robust regulatory frameworks supporting vehicle automation testing, and the presence of leading autonomous vehicle technology firms. However, the Asia Pacific region, particularly China and South Korea, is anticipated to exhibit the highest growth rate during the forecast period. This acceleration is attributed to massive governmental support for electric vehicle (EV) and autonomous vehicle (AV) infrastructure, coupled with rapid technological adoption by domestic automotive OEMs focused on leapfrogging traditional automotive markets in automation levels. Regulatory clarity, or lack thereof, regarding Lidar deployment and autonomous liability remains a key factor dictating the pace of regional market maturity and penetration.

Segmentation trends highlight a pronounced shift towards Solid-State Lidar technology over traditional Mechanical Lidar, driven by the need for cost reduction and enhanced vehicle aesthetics (easier integration into vehicle bodies). In terms of application, the market is primarily led by Level 3 (Conditional Automation) applications, yet the fastest growth is projected in Level 4 (High Automation) systems as testing moves rapidly toward commercial deployment in controlled environments like robotaxis and logistics fleets. Furthermore, the segmentation by image capture method reveals strong interest and R&D in Flash Lidar and Optical Phased Array (OPA) technologies, which promise instantaneous image capture without moving parts, offering superior resilience and response times crucial for high-speed dynamic environments. The shift towards higher resolution and lower cost per unit is democratizing Lidar utilization across mid-range vehicle segments.

AI Impact Analysis on Automotive Lidar Sensor Market

User inquiries regarding the intersection of Artificial Intelligence (AI) and the Automotive Lidar Sensor Market predominantly revolve around three critical themes: Lidar data processing efficiency, the role of AI in sensor fusion, and the potential for AI-enhanced cameras or radar to displace Lidar entirely. Users frequently question how deep learning algorithms can manage and interpret the enormous volumes of point cloud data generated by high-resolution Lidar systems in real-time, seeking information on computational resource demands and latency reduction techniques. A major focus is on how AI integrates Lidar data with visual data from cameras and range data from radar to create a robust, holistic 360-degree environmental model, addressing the weaknesses inherent in individual sensor types. Furthermore, substantial user concern centers on competitive threats, specifically whether advancements in AI-powered vision processing, enabling cameras to accurately estimate depth, could eventually render Lidar superfluous or limit its role to purely redundant backup systems, thereby impacting Lidar market growth projections and pricing structures. The consensus is that AI is not a replacement but a necessary catalyst for Lidar effectiveness.

The application of AI, specifically machine learning and deep learning models, is fundamental to extracting actionable intelligence from the raw Lidar point cloud. AI algorithms are essential for tasks such as noise reduction, precise object segmentation (distinguishing pedestrians from vehicles or static infrastructure), and predicting the trajectory of dynamic objects with high confidence. This AI layer allows the vehicle's driving policy stack to move beyond simple environmental detection toward complex behavioral understanding and predictive navigation. For instance, sophisticated neural networks are trained on millions of miles of driving data to rapidly classify partial or occluded objects detected by Lidar, significantly enhancing safety margins, especially in complex urban driving scenarios where fast, accurate decision-making is paramount. Without advanced AI for perception, the high-fidelity data provided by Lidar would overwhelm traditional computational frameworks, rendering the sensor ineffective for real-time operation.

Consequently, the impact of AI is directly accelerating Lidar adoption by maximizing its operational efficacy and reliability, addressing key performance requirements for Level 3+ autonomy. AI facilitates the development of intelligent sensor fusion architectures where Lidar’s precise geometry provides ground truth data for calibrating and validating camera and radar outputs. This synergy ensures high levels of redundancy and fault tolerance, essential for safety certification. Furthermore, AI is being deployed in the manufacturing and calibration phases of Lidar production, optimizing sensor alignment and quality control. The future trajectory of Lidar is inextricably linked to advancements in edge computing and specialized AI processors designed for rapid, low-power processing of 3D environmental data, ensuring that Lidar remains an indispensable component of the autonomous driving sensor suite.

- AI enables real-time, high-speed processing of dense Lidar point clouds, drastically reducing computational latency.

- Deep learning algorithms are crucial for accurate object classification, segmentation, and dynamic trajectory prediction based on Lidar data.

- AI drives sophisticated sensor fusion strategies, integrating Lidar’s depth accuracy with camera’s texture and color data for robust perception.

- Machine learning optimizes Lidar calibration and quality control during the manufacturing process, improving reliability and scalability.

- AI systems utilizing Lidar data are essential for Simultaneous Localization and Mapping (SLAM) in environments lacking GPS signals.

- Advanced neural networks enhance the performance of Lidar in adverse weather conditions by filtering rain, fog, or snow artifacts.

DRO & Impact Forces Of Automotive Lidar Sensor Market

The market for Automotive Lidar Sensors is significantly influenced by a dynamic interplay of Drivers (D), Restraints (R), Opportunities (O), and associated Impact Forces. The primary drivers include aggressive global pursuit of autonomous driving capabilities (L3-L5), which mandate Lidar's precise spatial mapping; increasingly stringent governmental safety mandates, particularly in Europe and North America, pushing for higher levels of ADAS integration; and the continuous advancement in Lidar technology resulting in smaller, more reliable, and ultimately lower-cost solid-state units. Conversely, major restraints encompass the historically high cost of Lidar units compared to cameras and radar, posing a significant hurdle for mass market penetration; challenges related to integrating Lidar aesthetically and functionally into vehicle design; and ongoing performance variability under extreme weather conditions, such as heavy snow or dense fog, which requires sophisticated algorithms and sensor redundancy to overcome. These driving and restraining forces exert considerable pressure on the technological roadmap and pricing strategies across the entire automotive supply chain.

Opportunities abound, centering on the burgeoning market for specialized Lidar applications, such as high-resolution short-range Lidar for blind-spot detection and parking assistance, extending Lidar usage beyond purely highway autonomy systems. Significant potential lies in the commercial deployment of robotaxis and logistics vehicles (Level 4 automation), which serve as early large-volume adopters willing to bear current Lidar costs due to clear operational returns. Furthermore, advancements in novel Lidar architectures like Frequency Modulated Continuous Wave (FMCW) Lidar present a major opportunity by promising instantaneous velocity measurement and superior immunity to solar glare and interference from other Lidar units, addressing current technological limitations. Strategic market expansion into the high-volume electric vehicle segment, where power efficiency is critical, is also a prime opportunity, driving demand for low-power solid-state designs.

The primary impact forces shaping the market trajectory include regulatory standardization efforts globally, which, once solidified, will dramatically accelerate adoption by providing clarity on necessary performance metrics and liability frameworks. Technological breakthroughs, specifically in semiconductor integration (Silicon Photonics), are a strong force pushing the market toward true mass-market scalability by enabling chip-scale Lidar units. Competitive pressure among Tier 1 suppliers and automotive OEMs to achieve perceived leadership in autonomous capabilities acts as a persistent force, compelling rapid investment and deployment. Lastly, consumer perception and acceptance of autonomous technology, influenced by publicized safety incidents or successful deployments, exert a significant sociological force that determines the ultimate pace of Lidar integration into everyday vehicles.

The inherent complexity of manufacturing and validating Lidar systems for automotive-grade reliability presents a persistent challenge. Automotive components must meet extremely strict standards regarding temperature cycling, vibration resistance, and longevity (typically 10-15 years of operational life). Achieving these standards, especially for mechanical scanning systems with moving parts, significantly increases development costs and time-to-market. The industry is currently in a transition phase, where multiple competing Lidar technologies (e.g., MEMS, Flash, OPA, FMCW) are vying for dominance, creating market fragmentation and reluctance among OEMs to commit fully to one proprietary technology, thereby slowing unified market growth. This fragmentation, coupled with the need for specialized calibration and integration expertise, acts as a subtle but powerful restraint on immediate widespread adoption across all vehicle segments, demanding continuous technological consolidation and standardization efforts to simplify the OEM adoption pathway.

Addressing the restraint of cost and integration complexity necessitates continued focused investment in next-generation manufacturing techniques, specifically utilizing standard CMOS processes where possible to leverage existing high-volume semiconductor fabrication infrastructure. The move towards highly integrated, software-defined Lidar modules that simplify the sensor stack architecture represents a crucial opportunity. OEMs are increasingly valuing Lidar solutions that offer not only raw performance but also seamless compatibility with diverse vehicle architectures and minimal computational overhead. Furthermore, the development of robust, AI-powered redundancy software that allows for the safe temporary degradation of Lidar performance (e.g., during heavy weather) while maintaining overall system safety is vital for gaining regulatory approval for Level 3+ systems. The ongoing race among Lidar providers to achieve the 'golden ratio' of high performance, compact size, and automotive-grade durability below a consumer-acceptable price point (often cited around $500 per unit) remains the single most critical driver for explosive market growth post-2027.

The opportunity landscape is also being shaped by the emerging concept of Vehicle-to-Everything (V2X) communication, where Lidar data can be shared and aggregated across a fleet of vehicles or infrastructure components, dramatically enhancing collective situational awareness. This data monetization potential offers a secondary revenue stream for OEMs and technology providers, justifying the initial investment in high-fidelity sensors. Furthermore, the rise of specialized ADAS applications in non-traditional vehicles, such as automated construction equipment, mining trucks, and agricultural machinery, represents a niche but highly lucrative market segment for ruggedized, high-performance Lidar units. These non-passenger vehicle applications often operate in highly structured, controlled environments (Level 4 geo-fenced operations), providing ideal testing and early commercialization avenues for Lidar technology before full integration into unpredictable consumer passenger vehicles.

Segmentation Analysis

The Automotive Lidar Sensor Market is systematically segmented based on technological architecture, component structure, vehicle autonomy level, application type, and regional geography, providing a granular view of market dynamics and adoption patterns. The architectural distinction between Mechanical and Solid-State Lidar is particularly critical, reflecting the industry's directional shift towards scalable, durable, and cost-efficient designs. Further segmentation by components, such as laser sources (e.g., Edge-Emitting Lasers, VCSELs) and detection mechanisms (e.g., APD, SPAD, SiPM), allows for detailed analysis of the supply chain and component innovation. Autonomy level segmentation (L1 to L5) dictates the performance specifications and sensor redundancy requirements, directly influencing market volume and average selling price (ASP). Application segmentation confirms the market's primary focus on ADAS and autonomous driving, while regional analysis highlights differing regulatory speeds and technological readiness across continents. This detailed segmentation aids stakeholders in strategic planning and targeting high-growth areas within the complex Lidar ecosystem.

- Type:

- Mechanical Lidar

- Solid-State Lidar (Micro-Electro-Mechanical Systems (MEMS), Flash Lidar, Optical Phased Array (OPA))

- Component:

- Laser Sources (EEL, VCSEL)

- Detectors (APD, SPAD, SiPM)

- Optics & Mirrors

- Processing Electronics

- Technology:

- Time-of-Flight (ToF)

- Frequency Modulated Continuous Wave (FMCW)

- Application/Autonomy Level:

- ADAS (L1 & L2)

- Semi-Autonomous (L3)

- Fully Autonomous (L4 & L5)

- Vehicle Type:

- Passenger Vehicles

- Commercial Vehicles (Trucks, Buses, Robotaxis)

Value Chain Analysis For Automotive Lidar Sensor Market

The value chain for the Automotive Lidar Sensor Market is complex and multi-layered, beginning with raw material sourcing and culminating in the final integration and validation by the Original Equipment Manufacturer (OEM). The upstream segment is dominated by highly specialized semiconductor and optical component manufacturers responsible for producing crucial elements such as laser diodes, photodetectors (like SPADs and SiPMs), custom optics, and specialized integrated circuits for signal processing. Innovation at this stage, particularly in silicon photonics, directly impacts the sensor's cost, size, and performance envelope. These component suppliers feed into the core Lidar System Developers, which constitute the midstream of the value chain. These developers focus on integrating these components, designing the specific Lidar architecture (MEMS, Flash, or FMCW), developing proprietary algorithms for point cloud processing, and ensuring the system meets stringent automotive-grade quality and reliability standards (AEC-Q100 equivalent validation). The successful management of intellectual property and fabrication process scaling in this midstream segment determines market competitiveness.

The downstream segment involves the distribution and integration of the finalized Lidar sensor units. Tier 1 automotive suppliers play a crucial role, often purchasing Lidar units from specialized developers and integrating them into larger ADAS or autonomous driving hardware stacks alongside radar and camera systems. These Tier 1 entities handle the system-level validation, environmental sealing, and ensuring compliance with vehicle protocols before supplying the entire perception stack to the automotive OEMs. Distribution channels are predominantly indirect, flowing from component suppliers to Lidar developers, then to Tier 1 integrators, and finally to the OEMs. Direct distribution occurs primarily when Lidar developers partner directly with specialized robotaxi companies or niche autonomous vehicle manufacturers for early deployment trials, bypassing the traditional Tier 1 structure for faster implementation and customized solutions.

Ultimately, the efficiency and profitability across the entire value chain are critically dependent on the ability to transition from high-cost, low-volume production characteristic of Mechanical Lidar to high-volume, automated production of solid-state units. Challenges include managing the long lead times for specialized optical components and the need for rigorous, high-speed testing procedures to validate millions of units annually. Optimized collaboration between Lidar developers and component manufacturers is essential to secure competitive component pricing and stable supply, particularly as global demand for autonomous driving components accelerates. Furthermore, the downstream relationship between Tier 1 integrators and OEMs is shifting, with some large OEMs moving towards in-house development of core sensor fusion software, placing greater pressure on Lidar providers to offer flexible, hardware-agnostic data interfaces rather than proprietary closed systems.

Automotive Lidar Sensor Market Potential Customers

The primary end-users and buyers in the Automotive Lidar Sensor Market are the Original Equipment Manufacturers (OEMs) of passenger vehicles, autonomous truck manufacturers, and specialized mobility service providers, often referred to as robotaxi operators. Passenger vehicle OEMs, including major global brands focused on both premium and high-volume segments, are the largest customer base, driven by the immediate requirement to implement Level 2+ (e.g., highway pilot features) and Level 3 conditional autonomous systems. These buyers prioritize cost efficiency, aesthetic integration (often demanding Lidar units small enough to be integrated behind the windshield or within headlamps), reliability, and scalability for their future electric vehicle platforms, where Lidar deployment is becoming a key differentiator. The procurement strategy of OEMs typically involves multi-year contracts and rigorous competitive sourcing to ensure long-term component supply and quality control.

Commercial vehicle manufacturers represent a rapidly growing segment of potential customers, particularly those producing heavy-duty trucks and last-mile delivery vans. For commercial applications, Lidar is crucial for enhancing safety (reducing high-cost accident liability) and enabling platooning capabilities and hub-to-hub autonomous operations (Level 4). These customers place a premium on durability, range (for high-speed highway driving), and resilience against environmental factors, as these vehicles operate continuously across diverse geographical and weather conditions. Logistics companies investing in autonomous fleets, either directly or through partnership with technology suppliers, are driving early high-volume orders for robust Lidar solutions specifically designed for challenging environments and 24/7 duty cycles. The return on investment (ROI) via reduced driver costs and improved fuel efficiency justifies a higher initial component price for these commercial buyers.

A third significant customer group comprises Mobility as a Service (MaaS) providers and technology developers focusing on Level 4 robotaxi fleets (e.g., Waymo, Cruise, Zoox). These entities are characterized by extremely high performance demands, often requiring a complex sensor array consisting of multiple Lidar units (short, mid, and long-range) to achieve military-grade redundancy and operational safety in dense urban settings. Cost per vehicle is secondary to maximizing sensor performance and ensuring uptime, making them key early adopters of the most advanced, often specialized, Lidar technologies (e.g., high-resolution 360-degree mechanical or hybrid solutions). Additionally, smaller niche customers include defense contractors developing tactical autonomous ground vehicles, mapping companies utilizing mobile Lidar systems for high-definition map creation, and specialized industrial automation firms requiring precise indoor/outdoor navigation capabilities.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 7.6 Billion |

| Growth Rate | 25.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Velodyne Lidar, Luminar Technologies, Innoviz Technologies, Aeva, Cepton, Ouster, Ibeo Automotive Systems, Hesai Technology, Quanergy Systems, Valeo, Bosch, ZF Friedrichshafen, Continental AG, LeddarTech, XenomatiX, Baraja, Scantinel Photonics, RoboSense, Waymo (In-house Lidar), Mobileye (Intel). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automotive Lidar Sensor Market Key Technology Landscape

The technological landscape of the Automotive Lidar Sensor Market is currently highly dynamic, characterized by a rapid transition away from bulky, expensive Mechanical Lidar towards various scalable Solid-State architectures. Time-of-Flight (ToF) remains the dominant operational principle, measuring the elapsed time between laser emission and return to calculate distance. Within the solid-state category, Micro-Electro-Mechanical Systems (MEMS) Lidar utilizes tiny, oscillating mirrors to steer the laser beam rapidly, achieving high resolution and a wide Field of View (FoV) while significantly reducing the size and cost compared to traditional mechanical spinning Lidar. Flash Lidar represents another critical solid-state variant, illuminating the entire scene simultaneously with a wide beam flash and using a large detector array (like a camera sensor) to capture the returning signals. Flash Lidar offers instantaneous 3D capture, which is advantageous for high-speed object tracking, though its range is typically limited compared to scanning Lidar systems.

A crucial technological disruption gaining traction is Frequency Modulated Continuous Wave (FMCW) Lidar. Unlike ToF, which measures pulse delay, FMCW Lidar measures the beat frequency between the emitted and received chirped laser signals. This technique provides simultaneous, direct measurement of both distance and velocity (Doppler effect), offering a significant advantage for predicting object movement instantly without complex post-processing. Furthermore, FMCW Lidar operates with high immunity to interference from other Lidar units (a critical issue in dense autonomous traffic) and external light sources like the sun. Although FMCW systems require highly coherent laser sources and sophisticated silicon photonics integration, they are widely viewed as the future standard, promising superior performance, particularly at longer ranges and in scenarios requiring precise velocity determination.

Component-level innovations are equally vital. The shift to 1550 nm wavelength lasers is notable, as this wavelength is eye-safe at higher power levels than the standard 905 nm, allowing for longer detection ranges and better performance in dusty or hazy environments. Detector technologies are rapidly evolving, with Single Photon Avalanche Diodes (SPADs) and Silicon Photomultipliers (SiPMs) replacing traditional Avalanche Photodiodes (APDs). SPADs and SiPMs offer dramatically improved sensitivity, enabling higher resolution and detection capabilities in challenging low-reflectivity scenarios. Overall, the technology roadmap is driven by miniaturization—integrating complex optics and processing electronics onto single silicon chips (Lidar-on-a-chip) through Silicon Photonics to finally achieve the cost point and reliability required for true mass-market automotive penetration across all vehicle segments, transitioning the Lidar unit from a specialized add-on to a standard, integrated sensory component.

Further exploration into advanced scanning methodologies highlights the development of Optical Phased Array (OPA) Lidar. OPA technology employs tiny antennae elements to steer the laser beam electronically, eliminating all moving parts, which promises unmatched reliability and speed. While still largely in the research and early development phase due to challenges in achieving wide FOV and managing manufacturing tolerances, OPA represents the ultimate goal of truly solid-state Lidar. Parallel to hardware innovation, sophisticated software and firmware development is crucial. Modern Lidar systems are becoming software-defined, meaning their performance parameters (such as range, resolution, and FOV) can be dynamically adjusted based on the driving scenario (e.g., wide FOV for urban driving, high-resolution central FOV for highway cruising). This software capability significantly enhances the versatility and cost-effectiveness of the Lidar unit, moving its value proposition beyond raw hardware specifications into intelligent sensor capabilities.

The integration challenge is also pushing technological limits. Automotive OEMs are increasingly demanding "invisible" Lidar solutions that do not compromise vehicle aesthetics. This requires Lidar developers to master techniques for seamlessly embedding sensors into headlamps, grilles, or even the roofline glass. This demand drives innovation in specialized, compact optical designs and heat dissipation solutions, especially critical for high-power 1550 nm systems. Moreover, the trend towards centralized computing architectures in autonomous vehicles necessitates that Lidar output data be efficiently processed and transmitted via high-speed automotive Ethernet or similar protocols. This requires specialized embedded hardware acceleration, often involving Field-Programmable Gate Arrays (FPGAs) or Application-Specific Integrated Circuits (ASICs), dedicated to the initial filtering and processing of the point cloud data before it reaches the central sensor fusion processor, ensuring minimum latency for critical safety functions.

Lastly, standards relating to data output and interoperability are a growing focus. As vehicles increasingly employ multiple Lidar sensors from different vendors, the need for standardized data formats (e.g., a standardized point cloud structure) and communication protocols is paramount for efficient sensor fusion. Companies are investing in middleware solutions that simplify the integration of heterogeneous sensor data streams. These ongoing technological efforts—spanning beam steering physics (OPA, MEMS), detection sensitivity (SiPM, SPAD), wavelength selection (1550nm), and system integration (Lidar-on-a-chip)—collectively define the competitive edge and the future trajectory of the automotive Lidar sensor market, emphasizing high performance, low cost, and ultimate reliability under all operating conditions.

Regional Highlights

- North America: North America, particularly the United States, is a foundational market for Automotive Lidar sensors, driven by extensive testing and early commercial deployment of Level 4 autonomous vehicle fleets (robotaxis and autonomous trucking). The region benefits from a favorable regulatory environment for testing and strong investment from technology giants and startups (e.g., in Silicon Valley). The demand is characterized by high-performance Lidar units necessary for safe operation in complex urban and high-speed highway environments. Key market drivers include the concentration of leading Lidar developers and the immediate commercialization efforts of Level 4 mobility services. Regulatory frameworks like those in California and Arizona, which permit widespread autonomous vehicle testing, have accelerated technology readiness and market penetration.

- Europe: Europe represents a mature market with a focus on integrating Lidar into premium passenger vehicles for advanced Level 3 conditional driving features. Regulatory initiatives from the European Union, emphasizing mandatory safety features and promoting ADAS integration, serve as primary market drivers. European OEMs are focusing heavily on quality, reliability, and aesthetic integration, favoring solid-state solutions that can be subtly incorporated into the vehicle design. Germany, France, and the UK lead the deployment efforts, particularly in high-end vehicle segments, prioritizing safe and validated Lidar systems that meet stringent ISO 26262 functional safety standards before mass commercialization.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, led primarily by substantial market momentum in China, Japan, and South Korea. China’s centralized strategic planning strongly supports the development of smart infrastructure and electric and autonomous vehicles, fostering a massive domestic Lidar supply chain and high volume adoption. OEMs in this region are rapidly integrating Lidar into mid-range and high-end EVs to achieve Level 2+ and L3 capabilities rapidly, focusing heavily on cost-effective, scalable solid-state solutions. Japan and South Korea are focusing on integrating Lidar for specific uses like public transport automation and automated logistics systems.

- Latin America, Middle East, and Africa (MEA): This combined region represents an emerging market segment. Adoption is slower due to infrastructure challenges and less stringent safety regulations, but growth is concentrated in specific high-value applications. The Middle East, particularly the UAE and Saudi Arabia, shows high potential due to ambitious smart city projects and planned investments in autonomous public transport and logistics fleets. Lidar adoption in these areas is often focused on pilot projects for specific geo-fenced applications, prioritizing robust, high-durability sensors capable of handling high temperatures and dusty conditions prevalent in the region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automotive Lidar Sensor Market.- Velodyne Lidar

- Luminar Technologies

- Innoviz Technologies

- Aeva

- Cepton

- Ouster

- Ibeo Automotive Systems

- Hesai Technology

- Quanergy Systems

- Valeo

- Bosch

- ZF Friedrichshafen

- Continental AG

- LeddarTech

- XenomatiX

- Baraja

- Scantinel Photonics

- RoboSense

- Waymo (In-house Lidar Development)

- Mobileye (Intel)

Frequently Asked Questions

Analyze common user questions about the Automotive Lidar Sensor market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Mechanical and Solid-State Lidar technologies for automotive use?

Mechanical Lidar utilizes physically spinning or rotating components (mirrors/prisms) to achieve a 360-degree Field of View (FoV), offering superior range and resolution but suffers from high cost, large size, and lower durability due to moving parts. Solid-State Lidar (e.g., MEMS, Flash, OPA) uses electronic or microscopic steering mechanisms with no macro-moving parts, resulting in smaller, more reliable, and significantly lower-cost units necessary for mass-market vehicle integration, though current implementations may have restricted FoV or range compared to high-end mechanical units. The industry strongly favors Solid-State Lidar due to scalability and automotive-grade reliability requirements.

How does the adoption of 1550 nm Lidar technology impact autonomous vehicle safety and performance?

The transition to 1550 nm wavelength Lidar significantly improves safety and operational performance because this wavelength is eye-safe at much higher laser power levels than the standard 905 nm. Higher power allows the sensor to transmit stronger light pulses, increasing the maximum detection range substantially (often exceeding 250 meters) and improving performance in challenging atmospheric conditions like rain or fog. This extended, high-fidelity range is critical for enabling safe highway speeds and complex decision-making required for Level 3 and Level 4 autonomous driving systems, providing the vehicle more time to react to far-off obstacles.

What role does FMCW Lidar play in competing with traditional Time-of-Flight (ToF) systems?

Frequency Modulated Continuous Wave (FMCW) Lidar is a disruptive technology that fundamentally differs from traditional pulsed Time-of-Flight (ToF) by measuring the beat frequency, allowing it to directly calculate both the distance and the instantaneous velocity (Doppler) of objects. This dual capability eliminates the need for complex tracking algorithms to estimate speed. Furthermore, FMCW offers superior immunity to interference from ambient light and other Lidar units, enhancing system robustness. While currently higher in complexity and cost, FMCW is projected to become the preferred technology for next-generation Lidar due to its superior data fidelity and performance advantages in dense, multi-vehicle environments.

What are the primary restraints preventing the immediate widespread integration of Lidar across all vehicle classes?

The most significant restraints are the high unit cost relative to cameras and radar, which limits Lidar adoption primarily to premium vehicles and autonomous fleets; the inherent challenges of achieving automotive-grade durability and reliability, particularly for mechanical or hybrid scanning systems; and persistent performance limitations in extreme adverse weather conditions (heavy snow, torrential rain), which necessitate comprehensive sensor fusion redundancy. Until solid-state Lidar achieves a target price point below $500 per unit for high-volume manufacturing, its widespread penetration into entry-level and mid-range consumer vehicles will remain constrained.

Which specific vehicle autonomy levels are driving the highest current demand for Lidar sensors?

Currently, the highest volume demand is driven by Level 3 (Conditional Automation) passenger vehicles, primarily in premium European and North American models, where Lidar provides the necessary environmental monitoring for conditional hands-off driving features (e.g., highway pilot). However, the fastest growth is stemming from Level 4 (High Automation) applications, specifically commercial autonomous logistics (trucking) and Mobility-as-a-Service (robotaxi) fleets, which require high sensor redundancy and advanced perception capabilities for safe operation in geo-fenced or defined operational domains, justifying the investment in multiple high-performance Lidar units per vehicle.

This report contains 29672 characters.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager