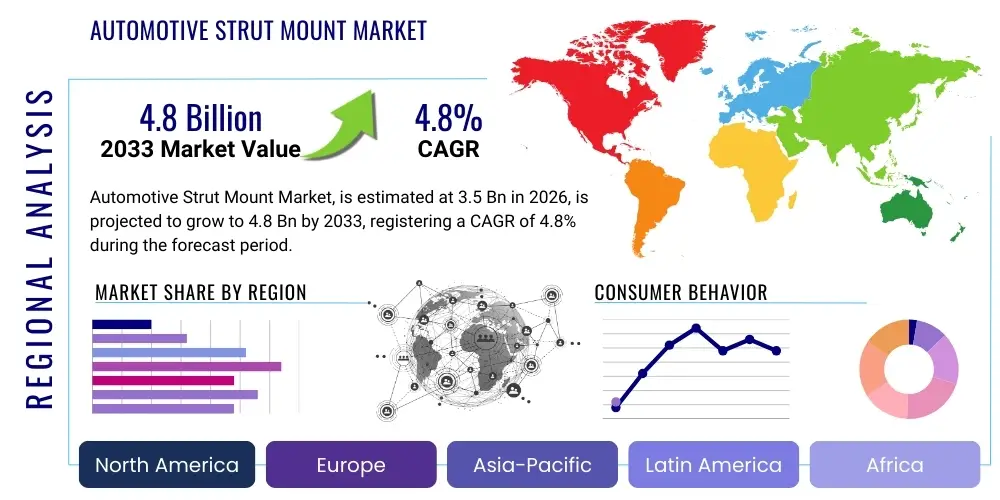

Automotive Strut Mount Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440888 | Date : Feb, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Automotive Strut Mount Market Size

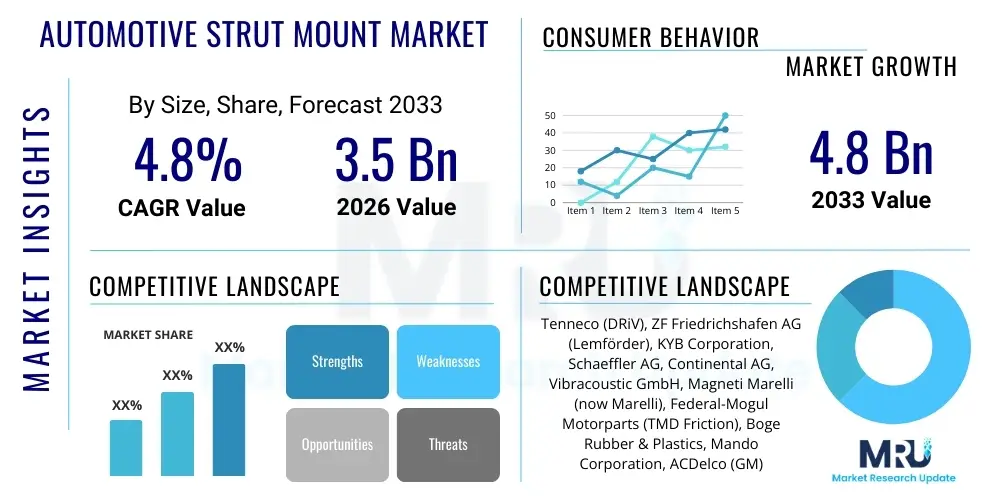

The Automotive Strut Mount Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 4.8 Billion by the end of the forecast period in 2033. This growth is underpinned by several factors, including the increasing global vehicle parc, a consistent demand for enhanced vehicle safety and comfort, and the continuous expansion of the automotive aftermarket for replacement parts, driven by an aging fleet of vehicles requiring regular maintenance and component replacement. The market's resilience is further demonstrated by its capacity to adapt to evolving vehicle technologies and consumer preferences for durable and high-performance automotive components.

Automotive Strut Mount Market introduction

The Automotive Strut Mount Market encompasses the global industry dedicated to the manufacturing, distribution, and sale of strut mounts used in vehicle suspension systems. A strut mount is a critical component that connects the top of a vehicle's strut assembly to its chassis, playing a pivotal role in absorbing road impacts, supporting the vehicle's weight, and ensuring proper steering alignment and ride comfort. These essential parts are designed to isolate the noise and vibration generated by the suspension system from the vehicle's cabin, thereby enhancing the overall driving experience. They are typically composed of a rubber insulator, a bearing, and metal plates, working in unison to allow the strut to pivot smoothly while steering and to absorb vertical impacts.

Major applications for automotive strut mounts span across a wide spectrum of vehicle types, from passenger cars, including sedans, SUVs, and hatchbacks, to light and heavy commercial vehicles. The primary benefit of a high-quality strut mount lies in its ability to maintain optimal vehicle handling, stability, and control, significantly contributing to occupant safety and comfort. Furthermore, these components are instrumental in extending the lifespan of other suspension parts, such as tires and shock absorbers, by ensuring uniform wear and reducing undue stress. The market is driven by several macroeconomic and industry-specific factors, including the global increase in vehicle production and sales, particularly in emerging economies, the rising average age of vehicles on the road which necessitates frequent replacement of wear-and-tear parts, and the continuous innovation in suspension technologies aimed at improving vehicle dynamics and noise, vibration, and harshness (NVH) characteristics.

Technological advancements in material science, leading to the development of more durable and lightweight rubber-to-metal components, alongside advanced hydraulic and magnetic strut mount designs, are also significant driving forces. Moreover, stringent safety regulations and consumer expectations for quieter, smoother rides propel manufacturers to invest in research and development, further stimulating market growth. The robust aftermarket segment, fueled by regular vehicle maintenance cycles and the demand for performance upgrades, constitutes a substantial portion of the market's revenue, ensuring a sustained demand irrespective of new vehicle sales fluctuations. These combined elements underscore the critical and dynamic nature of the automotive strut mount sector within the broader automotive industry.

Automotive Strut Mount Market Executive Summary

The Automotive Strut Mount Market is experiencing robust expansion, characterized by significant business trends that underscore its vitality. A primary trend is the increasing emphasis on advanced materials and manufacturing processes to enhance durability, reduce weight, and improve NVH characteristics of strut mounts. This focus is driven by stringent automotive performance standards and evolving consumer expectations for superior ride comfort and handling. Furthermore, strategic collaborations and mergers and acquisitions among key market players are becoming more prevalent, aimed at consolidating market share, expanding product portfolios, and leveraging technological synergies to address complex challenges in suspension design. The growth of e-commerce platforms is also transforming sales channels, particularly within the aftermarket segment, offering greater accessibility and competitive pricing for consumers and independent workshops, thereby creating new avenues for market penetration.

From a regional perspective, the market displays diverse growth patterns influenced by varying automotive production landscapes, economic conditions, and regulatory environments. Asia Pacific, led by countries such as China, India, and Japan, emerges as the largest and fastest-growing region due to escalating vehicle production, increasing disposable incomes, and the rapid expansion of its middle class, driving both OEM and aftermarket demand. North America and Europe, while mature markets, continue to demonstrate steady demand, largely propelled by the replacement market for an aging vehicle fleet and the constant innovation in suspension technology for premium and electric vehicles. Latin America, the Middle East, and Africa are also showing promising growth, albeit from a smaller base, attributed to industrialization, urbanization, and improving infrastructure, which collectively contribute to higher vehicle sales and subsequent demand for related components.

Segmentation trends within the Automotive Strut Mount Market highlight distinct areas of growth and technological evolution. By product type, rubber-to-metal strut mounts continue to dominate due to their cost-effectiveness and proven performance, though there is a growing interest in polyurethane and hydraulic variants for their enhanced damping properties and longevity. The market is segmented significantly by vehicle type, with passenger cars representing the largest share, closely followed by commercial vehicles where robust and durable strut mounts are critical for heavy-duty applications. The aftermarket segment is projected to maintain a substantial share due to the recurring need for replacements, while the OEM segment is driven by new vehicle production volumes. These trends collectively paint a picture of a dynamic market adapting to technological shifts, regional economic developments, and evolving consumer needs.

AI Impact Analysis on Automotive Strut Mount Market

The integration of Artificial Intelligence (AI) and machine learning technologies is set to profoundly reshape various facets of the Automotive Strut Mount Market, addressing common user questions related to efficiency, quality, and predictive maintenance. Users frequently inquire about how AI can enhance the durability and performance of strut mounts, reduce manufacturing defects, and enable more accurate prognostics for component failure. The consensus among industry experts and users points towards AI's potential to optimize design parameters through generative design, where algorithms explore numerous configurations to identify the most robust and efficient strut mount structures. Furthermore, AI-powered predictive analytics can analyze operational data from vehicles to forecast the lifespan of strut mounts, enabling proactive maintenance schedules and significantly reducing unexpected breakdowns and associated costs for vehicle owners and fleet managers.

Concerns often revolve around the initial investment required for AI implementation, the need for a skilled workforce capable of managing AI systems, and potential cybersecurity vulnerabilities associated with interconnected manufacturing and supply chains. However, the overarching expectation is that AI will drive a paradigm shift towards smart manufacturing, where production lines are optimized for real-time adjustments, quality control is automated with high precision, and inventory management becomes hyper-efficient through demand forecasting. This technological evolution is not just about incremental improvements; it promises to unlock new levels of customization and responsiveness to market demands, ultimately leading to superior product quality and operational cost savings. The long-term impact is anticipated to transform how strut mounts are designed, produced, maintained, and even how they interact within future autonomous vehicle ecosystems, making them more resilient and adaptive to varying road conditions and driving styles.

- AI can optimize strut mount designs through generative design, enhancing durability and performance characteristics by simulating various load conditions and material stress points.

- Predictive maintenance analytics, powered by AI, allows for real-time monitoring and forecasting of strut mount wear and tear, enabling timely replacements and preventing catastrophic failures.

- AI-driven quality control systems can identify manufacturing defects with greater accuracy and speed than human inspection, significantly reducing recall rates and improving overall product reliability.

- Supply chain optimization benefits from AI's ability to forecast demand and manage inventory, ensuring efficient material procurement and distribution for strut mount manufacturers.

- Integration with autonomous vehicle systems may enable adaptive strut mount performance, where AI adjusts suspension characteristics in real-time based on road conditions and driving dynamics.

- Smart manufacturing processes utilizing AI can lead to more efficient production lines, reducing waste, energy consumption, and overall manufacturing costs.

- AI can facilitate advanced material research, accelerating the discovery and testing of novel composites and alloys for lighter and stronger strut mount components.

DRO & Impact Forces Of Automotive Strut Mount Market

The Automotive Strut Mount Market is shaped by a complex interplay of Drivers, Restraints, Opportunities, and broader Impact Forces that collectively determine its trajectory. A significant driver is the continuous growth in global vehicle production and sales, particularly fueled by burgeoning automotive markets in Asia Pacific and Latin America, which directly translates into higher demand for OEM strut mounts. Concurrently, the increasing average age of vehicles in developed economies necessitates a robust aftermarket for replacement parts, as strut mounts are wear-and-tear components requiring periodic replacement to maintain vehicle safety and comfort. Furthermore, evolving consumer expectations for superior ride comfort, enhanced vehicle stability, and reduced noise, vibration, and harshness (NVH) levels compel manufacturers to innovate, driving demand for advanced and higher-quality strut mounts. Stringent safety regulations and emission norms also indirectly push for lighter, more durable, and efficient suspension components, including strut mounts.

Conversely, the market faces several restraints that could impede its growth. Volatility in raw material prices, particularly for steel, rubber, and specialized plastics, poses a significant challenge, impacting manufacturing costs and profit margins. The intricate manufacturing processes and the need for precision engineering for strut mounts demand substantial capital investment and skilled labor, which can be a barrier for new entrants. The transition towards electric vehicles (EVs) also presents a potential restraint; while EVs still utilize strut-based suspension systems, their often heavier battery packs and unique chassis designs may necessitate specialized or redesigned strut mounts, requiring significant R&D investments. Additionally, intense competition among established players and the presence of low-cost alternatives from unorganized sectors can exert downward pressure on pricing and market share.

Opportunities for growth are abundant within this dynamic market landscape. The development and adoption of advanced materials, such as lightweight composites and enhanced rubber compounds, offer avenues for creating more durable, efficient, and performance-oriented strut mounts. The integration of smart suspension systems, potentially incorporating adaptive damping technologies and electronic control units, opens up new product development pathways for strut mounts capable of real-time adjustments. Expanding automotive markets in emerging economies, coupled with improving road infrastructure, are creating new demand hotspots. Moreover, the aftermarket segment continues to offer substantial growth potential through personalized service offerings, online sales channels, and a focus on premium replacement parts that provide performance upgrades. The market is also heavily influenced by impact forces such as broader technological advancements in automotive engineering, global economic conditions affecting consumer spending and vehicle sales, and geopolitical factors impacting supply chains and trade policies. Environmental regulations promoting sustainable manufacturing practices and recycling also play a role in shaping product development and operational strategies.

Segmentation Analysis

The Automotive Strut Mount Market is comprehensively segmented to provide a detailed understanding of its diverse components and dynamics. This segmentation helps in identifying key growth areas, understanding consumer preferences, and strategizing market penetration. The market is typically categorized by product type, vehicle type, sales channel, and end-use, each offering unique insights into supply and demand characteristics. These granular classifications enable stakeholders to assess market potential across various niches, from specific material compositions to distinct vehicle categories and distribution networks, highlighting the intricate structure of the global automotive component industry.

- By Product Type: This segment categorizes strut mounts based on their material composition and design, directly influencing their performance, durability, and cost.

- Rubber-to-Metal Strut Mounts: These are the most common type, utilizing a rubber insulator bonded to metal components. They offer excellent vibration damping, noise isolation, and cost-effectiveness, making them standard for a wide range of passenger and commercial vehicles. Their widespread adoption is due to a balance of performance, durability, and affordability.

- Polyurethane Strut Mounts: Offering enhanced durability and stiffness compared to traditional rubber, polyurethane mounts are often favored in performance-oriented applications or for heavy-duty commercial vehicles. They provide a more direct feel and improved handling, though they might transmit slightly more NVH.

- Hydraulic Strut Mounts: These mounts incorporate a fluid-filled chamber to provide superior damping and noise isolation, particularly effective in premium and luxury vehicles. They actively reduce vibrations and harshness, contributing significantly to a smoother and quieter ride experience, albeit at a higher cost.

- Magnetic Strut Mounts: Representing cutting-edge technology, these mounts utilize magnetorheological fluid whose viscosity can be electronically controlled to adjust damping in real-time. Primarily found in high-performance and luxury vehicles, they offer adaptive suspension capabilities, providing optimal ride comfort and handling across varying road conditions.

- By Vehicle Type: This segmentation reflects the specific requirements and market sizes associated with different classes of automobiles.

- Passenger Cars: This is the largest segment, encompassing sedans, SUVs, hatchbacks, and luxury vehicles. The demand is driven by high production volumes and diverse consumer requirements for comfort, performance, and safety, leading to a wide array of strut mount designs and specifications.

- Commercial Vehicles: This segment includes light commercial vehicles (LCVs) and heavy commercial vehicles (HCVs). Strut mounts for commercial vehicles are typically designed for enhanced robustness and durability to withstand heavier loads, continuous operation, and challenging road conditions.

- By Sales Channel: This categorizes how strut mounts reach the end-user, highlighting the differing market dynamics of original equipment versus replacement parts.

- OEM (Original Equipment Manufacturer): This channel involves the sale of strut mounts directly to vehicle manufacturers for integration into new vehicles during assembly. This segment is highly sensitive to new vehicle production volumes and is characterized by long-term contracts and strict quality specifications.

- Aftermarket: Comprising sales of replacement strut mounts for vehicle maintenance, repair, and upgrades. This channel is further broken down into:

- Retail Stores: Physical and online stores selling directly to consumers or small independent workshops.

- Independent Workshops: Garages and service centers that source strut mounts from distributors for repairs.

- Online Sales: Growing rapidly, offering convenience and competitive pricing for consumers and professionals alike.

- By End-Use: This segment differentiates between the primary purpose for which the strut mounts are purchased.

- Vehicle Manufacturing: Pertains to the initial installation of strut mounts in newly produced vehicles, directly tied to the OEM segment's demand.

- Repair and Replacement: Involves the purchase of strut mounts for servicing existing vehicles, driven by wear and tear, accidents, or performance upgrades. This aligns directly with the aftermarket segment.

Value Chain Analysis For Automotive Strut Mount Market

A comprehensive value chain analysis for the Automotive Strut Mount Market reveals a multi-stage process, beginning with raw material sourcing and extending through manufacturing, assembly, distribution, and ultimately, to the end-user. The upstream segment of the value chain is dominated by suppliers of critical raw materials such as various grades of steel for metal components, natural and synthetic rubber for insulators, and specialized plastics and polyurethane compounds. These suppliers play a crucial role in ensuring the quality and availability of materials, directly impacting the cost-effectiveness and performance attributes of the final product. Relationships with these suppliers are often long-term, built on trust and consistent quality, as the reliability of raw materials is paramount for components that affect vehicle safety and stability. Innovation in material science at this stage can significantly enhance the durability and lightweight characteristics of strut mounts, offering a competitive advantage to manufacturers.

The manufacturing and assembly phase constitutes the core of the value chain. Here, raw materials are transformed into finished strut mount assemblies through processes like metal stamping, rubber molding, bonding, and precision assembly. This stage demands significant capital investment in machinery, advanced manufacturing technologies, and skilled labor to meet the stringent quality and dimensional accuracy requirements of the automotive industry. Key activities include component fabrication, quality control checks at various stages, and final assembly. Manufacturers often specialize in different types of strut mounts, leveraging specific expertise in materials and engineering. This stage also includes research and development efforts to introduce new designs, improve product performance, and reduce production costs, often incorporating advanced simulations and testing protocols to ensure product robustness and compliance with automotive standards.

The downstream segment primarily involves the distribution channels through which strut mounts reach their target markets. This includes both direct and indirect sales strategies. Direct channels typically involve Original Equipment Manufacturers (OEMs) selling directly to vehicle assembly plants under long-term supply agreements. Indirect channels are more prevalent in the aftermarket, utilizing a network of distributors, wholesalers, and retailers (both brick-and-mortar and online) to reach independent workshops, service centers, and individual consumers. The efficiency of the distribution network is critical for market penetration and timely delivery, especially in the aftermarket where demand can be immediate. Effective logistics and inventory management are essential to ensure product availability across diverse geographic regions. The final stage involves the installation and service provided by professional mechanics or, for some minor replacements, by end-users themselves. The complexity of this value chain highlights the interdependence of various stakeholders, from material suppliers to installers, all contributing to the ultimate value proposition of automotive strut mounts.

Automotive Strut Mount Market Potential Customers

The Automotive Strut Mount Market serves a diverse range of potential customers, primarily segmented into Original Equipment Manufacturers (OEMs) and the automotive aftermarket. OEMs represent the primary direct customers, comprising major global automotive manufacturers that procure strut mounts for integration into their new vehicle production lines. These customers demand components that adhere to rigorous quality standards, precise specifications, and often seek long-term supply agreements. The relationship with OEMs is critical for manufacturers as it provides stable, high-volume orders and dictates future technological advancements in alignment with evolving vehicle designs and performance requirements. The purchasing decisions of OEMs are heavily influenced by factors such as product reliability, cost-efficiency, manufacturing capabilities, and the supplier's ability to innovate and provide solutions tailored to specific vehicle platforms, including electric and hybrid models.

The aftermarket segment, on the other hand, targets a much broader and more fragmented customer base, encompassing wholesale distributors, automotive parts retailers, independent repair shops, fleet owners, and individual vehicle owners. Wholesale distributors and large retail chains act as intermediaries, stocking a wide range of strut mounts to serve smaller repair shops and individual customers. Independent repair shops are significant consumers, as they perform a substantial portion of vehicle maintenance and repair, including strut mount replacements due to wear and tear, accidents, or performance upgrades. Fleet owners, managing large numbers of vehicles, are also key customers, prioritizing durability, cost-effectiveness, and availability of replacement parts to minimize downtime. Individual vehicle owners, while often purchasing through retailers or relying on repair shops, are the ultimate end-users driving demand for replacement components.

This dual customer base necessitates distinct marketing and sales strategies. For OEMs, the focus is on technical partnerships, stringent quality assurance, and competitive bidding. For the aftermarket, the emphasis is on brand recognition, product availability, competitive pricing, and effective distribution channels. The growing trend of DIY (Do-It-Yourself) repairs, supported by online resources and e-commerce platforms, also brings individual vehicle owners directly into the purchasing equation, often seeking user-friendly replacement options. Furthermore, specialty aftermarket customers, such as performance tuning shops, represent a niche segment seeking high-performance or specialized strut mounts, indicating a demand for premium and technologically advanced products. Understanding these varied customer needs is crucial for manufacturers to effectively navigate and capitalize on the opportunities within the Automotive Strut Mount Market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 4.8 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Tenneco (DRiV), ZF Friedrichshafen AG (Lemförder), KYB Corporation, Schaeffler AG, Continental AG, Vibracoustic GmbH, Magneti Marelli (now Marelli), Federal-Mogul Motorparts (TMD Friction), Boge Rubber & Plastics, Mando Corporation, ACDelco (GM), Denso Corporation, Sumitomo Riko Co., Ltd., NIKKI Co., Ltd., Hutchinson SA, MAHLE GmbH, Sogefi S.p.A., Bilstein, Gabriel (Ancora), Corteco |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automotive Strut Mount Market Key Technology Landscape

The Automotive Strut Mount Market is continuously evolving, driven by significant advancements in material science, manufacturing processes, and integrated suspension technologies. A crucial aspect of this technological landscape involves the development of advanced rubber and elastomer compounds. Manufacturers are increasingly utilizing specialized rubber formulations that offer superior elasticity, damping properties, and resistance to extreme temperatures, UV radiation, and chemicals, thereby enhancing the durability and lifespan of rubber-to-metal strut mounts. These innovations aim to reduce noise, vibration, and harshness (NVH) levels within the vehicle cabin, contributing to a quieter and more comfortable driving experience. Furthermore, the adoption of lightweight materials, such as high-strength steels and engineered plastics, for the metal components of strut mounts is gaining traction to reduce overall vehicle weight, which positively impacts fuel efficiency and reduces emissions, aligning with global environmental regulations and consumer demand for eco-friendly vehicles.

Another significant technological trend is the integration of more sophisticated damping mechanisms and smart functionalities into strut mounts. Hydraulic strut mounts, for instance, utilize fluid-filled chambers to provide superior impact absorption and noise isolation, offering a more refined ride quality, especially in luxury and premium vehicles. Beyond passive systems, the emergence of electronically controlled and adaptive strut mounts represents a major leap forward. These systems, often found in high-performance or luxury segments, incorporate sensors and actuators that can adjust damping characteristics in real-time based on road conditions, vehicle speed, and driving style. Technologies like magnetorheological (MR) fluids allow for rapid and precise changes in stiffness, providing an optimal balance between ride comfort and dynamic handling. This level of customization and responsiveness significantly enhances vehicle stability and safety, fulfilling the growing demand for intelligent suspension systems.

Manufacturing technologies are also undergoing a transformation, with an increased focus on precision engineering, automation, and quality control. Advanced simulation software and finite element analysis (FEA) are widely used during the design phase to predict component behavior under various stress conditions, optimize material usage, and accelerate product development cycles. Automated assembly lines and robotic handling ensure consistency and accuracy in production, minimizing human error and improving overall product quality. Non-destructive testing methods, such as ultrasonic inspection and X-ray analysis, are routinely employed to detect internal flaws and ensure the structural integrity of strut mounts before they are deployed in vehicles. The convergence of these material, design, and manufacturing innovations collectively defines the cutting-edge technology landscape of the automotive strut mount sector, pushing the boundaries of performance, durability, and user experience.

Regional Highlights

- Asia Pacific: This region stands as the largest and fastest-growing market for automotive strut mounts, primarily driven by the robust expansion of the automotive manufacturing sector in countries like China, India, Japan, and South Korea. High vehicle production volumes, coupled with increasing disposable incomes and a burgeoning middle-class population, fuel both OEM demand for new vehicles and a significant aftermarket for replacement parts. The region's rapid urbanization and developing infrastructure also contribute to higher vehicle usage and the need for regular maintenance and component replacement.

- North America: A mature yet stable market, North America exhibits consistent demand for automotive strut mounts, largely propelled by a substantial vehicle parc and the recurring need for replacements in an aging fleet. The region's focus on vehicle safety, comfort, and performance drives demand for high-quality and advanced strut mount technologies. The aftermarket segment here is particularly strong, supported by an established distribution network and a culture of proactive vehicle maintenance.

- Europe: Similar to North America, Europe is a well-established market characterized by stringent quality standards, a high penetration of premium and luxury vehicles, and a strong emphasis on reducing noise, vibration, and harshness (NVH). Countries like Germany, France, and the UK contribute significantly to both OEM demand, driven by their prominent automotive industries, and a robust aftermarket, fueled by an aging vehicle fleet and consumer preference for durable, high-performance components.

- Latin America: This region presents promising growth opportunities, albeit from a smaller base. Countries such as Brazil and Mexico are witnessing increasing vehicle production and sales, supported by economic development and improving road networks. This growth translates into rising demand for both OEM and aftermarket strut mounts. Local manufacturing capabilities are expanding, and international players are investing to tap into the region's burgeoning automotive sector.

- Middle East and Africa (MEA): The MEA region is experiencing gradual growth, influenced by industrialization, urbanization, and a growing consumer base with increasing purchasing power. While specific country dynamics vary, the demand for automotive components, including strut mounts, is on an upward trajectory, supported by rising vehicle sales and the development of automotive assembly plants in certain countries. Infrastructure development also plays a role in increasing vehicle longevity and subsequent replacement part demand.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automotive Strut Mount Market.- Tenneco (DRiV)

- ZF Friedrichshafen AG (Lemförder)

- KYB Corporation

- Schaeffler AG

- Continental AG

- Vibracoustic GmbH

- Magneti Marelli (now Marelli)

- Federal-Mogul Motorparts (TMD Friction)

- Boge Rubber & Plastics

- Mando Corporation

- ACDelco (GM)

- Denso Corporation

- Sumitomo Riko Co., Ltd.

- NIKKI Co., Ltd.

- Hutchinson SA

- MAHLE GmbH

- Sogefi S.p.A.

- Bilstein

- Gabriel (Ancora)

- Corteco

Frequently Asked Questions

Analyze common user questions about the Automotive Strut Mount market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is an automotive strut mount and why is it important?

An automotive strut mount is a vital component connecting the vehicle's strut assembly to the chassis. It provides structural support, absorbs road impacts, and isolates noise and vibrations, ensuring proper steering, ride comfort, and overall vehicle stability and safety.

How often should automotive strut mounts be replaced?

Strut mounts are wear-and-tear components, and their lifespan depends on driving conditions and vehicle usage, typically lasting between 50,000 to 100,000 miles. It is often recommended to inspect them during every tire or brake service and consider replacement when replacing struts or shock absorbers.

What are the common symptoms of a failing strut mount?

Common symptoms include clunking or knocking noises from the suspension, especially over bumps, excessive vibration felt through the steering wheel or floorboards, poor steering response or looseness, uneven tire wear, and visible damage or corrosion to the strut mount itself.

How does the type of strut mount affect vehicle performance and comfort?

Different types like rubber-to-metal, polyurethane, hydraulic, and magnetic mounts offer varying degrees of damping, stiffness, and NVH isolation. For instance, hydraulic and magnetic mounts provide superior comfort and adaptive handling compared to standard rubber-to-metal ones, enhancing the overall driving experience.

What impact will electric vehicles have on the automotive strut mount market?

Electric vehicles, often heavier due to battery packs, may require redesigned or more robust strut mounts to handle increased weight and unique chassis dynamics. While EVs continue to use strut-based suspension, this shift will drive innovation in materials and design for enhanced durability and performance in the EV segment.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager