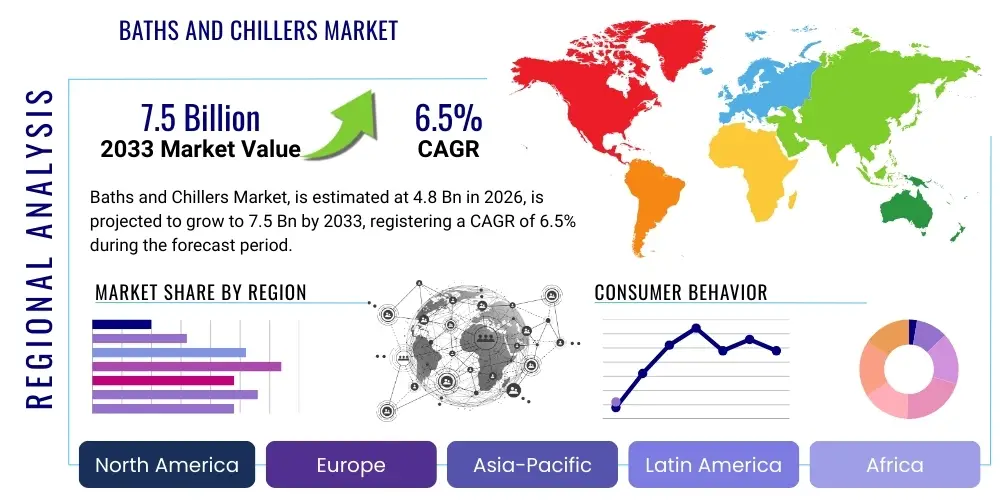

Baths and Chillers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442377 | Date : Feb, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Baths and Chillers Market Size

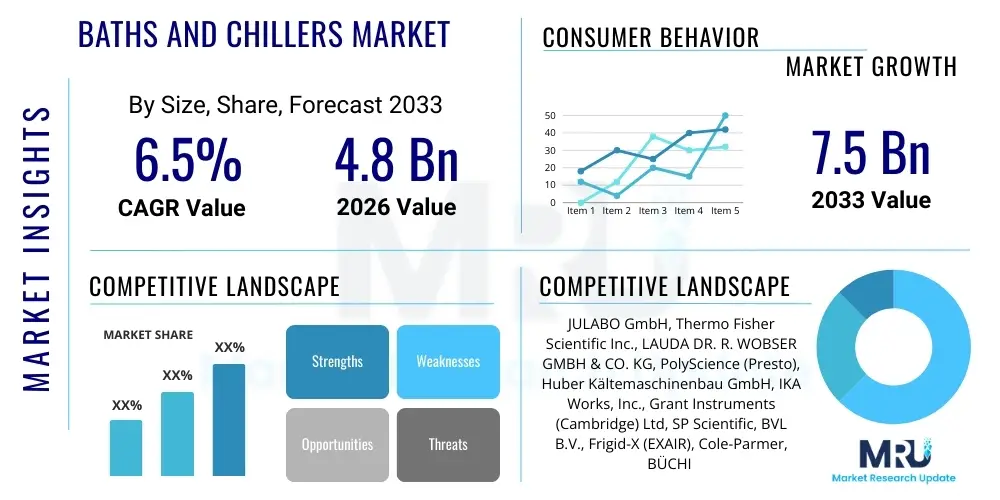

The Baths and Chillers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 4.8 Billion in 2026 and is projected to reach USD 7.5 Billion by the end of the forecast period in 2033.

Baths and Chillers Market introduction

The Baths and Chillers Market encompasses a vital segment of the laboratory and industrial equipment landscape, providing precise temperature control necessary for chemical reactions, stability testing, material processing, and biological sample preservation. Baths, including water baths, oil baths, and specialized circulating baths, offer highly uniform heating and sometimes cooling capabilities for sensitive experiments, ensuring reproducibility and accuracy in research and quality control environments. Chillers, conversely, are designed for the removal of heat from processes, maintaining specific low temperatures critical for condensation, extraction, calibration, and cooling of instrumentation such as analytical devices (e.g., mass spectrometers, electron microscopes) and fermentation vessels in biotechnology.

These devices are fundamental tools across numerous high-value applications, including pharmaceutical development, where they are essential for drug dissolution testing and long-term stability studies; in academic research for cell culture maintenance and complex synthesis; and in industrial sectors like food and beverage, petrochemicals, and semiconductor manufacturing for process temperature management. The increasing demand for automation in laboratories and stringent regulatory requirements regarding product quality and experimental accuracy are primary drivers bolstering the adoption of advanced, high-precision thermoregulation systems. Furthermore, the push towards green chemistry and energy efficiency is driving manufacturers to innovate with hydrocarbon refrigerants and variable speed technologies in chiller units.

Baths and Chillers Market Executive Summary

The Baths and Chillers Market is experiencing robust growth fueled by accelerated investments in biotechnology, pharmaceutical R&D, and expanding quality assurance mandates across regulated industries globally. Current business trends indicate a strong pivot toward intelligent, network-enabled units featuring touchscreens, remote monitoring capabilities, and compliance features, addressing the needs of modern, automated laboratories (Lab 4.0). Regionally, North America and Europe currently dominate the market due to established life science research hubs and stringent quality control protocols, though the Asia Pacific region is rapidly emerging as the fastest-growing market, driven by massive government investments in expanding domestic pharmaceutical manufacturing capacity and academic research infrastructure, particularly in China and India. Segment-wise, recirculating chillers, favored for their closed-loop efficiency and precision, are leading the growth trajectory, while end-users in the biotechnology and clinical diagnostic sectors represent the largest and most dynamic consumer groups, pushing demand for ultra-low temperature precision and reliability in highly sensitive applications.

AI Impact Analysis on Baths and Chillers Market

Common user questions regarding AI's impact on temperature control equipment revolve around how Artificial Intelligence can enhance energy efficiency, predict system failures (predictive maintenance), and optimize experimental protocols involving thermal regulation. Users are keen to understand if AI integration will lead to fully autonomous temperature monitoring systems capable of self-calibrating or adjusting cooling/heating cycles based on real-time sample dynamics or environmental fluctuations. The primary themes center on achieving higher operational precision, minimizing downtime associated with equipment failure, and streamlining data logging and compliance processes. Expectations suggest AI will move beyond simple data capture, offering prescriptive analytics that inform researchers on the optimal parameters for complex thermal profiles, thereby accelerating research cycles and reducing material waste.

AI's influence in the Baths and Chillers market is increasingly manifested through integrated software solutions that leverage machine learning algorithms to analyze large datasets derived from historical performance, environmental conditions, and user inputs. This sophisticated analysis allows for dynamic optimization of compressor and pump speeds, leading to significant reductions in energy consumption—a critical factor given the high power draw of continuous cooling operations. Furthermore, AI-driven diagnostic capabilities can detect subtle anomalies in vibration, temperature stability, or flow rates, predicting potential component degradation weeks before catastrophic failure occurs. This shift from reactive maintenance to predictive servicing fundamentally enhances laboratory efficiency and ensures the uninterrupted integrity of sensitive experimental work, bolstering user confidence in long-term equipment reliability.

- AI optimizes energy consumption by dynamically adjusting thermal output based on predictive load forecasting.

- Predictive maintenance algorithms reduce system downtime by identifying and flagging component wear and impending failures.

- Automated compliance reporting systems use AI to seamlessly log and analyze temperature stability data for regulatory audits (e.g., FDA).

- Enhanced thermal uniformity and precision are achieved through AI feedback loops that compensate for environmental and internal process variability.

- Integration with Laboratory Information Management Systems (LIMS) allows for AI-driven protocol optimization and remote thermal cycle management.

DRO & Impact Forces Of Baths and Chillers Market

The Baths and Chillers market expansion is significantly driven by escalating global investments in life sciences R&D, particularly in biologics and personalized medicine, which demand highly precise and reliable temperature control mechanisms for cell culture, fermentation, and sample storage. However, the market faces considerable restraints, including the high initial capital expenditure required for advanced, ultra-low temperature, and high-capacity recirculating chillers, alongside the complexities associated with phasing out traditional, high Global Warming Potential (GWP) refrigerants in compliance with international environmental protocols. The core opportunity lies in the burgeoning application areas like cryopreservation and high-throughput screening, demanding innovative, compact, and highly efficient modular systems. These dynamics create a powerful impact force where regulatory compliance (Restraint/Driver) accelerates technological innovation (Opportunity), particularly favoring manufacturers who successfully develop eco-friendly, IoT-enabled, and modular temperature control solutions.

Driving forces specifically include the mandatory requirements for quality control in food processing and beverage production, where maintaining specific temperature profiles is crucial for product safety and shelf stability. Additionally, the proliferation of sophisticated analytical instruments, such as high-resolution mass spectrometers and MRI systems, which rely heavily on dedicated, high-capacity cooling systems for optimal performance, continuously expands the end-user base. Conversely, the market is constrained by the cyclical nature of academic funding and the long replacement cycles typical of durable laboratory equipment, which can slow immediate adoption rates in established institutions. The pervasive impact forces ultimately propel manufacturers towards developing solutions that offer not only superior thermal performance but also substantially lower Total Cost of Ownership (TCO) through improved energy efficiency and enhanced longevity.

Opportunities are exceptionally strong in the development of specialized, non-standard units tailored for emerging industrial processes, such as advanced material synthesis and specialized battery manufacturing, which require extremely tight thermal tolerances across broad operating ranges. Furthermore, the global expansion of vaccine production and cold chain logistics necessitates robust, reliable chilling infrastructure. The primary risk, acting as a restraint, remains the volatile pricing and supply chain stability of specialized components, particularly semiconductors and compressors, which can disrupt manufacturing timelines and inflate final product costs, challenging market stability and pricing strategies.

Segmentation Analysis

The Baths and Chillers market is broadly segmented based on the type of equipment (Baths vs. Chillers), the specific technology employed (e.g., Compressor-based vs. Thermoelectric), the operational temperature range, the capacity, and the dominant end-user applications. Segmentation is crucial as the performance requirements vary drastically between, for example, a general-purpose laboratory water bath used for incubation and a high-capacity industrial chiller supporting a petrochemical reactor. The analysis of these segments reveals distinct growth patterns, with recirculating chillers consistently outpacing traditional bath sales due to their enhanced precision, ability to support external systems, and superior efficiency in closed-loop thermal management across diverse industries.

The core segments demonstrate varying maturity levels. Water baths are highly mature and commoditized, focusing primarily on cost and basic reliability, whereas complex, ultra-low temperature chillers represent the high-growth, high-value segment driven by advanced research needs in cryogenics and vaccine development. Understanding these nuanced demands allows market players to tailor their product development—for instance, focusing on environmentally friendly refrigerants (a key trend in the chiller segment) or developing modular, easy-to-clean designs (important for high-throughput laboratory baths).

- By Product Type:

- Baths (Water Baths, Oil Baths, Circulating Baths, Shaking Baths)

- Chillers (Recirculating Chillers, Immersion Chillers, Cold Traps)

- By Temperature Range:

- Below 0°C (Ultra-low, Low Temperature)

- 0°C to 100°C (Medium Temperature)

- Above 100°C (High Temperature)

- By Capacity:

- Small (Under 5 Liters/Less than 1kW)

- Medium (5-20 Liters/1kW-5kW)

- Large (Above 20 Liters/Above 5kW)

- By End-User:

- Pharmaceutical & Biotechnology Companies

- Academic & Research Institutions

- Clinical & Diagnostic Laboratories

- Industrial (Chemical, Food & Beverage, Semiconductor)

- By Technology:

- Compressor-Based

- Thermoelectric (Peltier)

Value Chain Analysis For Baths and Chillers Market

The value chain for the Baths and Chillers market begins with upstream analysis involving the sourcing of specialized raw materials and critical components, most notably high-efficiency compressors (the heart of chiller systems), precision temperature sensors (thermocouples, RTDs), refrigeration circuits, pumps, and insulation materials. Key suppliers in this phase often include global specialized electronics and compressor manufacturers, whose technological advancements directly impact the final product's efficiency and environmental compliance. Price volatility and technological maturity of these components significantly dictate manufacturing costs and product innovation timelines, requiring strong, strategic partnerships with Tier 1 component providers to ensure supply chain resilience and quality control.

The midstream focuses on manufacturing and assembly, where specialized thermal engineering expertise is required to integrate complex cooling/heating circuits, precision electronics, and user interfaces into durable, reliable systems. Distribution channels are typically a combination of direct sales for high-value, custom industrial chiller installations and a robust network of indirect distributors and laboratory supply houses for standard laboratory baths and small-to-medium recirculating chillers. The effectiveness of the indirect channel is critical for market penetration into diverse academic and clinical settings, where established relationships and localized technical support are paramount for securing sales and providing after-market services.

Downstream activities center on the installation, maintenance, calibration, and disposal/recycling of equipment. Direct channels usually handle large industrial installations requiring specialized training, whereas general laboratory products are supported by distributor-led technical services. Post-sales service is a major differentiator in this market, as equipment malfunction can critically halt high-stakes R&D or production lines. End-users demand rapid response and reliable calibration services to maintain accreditation and experimental integrity. Furthermore, the final stage includes the ethical and compliant handling of refrigerants and electronic waste upon equipment decommissioning, aligning with stringent global environmental regulations, which adds complexity to the final lifecycle management phase.

Baths and Chillers Market Potential Customers

Potential customers for baths and chillers span a wide array of sectors fundamentally reliant on precision thermal management for their operational integrity and product quality. The largest and most lucrative segment consists of pharmaceutical and biotechnology companies, which utilize these systems for critical processes such as drug formulation, stability storage of active pharmaceutical ingredients (APIs), biological reaction optimization in bioreactors, and sample preparation for analytical chemistry. These customers demand highly reliable, validated, and often specialized (e.g., explosion-proof or ultra-low temperature) equipment that complies strictly with Good Manufacturing Practice (GMP) and regulatory standards, making long-term operational costs and validation support key purchasing criteria.

Academic and government research institutions represent another crucial customer segment, utilizing baths and chillers for fundamental research in chemistry, physics, and life sciences. While often constrained by budget, these institutions require versatility and durability, frequently opting for standardized, modular units suitable for diverse experimental needs. Clinical diagnostic laboratories also constitute significant buyers, relying on precision baths for hematology, immunoassay testing, and sample incubation, where temperature accuracy directly impacts patient diagnostic results. The expanding global network of clinical testing facilities, particularly in emerging markets, promises consistent growth in this segment.

Furthermore, the industrial sector, including specialized chemical manufacturing, materials testing, and particularly the rapidly expanding semiconductor and electronics cooling industry, offers substantial growth potential. These industrial customers typically require high-capacity, heavy-duty chillers capable of continuous operation and complex thermal loads, often seeking bespoke systems designed for integration into large-scale production lines. The decision-making process in this segment is heavily influenced by energy efficiency (COP value), system longevity, and integration ease with existing facility management systems, positioning high-performance industrial chillers as high-value assets.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.8 Billion |

| Market Forecast in 2033 | USD 7.5 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | JULABO GmbH, Thermo Fisher Scientific Inc., LAUDA DR. R. WOBSER GMBH & CO. KG, PolyScience (Presto), Huber Kältemaschinenbau GmbH, IKA Works, Inc., Grant Instruments (Cambridge) Ltd, SP Scientific, BVL B.V., Frigid-X (EXAIR), Cole-Parmer, BÜCHI Labortechnik AG, Peter Huber Kältemaschinenbau AG, RMT Ltd., Technel Engineering Inc., VWR International, Corning Incorporated, Neslab Instruments, Inc., Heidolph Instruments GmbH & CO. KG, Across International. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Baths and Chillers Market Key Technology Landscape

The core technological landscape in the Baths and Chillers market is defined by the ongoing pursuit of increased thermal efficiency, superior temperature stability, and environmentally sustainable operation. A pivotal technological shift involves the transition from traditional vapor compression systems utilizing high-GWP HFC refrigerants (like R-404A or R-134a) toward more sustainable, low-GWP natural refrigerants, such as propane (R-290) and isobutane (R-600a), which are compliant with global regulations like the European F-Gas Regulation and similar mandates elsewhere. This transition requires significant redesigns of compressor technologies and heat exchangers to safely handle these flammable yet highly efficient refrigerants, driving innovation in microchannel heat exchangers and advanced hermetic compressor designs that minimize leakage and maximize performance in a compact footprint.

Another major technological advancement is the integration of advanced control systems utilizing proportional-integral-derivative (PID) controllers and fuzzy logic algorithms. These sophisticated controls enable micro-level adjustments to heating and cooling cycles, leading to exceptional temperature uniformity and rapid attainment of setpoints, crucial for sensitive analytical applications. The adoption of IoT and connectivity features—including integrated Ethernet ports, Wi-Fi capabilities, and cloud-based data logging platforms—is transforming these devices into 'smart laboratory equipment.' This allows for remote diagnostics, centralized performance monitoring across multiple units, and automated data archiving, which significantly aids in meeting stringent validation and auditing requirements in regulated industries like pharmaceuticals.

Furthermore, the market is seeing increased development of solid-state cooling solutions, predominantly utilizing the Peltier effect (thermoelectric cooling), especially for smaller, lower-capacity temperature control needs. While currently less powerful than compressor-based systems, Peltier technology offers advantages in size, silence, and the complete elimination of refrigerants, making them ideal for integration into robotics and automated workstations requiring rapid temperature shifts without the bulk of a traditional compressor system. Manufacturers are heavily investing in material science research to enhance the efficiency and operational range of these solid-state devices, aiming to challenge the dominance of compressor technology in medium-capacity applications.

Regional Highlights

- North America: North America holds the largest market share, predominantly driven by the robust presence of leading pharmaceutical and biotechnology companies and substantial government funding directed towards academic research and cutting-edge drug discovery initiatives. The region is characterized by high adoption rates of advanced, automated chilling systems and ultra-low temperature equipment necessary for clinical trials and large-scale bioreactor cooling. Strict regulatory oversight by bodies like the FDA necessitates the use of validated and highly reliable thermal control equipment, creating a premium market focused on quality, compliance, and energy efficiency.

- Europe: Europe represents a mature and technologically advanced market, second only to North America. Growth is significantly influenced by the European Union’s strong commitment to green technology, specifically the stringent enforcement of the F-Gas Regulation, which mandates the phase-down of high-GWP refrigerants. This regulatory environment fuels demand for innovative, eco-friendly systems utilizing natural refrigerants (R-290, R-600a). Major contributing factors include leading chemical and automotive research hubs, strong academic collaboration, and widespread investment in industrial quality control testing, particularly in Germany and the UK.

- Asia Pacific (APAC): The APAC region is poised to exhibit the fastest growth over the forecast period. This accelerated expansion is primarily attributable to massive government investments aimed at boosting domestic pharmaceutical production (e.g., 'Make in India' and China's strategic plans), the establishment of new clinical diagnostic centers, and the rapid urbanization and industrialization across Southeast Asia. While price sensitivity remains a factor, the increasing need for high-precision equipment in emerging R&D centers in countries like South Korea, Japan, and Singapore is rapidly shifting demand toward medium-to-high capacity, high-performance chillers and baths.

- Latin America (LATAM): The LATAM market shows moderate, steady growth, mainly centered in Brazil, Mexico, and Argentina. Market adoption is fragmented, with significant demand originating from food processing, beverage production, and localized generic drug manufacturing. While budget constraints often favor basic or mid-range equipment, the expanding clinical laboratory infrastructure, particularly in major urban centers, is creating pockets of demand for reliable, standard-capacity water baths and chillers.

- Middle East and Africa (MEA): The MEA region is developing, characterized by focused investments in healthcare infrastructure and petrochemical research, particularly in the Gulf Cooperation Council (GCC) countries. The demand is often project-based, linked to the establishment of new university science parks or major oil and gas research facilities. The extreme ambient temperatures in many parts of the region necessitate high-durability and high-efficiency cooling equipment designed to withstand challenging operating conditions, driving adoption of robust, specialized industrial chilling solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Baths and Chillers Market.- JULABO GmbH

- Thermo Fisher Scientific Inc.

- LAUDA DR. R. WOBSER GMBH & CO. KG

- PolyScience (Presto)

- Huber Kältemaschinenbau GmbH

- IKA Works, Inc.

- Grant Instruments (Cambridge) Ltd

- SP Scientific

- BVL B.V.

- Frigid-X (EXAIR)

- Cole-Parmer

- BÜCHI Labortechnik AG

- Peter Huber Kältemaschinenbau AG

- RMT Ltd.

- Technel Engineering Inc.

- VWR International

- Corning Incorporated

- Neslab Instruments, Inc.

- Heidolph Instruments GmbH & CO. KG

- Across International

Frequently Asked Questions

Analyze common user questions about the Baths and Chillers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Baths and Chillers in a laboratory setting?

Baths primarily function to maintain precise, uniform temperatures, typically for heating or incubation of samples in an open or circulatory vessel. Chillers, specifically recirculating chillers, are designed to continuously remove heat from external instrumentation or processes using a closed-loop system, ensuring stable, controlled cooling for equipment like rotary evaporators or analytical devices.

Which environmental regulations are most significantly impacting chiller technology design?

The most significant impact comes from regulations like the European F-Gas Regulation and similar global mandates aimed at phasing out high Global Warming Potential (GWP) hydrofluorocarbon (HFC) refrigerants. This shift compels manufacturers to innovate using natural, low-GWP refrigerants such as propane (R-290) and carbon dioxide (R-744).

How is the integration of IoT influencing the performance and maintenance of modern Baths and Chillers?

IoT integration allows for remote monitoring, predictive maintenance, and cloud-based data logging, dramatically improving operational efficiency. It enables real-time system diagnostics to anticipate failures, ensures continuous temperature stability documentation for compliance, and allows researchers to manage thermal profiles remotely.

What is driving the high demand for ultra-low temperature chilling equipment?

High demand for ultra-low temperature equipment (below -40°C) is primarily driven by expanding pharmaceutical R&D, specifically in vaccine production (requiring stringent storage conditions), cryopreservation of biological materials, and advanced material science research requiring extremely cold thermal environments for synthesis and testing.

Which end-user segment is forecasted to show the highest growth rate in the market?

The Pharmaceutical and Biotechnology segment, particularly fueled by the expansion of biologics manufacturing and personalized medicine research across APAC, is forecasted to exhibit the highest sustained growth rate due to its critical need for validated, high-precision thermal control systems across all stages of development and manufacturing.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager