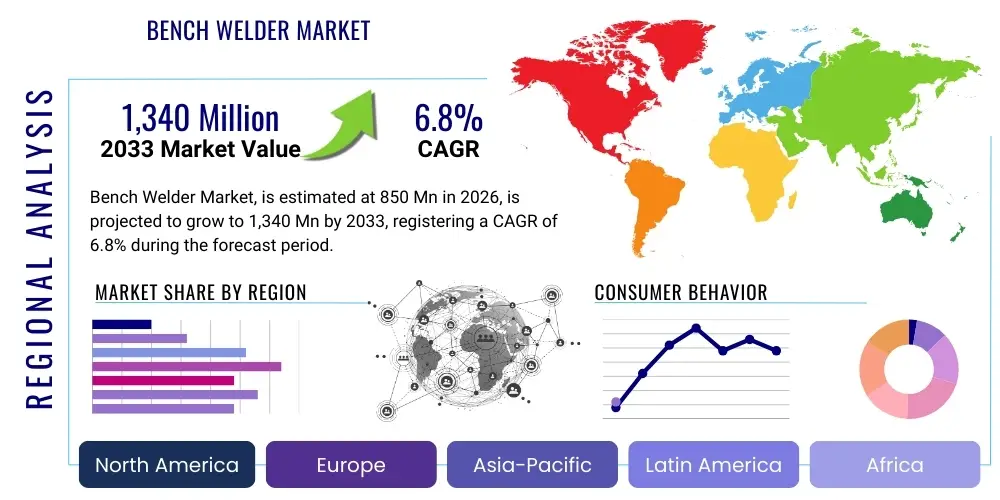

Bench Welder Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441910 | Date : Feb, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Bench Welder Market Size

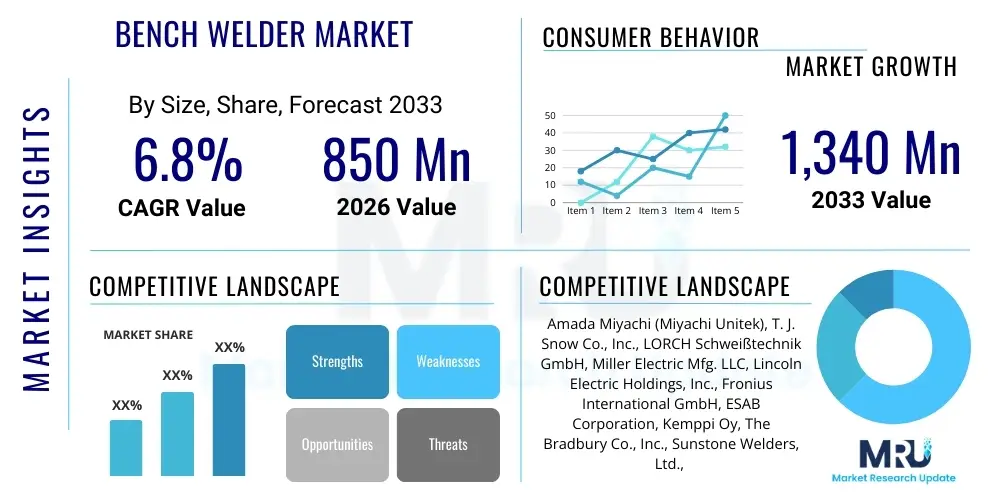

The Bench Welder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1,340 Million by the end of the forecast period in 2033.

Bench Welder Market introduction

The Bench Welder Market encompasses the production, distribution, and utilization of compact, stationary welding apparatus designed primarily for precision tasks and small-scale manufacturing or repair operations. These devices, which include various technologies such as resistance welding, spot welding, TIG, and specialized micro-welding systems, are essential tools in industries requiring meticulous joining of materials where portability is secondary to stability and accuracy. The primary applications span electronics assembly, jewelry fabrication, dental laboratories, small component repair in automotive sectors, and general hobbyist or prototype development workshops. Bench welders offer significant advantages over larger industrial units, including reduced footprint, lower energy consumption, and superior control over intricate welding parameters, making them ideal for high-precision, low-volume environments. This widespread applicability across diverse technical fields underscores the market's stability and consistent growth trajectory, driven by increasing automation in niche manufacturing and the rising demand for bespoke fabricated goods.

Key drivers propelling the adoption of bench welders include the miniaturization of electronic components, necessitating highly precise and controlled joining methods, and the expansion of small and medium-sized enterprises (SMEs) globally, which often prioritize cost-effective, space-saving equipment. Furthermore, the growing trend of personalized manufacturing and the popularity of DIY and artisanal trades, particularly in developed economies, fuel demand for reliable and accessible benchtop welding solutions. The continuous evolution of welding technology, specifically the integration of digital controls and advanced feedback systems, enhances the usability and repeatability of these machines, thereby expanding their market penetration. However, the market is also characterized by intense competition among manufacturers striving to offer higher power density and multi-process capabilities within a compact form factor.

Bench Welder Market Executive Summary

The Bench Welder Market is demonstrating robust business trends characterized by a foundational shift towards intelligent, digitally integrated welding systems, emphasizing precision and energy efficiency. Key business trends involve the consolidation of smaller manufacturers by major global players aiming to achieve economies of scale and integrate advanced sensor technology for real-time quality control. Furthermore, the rising adoption of specialized bench welding techniques, such as laser welding and micro-TIG, is creating premium market segments. Suppliers are increasingly focusing on modular designs that allow users to adapt their bench welders for different materials (e.g., titanium, stainless steel, precious metals) and diverse process requirements, catering to the highly specialized needs of the aerospace and medical device sectors. The growing emphasis on sustainability also drives demand for bench welders that minimize waste and optimize power usage.

Regionally, the Asia Pacific (APAC) region continues to dominate the market in terms of volume, driven by high concentrations of electronics manufacturing and expansive automotive supply chains in China, Japan, and South Korea. However, North America and Europe are leading in terms of value growth, primarily due to the rapid adoption of high-end automated bench welders used in advanced manufacturing, particularly medical devices and defense applications, where stringent quality standards necessitate state-of-the-art equipment. Segment trends indicate that resistance bench welders still hold a substantial market share due to their affordability and widespread use in sheet metal and general assembly, while the fastest growth is observed in the high-frequency and laser bench welder segments, reflecting the broader industrial shift towards high-speed, non-contact joining methodologies. The educational and professional training segment is also seeing an uptick, integrating bench welders into vocational curricula to train the next generation of technicians.

AI Impact Analysis on Bench Welder Market

Analysis of common user questions reveals a significant interest regarding how Artificial Intelligence (AI) and Machine Learning (ML) will transform the operational efficiency and quality control within bench welding applications. Users frequently ask about the feasibility of AI optimizing complex weld paths, adjusting parameters based on real-time material feedback (e.g., changes in metal thickness or surface contamination), and automating fault detection to minimize rework. Concerns center on the cost of implementing AI-driven systems in traditionally cost-sensitive benchtop environments and the necessary skill evolution for technicians. Expectations are high regarding predictive maintenance capabilities, seamless integration with CAD/CAM software for prototype work, and the potential for AI algorithms to achieve welding precision currently unattainable by manual or simple automated systems, thereby improving throughput and consistency, especially in intricate and repetitive tasks common in microelectronics and medical component manufacturing.

The implementation of AI algorithms, particularly deep learning models, is projected to revolutionize quality assurance in the Bench Welder Market. Instead of relying solely on post-process inspection, AI enables real-time monitoring through vision systems and sensor fusion, immediately identifying and correcting deviations in arc stability, heat input, or material distortion. This capability translates directly into higher yield rates and reduced material waste, offering a compelling return on investment for high-volume, high-precision manufacturers utilizing advanced bench welding equipment. Moreover, AI is instrumental in simulating welding outcomes before physical execution, allowing technicians and engineers to rapidly prototype optimal welding schedules for new materials or geometries, significantly shortening the development lifecycle for specialized components manufactured using bench welders.

Furthermore, AI facilitates the democratization of expertise. By embedding specialized knowledge—such as best practices for welding exotic alloys—into the machine control systems, operators with moderate experience can achieve results comparable to those of highly skilled master welders. This shift addresses the global shortage of certified welding technicians. AI-powered benchmarking systems continuously analyze operational data across multiple machines, identifying efficiency bottlenecks and automatically deploying firmware updates or parameter adjustments to optimize performance across an entire fleet of bench welders. This enhanced level of self-optimization elevates the overall standard of bench welding processes from simple assembly to critical precision engineering.

- AI-driven real-time parameter adjustment based on sensor fusion and material feedback.

- Automated defect detection and quality assessment using machine vision systems, minimizing rework.

- Predictive maintenance schedules for bench welder components, enhancing uptime.

- Optimization of complex weld sequences and path planning through sophisticated ML algorithms.

- Integration of digital twins for simulating welding outcomes and rapid process prototyping.

- Reduction of dependence on highly specialized manual skills through embedded expertise.

DRO & Impact Forces Of Bench Welder Market

The Bench Welder Market's dynamics are shaped by a complex interplay of Drivers (D), Restraints (R), Opportunities (O), and internal/external Impact Forces. Key drivers include the global expansion of precision manufacturing sectors, such as medical devices, aerospace component fabrication, and electronics assembly, all of which rely heavily on stable, controlled benchtop welding processes. The ongoing trend of miniaturization across consumer and industrial products necessitates highly accurate joining technologies that bench welders provide. Restraints primarily involve the high initial capital expenditure associated with advanced bench welders (e.g., laser and micro-TIG systems), particularly challenging for smaller workshops, alongside the regulatory complexities and standardization requirements for welded parts in highly regulated industries. The impact forces are currently skewed positively, driven by rapid technological advancements in power electronics and digital controls, pushing performance boundaries while simultaneously increasing competitive intensity among global vendors.

Significant opportunities arise from the increasing demand for specialized material welding capabilities, such as joining dissimilar metals and advanced composites, pushing manufacturers toward developing multi-process bench welders capable of handling varied material science challenges. Furthermore, the burgeoning market for customized medical implants and specialized tooling presents a lucrative niche for high-precision bench welding solutions. The primary internal impact force is the relentless pursuit of increased automation and integration capabilities, enabling bench welders to function seamlessly within robotic cells or automated production lines, maximizing throughput and minimizing human error. Externally, geopolitical shifts impacting global supply chains incentivize local, smaller-scale manufacturing setups, thereby driving demand for localized, efficient, and compact welding solutions like bench welders.

However, the market faces structural restraints related to skill gaps. While the machines become more sophisticated, finding skilled technicians capable of maintaining and programming advanced bench welders remains a challenge, particularly in developing markets. This skill deficiency often hampers the full utilization of the high-end features available. Furthermore, intensified raw material price volatility, particularly for components like rare earth magnets used in advanced power supplies, poses a cost pressure constraint. Successfully navigating these restraints necessitates manufacturers offering comprehensive training and robust technical support alongside their equipment, turning potential barriers into avenues for value-added service provision and deeper customer relationships.

Segmentation Analysis

The Bench Welder Market is comprehensively segmented based on technology type, power source, application, and end-user industry. This granular analysis is crucial for stakeholders to identify key growth areas and tailor product development strategies. The technology segmentation differentiates between traditional resistance welding, specialized spot welding, and advanced laser/micro-TIG options, reflecting the varying levels of precision and material compatibility required by different end-users. Power source segmentation highlights the shift from conventional AC systems towards more stable and precise DC and high-frequency inverter-based technologies, which offer superior control necessary for delicate assembly work. Application segmentation is vital, separating standard repair/fabrication tasks from highly critical procedures in medical or aerospace manufacturing.

- By Technology Type:

- Resistance Bench Welders

- Spot Bench Welders

- TIG/Micro-TIG Bench Welders

- Laser Bench Welders

- Ultrasonic Bench Welders

- By Power Source:

- AC Powered

- DC/Inverter Powered

- Battery Powered (Portable Benchtop Units)

- By Application:

- Electronics and Micro-component Assembly

- Jewelry and Precious Metal Fabrication

- Dental and Medical Device Manufacturing

- Small Automotive Component Repair

- General Fabrication and Workshop Use

- By End-User Industry:

- Aerospace and Defense

- Medical and Healthcare

- Automotive (Tier 2/3 Suppliers)

- Consumer Electronics

- R&D and Academic Institutions

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Bench Welder Market

The value chain for the Bench Welder Market commences with the upstream segment, encompassing the sourcing and processing of core raw materials and components. This includes specialized power semiconductor modules (inverters), precision mechanical parts, sophisticated control chips, and high-purity metals for electrodes and welding tips. Key upstream activities are dominated by specialized electronic component manufacturers and precision engineering firms. High dependency on global suppliers for microprocessors and advanced power supplies makes this segment vulnerable to geopolitical supply chain disruptions. Efficiency in the upstream phase, particularly cost management for proprietary technology components, directly impacts the final manufacturing cost and competitive pricing of bench welders.

The midstream segment involves the core manufacturing, assembly, and integration of the bench welding systems. Manufacturers focus on engineering design, quality assurance, calibration, and software development (including AI/ML integration for newer models). This stage adds the most significant value, translating raw components into highly precise and reliable industrial tools. Differentiation often occurs here through proprietary welding control algorithms and ergonomic design tailored for benchtop operation. Following manufacturing, the distribution channel plays a critical role, involving both direct sales models, especially for high-value specialized equipment sold to large medical or aerospace clients, and indirect channels leveraging regional distributors and e-commerce platforms to reach SMEs, educational institutions, and hobbyists. E-commerce platforms are increasingly important for standardized spot and resistance bench welders due to their wide reach and streamlined logistics.

The downstream segment primarily involves end-user deployment, maintenance, and technical support. Crucial elements here are training services, calibration checks, and the provision of consumables and spare parts (electrodes, shielding gases, etc.). Long-term value capture is often realized through maintenance contracts and upgrades, particularly as manufacturers push new software features and improved automation capabilities. Direct distribution channels allow manufacturers to maintain control over after-sales service quality, which is paramount in high-precision sectors. Conversely, indirect channels rely heavily on the technical competence of third-party distributors to maintain brand reputation and ensure customer satisfaction across diverse geographical regions and technical needs, completing the lifecycle of the bench welding apparatus.

Bench Welder Market Potential Customers

Potential customers for the Bench Welder Market are highly diverse, spanning specialized engineering firms to individual artisans, all characterized by the common need for stable, precise, and compact welding solutions. The largest segment of end-users consists of Small and Medium-sized Enterprises (SMEs) engaged in general fabrication, repair workshops, and custom metalworking, seeking cost-effective and reliable equipment for moderate-volume production. High-value customers include manufacturers in the medical device industry (e.g., producing catheters, pacemakers, surgical tools), where micro-welding and TIG bench systems are indispensable for joining biocompatible materials under stringent quality control standards. These buyers prioritize repeatability, documentation features, and regulatory compliance.

Another rapidly growing customer base is found in the consumer electronics sector, particularly in the assembly of printed circuit boards (PCBs), battery packs, and sensors, demanding specialized resistance and ultrasonic bench welders for microscopic connections. Academic institutions and vocational training centers represent consistent buyers, utilizing bench welders for educational purposes, rapid prototyping, and material science research, valuing durability and ease of use. Furthermore, defense and aerospace contractors constitute a premium customer segment, utilizing advanced laser bench welders for mission-critical components that require flawless welds on exotic and high-performance alloys, where failure is not an option and precision is paramount to structural integrity and operational safety.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1,340 Million |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Amada Miyachi (Miyachi Unitek), T. J. Snow Co., Inc., LORCH Schweißtechnik GmbH, Miller Electric Mfg. LLC, Lincoln Electric Holdings, Inc., Fronius International GmbH, ESAB Corporation, Kemppi Oy, The Bradbury Co., Inc., Sunstone Welders, Ltd., Orbitalum Tools GmbH, LaserStar Technologies, Co., Sisma S.p.A., Rofin-Sinar Technologies (Coherent), Huayi Electric Appliance Group, Swisstec Micro Weld AG, Maxtek Micro Weld, Thermal Arc (Victor Technologies), Carl Cloos Schweisstechnik GmbH, CEA S.p.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Bench Welder Market Key Technology Landscape

The Bench Welder Market is undergoing rapid technological evolution, moving beyond traditional transformer-based resistance welding toward sophisticated inverter and solid-state systems. The shift is primarily driven by the need for superior control over energy delivery, crucial for welding delicate materials and achieving micro-scale precision. Inverter technology, using high-frequency switching, enables highly stable current output regardless of line voltage fluctuations, resulting in consistently high-quality welds and significantly smaller machine footprints compared to older AC systems. Furthermore, the integration of digital Signal Processing (DSP) allows for complex current profiles (e.g., pulsed sequences, slope control) essential for materials like titanium and specialized stainless steels common in high-tech industries. This precision capability positions inverter bench welders as the preferred choice for critical applications.

A major advancement defining the modern bench welder landscape is the proliferation of laser welding technology. Fiber lasers and Nd:YAG lasers offer non-contact, extremely focused heat input, minimizing the Heat-Affected Zone (HAZ) and distortion, which is vital for thin-gauge metals and sensitive electronic components. Benchtop laser welders are characterized by rapid processing speeds and high automation potential, often integrated with robotic positioning systems for high-throughput micro-assembly. Complementary to this, the development of sophisticated vision systems and optical feedback loops is now standard, enabling real-time monitoring and closed-loop control of the welding process, drastically improving traceability and adherence to quality specifications in sectors like medical device manufacturing, where regulatory documentation is mandatory.

In addition to hardware innovations, the technological landscape includes significant software and connectivity enhancements. Modern bench welders often feature industrial IoT (IIoT) capabilities, allowing for remote diagnostics, centralized data logging, and seamless integration with factory management systems (MES/ERP). This connectivity facilitates compliance tracking and enables global manufacturers to monitor performance across dispersed facilities. Furthermore, the incorporation of Human-Machine Interfaces (HMIs) has become highly intuitive, utilizing touchscreens and graphical interfaces to simplify complex parameter setup, thereby reducing training time and operational errors. The combination of precision hardware, sophisticated vision systems, and enhanced digital connectivity underpins the competitive advantage of leading market players.

Regional Highlights

Regional dynamics play a crucial role in shaping the demand and technological adoption within the Bench Welder Market, reflecting varying levels of industrialization, regulatory environments, and manufacturing concentration.

- Asia Pacific (APAC): APAC is the dominant market globally, primarily driven by massive production volumes in consumer electronics, automotive components, and general manufacturing, particularly in China, South Korea, and India. The region demonstrates high adoption rates of resistance and spot bench welders due to their cost-effectiveness and scalability in mass production environments. Furthermore, emerging economies within Southeast Asia are increasing their investment in vocational training and small-scale manufacturing infrastructure, bolstering demand for accessible benchtop solutions, solidifying its position as the largest consumer market.

- North America: Characterized by a strong focus on high-value, high-precision manufacturing, North America leads in the adoption of advanced laser and micro-TIG bench welders. Key demand segments include aerospace (e.g., specialized repairs and component fabrication) and the biomedical industry, driven by strict quality standards and the necessity for exceptional weld integrity and traceability. The presence of major R&D institutions and a strong emphasis on automation further boosts market value and technological advancement in the region.

- Europe: Europe exhibits mature market characteristics, with Germany, Italy, and Switzerland being central hubs for advanced engineering and automotive component manufacturing. The region emphasizes quality, sustainability, and industrial efficiency, leading to high penetration of energy-efficient inverter-based and robotic-integrated bench welding systems. Stringent environmental regulations also favor cleaner welding technologies, such as laser systems, minimizing fumes and material waste and promoting niche specialization in high-end machinery.

- Latin America (LATAM): The LATAM market is growing steadily, propelled by infrastructure development and local assembly operations, particularly in Brazil and Mexico (part of the North American automotive supply chain). Demand is concentrated primarily in general fabrication and mid-range spot welding equipment, though increasing foreign direct investment is starting to drive adoption of more specialized equipment in electronics assembly and small component manufacturing sectors.

- Middle East and Africa (MEA): Growth in MEA is sector-specific, largely driven by investments in energy infrastructure, defense, and localized repair operations. While overall market size is smaller, capital-intensive projects necessitate specialized, robust bench welders for maintenance and assembly in oil & gas and construction support industries, often prioritizing ruggedness and reliability under harsh operating conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Bench Welder Market.- Amada Miyachi (Miyachi Unitek)

- T. J. Snow Co., Inc.

- LORCH Schweißtechnik GmbH

- Miller Electric Mfg. LLC

- Lincoln Electric Holdings, Inc.

- Fronius International GmbH

- ESAB Corporation

- Kemppi Oy

- The Bradbury Co., Inc.

- Sunstone Welders, Ltd.

- Orbitalum Tools GmbH

- LaserStar Technologies, Co.

- Sisma S.p.A.

- Rofin-Sinar Technologies (Coherent)

- Huayi Electric Appliance Group

- Swisstec Micro Weld AG

- Maxtek Micro Weld

- Thermal Arc (Victor Technologies)

- Carl Cloos Schweisstechnik GmbH

- CEA S.p.A.

Frequently Asked Questions

Analyze common user questions about the Bench Welder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected growth rate (CAGR) for the Bench Welder Market through 2033?

The Bench Welder Market is anticipated to exhibit a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033, driven by increasing demand for precision welding in electronics and medical manufacturing and the continuous miniaturization of industrial components.

Which technology segment is experiencing the fastest growth in the market?

The Laser Bench Welder and Micro-TIG segments are projected to record the fastest growth, primarily due to their superior precision, non-contact operation, and minimal heat input, which are essential for miniaturized components and exotic alloy fabrication in high-tech industries.

How is AI impacting the quality control processes of bench welding?

AI is significantly enhancing quality control by enabling real-time monitoring, automated defect detection via machine vision, and precise parameter adjustment based on instantaneous feedback, leading to higher yield rates and improved weld consistency and traceability.

Which geographic region currently dominates the global Bench Welder Market?

The Asia Pacific (APAC) region currently dominates the market volume, fueled by its expansive manufacturing base in consumer electronics and automotive sectors. North America and Europe, however, lead in value-based adoption of high-end, specialized systems used in aerospace and medical applications.

What are the primary restraints affecting the expansion of the Bench Welder Market?

Key restraints include the high initial capital investment required for advanced laser and inverter-based bench welders, which challenges SMEs, and the persistent global shortage of skilled technical personnel capable of operating, programming, and maintaining sophisticated equipment efficiently.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager