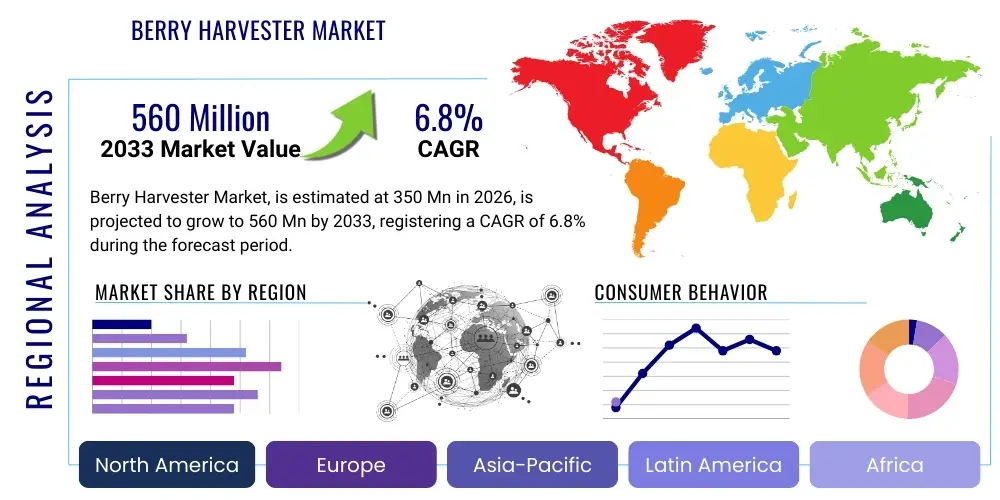

Berry Harvester Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443567 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Berry Harvester Market Size

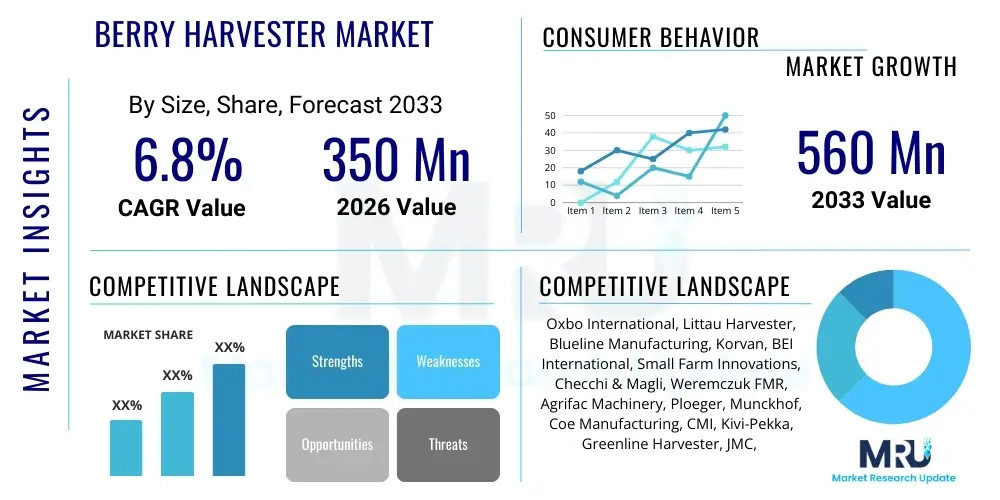

The Berry Harvester Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $350 Million USD in 2026 and is projected to reach $560 Million USD by the end of the forecast period in 2033.

Berry Harvester Market introduction

The Berry Harvester Market encompasses specialized agricultural machinery designed for the efficient, large-scale, and often selective collection of various soft fruits, primarily focusing on commercially significant berries such as highbush and lowbush blueberries, cane fruits like raspberries and blackberries, ground-level strawberries, and marsh-grown cranberries. This sophisticated equipment represents a crucial link in the modern supply chain, addressing the fundamental challenge of harvesting highly perishable crops efficiently during short, intensive picking windows. Harvesters utilize complex mechanical, pneumatic, and increasingly, robotic systems tailored to minimize fruit damage, maximize recoverable yield, and ensure the quality required for either fresh consumption or industrial processing. The evolution of these machines reflects the industry's sustained effort to decouple production volume from the limitations and increasing costs associated with manual labor availability.

Modern berry harvesters are not monolithic; they range significantly in scale and functionality, from massive self-propelled tunnel harvesters used in expansive North American blueberry fields to versatile tractor-mounted units favored in European mixed-crop farming, and specialized robotic platforms currently under intensive development for delicate fruits like strawberries. The core benefit derived from their adoption is the drastic reduction in harvest time and associated labor expenses, transforming what was once a bottleneck operation into a highly predictable industrial process. Furthermore, the integration of precision technologies allows for uniform picking maturity, contributing directly to an extended shelf life and higher market value for the final produce. These machines are increasingly viewed as foundational infrastructure for any commercial berry operation seeking global competitiveness and operational scalability in a highly demanding food market.

Driving factors propelling sustained market expansion are multifaceted, including the global rise in per capita berry consumption driven by health consciousness, the critical need to automate farm processes due to acute labor shortages worldwide, and favorable governmental policies supporting agricultural mechanization in both developed and emerging economies. Product descriptions increasingly emphasize machine learning and sensor integration for selective harvesting, which expands the applicability of mechanization to previously manual-only crops like fresh-market raspberries. The persistent challenge posed by climate variability and the need for rapid, guaranteed harvest completion further solidifies the economic justification for high-reliability, high-throughput berry harvesting equipment, establishing them as essential assets for mitigating climate-related risks to annual crop yields and maximizing return on investment across the agricultural cycle.

Berry Harvester Market Executive Summary

The Berry Harvester Market is defined by intense technological evolution and strategic consolidation among key players, reflecting a broader trend towards smart farming and automation in the agricultural sector. Current business trends are heavily influenced by the imperative to increase harvesting precision; manufacturers are investing heavily in technologies that mimic the gentleness of human hands, using 3D vision systems, advanced robotics, and air-cushion transport mechanisms. A major shift is the increasing focus on electrification and sustainability, with OEMs developing hybrid and fully electric self-propelled units to meet stricter emission standards and satisfy corporate sustainability goals of large agribusinesses. Strategic alliances between traditional machinery makers and specialized technology firms are accelerating the integration of AI-powered sorting and grading capabilities directly into the harvester chassis.

Regionally, the market exhibits a dichotomy: North America and Western Europe dominate in terms of market value and adoption of high-end, self-propelled machines, driven by high existing mechanization levels and critical labor shortages. However, the future trajectory points towards exponential growth in the Asia Pacific region, primarily fueled by massive infrastructure projects aimed at modernizing agriculture in nations like China and India, where manual labor transition to mechanical harvesting is still in its early stages. Latin America maintains strong relevance due to its role as a key global exporter of blueberries, mandating robust, efficient equipment to manage the large export volumes required during the counter-seasonal harvest period. These regional differences dictate the diversity in product mix and pricing strategies employed by leading market participants.

Segmental trends reveal persistent dominance of blueberry harvesters, reflecting the global ubiquity and robustness of the crop, but significant R&D efforts are concentrated on cracking the technological challenge of strawberry harvesting for the fresh market, which promises the largest future revenue opportunities. Within the equipment segment, while large commercial operations prefer the efficiency of self-propelled machines, the tractor-mounted segment continues to experience steady demand, largely supported by the expansive base of small and medium-sized farms seeking cost-effective entry into mechanization. Overall, the market trajectory indicates a future where digital integration—including telematics, remote diagnostics, and prescriptive harvesting—will become standard features, transforming harvesters from simple mechanical tools into interconnected data collection and optimization platforms.

AI Impact Analysis on Berry Harvester Market

The discourse surrounding AI in the Berry Harvester Market is centered on moving beyond basic automation to achieving intelligent, high-precision resource management. User inquiries frequently probe the maturity of AI-driven selective picking—specifically, the ability to reliably identify subtle variances in ripeness, pest damage, and physical integrity across large fields under varying lighting and dust conditions. Users are deeply concerned with the training requirements for these machine learning models, asking about the volume of data needed and the frequency of re-calibration. Furthermore, the economic viability of retrofitting older harvester models with new AI vision systems versus purchasing new specialized robotic units is a consistent theme, highlighting the investment dilemma faced by farmers balancing modernization costs against immediate efficiency gains in labor reduction and quality control.

AI's immediate tangible impact is transforming the quality control process. By employing Convolutional Neural Networks (CNNs) trained on thousands of berry images, integrated vision systems atop the harvester conveyor belt can rapidly and accurately identify defective, undersized, or under-ripe fruits. This real-time sorting drastically reduces the reliance on subsequent stationary packing house grading, allowing only premium produce to enter the cooling chain, thereby maximizing freshness retention and minimizing post-harvest logistics costs. This capability ensures compliance with increasingly strict retailer quality specifications, enabling farmers to command higher prices for their harvested volumes. The efficacy of these systems is crucial, as even minor errors can lead to substantial financial losses due to rejection rates.

Moreover, AI extends its influence into operational efficiency and predictive farm management. Machine learning algorithms analyze historical and current performance data—including weather patterns, soil moisture readings, yield mapping, and mechanical sensor outputs—to provide prescriptive adjustments for the harvester operator or the autonomous control system. This predictive capability allows the machine to adjust speed, shaker force, and conveyor tilt dynamically, optimizing performance against varying crop density or terrain gradients, which is essential for minimizing fruit drop and machine wear. Ultimately, the long-term impact of AI is the transition toward fully autonomous harvesting fleets that integrate seamlessly with broader farm management platforms, optimizing not just the harvest but the entire crop lifecycle from planting to delivery, resulting in a sustainable and resource-efficient farming model.

- AI-Powered Selective Harvesting: Differentiation between ripe and unripe fruit based on advanced computer vision and deep learning models, particularly crucial for cane and ground-level fruits.

- Real-Time Quality Grading: Instantaneous assessment of defects, size, and color during collection, improving post-harvest quality control and reducing packing house labor needs.

- Predictive Maintenance: Utilization of machine learning on sensor data to forecast mechanical failures, ensuring maximum operational uptime during the short, high-stakes harvest season.

- Dynamic Operational Optimization: AI adjustment of mechanical settings (shaker force, fan speed) based on real-time crop density and field conditions, minimizing fruit damage and energy consumption.

- Autonomous Navigation and Path Planning: Implementation of AI for self-driving harvesters, optimizing field coverage, minimizing fuel consumption, and coordinating inter-machine logistics.

- Yield Mapping and Forecasting: Integration with farm management systems to provide spatial data on productivity variation, allowing for highly targeted nutrient application in subsequent seasons.

- Robotics Control Systems: AI algorithms managing the delicate movements of robotic picking arms, ensuring gentle grasping and placement suitable for fresh-market berries.

DRO & Impact Forces Of Berry Harvester Market

The fundamental drivers fueling the Berry Harvester Market center on overcoming resource scarcity and optimizing capital utilization in agriculture. The severe and structural shortage of seasonal labor, exacerbated by stricter immigration policies and demographic shifts away from farm work in developed nations, mandates the shift toward mechanization as an indispensable alternative for sustaining production capacity. Parallel to this, the rapidly expanding global market for berries, driven by consumer recognition of their nutritional value and incorporation into diverse food products, requires production scales and efficiencies achievable only through high-speed, mechanical means. Furthermore, the consistent pressure on growers to reduce input costs while improving output quality necessitates the adoption of precision agriculture tools integrated into harvesters to optimize fuel usage, minimize fruit loss, and ensure uniform product quality.

Key constraints tempering market expansion primarily relate to investment hurdles and technical limitations regarding product delicacy. The substantial initial capital investment required for state-of-the-art self-propelled harvesters often exceeds the financing capabilities of small and medium enterprises, leading to slower adoption rates despite clear efficiency benefits. Technically, the inherent vulnerability of certain berries (e.g., strawberries, raspberries intended for the fresh-eating market) to mechanical damage imposes a significant restraint, forcing manufacturers into protracted R&D cycles to develop systems gentle enough to maintain premium quality. Additionally, geographical and infrastructural constraints, such as small or oddly shaped fields common in Europe and parts of Asia, limit the deployment of large, highly efficient self-propelled machinery, favoring the less efficient, but more versatile, tractor-mounted alternatives.

Opportunities for market stakeholders are anchored in technological breakthroughs and geographic expansion. The most impactful opportunity lies in successfully commercializing gentle harvesting robots for the high-value fresh-market strawberry and raspberry segments, unlocking a substantial portion of the berry market currently reliant solely on manual labor. Geographically, significant opportunities exist in developing nations, particularly in regions receiving substantial governmental or international aid aimed at agricultural modernization, where the transition to mechanization is occurring rapidly. Furthermore, the global mandate for sustainable farming presents an opportunity for manufacturers to lead in electric powertrain development and waste reduction technologies, appealing directly to large corporate buyers committed to environmental stewardship. These forces create a dynamic market environment where technological innovation directly translates into competitive advantage and market share gain.

Segmentation Analysis

Segmentation by machine type is paramount in understanding the operational scale and capital investment strategies across the berry farming industry. Self-Propelled Harvesters represent the pinnacle of investment and efficiency, designed for uninterrupted operation on vast commercial plantations. These high-throughput machines offer superior chassis stability, dedicated power systems, and enhanced operator comfort, translating directly into maximum yield recovery during intense harvesting periods. Conversely, Tractor-Mounted Harvesters, including pull-type and three-point hitch units, provide a more affordable and flexible solution, leveraging the farmer’s existing tractor fleet. This segment is highly popular among smaller farms and those cultivating diverse crops, offering an entry point into mechanization with a lower initial economic barrier.

The segmentation based on Berry Type reflects the extreme technical specialization required in this market. Blueberry Harvesters dominate due to the crop's robust nature, allowing for effective use of vibrational harvesting technology. Cranberry Harvesters, specialized for wetland or flooded harvesting, represent a niche requiring distinct aquatic capabilities. The most challenging segments, Strawberry and Raspberry Harvesters, are driving innovation towards advanced robotics and complex mechanical systems designed to minimize bruising and detachment force, essential for fresh-market quality. Success in these delicate berry segments requires precise engineering that accounts for plant structure, berry weight, and specific detachment resistance characteristics of each varietal, making generic, multi-crop machines less effective.

Further analysis into segmentation by Mechanism highlights the technological complexity deployed. Vibrational/Shaker Harvesting is the established standard for firm berries like highbush blueberries and cranberries, relying on controlled shaking to detach fruit. Mechanical Harvesting often involves specialized combs or tines for cane fruits. The emerging segments, Pneumatic/Air-Assisted and Robotic/Vision-Based Harvesting, are critical for accessing the fresh-market segment. Robotic systems leverage advanced sensing and AI for non-damaging, selective picking, representing the future direction of the industry. Segmentation by Application confirms that Commercial Farms are the largest consumers of high-end equipment, while Small & Medium Farms primarily drive demand for lower-cost, flexible, and versatile equipment purchased through indirect distribution channels, influencing the overall pricing elasticity across the market.

- By Type:

- Self-Propelled Harvesters: High investment, maximum efficiency, large-scale operations focus.

- Tractor-Mounted Harvesters (Pull-Type and Mounted): Lower capital cost, versatile, popular among SMEs.

- Handheld/Walk-Behind Harvesters: Niche applications, small plots, or research use.

- By Berry Type:

- Blueberry Harvesters: Dominant segment, utilizes advanced vibrational techniques.

- Raspberry Harvesters: High-growth segment, requires gentle mechanical or robotic systems.

- Strawberry Harvesters: Focus of intense R&D for fresh-market robotic solutions.

- Cranberry Harvesters: Specialized wetland/dry harvest equipment.

- Others (Blackberry, Currant, Elderberry): Covered by specialized or adaptable multi-fruit machines.

- By Mechanism:

- Mechanical Harvesting (Tine/Comb systems): Standard for cane fruits and some highbush varieties.

- Vibrational/Shaker Harvesting: Most common for high-volume, processed-grade fruits.

- Pneumatic/Air-Assisted Harvesting: Emerging technology for gentler detachment and transport.

- Robotic/Vision-Based Harvesting: Precision picking, targeting fresh-market quality.

- By Sales Channel:

- Direct Sales (OEM): Preferred channel for large commercial fleets and bespoke orders.

- Indirect Sales (Distributors/Dealers): Essential for reaching SMEs and providing local service support.

- By Application:

- Commercial Farms (Large Scale Operations): Focus on high throughput and continuous operation capability.

- Small & Medium Farms: Demand for multi-purpose, cost-efficient machinery.

- Research Institutions & Specialized Nurseries: Need for highly adjustable, precise small-scale equipment for data collection.

Value Chain Analysis For Berry Harvester Market

The upstream segment of the Berry Harvester value chain is characterized by the procurement of complex, high-specification components necessary for durability and precision. This includes sophisticated power sources, such as heavy-duty diesel engines adhering to Tier 4 Final/Stage V emissions standards, or advanced lithium-ion battery packs for electric models. Essential structural components involve high-tensile steel for chassis construction and specialized wear-resistant plastics and composite materials for fruit contact surfaces, ensuring both longevity and minimal abrasion damage to the delicate berries. Key upstream relationships are strategic, often involving long-term supply agreements with specialized component manufacturers who can provide reliable hydraulic systems, precise electronic control units, and sensor packages necessary for guidance and monitoring functions, guaranteeing the operational reliability crucial during the short harvest windows.

The midstream process, centered on Original Equipment Manufacturing (OEM), involves intensive research and development, particularly focused on optimizing the picking mechanism (shaker alignment, robotic arm speed) and the internal fruit handling system (conveyor speed, air flow) to enhance efficiency and fruit quality preservation. Fabrication and final assembly are highly customized processes, differing significantly between a self-propelled cranberry harvester and a raspberry pull-type unit. Distribution channels are bifurcated: direct sales serve the dominant commercial growers, facilitating close collaboration on custom specifications, financing, and maintenance contracts. Indirect sales, relying on extensive global networks of authorized dealers and distributors, manage inventory, financing, and critical local after-sales support for the geographically dispersed segment of small and medium-sized farms, which rely heavily on accessible maintenance expertise and spare parts inventory.

Downstream activities involve machine installation, operator training, ongoing maintenance, and spare parts supply, all crucial determinants of customer satisfaction and long-term asset profitability. Effective after-sales service is a key competitive differentiator, particularly during the peak harvest season when machine downtime translates directly into revenue loss. The demand signals originating from the end-users—specifically requirements for reduced fruit loss, cleaner separation of leaves and debris, and integration with existing farm management software—feedback directly into the OEM’s product development cycle. Furthermore, this downstream demand influences technological convergence, pushing manufacturers toward standardized communication protocols (like ISOBUS) to ensure harvesters integrate seamlessly into the broader ecosystem of farm machinery and digital agricultural platforms, enhancing the overall value proposition for the ultimate buyer.

Berry Harvester Market Potential Customers

The quintessential potential customer for advanced Berry Harvesters is the large-scale commercial agribusiness entity, often spanning multiple regional locations and operating with thousands of acres dedicated to high-density, processed-grade berry production, such as blueberries or cranberries. These operations are capital-intensive, technologically sophisticated, and driven by maximizing export volumes and minimizing variable costs, making the investment in high-throughput, self-propelled harvesters economically imperative. Purchasing decisions in this segment are led by total cost of ownership (TCO), efficiency metrics (harvested volume per hour), technological sophistication (AI sorting, telematics), and reliable, guaranteed 24/7 service availability during the critical harvest period. These customers typically engage in multi-unit contracts directly with leading OEMs to ensure fleet standardization and preferential service agreements.

The secondary, yet numerically larger, customer segment consists of small and medium-sized enterprises (SMEs) and family-owned farms. These growers often cultivate less acreage, focus on local or niche markets, and prioritize versatility and low operating costs over absolute throughput capacity. For this customer group, the tractor-mounted or pull-type harvester represents the ideal solution, providing mechanization benefits without the massive capital expenditure of a self-propelled unit. Their purchasing power is frequently subsidized by regional agricultural grants or soft loans, and their decision-making is strongly influenced by local dealer support, ease of maintenance, and the machine's ability to handle potentially diverse crop types. The demand from this sector is more sensitive to commodity price fluctuations and regional policy support.

A burgeoning customer segment involves contract harvesting service providers. These businesses invest in fleets of high-performance harvesters and offer harvesting services to multiple farms that cannot justify the full purchase cost of their own machinery. Their demand is driven by machinery ruggedness, rapid transport capability, and high utilization rates across different farm landscapes and berry varieties. Finally, governmental agricultural experimental stations and private breeding nurseries represent a niche but important customer base. They require specialized, small-scale, precise harvesters for collecting genetic material, measuring plot yields accurately, and testing new varietals under controlled mechanical harvesting stress. These customers prioritize data collection features and minute operational adjustments over sheer volume capacity.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $350 Million USD |

| Market Forecast in 2033 | $560 Million USD |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Oxbo International, Littau Harvester, Blueline Manufacturing, Korvan, BEI International, Small Farm Innovations, Checchi & Magli, Weremczuk FMR, Agrifac Machinery, Ploeger, Munckhof, Coe Manufacturing, CMI, Kivi-Pekka, Greenline Harvester, JMC, Alma, Volentini, Guarneri Technology S.r.l., S.P.P.L. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Berry Harvester Market Key Technology Landscape

The current technological landscape of the Berry Harvester Market is undergoing a rapid metamorphosis, moving from purely mechanical engineering towards sophisticated mechatronics. Central to this evolution is the refinement of selective detachment mechanisms. While vibrational harvesting remains the standard for processed berries, manufacturers are deploying advanced sensor arrays and telematics to precisely control shaker speeds and patterns. Technologies such as high-frequency, low-amplitude vibration systems are designed to detach only ripe berries while minimizing 'shaking off' unripe or damaged fruits, significantly enhancing the purity of the collected batch. Furthermore, integrated air-cushion transport systems are gaining prominence, utilizing precisely calibrated airflow to gently move harvested fruit from the picking mechanism to the collection bins, drastically reducing impact damage and bruising crucial for fresh-market viability.

A critical area of innovation is in guidance and operational stability, essential for maximizing efficiency in dense planting systems and on uneven terrain. Modern harvesters utilize Real-Time Kinematic (RTK) GPS for centimeter-level accuracy in row alignment, coupled with sophisticated ultrasonic sensors that track the crop rows continuously. This precision allows for faster operational speeds while preventing damage to the plants themselves. Hydraulic self-leveling chassis systems are standard on high-end self-propelled units, automatically compensating for slopes up to 20 degrees, ensuring the picking head and sorting tables remain horizontal. This not only maintains picking consistency but is also a paramount safety feature. The development of advanced Human-Machine Interfaces (HMIs) featuring touchscreen control, integrated diagnostics, and seamless data logging allows operators to monitor and adjust all critical machine parameters in real-time, improving operational efficiency and accountability.

The future technology landscape is dominated by robotics, autonomy, and sustainable powertrains. The development of dedicated robotic harvesters for strawberries and fresh-market cane berries represents the highest level of technological investment. These systems employ high-resolution 3D camera arrays and AI-driven image processing to identify optimal picking targets, utilizing specialized end-effectors (grippers or suction cups) managed by complex motion control algorithms to perform non-damaging detachment. Parallel to this, the push towards electrification is transformative. Electric and hybrid harvesters offer precise torque management, lower noise, zero local emissions, and reduced running costs compared to conventional diesel engines. Autonomy, powered by enhanced AI and sensor fusion (Lidar, Radar, Vision), promises to deliver fully self-driving harvester fleets, capable of 24-hour operation with minimal human oversight, thereby providing a robust, scalable, and environmentally conscious solution to the persistent agricultural labor crisis, marking the final frontier of modernization in the berry harvesting industry.

Regional Highlights

- North America: This region is characterized by immense economies of scale, particularly in the production of highbush blueberries in states like Michigan, Georgia, and the Pacific Northwest, and cranberries in Massachusetts and Wisconsin. Driven by prohibitive labor costs and stringent food safety standards, North America represents the primary market for large, high-power, self-propelled harvesters equipped with the latest telematics and AI sorting technologies. The market is saturated but highly profitable, relying on replacement cycles and the adoption of cutting-edge robotic solutions for specialized crops. Key competitive factors include dealer network reliability and the provision of sophisticated financial leasing options.

- Europe: The European market displays greater fragmentation, balancing large farms in Spain and Poland with smaller, tradition-focused holdings in Scandinavia and Central Europe. Demand is diverse, favoring robust tractor-mounted harvesters for raspberry and currant production in Eastern Europe, while Western European markets seek highly specialized, gentle harvesters for premium fresh-market cane fruits. Regulatory mandates concerning environmental protection and noise reduction heavily influence product design, driving significant interest in electric and hybrid harvester models. Policy support from the Common Agricultural Policy (CAP) provides crucial funding for technology adoption, especially for SMEs looking to upgrade from manual to mechanical methods.

- Asia Pacific (APAC): APAC is the engine of future growth, spurred by rising middle-class disposable income, resulting in exponential growth in domestic berry consumption, particularly in China and India. While mechanized harvesting remains underdeveloped compared to the West, government-led initiatives to consolidate fragmented farmlands and subsidize agricultural machinery purchases are rapidly accelerating adoption. The regional demand focuses on smaller, highly maneuverable harvesters suitable for diverse topography and existing small-to-medium-sized tractors, demanding equipment that balances low cost with reliable performance and ease of maintenance in varied climatic conditions.

- Latin America (LATAM): LATAM is a crucial export market, with countries like Chile, Argentina, and Mexico serving as counter-seasonal suppliers to North American and European demand, ensuring year-round global availability. The requirement for high export quality necessitates robust and reliable harvesters capable of massive throughput under challenging logistical conditions. The market favors proven technologies and durability, often preferring highly maintained second-hand or imported equipment alongside new purchases, prioritizing longevity and ease of repair in remote agricultural zones. Labor availability fluctuates significantly, making mechanization essential for maintaining global market share and contractual obligations.

- Middle East and Africa (MEA): This region constitutes a niche, emerging market, primarily concentrated in commercial farming ventures utilizing controlled environment agriculture (CEA) or intensive irrigation techniques for high-value berries. Adoption is highly fragmented, driven largely by foreign investment in large-scale farms in South Africa, Morocco, and select Gulf Cooperation Council (GCC) countries. The demand is specific, often requiring customized harvesters suitable for unusual plant structures or extreme heat tolerance. Market growth is contingent upon sustained foreign direct investment in permanent crop infrastructure and the successful scaling of commercial berry production suitable for mechanized harvest.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Berry Harvester Market.- Oxbo International Corporation (Market Leader for Blueberries and Cranberries)

- Littau Harvester, Inc. (Specialist in Blueberry and Raspberry Harvesters)

- Blueline Manufacturing, Inc. (Focus on Cranberry and Specialty Crop Harvesters)

- Korvan (a division of Oxbo International, known for pull-type harvesters)

- BEI International (Bemco)

- Small Farm Innovations, LLC (Catering to smaller scale and niche market needs)

- Checchi & Magli S.r.l. (European specialist, often in tractor-mounted equipment)

- Weremczuk FMR Sp. z o.o. (Prominent Polish manufacturer for soft fruit)

- Agrifac Machinery B.V. (Developing sophisticated self-propelled platforms)

- Ploeger Machines B.V. (Heavy machinery specialist with harvesting solutions)

- Munckhof Manufacturing Inc.

- Coe Manufacturing Co.

- CMI (Cleaning & Maintenance Innovation)

- Kivi-Pekka Oy (Nordic market player with versatile solutions)

- Greenline Harvester, Inc.

- JMC (Jiangsu Muyang Group - Key player in APAC agricultural machinery)

- Alma S.A.S. (French company with a focus on vine and berry harvesters)

- Volentini Macchine Agricole (Italian manufacturer)

- Guarneri Technology S.r.l.

- S.P.P.L. (Self Propelled Picker Loaders)

Frequently Asked Questions

Analyze common user questions about the Berry Harvester market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the adoption of mechanical berry harvesters?

The central driver is the persistent and escalating shortage of manual agricultural labor coupled with rapidly rising labor costs in major berry-producing regions globally. Mechanization ensures harvest timeliness, consistency, and essential scalability for modern commercial operations.

How are strawberry and raspberry harvesting challenges being addressed by new technology?

Challenges related to the delicacy of fresh-market berries are being addressed through the development of specialized robotic systems utilizing advanced computer vision, gentle pneumatic suction, and 3D mapping to selectively pick ripe fruit without causing physical damage, thereby preserving premium quality and market value.

Which geographical region exhibits the highest growth potential for berry harvester sales?

The Asia Pacific (APAC) region, driven by extensive agricultural modernization programs, increasing domestic demand for berries, and substantial government support for mechanization in rapidly developing agricultural economies, is projected to show the highest compound annual growth rate.

What are the main advantages of self-propelled berry harvesters over tractor-mounted units?

Self-propelled harvesters offer superior operational efficiency, dedicated engine power, consistent performance, greater maneuverability, and higher hourly harvesting capacity (throughput). They are specifically designed for continuous operation on large commercial farms where cost per harvested unit must be minimized.

How is AI being utilized to enhance the performance of modern berry harvesting equipment?

AI is primarily used for real-time quality grading and selective picking via computer vision, optimizing operational parameters (shaker speed, fan flow) dynamically based on crop conditions, and enabling predictive maintenance to minimize costly machine downtime during critical harvesting seasons, maximizing farm profitability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager