Beta Picoline Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440942 | Date : Feb, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Beta Picoline Market Size

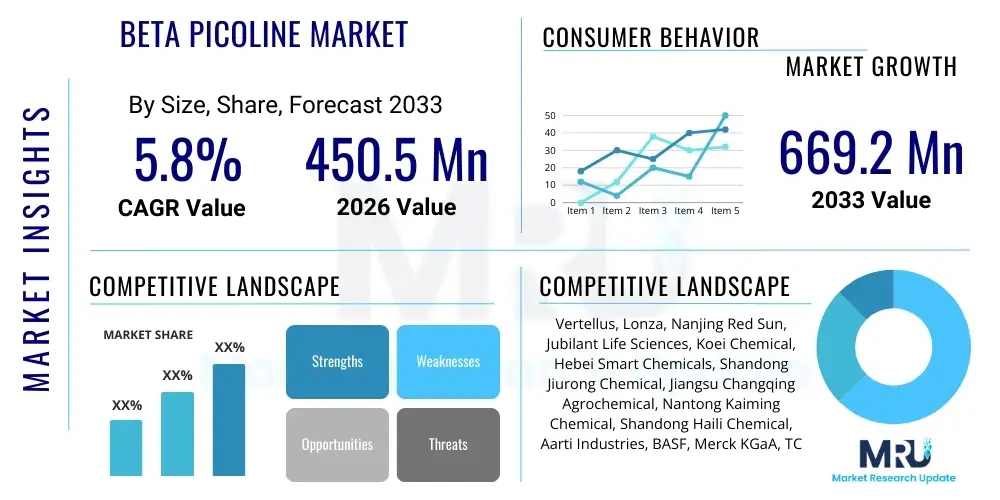

The Beta Picoline Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 185.3 Million in 2026 and is projected to reach USD 288.7 Million by the end of the forecast period in 2033. This growth trajectory is significantly influenced by the escalating demand for Niacin (Vitamin B3) in both human and animal nutrition sectors, coupled with the critical role Beta Picoline plays as a key intermediate in the synthesis of various high-efficacy agrochemicals. Market expansion is strategically tied to continuous improvements in manufacturing efficiency and navigating the complex regulatory environments governing chemical intermediates globally.

Beta Picoline Market introduction

Beta Picoline, chemically known as 3-methylpyridine, is a clear, colorless liquid belonging to the pyridine derivatives class. It is distinguished by its methyl group substitution at the third carbon position of the pyridine ring, affording it unique chemical reactivity suitable for diverse industrial syntheses. The primary method of commercial production involves the reaction of acetaldehyde, ammonia, and formaldehyde, often employing catalytic processes that strive for high selectivity and conversion rates to minimize waste and reduce production costs. Due to its bifunctional nature, acting as both a base and a synthetic building block, Beta Picoline is an indispensable intermediate in the global specialty chemicals value chain.

The major applications of Beta Picoline are heavily concentrated within the pharmaceutical and agrochemical industries. In pharmaceuticals, it serves as the essential precursor for the synthesis of Niacin and Niacinamide, compounds vital for metabolic processes, cardiovascular health, and dietary supplements. The persistent rise in global health awareness and the increasing use of fortified animal feed are core drivers for this application segment. In the agrochemical sector, Beta Picoline is crucial for the production of potent herbicides, particularly those used in non-selective weed control, thereby supporting modern, high-yield agricultural practices across major food-producing regions.

The benefits derived from the use of Beta Picoline intermediates include the creation of highly effective and stable end-products, essential for maintaining efficacy in diverse fields like nutrition and crop protection. Key driving factors propelling the market forward include the robust expansion of the global dietary supplement industry, particularly in emerging economies, and the continuous need for innovative and potent crop protection solutions to combat resistance and enhance food security. Furthermore, technological advancements in catalytic processes aimed at improving purity and yield are reinforcing the market's stability and future growth potential.

Beta Picoline Market Executive Summary

The Beta Picoline market's executive landscape is characterized by moderate consolidation among leading chemical manufacturers, predominantly located in Asia Pacific, particularly China and India, which serve as the world's major production hubs due to competitive manufacturing costs and established chemical infrastructure. Current business trends indicate a strong focus on backward integration strategies among key players to secure stable access to critical raw materials like acetaldehyde and ammonia, mitigating supply chain volatility. Geopolitical shifts and international trade dynamics significantly influence pricing structures and export capabilities, making supply chain resilience a paramount strategic concern for market participants. The push toward sustainable chemistry is also driving R&D efforts aimed at developing greener synthesis routes, reducing reliance on conventional, energy-intensive processes.

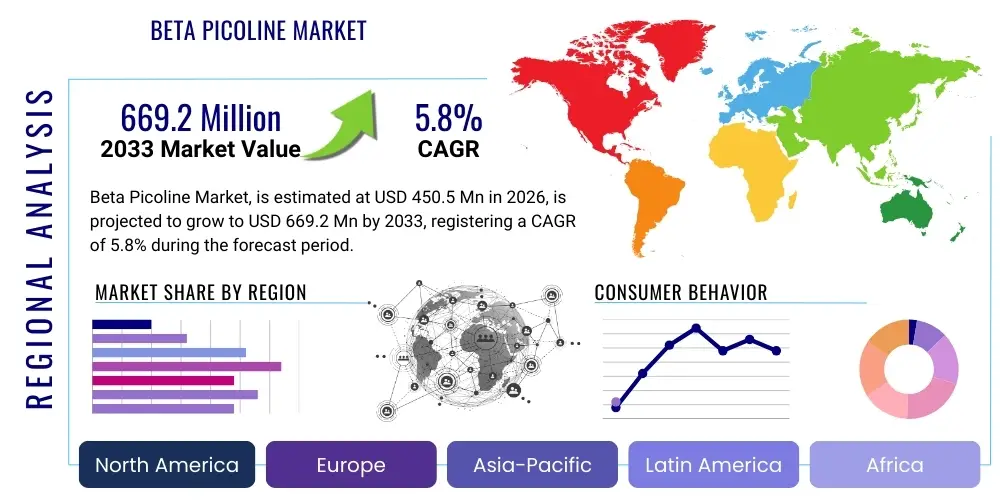

Regionally, Asia Pacific (APAC) not only leads in production capacity but also exhibits the fastest growth in consumption, driven by burgeoning agricultural industries and expanding middle-class populations fueling demand for nutritional supplements. North America and Europe remain mature markets characterized by stringent regulatory oversight, high consumption of high-purity grades, and a strong emphasis on research and development for novel derivatives. These regions primarily function as high-value end-product manufacturing centers, importing large quantities of Beta Picoline to feed pharmaceutical and specialty chemical synthesis lines. Market growth is closely tied to economic stability and regulatory harmonisation concerning agricultural chemical use and dietary supplement standards across these diverse geographic areas.

Segmentation trends highlight the dominance of the Agrochemicals segment by volume, fueled by global farming requirements for effective weed management, although the Pharmaceutical segment commands higher pricing and stricter quality specifications. Within the product segment, the high-purity grade of Beta Picoline, essential for Niacin synthesis to meet Pharmacopeia standards, is experiencing increased demand and fetching premium pricing, distinguishing it from industrial grades used in bulk chemical applications. Furthermore, there is a distinct trend towards customization and specialized derivatives tailored for next-generation specialty polymers and advanced materials, reflecting diversification away from traditional core applications, which provides opportunities for niche market players.

AI Impact Analysis on Beta Picoline Market

Common user questions regarding AI's influence on the Beta Picoline market often revolve around efficiency gains in complex chemical synthesis, predictive modeling for volatile feedstock pricing, and enhancing regulatory compliance traceability. Users are primarily concerned with whether AI can fundamentally reduce production costs by optimizing reaction conditions in real-time, moving beyond traditional statistical process control. Another major theme is the potential for AI to manage supply chain risks inherent in global chemical distribution, specifically predicting bottlenecks and managing inventory levels for high-purity pharmaceutical grades. Expectations are high that AI tools will accelerate R&D cycles for developing new, more sustainable catalytic methods for Beta Picoline production, thereby addressing growing environmental pressures and the need for higher yields.

The incorporation of Artificial Intelligence and Machine Learning (ML) technologies into the Beta Picoline production lifecycle is poised to deliver transformative benefits across manufacturing and commercial operations. AI models can analyze vast datasets concerning reaction kinetics, catalyst performance, temperature, and pressure, identifying non-obvious correlations that lead to optimal manufacturing parameters. This advanced process optimization minimizes energy consumption, reduces by-product formation, and ensures consistent high-quality output, which is especially critical for pharmaceutical-grade applications where impurity profiles must be rigorously controlled. The ability of ML algorithms to simulate thousands of experimental conditions virtually drastically cuts down on traditional laboratory time and expenditure, accelerating process scale-up and commercialization.

Furthermore, beyond the production floor, AI plays a crucial role in strategic market operations. Predictive analytics models leverage global economic indicators, commodity market trends (for acetaldehyde and ammonia), and geopolitical factors to forecast fluctuations in raw material costs and final product demand with enhanced accuracy. This capability allows Beta Picoline manufacturers to engage in smarter procurement strategies, hedging against price volatility, and optimizing inventory holding costs. In sales and distribution, AI-powered systems improve logistics planning, optimizing freight routes and scheduling, which is vital for maintaining freshness and quality control during the transport of sensitive chemical intermediates across international boundaries.

- AI-driven optimization of catalytic processes leading to increased yield and purity.

- Machine Learning models predicting feedstock price volatility (acetaldehyde, ammonia) for procurement hedging.

- Enhanced quality control through real-time spectral analysis and anomaly detection in batch synthesis.

- Accelerated discovery of novel, environmentally friendly catalysts for sustainable production routes.

- Improved supply chain resilience via predictive logistics and risk assessment modeling.

- Automated compliance monitoring and documentation generation for stringent pharmaceutical regulations.

DRO & Impact Forces Of Beta Picoline Market

The Beta Picoline market is subject to a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively constitute the primary impact forces shaping its trajectory. The fundamental market driver is the ubiquitous need for Niacin (Vitamin B3), essential for both human dietary supplements and animal feed, a demand that is inelastic and continually growing with global population and income increases. This demand ensures a stable, high-volume requirement for pharmaceutical-grade Beta Picoline. Conversely, the market is restrained by the highly cyclical nature and intense competition in the core agrochemical industry, where price sensitivity is high and large-volume contracts are fiercely contested. Opportunities exist primarily in developing specialized derivatives for advanced material science and leveraging biotechnological advancements for bio-based production methods, offering long-term sustainability advantages.

Key drivers include the global mandate for food security, which necessitates continuous investment in effective crop protection chemicals derived from Beta Picoline, such as Paraquat and Diquat. Furthermore, the persistent growth of the aquaculture industry and the need for fortified animal nutrition significantly boost the demand for feed-grade Niacinamide, directly translating to higher consumption of the chemical intermediate. These drivers exert a strong, sustained positive impact force, ensuring baseline profitability and growth. However, this growth is constantly challenged by formidable restraints, chief among them being the increasing regulatory scrutiny, particularly in developed regions like Europe, regarding the use of specific agrochemicals derived from Beta Picoline, which sometimes leads to usage restrictions or outright bans, forcing manufacturers to diversify their product portfolios.

Opportunities for market players involve investing in high-purity processes to capitalize on the lucrative pharmaceutical segment, which offers better margins than bulk agrochemical inputs. The emergence of green chemistry principles provides an opening for companies that can pioneer cleaner, less polluting synthesis methods, differentiating themselves in an environmentally conscious market. The primary impact forces thus pivot around balancing cost-efficiency in high-volume agrochemical production against the demanding quality and environmental standards of the high-margin pharmaceutical and specialty chemical applications, driving strategic investment decisions toward innovation and regulatory compliance management across all operational theaters.

Segmentation Analysis

The Beta Picoline market is extensively segmented based on application, end-use industry, and purity grade, reflecting the diverse requirements of its downstream markets. This segmentation is crucial for manufacturers to target specific, high-value niches, particularly within the highly regulated pharmaceutical sector, which demands stringent quality control. The primary application segments differentiate between use in Niacin synthesis, agrochemical manufacturing, and use as a general solvent or specialty intermediate. Geographically, segmentation highlights the distinct supply and demand dynamics between high-production regions like APAC and high-consumption, high-regulation regions like North America and Europe, driving trade flows and investment patterns across the global chemical landscape. Analyzing these segments provides deep insight into competitive positioning and potential areas for market penetration.

- By Application:

- Niacin/Vitamin B3 Synthesis

- Agrochemicals (e.g., Herbicides, Insecticides)

- Specialty Solvents

- Chemical Intermediates

- By End-Use Industry:

- Pharmaceutical and Healthcare

- Agriculture

- Nutritional Supplements (Human and Animal Feed)

- Chemical Manufacturing

- By Purity Grade:

- Pharmaceutical Grade (High Purity)

- Technical Grade (Industrial Use)

Value Chain Analysis For Beta Picoline Market

The Beta Picoline value chain commences with the upstream supply of essential petrochemical feedstocks. The primary raw materials are highly volume-dependent commodity chemicals: acetaldehyde, formaldehyde, and ammonia. The profitability and stability of Beta Picoline production are critically sensitive to the global pricing and logistical reliability of these inputs, often sourced from large integrated petrochemical complexes. Upstream analysis focuses on securing long-term supply contracts and managing the volatility inherent in commodity chemical markets, which necessitates strategic partnerships or, ideally, backward integration by major Beta Picoline producers to ensure cost control and uninterrupted manufacturing capacity. Disruptions in global oil and gas markets directly impact these feedstock costs, cascading effects throughout the value chain.

The core manufacturing stage involves complex chemical synthesis and purification, where the raw materials are reacted, typically via highly optimized catalytic routes, to produce crude Beta Picoline, which then undergoes extensive refining steps to meet required purity standards, especially for the pharmaceutical grade. The distribution channel is bifurcated: direct sales and indirect channels. Direct distribution involves large-volume transactions where Beta Picoline manufacturers supply directly to Tier 1 pharmaceutical giants or major agrochemical formulating companies under long-term supply agreements. This channel emphasizes customization, technical support, and stringent quality assurance documentation required by large, sophisticated buyers.

The indirect channel relies on specialized chemical distributors and regional agents who manage smaller volumes, provide localized inventory, and handle logistics for medium and small-scale end-users across various geographical regions, including those in developing markets. Downstream analysis focuses on the final application markets, predominantly agriculture and healthcare, where Beta Picoline's performance as an intermediate directly influences the efficacy and cost-competitiveness of end products like herbicides and Vitamin B3 supplements. Market power distribution is heavily skewed toward downstream major pharmaceutical and agrochemical formulators who dictate quality specifications and pricing pressure on intermediate manufacturers.

Beta Picoline Market Potential Customers

The potential customers for Beta Picoline span critical sectors that rely on high-purity chemical intermediates for large-scale production. The largest buying segment comprises global pharmaceutical manufacturers specializing in nutritional supplements and active pharmaceutical ingredients (APIs), whose procurement needs are characterized by requirements for strict regulatory documentation, adherence to GMP (Good Manufacturing Practice) standards, and high demand for purity necessary for Niacin (Nicotinic Acid) and Niacinamide synthesis. These customers often require audits of manufacturing facilities and demand reliable, long-term supply contracts to maintain continuous production of essential medicines and over-the-counter supplements.

A second major customer group consists of multinational agrochemical corporations and regional formulating companies. These entities utilize Beta Picoline as a key starting material for synthesizing high-performance herbicides, such as Paraquat and Diquat, which are vital components of modern, efficient farming systems. Their procurement is highly volume-driven and sensitive to global crop cycles and agricultural policy, prioritizing cost-effectiveness, consistency in technical grade specifications, and robust supply chain logistics capable of handling large batch deliveries worldwide. Contract renewals in this sector are heavily influenced by competitive pricing and the ability of the Beta Picoline producer to navigate export regulations efficiently.

Beyond these two core industries, smaller but significant customer bases exist within specialty chemical manufacturers and research institutions. Specialty chemical producers use Beta Picoline for creating advanced polymers, specialized solvents, or niche chemical derivatives with applications ranging from material science to electronics. These buyers prioritize innovation, flexibility in batch size, and technical collaboration to develop proprietary compounds. All potential customers share a common need for documented quality assurance and verifiable supply chain integrity to meet their respective industry standards and consumer safety expectations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 185.3 Million |

| Market Forecast in 2033 | USD 288.7 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Jubilant Life Sciences, Vertellus, Shandong Luba Chemical Co., Ltd., Realsun Chemical Co., Ltd., Koei Chemical Co., Ltd., Lonza Group Ltd., Tianjin Guangfu Chemical Co., Ltd., Nanjing Redsun Co., Ltd., Lier Chemical Co., Ltd., BASF SE, Merck KGaA, Avantor, Toronto Research Chemicals, TCI Chemicals (India) Pvt. Ltd., Synquest Laboratories, Inc., Hangzhou Dayang Chemical Co., Ltd., Weifang Sanyuan Chemical Co., Ltd., Hebei Jinchuang Chemical Co., Ltd., Spectrum Chemical Manufacturing Corp., Finar Chemicals. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Beta Picoline Market Key Technology Landscape

The production of Beta Picoline is anchored primarily by variations of the Chichibabin pyridine synthesis reaction, which typically involves the liquid-phase condensation of acetaldehyde, formaldehyde, and ammonia in the presence of solid acid catalysts, usually zeolites or metal oxides, operating under high temperatures and pressure. The key technological challenge lies in maximizing the selectivity towards Beta Picoline (3-methylpyridine) while minimizing the formation of isomers like Alpha (2-methylpyridine) and Gamma (4-methylpyridine) picolines, which requires complex and energy-intensive separation processes if the initial selectivity is low. Recent technological advances focus intensely on developing highly selective, heterogeneous catalysts that can operate efficiently under milder conditions, thereby reducing utility costs and improving the environmental footprint of the synthesis process. Continuous flow reactors are increasingly being investigated and adopted over traditional batch processing to enhance safety, improve heat transfer, and maintain consistent product quality over extended production runs, offering substantial operational savings.

A significant trend in the technology landscape involves the adoption of advanced process control (APC) systems, often integrated with AI and machine learning algorithms, to monitor and dynamically adjust reaction parameters in real-time. These sophisticated systems utilize sensor data to detect subtle changes in catalyst activity or raw material consistency, preemptively making adjustments that optimize conversion and minimize off-spec production. This shift is particularly crucial for meeting the hyper-strict quality standards required for pharmaceutical-grade Beta Picoline, where minute impurities can render a batch unusable. Furthermore, there is growing research into leveraging biotechnology, specifically microbial fermentation or enzymatic processes, as a sustainable alternative to petrochemical-based synthesis, though these technologies are still largely in the research or pilot phase for large-scale commercial viability, presenting a long-term transformative opportunity for the industry.

Finally, separation and purification technologies represent a vital component of the production process, directly influencing the final product cost and purity. Techniques such as high-efficiency fractional distillation, extractive distillation, and specialized membrane separation technologies are employed to achieve the high-purity levels demanded by the Niacin synthesis market. Investment in modern, highly efficient distillation columns and energy recovery systems is paramount to maintaining competitiveness, as the separation of picoline isomers is inherently energy-intensive. Manufacturers are continuously seeking patented processes that offer superior separation at reduced operational costs, securing intellectual property around these advanced purification techniques to gain a sustained market advantage in the high-value segments.

Regional Highlights

- Asia Pacific (APAC) Dominance and Manufacturing Hub: APAC, led primarily by China and India, constitutes the largest market share in terms of production capacity globally. This region benefits from abundant availability of key raw materials, relatively lower operating costs, and strong government support for chemical manufacturing, positioning it as the primary global exporter of Beta Picoline. The rapid expansion of agricultural sectors and increasing livestock production in Southeast Asia further drives regional demand for agrochemicals and feed supplements, creating a robust domestic consumption base alongside its export capabilities.

- North America Market Dynamics: North America represents a mature, high-value consumption market, characterized by stringent environmental and safety regulations. The demand is heavily concentrated in the pharmaceutical and advanced specialty chemicals segments, focusing on high-purity, imported Beta Picoline to feed local API and formulated product manufacturing. Innovation in agrochemical derivatives and a strong focus on sustainable manufacturing practices define the regional strategic investments.

- Europe's Regulatory Influence: Europe is characterized by strict regulatory frameworks (e.g., REACH) governing chemical production and usage, particularly concerning agrochemicals. While production capacity has seen limited growth due to high compliance costs, the region remains a vital consumer market, particularly for high-quality Niacin synthesis materials. Market players focus on navigating evolving regulations and emphasizing sustainability and low environmental impact in their supply chains to maintain market access.

- Latin America's Agricultural Growth: The Latin American market, particularly Brazil and Argentina, exhibits significant growth driven almost entirely by the massive scale of their agricultural industries. High demand for crop protection products, necessitated by large-scale farming operations, makes this region a crucial market for Beta Picoline-derived herbicides. Market growth here is sensitive to commodity crop prices and governmental policies regarding agricultural subsidies and chemical imports.

- Middle East and Africa (MEA) Emerging Opportunities: The MEA region is currently a developing market for Beta Picoline, characterized by growing infrastructure and increasing governmental focus on diversifying away from oil revenues into domestic manufacturing and improving food security. While consumption volumes are currently lower than other regions, increasing investment in pharmaceutical manufacturing and modern agricultural techniques in countries like Saudi Arabia and South Africa presents long-term market opportunities for imported intermediates.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Beta Picoline Market.- Jubilant Life Sciences Ltd.

- Vertellus Holdings LLC

- Shandong Luba Chemical Co., Ltd.

- Realsun Chemical Co., Ltd.

- Koei Chemical Co., Ltd.

- Lonza Group Ltd.

- Tianjin Guangfu Chemical Co., Ltd.

- Nanjing Redsun Co., Ltd.

- Lier Chemical Co., Ltd.

- BASF SE

- Merck KGaA

- Avantor, Inc.

- Toronto Research Chemicals Inc.

- TCI Chemicals (India) Pvt. Ltd.

- Synquest Laboratories, Inc.

- Hangzhou Dayang Chemical Co., Ltd.

- Weifang Sanyuan Chemical Co., Ltd.

- Hebei Jinchuang Chemical Co., Ltd.

- Spectrum Chemical Manufacturing Corp.

- Finar Chemicals Pvt. Ltd.

Frequently Asked Questions

Analyze common user questions about the Beta Picoline market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary commercial use of Beta Picoline?

The primary commercial use of Beta Picoline (3-methylpyridine) is as a vital chemical intermediate for the large-scale synthesis of Niacin (Vitamin B3) and Niacinamide, compounds essential for nutritional supplements and animal feed fortification, alongside its use in high-efficacy agrochemical production, particularly herbicides.

Which geographical region dominates the production of Beta Picoline?

The Asia Pacific (APAC) region, specifically manufacturing centers in China and India, dominates the global production of Beta Picoline due to competitive operational costs, abundant feedstock availability, and well-established industrial chemical infrastructure, making it the largest supply hub.

How do raw material costs impact the Beta Picoline market?

Raw material volatility, primarily concerning acetaldehyde and ammonia, significantly impacts the manufacturing cost and final pricing of Beta Picoline. Price fluctuations necessitate robust supply chain management and hedging strategies among producers to maintain competitive market positioning.

What purity grade is required for pharmaceutical applications?

Pharmaceutical applications, such as Niacin synthesis, require Beta Picoline of the highest purity grade, often adhering to strict pharmacopeial standards (e.g., USP or EP). This grade demands rigorous purification processes to ensure minimal isomer or other impurity content, which drives a significant price premium.

What emerging technologies are influencing Beta Picoline manufacturing?

Emerging technologies include the adoption of highly selective, heterogeneous catalysts to improve reaction yields, advanced process control (APC) systems integrated with AI for real-time optimization, and research into sustainable, bio-based synthesis routes to reduce environmental impact and energy consumption.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager