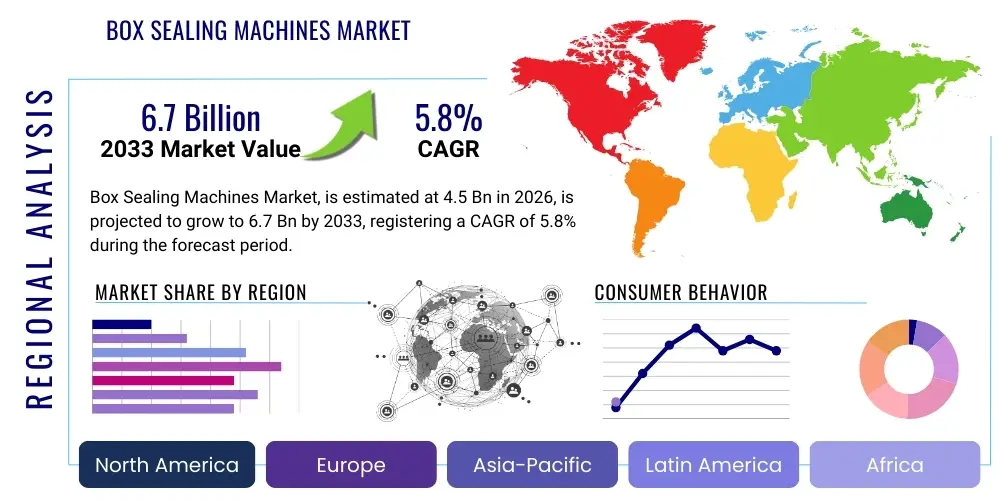

Box Sealing Machines Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442689 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Box Sealing Machines Market Size

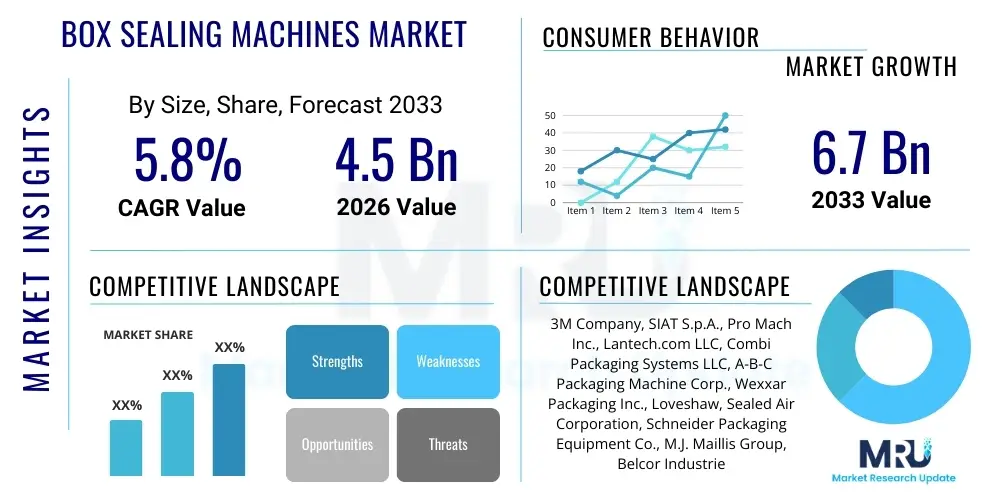

The Box Sealing Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 6.7 Billion by the end of the forecast period in 2033.

Box Sealing Machines Market introduction

The Box Sealing Machines Market encompasses equipment designed to efficiently close and seal cartons or boxes using adhesive tape, hot melt glue, or other sealing methods. These machines are crucial components of automated packaging lines across diverse industries, ensuring product safety, enhancing supply chain logistics, and improving presentation. The core product offering ranges from basic semi-automatic tape dispensers requiring operator intervention to sophisticated fully automatic, high-speed case sealers integrated with robotic palletizing systems. Key product attributes include enhanced operational speed, consistent seal quality, and reduced labor reliance, which directly addresses modern industrial requirements for efficiency and cost reduction.

Major applications of box sealing machines span fast-moving consumer goods (FMCG), pharmaceuticals, electronics, food and beverage processing, and, critically, the booming e-commerce and 3PL (Third-Party Logistics) sectors. The accelerating shift towards automated warehousing and distribution centers, driven by global e-commerce volumes, positions box sealing equipment as an indispensable asset for continuous, high-throughput packaging operations. These machines accommodate various box sizes and materials, offering versatility crucial for customized or mixed-product packaging lines, thereby sustaining operational flexibility in highly dynamic environments.

The market growth is primarily driven by the imperative for automation to counter rising labor costs, the need for consistent and tamper-evident packaging required by regulatory bodies and consumers, and the rapid expansion of cross-border trade facilitated by robust logistics networks. Furthermore, technological advancements, such as the incorporation of Internet of Things (IoT) sensors for predictive maintenance and systems optimizing tape usage for sustainability, are key factors propelling market adoption globally. The demand for reliable and fast end-of-line packaging solutions ensures the sustained relevance and expansion of the Box Sealing Machines Market throughout the forecast period.

Box Sealing Machines Market Executive Summary

The Box Sealing Machines Market is characterized by a strong global drive toward industrial automation, heavily influenced by the exponential growth of the e-commerce sector and the corresponding demand for high-speed, reliable end-of-line packaging solutions. Key business trends indicate a shift towards fully automatic, integrated systems capable of handling variable box sizes (random case sealers) and supporting sustainable packaging practices, particularly the use of recyclable paper tape and glue-based sealing systems over traditional plastic tapes. Strategic imperatives for leading manufacturers involve enhancing machine intelligence through IoT connectivity and optimizing total cost of ownership (TCO) by improving durability and reducing maintenance downtime.

Regionally, the Asia Pacific (APAC) region is projected to exhibit the highest growth rate, fueled by expanding manufacturing bases, rapid urbanization, and massive domestic e-commerce markets (e.g., China and India). North America and Europe, while mature markets, maintain high adoption rates due to strict labor laws necessitating automation and a strong emphasis on smart factory initiatives. These regions lead in adopting advanced technologies such as robotic pick-and-place integration and sophisticated quality assurance vision systems embedded within the sealing process. Manufacturers are focusing on localized production and servicing capabilities to cater to the unique regulatory and operational requirements of these diverse geographic landscapes.

Segment-wise, fully automatic box sealing machines dominate the revenue landscape, reflecting the industry's commitment to minimizing human error and maximizing throughput in 24/7 operational environments. Furthermore, tape-based sealing, while facing competition from hot melt glues in specific applications, remains the most utilized segment due to its versatility and low operational cost. A noticeable trend is the increasing demand for customized sealing solutions tailored for specialized industries, such as cold chain logistics within pharmaceuticals and food preservation, ensuring the integrity and temperature stability of packages throughout the supply chain.

AI Impact Analysis on Box Sealing Machines Market

User queries regarding AI in the Box Sealing Machines Market primarily center on how artificial intelligence can move the equipment beyond simple mechanical functions toward smart, predictive, and adaptable systems. Common questions revolve around predictive maintenance capabilities, the feasibility of AI-driven defect detection in sealing quality, and how machine learning algorithms can optimize machine settings for efficiency when handling diverse packaging materials or changing box sizes. Users are intensely interested in AI's role in reducing material waste (e.g., optimizing tape length) and minimizing unplanned downtime, suggesting a clear expectation that AI should directly contribute to operational savings and enhanced sustainability metrics. The underlying theme is the transition from static, programmed automation to dynamic, learning-based manufacturing environments.

The introduction of AI and associated machine learning models is fundamentally transforming box sealing operations by enhancing real-time decision-making processes. AI algorithms analyze sensor data collected from the sealing head, motors, and conveyance systems to identify anomalies and predict potential mechanical failures with high accuracy, shifting maintenance strategies from reactive or calendar-based to condition-based and predictive. This predictive capability significantly boosts overall equipment effectiveness (OEE) by reducing the incidence of catastrophic failures and scheduling maintenance during planned downtimes, thereby preserving throughput.

Furthermore, AI-powered vision systems are becoming standard features in high-end automatic sealers. These systems utilize deep learning to recognize subtle defects in the sealing process—such as misaligned tape, improper adhesion, or carton damage—that are invisible to the human eye or standard sensors. By learning acceptable tolerance thresholds, these systems ensure that every sealed box meets stringent quality control standards, automatically rejecting non-conforming packages and providing feedback to the machine control system for immediate parameter adjustment, leading to unparalleled consistency and reduced liability risks.

- AI-driven Predictive Maintenance: Forecast component failure, optimizing service intervals.

- Automated Quality Inspection: Real-time defect detection using computer vision algorithms.

- Parameter Self-Optimization: Machine learning adjusts sealing tension, temperature, or tape length based on box attributes and speed.

- Energy Efficiency Management: AI systems regulate motor speeds and thermal components based on real-time workload.

- Inventory and Material Forecasting: Integration with ERP systems to predict tape/adhesive consumption.

- Random Case Handling Enhancement: Faster identification and configuration adjustments for variable box dimensions.

DRO & Impact Forces Of Box Sealing Machines Market

The dynamics of the Box Sealing Machines Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively constitute the primary Impact Forces determining market trajectory. The overwhelming demand for streamlined supply chains, particularly driven by the explosive growth in global e-commerce, acts as the primary driver, compelling companies to invest heavily in automated end-of-line packaging solutions to manage high volume and expedite fulfillment. Simultaneously, the persistent rise in global industrial labor costs and the scarcity of skilled workforce necessitate the deployment of advanced automation equipment like box sealing machines to maintain competitive operational costs. These forces create a positive feedback loop, solidifying automation as an essential rather than optional investment.

However, the market faces significant restraints that temper growth, most notably the high initial capital investment required for fully automatic and highly specialized sealing equipment. Small and medium-sized enterprises (SMEs), particularly in developing regions, may find the acquisition cost prohibitive, opting instead for less efficient semi-automatic or manual solutions. Furthermore, the complexity of integrating advanced sealing machines with legacy packaging infrastructure, alongside the required training for maintenance personnel to handle sophisticated sensors and controls, presents operational challenges. Concerns over the environmental impact of traditional plastic packaging tapes also act as a structural restraint, pressuring manufacturers to innovate sustainable alternatives.

Opportunities for market expansion are abundant, particularly in the realm of technological convergence. The integration of sealing machines with Industry 4.0 elements—such as IoT for remote monitoring, cloud connectivity for data analytics, and collaborative robotics for flexible handling—represents a massive opportunity for value-added service offerings and enhanced machine efficiency. Moreover, the increasing regulatory focus on sustainable packaging materials and waste reduction opens avenues for machines specialized in using paper-based tapes, water-activated gummed tape, or hot melt adhesive systems. The growth in specialized logistics, like cold chain packaging for vaccines and temperature-sensitive food, also demands highly customized sealing solutions that promise premium pricing and niche market expansion.

Segmentation Analysis

The Box Sealing Machines Market is fundamentally segmented based on factors such as Operation Mode, Type of Sealing, End-Use Industry, and Configuration (Size Handling). This structural breakdown allows market participants to tailor their offerings to specific operational needs, ranging from low-volume, semi-manual operations to high-volume, fully integrated automated lines. The Operation Mode segmentation (Semi-Automatic vs. Automatic) dictates the labor requirement and throughput capacity, with the Automatic segment continuing its rapid dominance due to efficiency gains. Sealing Type segmentation is critical as industries increasingly seek environmentally friendly or higher-security sealing methods, thus driving innovation in tape and adhesive technologies. Analyzing these segments provides a clear understanding of where growth capital is being invested and which technologies are achieving critical mass adoption across industrial sectors.

- By Operation Mode:

- Semi-Automatic Box Sealing Machines

- Fully Automatic Box Sealing Machines

- By Sealing Type:

- Tape Sealing (Pressure Sensitive Adhesive - PSA)

- Hot Melt Adhesive Sealing (Glue Sealing)

- Water-Activated Tape (WAT) Sealing

- Specialty Sealing (e.g., heat sealing, ultrasonic welding)

- By Configuration (Box Size Handling):

- Uniform/Fixed Size Case Sealers

- Random/Variable Size Case Sealers

- By End-Use Industry:

- Food and Beverage

- Pharmaceuticals and Healthcare

- Cosmetics and Personal Care

- E-commerce and 3PL

- Automotive and Industrial Manufacturing

- Electronics and Semiconductors

Value Chain Analysis For Box Sealing Machines Market

The value chain for the Box Sealing Machines Market begins with upstream suppliers providing critical raw materials and components, including steel and aluminum for machine fabrication, motors, sensors, pneumatic systems, and advanced electronic controls (PLCs and HMI screens). Highly specialized component manufacturers focusing on precision engineering and automation technology hold significant leverage in this upstream segment, driving innovation in reliability and speed. Manufacturers of the sealing consumables, particularly adhesive tapes and hot melt glues, also represent a crucial upstream node, where sustainability requirements are now dictating product development toward bio-based or recyclable materials. Efficiency in this initial stage directly impacts the final machine's performance, cost of production, and adherence to global quality standards.

The midstream segment involves the core box sealing machine manufacturers, ranging from specialized niche players to large multinational packaging solution providers. These companies focus on design, assembly, software integration, and system testing. Key activities involve R&D into intelligent automation, miniaturization, speed enhancement, and modular design to facilitate customization and scalability. A significant trend in this segment is the strategic partnership between hardware providers and software/AI firms to embed advanced analytics and predictive maintenance capabilities. Successful midstream players differentiate themselves not just through machine robustness but through comprehensive service agreements and rapid installation capabilities.

The downstream flow involves distribution channels and eventual deployment at the end-user facilities. Distribution is typically handled directly by large manufacturers for major clients (direct sales) or through a network of specialized packaging machinery distributors, system integrators, and value-added resellers (indirect sales). System integrators play a vital role by configuring and integrating the sealing machines into existing or new automated packaging lines. The ultimate customer, spanning logistics centers, factories, and fulfillment centers, evaluates machines based on throughput, reliability, footprint, and lifetime operational cost, ensuring that the machine delivers maximum efficiency and contributes positively to the overall packaging workflow.

Box Sealing Machines Market Potential Customers

Potential customers for box sealing machines are broadly categorized across sectors that require high-volume, consistent, and secure packaging for transportation and storage. The most prominent end-user segment is the E-commerce and 3PL industry, which demands fully automatic random case sealers capable of handling mixed SKU orders at extremely high speeds to meet stringent delivery timelines. These operators prioritize machine uptime, integration ease with warehouse management systems (WMS), and flexibility in accommodating various packaging types necessitated by diverse product catalogs.

The Food and Beverage sector represents another significant customer base, particularly manufacturers of packaged foods, beverages, and dairy products. Their stringent hygienic requirements and high production speeds drive demand for stainless steel, wash-down compatible machines that utilize specialized sealing methods (often hot melt or tape) designed to withstand cold storage or moisture. Similarly, the Pharmaceuticals and Healthcare sector requires high-integrity, tamper-evident sealing solutions to comply with regulatory mandates regarding product safety and traceability, driving demand for specialized validation and security features within the sealing process.

Beyond these high-throughput areas, manufacturing industries, including automotive parts, electronics, and durable consumer goods, also constitute vital buyers. These industries often require uniform sealing machines for standardized parts packaging or specialized applications requiring robust, heavy-duty sealing to protect valuable, sensitive components during transit. The decision-making process for these customers is heavily weighted toward reliability, long-term durability, and the machine's ability to seamlessly integrate into existing assembly and distribution infrastructure without disrupting production flow.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 6.7 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, SIAT S.p.A., Pro Mach Inc., Lantech.com LLC, Combi Packaging Systems LLC, A-B-C Packaging Machine Corp., Wexxar Packaging Inc., Loveshaw, Sealed Air Corporation, Schneider Packaging Equipment Co., M.J. Maillis Group, Belcor Industries, Inc., ENDPACK, IPG (Intertape Polymer Group), Little David, PMI Cartoning, Mactec Packaging Technologies, GOCMEN, Eastey, and Zappe. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Box Sealing Machines Market Key Technology Landscape

The Box Sealing Machines Market is undergoing a rapid technological evolution, moving away from purely mechanical systems toward smart, interconnected packaging solutions aligned with Industry 4.0 principles. The most impactful technological trend is the pervasive implementation of smart sensors, enabling real-time performance monitoring, condition-based maintenance, and seamless data exchange with MES (Manufacturing Execution Systems) and ERP (Enterprise Resource Planning) software. This integration allows for superior operational transparency and centralized control over dispersed packaging lines, crucial for multinational corporations managing global supply chains. Furthermore, advanced servo motor technology is replacing traditional pneumatic systems, leading to quieter operation, higher precision in tape application, faster indexing speeds, and significant energy consumption reduction.

Another significant area of innovation is the development of versatile sealing systems capable of adapting quickly to the dynamic packaging landscape. Random case sealers utilizing sophisticated dimensional scanning technology (vision systems) and rapid-changeover mechanisms are vital for e-commerce and 3PL fulfillment centers handling highly variable box dimensions and weights. These systems minimize the non-productive time associated with manual adjustments. Concurrently, the focus on sustainable packaging mandates the development of specialized heads capable of efficiently handling paper-based tapes and water-activated gummed tapes. These technological adaptations require precise temperature control and application force management to ensure the integrity of the seal without compromising the structural stability of environmentally friendly packaging materials.

The convergence of robotics and sealing technology is also becoming increasingly prevalent, particularly in high-speed applications where seamless end-of-line integration is paramount. Collaborative robots (cobots) are being deployed for tasks such as automated box erection and placement prior to sealing, or for palletizing after the sealing process, further enhancing efficiency and reducing the need for manual intervention in repetitive tasks. Furthermore, sophisticated software interfaces (HMI) with built-in diagnostic tools and remote accessibility are simplifying operation, troubleshooting, and programming, making advanced sealing machinery accessible to a broader range of operational personnel and drastically cutting down service response times through remote diagnostics capabilities.

Regional Highlights

- North America: This region holds a significant market share, driven by mature automation adoption, high labor costs, and the presence of major logistics and e-commerce giants demanding high-speed, fully automatic random case sealing solutions. Investment is heavily focused on integrating machines with sophisticated warehouse automation systems, predictive maintenance using IoT, and adopting high-efficiency, durable machinery to ensure maximum uptime in 24/7 fulfillment centers. Strict safety and ergonomic standards also accelerate the replacement of semi-automatic equipment with modern, integrated systems.

- Europe: Characterized by stringent environmental regulations and a strong emphasis on sustainability, the European market shows robust demand for sealing machines utilizing eco-friendly consumables, such as hot melt glues and reinforced paper tapes. Growth is sustained by the sophisticated manufacturing sector (Germany, Italy) and the expansion of pharmaceutical packaging requiring validated, high-integrity sealing processes. Eastern Europe is emerging as a critical growth pocket due to rapid industrialization and modernization of packaging infrastructure funded by foreign direct investment.

- Asia Pacific (APAC): APAC is the fastest-growing market globally, propelled by burgeoning manufacturing output (especially China, India, and Southeast Asia) and the astronomical growth of domestic e-commerce platforms. The market here is diverse, ranging from basic semi-automatic machines meeting SME demand to state-of-the-art, high-throughput systems deployed by international 3PL providers. Governments’ push for advanced manufacturing and foreign investment in food processing and pharmaceuticals ensures sustained, aggressive growth in automation equipment like box sealers.

- Latin America (LATAM): Market expansion in LATAM is gradually accelerating, primarily focused on modernizing existing packaging lines in Brazil and Mexico to improve efficiency and reduce packaging costs. Demand is concentrated in the food and beverage sectors and the increasing penetration of international retailers requiring consistent packaging quality. Economic volatility, however, often favors cost-effective, durable semi-automatic machines, although key players are investing in selective automation for competitive advantage.

- Middle East and Africa (MEA): Growth in the MEA region is sector-specific, with major investments linked to large-scale infrastructure projects, expansion of logistics hubs (especially UAE and Saudi Arabia), and the development of local food processing capabilities. High reliance on imports and the establishment of sophisticated distribution centers are driving the adoption of both semi-automatic sealers for local distribution and fully automatic systems for port logistics and FMCG manufacturing.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Box Sealing Machines Market.- 3M Company

- SIAT S.p.A.

- Pro Mach Inc.

- Lantech.com LLC

- Combi Packaging Systems LLC

- A-B-C Packaging Machine Corp.

- Wexxar Packaging Inc.

- Loveshaw

- Sealed Air Corporation

- Schneider Packaging Equipment Co.

- M.J. Maillis Group

- Belcor Industries, Inc.

- ENDPACK

- IPG (Intertape Polymer Group)

- Little David

- PMI Cartoning

- Mactec Packaging Technologies

- GOCMEN

- Eastey

- Zappe

Frequently Asked Questions

Analyze common user questions about the Box Sealing Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving demand for automatic box sealing machines?

The exponential growth of the global e-commerce industry, coupled with the critical necessity to reduce operational labor costs and achieve consistent, high-speed packaging throughput in distribution centers, is the primary market driver.

How are environmental concerns impacting the Box Sealing Machines Market?

Environmental concerns are driving innovation towards sealing machines designed for sustainable packaging materials, specifically those optimized for paper-based tapes, water-activated tapes (WAT), and non-plastic hot melt adhesive systems, reducing reliance on conventional plastic tapes.

What is the difference between Uniform and Random Case Sealers?

Uniform case sealers handle boxes of the same fixed size and are typically used in dedicated manufacturing lines. Random case sealers utilize advanced sensors to automatically adjust to variable box dimensions and are essential for e-commerce and 3PL operations that process mixed-size orders.

Which sealing technology is growing fastest in adoption?

While traditional tape sealing remains dominant, the adoption of hot melt adhesive (glue) sealing and water-activated tape (WAT) sealing is increasing rapidly, particularly in sectors requiring high security, tamper evidence, or sustainable packaging outputs.

How is Industry 4.0 technology applied to box sealing equipment?

Industry 4.0 integration includes embedding IoT sensors for real-time monitoring, utilizing AI for predictive maintenance and quality control, and providing cloud connectivity for remote diagnostics and centralized performance data analysis to optimize Overall Equipment Effectiveness (OEE).

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager