Building Spandrel Glass Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440723 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Building Spandrel Glass Market Size

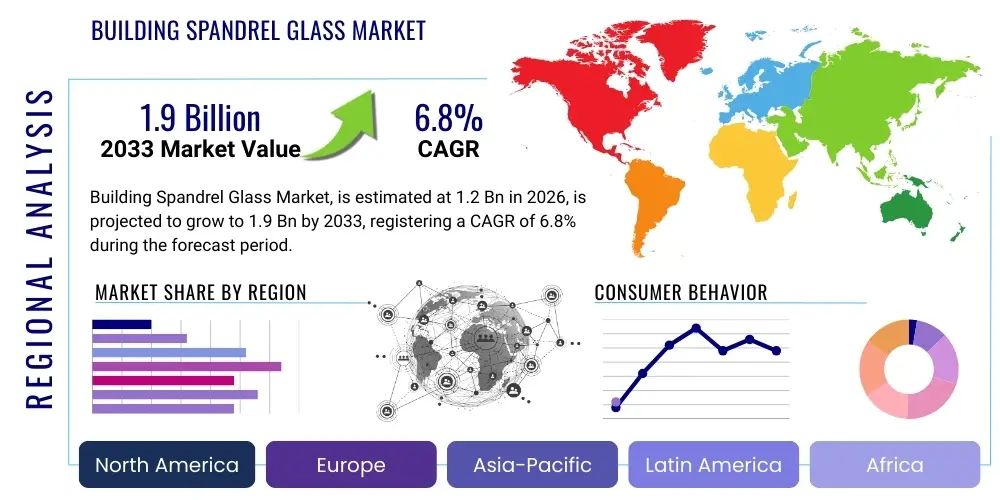

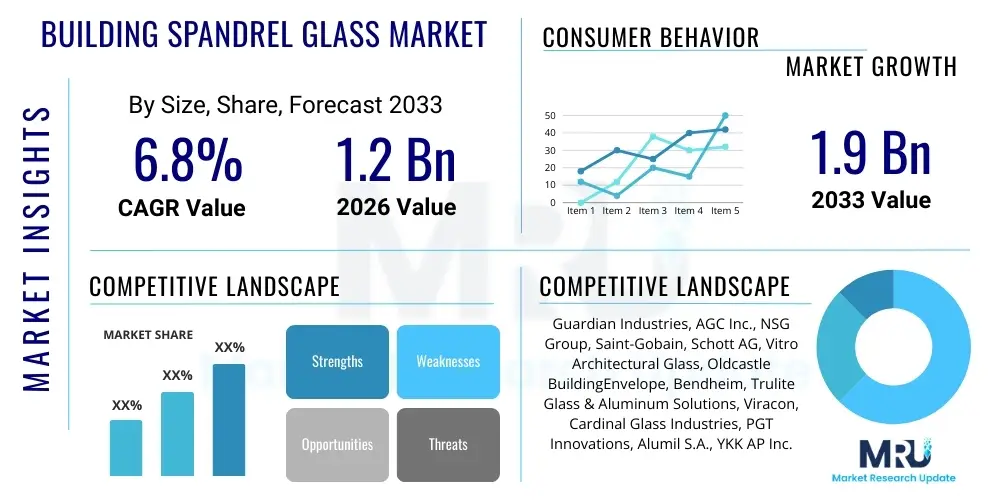

The Building Spandrel Glass Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 1.9 Billion by the end of the forecast period in 2033.

Building Spandrel Glass Market introduction

The Building Spandrel Glass Market encompasses specialized glass panels designed to conceal structural elements, insulation, and wiring within a building's curtain wall or window system. These opaque or translucent glass panels are typically installed in non-vision areas between floors, above ceilings, or below floors, creating a seamless and aesthetically pleasing facade. Their primary function extends beyond mere concealment, contributing significantly to a building's thermal performance, fire resistance, and overall architectural integrity, offering a sophisticated alternative to traditional opaque materials.

The product, spandrel glass, is distinguished by its durable, heat-strengthened, or tempered composition, often featuring ceramic frit, silicone coatings, or opacifying films applied to one of its surfaces. These treatments provide the necessary opacity to obscure the building's internal components while maintaining a consistent exterior appearance with the vision glass. Major applications span across commercial edifices, including corporate offices, hotels, retail complexes, and educational institutions, as well as high-rise residential buildings and various public infrastructure projects, where both aesthetic continuity and functional concealment are paramount.

The benefits of utilizing building spandrel glass are multifaceted, including enhanced thermal insulation, improved energy efficiency, superior sound attenuation, and a broad spectrum of design flexibility in terms of color, texture, and reflectivity. Key driving factors propelling market expansion include the accelerating pace of urbanization and global construction activities, a growing emphasis on green building certifications and sustainable architectural practices, stringent energy efficiency regulations mandating improved thermal envelopes, and the increasing demand for advanced facade systems that offer both aesthetic appeal and robust functional performance.

Building Spandrel Glass Market Executive Summary

The Building Spandrel Glass Market is experiencing dynamic shifts driven by evolving architectural trends and a heightened focus on building performance. Business trends indicate a rising preference for integrated facade solutions that combine vision and spandrel glass harmoniously, leading to increased demand for customized and high-performance spandrel products. Manufacturers are investing in advanced coating technologies and digital printing capabilities to offer a wider array of aesthetic options, catering to diverse design specifications and enhancing market competitiveness. Strategic partnerships between glass manufacturers, fabricators, and curtain wall system providers are also becoming more prevalent, aimed at streamlining supply chains and delivering comprehensive facade solutions.

Regional trends highlight the Asia Pacific region as a significant growth engine, fueled by rapid infrastructural development, burgeoning urban populations, and a boom in commercial and residential construction projects across emerging economies like China and India. North America and Europe continue to be strong markets, characterized by a demand for premium, energy-efficient, and aesthetically refined spandrel glass solutions, often driven by strict building codes and a strong emphasis on sustainable construction. The Middle East and Africa regions are also witnessing substantial growth due to large-scale development projects and an increasing inclination towards modern, iconic architectural designs requiring sophisticated facade materials.

In terms of segment trends, ceramic frit spandrel glass continues to dominate due to its proven durability and aesthetic versatility, while silicone-coated and opacified spandrel glass types are gaining traction for their cost-effectiveness and ease of application. The commercial buildings segment remains the largest application area, although residential high-rise constructions are demonstrating promising growth. Furthermore, there is a clear trend towards thicker spandrel glass panels and specialized compositions that offer superior insulation and fire resistance, aligning with stringent safety standards and the demand for more resilient building envelopes.

AI Impact Analysis on Building Spandrel Glass Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Building Spandrel Glass Market frequently revolve around optimizing design processes, enhancing manufacturing efficiency, improving material innovation, and integrating spandrel glass within smart building ecosystems. Key themes include how AI can assist architects in selecting optimal spandrel glass specifications for energy performance and aesthetics, its role in automating and refining manufacturing quality control, and the potential for AI-driven analytics to predict material durability and maintenance needs. Users also express interest in AI's capacity to facilitate advanced customization, reduce waste in production, and contribute to the overall sustainability goals of modern construction through intelligent material selection and lifecycle management.

- AI can optimize spandrel glass design parameters for thermal performance and visual integration using generative design algorithms.

- Predictive analytics powered by AI can enhance manufacturing precision and reduce defects in ceramic frit application or coating processes.

- AI-driven robotics can automate handling and inspection of large spandrel glass panels, improving safety and production speed.

- Supply chain optimization using AI algorithms can forecast demand, manage inventory, and streamline logistics for spandrel glass components.

- AI integration with Building Information Modeling (BIM) can facilitate intelligent material specification and performance simulation for entire facade systems.

- Machine learning can analyze sensor data from smart facades to monitor spandrel glass thermal performance and inform predictive maintenance strategies.

- AI tools can personalize aesthetic options, allowing architects and clients to visualize countless spandrel glass combinations in real-time.

- Waste reduction in fabrication can be achieved through AI-optimized cutting patterns and material usage analysis.

DRO & Impact Forces Of Building Spandrel Glass Market

The Building Spandrel Glass Market is significantly influenced by a confluence of drivers, restraints, opportunities, and pervasive impact forces. A primary driver is the global surge in urban development and construction, particularly the proliferation of high-rise commercial and residential structures that heavily rely on advanced curtain wall systems incorporating spandrel glass for both aesthetic coherence and functional concealment. Furthermore, increasing regulatory pressures and a growing commitment to green building standards are pushing architects and developers towards energy-efficient facade materials, positioning spandrel glass with enhanced thermal properties as an indispensable component for achieving environmental sustainability goals and reducing operational energy consumption.

However, the market faces notable restraints, including the relatively higher initial cost of specialized spandrel glass solutions compared to conventional opaque facade materials, which can sometimes deter budget-conscious projects. Material limitations, such as the specific opacity requirements and potential for thermal stress breakage in certain applications, also present challenges. Moreover, the intense competition from alternative facade materials like metal panels, composite materials, and opaque masonry systems, which offer different aesthetic and performance profiles, requires continuous innovation and value proposition enhancement from spandrel glass manufacturers to maintain market share.

Opportunities for growth are abundant, particularly in the integration of smart glass technologies with spandrel panels, offering dynamic control over light transmission and privacy, and thereby expanding their functional utility. The burgeoning trend of modular and prefabricated construction offers new avenues for streamlined installation and cost efficiencies for spandrel glass systems. Additionally, continuous research and development into sustainable spandrel glass materials, including recycled content and low-emissivity coatings, present significant growth potential, aligning with broader industry shifts towards eco-friendly building practices. The ongoing exploration of emerging markets, especially in rapidly urbanizing regions, provides fertile ground for market expansion.

The market is also shaped by several overarching impact forces. Technological advancements in glass manufacturing, coating technologies, and digital printing continue to refine product aesthetics and performance, enabling greater customization and functionality. Shifts in architectural design philosophies, favoring minimalist aesthetics, expansive glazing, and seamless facade transitions, directly influence demand for high-quality spandrel glass. Global economic conditions and fluctuations in raw material prices (e.g., silica, ceramics, coatings) inevitably affect production costs and market pricing strategies. Lastly, evolving building codes, fire safety regulations, and environmental standards consistently drive innovation in spandrel glass to meet increasingly stringent compliance requirements, compelling manufacturers to invest in product development that addresses these critical performance criteria.

Segmentation Analysis

The Building Spandrel Glass Market is meticulously segmented to provide a granular understanding of its diverse components and evolving dynamics. This segmentation facilitates targeted market analysis, allowing stakeholders to identify specific growth drivers, competitive landscapes, and emerging opportunities across various product types, application areas, and coating technologies. The comprehensive categorization assists in formulating strategic business decisions, from product development and manufacturing to marketing and distribution, ensuring that market offerings are aligned with specific end-user demands and industry trends.

- By Type:

- Ceramic Frit Spandrel Glass

- Silicone Coated Spandrel Glass

- Opacified Spandrel Glass

- Digital Printed Spandrel Glass

- Others (e.g., Sandblasted, Etched)

- By Application:

- Commercial Buildings

- Offices

- Retail & Shopping Centers

- Hospitality (Hotels, Resorts)

- Healthcare Facilities

- Educational Institutions

- Residential Buildings

- High-Rise Apartments

- Condominiums

- Custom Homes

- Industrial & Institutional Buildings

- Public Infrastructure (e.g., Airports, Train Stations)

- Commercial Buildings

- By Coating Type:

- Opaque

- Translucent

- By Thickness:

- Less than 6mm

- 6mm to 10mm

- Greater than 10mm

- By End-Use Industry:

- Construction & Architecture

- Interior Design

- Renovation & Retrofitting

Value Chain Analysis For Building Spandrel Glass Market

The value chain for the Building Spandrel Glass Market is a complex network involving multiple stages, from raw material sourcing to final installation and after-sales support. Upstream analysis typically begins with the extraction and processing of raw materials such as silica sand, soda ash, and limestone for glass manufacturing, alongside the production of specialized coatings, ceramic frits, and silicone sealants. Key players in this stage focus on securing high-quality, cost-effective inputs to ensure the foundational integrity and aesthetic properties of the spandrel glass. The efficiency and environmental impact of these raw material suppliers directly influence the overall sustainability and cost structure of the end product.

Midstream activities involve the primary glass manufacturers who produce float glass sheets, which are then further processed by specialized fabricators. These fabricators perform critical steps such as cutting, edge working, heat treatment (tempering or heat-strengthening), and the application of opaque coatings (ceramic frit, silicone coating, or film lamination) that transform clear glass into spandrel glass. The innovation and technological capabilities of these fabricators in achieving precise colors, textures, and performance specifications are crucial for meeting diverse architectural demands. Quality control and adherence to industry standards at this stage are paramount to ensure the durability and safety of the spandrel panels.

Downstream analysis focuses on the distribution channels and the ultimate end-users. Distribution primarily occurs through a network of specialized glass distributors, building material suppliers, and directly from fabricators to curtain wall manufacturers or glazing contractors. These channels ensure that the customized spandrel glass panels reach construction sites efficiently. Direct channels often involve larger projects or specialized requirements, while indirect channels cater to a broader market. The end-users, encompassing architects, general contractors, developers, and building owners, specify and procure spandrel glass based on design requirements, performance criteria, and budget. The final installation is typically handled by expert glazing contractors who integrate the spandrel glass into the building's facade system, ensuring proper sealing, structural integrity, and aesthetic alignment.

Building Spandrel Glass Market Potential Customers

The Building Spandrel Glass Market caters to a diverse range of potential customers, primarily driven by the dynamic needs of the construction and architectural sectors. Leading among these are large-scale commercial developers and real estate firms that undertake projects for office buildings, retail complexes, hotels, and institutional facilities. These entities prioritize spandrel glass for its ability to create visually striking, energy-efficient facades that enhance property value and align with modern design aesthetics, ensuring a cohesive exterior appearance while concealing structural elements.

Another significant customer segment comprises architectural firms and design consultants who specify spandrel glass as a critical component in their facade designs. Their decisions are influenced by performance criteria such as thermal insulation, fire resistance, and durability, alongside aesthetic considerations like color matching, reflectivity, and texture. These professionals often seek custom solutions to achieve unique architectural visions, making them pivotal in driving demand for innovative spandrel glass products. Glazing contractors and curtain wall manufacturers also represent key customers, as they are responsible for the procurement and installation of spandrel glass systems as part of comprehensive facade packages, requiring reliable supply chains and high-quality materials.

Beyond new construction, renovation and retrofitting projects for existing buildings also present a substantial customer base. Building owners and facility managers looking to upgrade outdated facades to improve energy efficiency, enhance aesthetic appeal, or comply with stricter building codes often invest in modern spandrel glass solutions. Furthermore, governmental bodies and public sector organizations undertaking infrastructure projects, such as airports, train stations, and public institutions, frequently incorporate spandrel glass into their designs, driven by needs for robust, long-lasting, and aesthetically pleasing building envelopes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 1.9 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Guardian Industries, AGC Inc., NSG Group, Saint-Gobain, Schott AG, Vitro Architectural Glass, Oldcastle BuildingEnvelope, Bendheim, Trulite Glass & Aluminum Solutions, Viracon, Cardinal Glass Industries, PGT Innovations, Alumil S.A., YKK AP Inc., Kawneer Company Inc., CSG Holding Co., Ltd., Xinyi Glass Holdings Limited, Taiwan Glass Industry Corporation, Asahi India Glass Ltd., Euroglas GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Building Spandrel Glass Market Key Technology Landscape

The Building Spandrel Glass Market is continually shaped by advancements in several key technological areas, all aimed at enhancing product performance, aesthetic versatility, and manufacturing efficiency. One prominent aspect is the evolution of advanced coating technologies, which are crucial for achieving the desired opacity, color consistency, and thermal performance of spandrel panels. Low-emissivity (low-E) coatings, for instance, are increasingly integrated with spandrel glass to improve its insulation properties, contributing significantly to a building's energy efficiency by reducing heat transfer. Similarly, specialized ceramic frit applications have advanced to offer a wider spectrum of colors, patterns, and durable finishes, applied through sophisticated screen-printing or roller-coating techniques that ensure longevity and resistance to environmental factors.

Digital printing technology represents another transformative force within the spandrel glass landscape. This innovation allows for the direct application of high-resolution images, intricate patterns, and custom designs onto glass surfaces, offering unparalleled artistic freedom and customization possibilities for architects. Digital printing eliminates the need for traditional screens, enabling rapid prototyping and cost-effective production of unique facade elements, thereby pushing the boundaries of architectural expression. Furthermore, the development of intelligent or smart glass functionalities, although more commonly associated with vision glass, is beginning to influence spandrel applications, particularly in terms of dynamic opacity control or the integration of embedded sensors for performance monitoring.

In manufacturing, automation and robotics are playing an increasingly vital role, from automated glass cutting and edge processing to robotic handling of large panels during coating and tempering processes. These technologies not only improve production speed and accuracy but also enhance worker safety and reduce the incidence of defects. The integration of Building Information Modeling (BIM) with manufacturing processes is also becoming crucial, allowing for precise specification and fabrication of spandrel glass panels that seamlessly fit into the overall building design. Additionally, ongoing research into novel opacifying materials, more sustainable glass compositions, and improved adhesion technologies for films and coatings are continuously pushing the envelope for the next generation of high-performance and environmentally responsible spandrel glass products.

Regional Highlights

- North America: This region stands as a mature market characterized by stringent building codes emphasizing energy efficiency and high demand for aesthetically integrated facade solutions. Innovation in smart glass and sustainable building materials is a key driver, with a strong focus on high-performance spandrel glass for commercial skyscrapers and institutional projects. The presence of leading architectural firms and a preference for advanced glazing systems sustain its market prominence.

- Europe: Europe exhibits a robust market for spandrel glass, strongly influenced by ambitious environmental regulations and a deep-rooted architectural tradition that values design quality and energy conservation. The region is a leader in green building certifications and passive house standards, driving demand for spandrel glass with superior thermal insulation and low-emissivity properties. Germany, France, and the UK are prominent contributors to market growth, emphasizing both performance and sophisticated aesthetics.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, propelled by rapid urbanization, significant infrastructure development, and a construction boom in emerging economies like China, India, and Southeast Asian countries. The escalating demand for modern high-rise commercial and residential buildings, coupled with increasing disposable incomes and a shift towards contemporary architectural designs, fuels the adoption of spandrel glass across the region. Cost-effectiveness and production capacity are critical factors here.

- Latin America: This region presents an emerging market with substantial growth potential, driven by expanding economies, increasing foreign investment in real estate, and ongoing urbanization trends in countries like Brazil, Mexico, and Chile. While slightly lagging behind more developed regions in terms of high-performance product adoption, there's a growing awareness and demand for modern facade solutions that offer both visual appeal and improved building efficiency.

- Middle East and Africa (MEA): The MEA market is characterized by ambitious mega-projects and a strong inclination towards iconic, aesthetically striking architecture, particularly in the Gulf Cooperation Council (GCC) countries. High temperatures necessitate spandrel glass with excellent thermal performance, while the pursuit of luxury and unique design drives demand for highly customized and specialized glass solutions. Investment in tourism, commercial infrastructure, and residential developments underpins significant market expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Building Spandrel Glass Market.- Guardian Industries

- AGC Inc.

- NSG Group

- Saint-Gobain

- Schott AG

- Vitro Architectural Glass

- Oldcastle BuildingEnvelope

- Bendheim

- Trulite Glass & Aluminum Solutions

- Viracon

- Cardinal Glass Industries

- PGT Innovations

- Alumil S.A.

- YKK AP Inc.

- Kawneer Company Inc.

- CSG Holding Co., Ltd.

- Xinyi Glass Holdings Limited

- Taiwan Glass Industry Corporation

- Asahi India Glass Ltd.

- Euroglas GmbH

Frequently Asked Questions

Analyze common user questions about the Building Spandrel Glass market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is building spandrel glass and how does it differ from vision glass?

Building spandrel glass is an opaque or translucent glass panel used in non-vision areas of a facade to conceal structural elements, insulation, and wiring. Unlike vision glass, which is transparent and allows light to pass through, spandrel glass is designed for concealment while maintaining aesthetic continuity with the building's glazing. It often features ceramic frit, silicone coatings, or films to achieve its opacity.

What are the primary benefits of using spandrel glass in building construction?

The key benefits include enhancing facade aesthetics by creating a seamless glass exterior, concealing unsightly building components, improving thermal insulation and energy efficiency, contributing to sound attenuation, and offering significant design flexibility in terms of color, texture, and finish. It also provides a durable and weather-resistant envelope for the building.

How does spandrel glass contribute to a building's energy efficiency?

Spandrel glass panels, especially those with advanced coatings like low-emissivity (low-E) treatments or insulating glass units (IGUs), significantly improve the thermal performance of a building's envelope. They help reduce heat gain in warm climates and heat loss in cold climates, thereby minimizing reliance on HVAC systems and lowering overall energy consumption for heating and cooling.

What types of coatings or treatments are commonly applied to spandrel glass?

Common treatments include ceramic frit, where a ceramic paint is fused onto the glass surface through a tempering process, silicone coatings for a durable opaque finish, and laminated films for opacification. Digital printing is also increasingly used to create custom patterns and high-resolution designs, offering wide aesthetic versatility and performance customization.

What factors should be considered when selecting spandrel glass for a project?

Key considerations include aesthetic matching with vision glass (color, reflectivity), desired opacity, thermal performance requirements (U-value, solar heat gain coefficient), fire resistance ratings, durability, project budget, ease of installation, and compliance with local building codes and standards. The overall architectural design and environmental conditions of the building's location are also critical factors.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager