Cabinet Door Hinges Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441242 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Cabinet Door Hinges Market Size

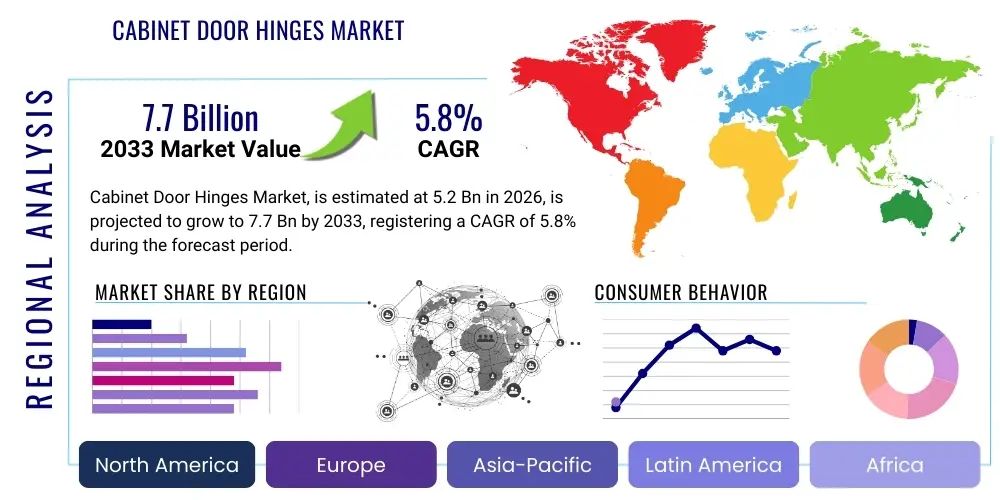

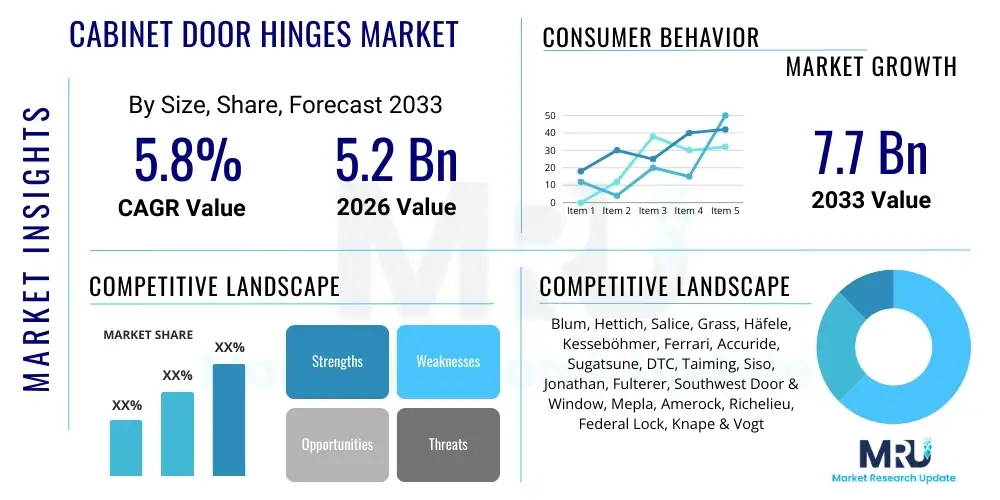

The Cabinet Door Hinges Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 5.2 Billion in 2026 and is projected to reach USD 7.7 Billion by the end of the forecast period in 2033.

Cabinet Door Hinges Market introduction

The Cabinet Door Hinges Market encompasses the global trade and utilization of mechanical devices designed to connect cabinet doors to their respective frames, allowing for rotational movement (opening and closing). These components are fundamental to the functionality and aesthetic integrity of cabinetry across residential, commercial, and institutional sectors. The product portfolio ranges from basic butt hinges to sophisticated European-style concealed hinges, including specialized variations such as soft-close, self-closing, and specialized angle hinges. The continuous evolution in furniture design, coupled with heightened consumer demand for functional, durable, and aesthetically pleasing hardware, drives the innovation within this sector. Manufacturers are increasingly focusing on precision engineering, material science advancements (such as robust stainless steel and specialized alloys), and incorporating damping technologies to enhance user experience, thereby reinforcing the market’s growth trajectory.

Major applications for cabinet door hinges span across kitchen cabinetry, bathroom vanities, bedroom wardrobes, office furniture, and specialized commercial fixtures in hospitality and retail environments. The shift towards modular kitchen systems and ready-to-assemble (RTA) furniture globally has significantly boosted the demand for standardized yet highly reliable hinge mechanisms. The primary benefits offered by modern cabinet hinges include improved door alignment, enhanced durability and load-bearing capacity, noise reduction through soft-close features, and aesthetic integration, particularly with concealed hinge types that maintain clean cabinet lines. These functional and design benefits are crucial factors influencing procurement decisions among furniture manufacturers, professional contractors, and DIY consumers alike, cementing the hinge as a critical element in interior design.

Key driving factors accelerating the growth of the Cabinet Door Hinges Market include sustained expansion in the global construction and real estate sectors, particularly in emerging economies where urbanization rates remain high. Furthermore, the robust renovation and remodeling activities observed in developed nations, often driven by consumer interest in smart homes and high-end aesthetics, necessitate the replacement or upgrade of existing hardware to premium options. Technological innovations, such as advanced manufacturing techniques enabling mass production of precision components and the integration of electronic or sensor-based features in high-end cabinetry, also serve as significant market accelerators. The focus on ergonomic design and accessibility (ADA compliance) further promotes the adoption of specialized and easily adjustable hinge systems.

Cabinet Door Hinges Market Executive Summary

The Cabinet Door Hinges Market is characterized by intense competition and sustained technological innovation, with core business trends revolving around the integration of soft-close technology as a standard feature, rather than a premium upgrade. Furniture manufacturers are increasingly prioritizing supply chain resilience and seeking partners capable of providing high-volume, precision-engineered hinges that meet rigorous quality and lifespan standards. The trend towards sustainable materials and streamlined production processes is also prominent, influencing investment decisions in automated manufacturing facilities. Furthermore, digitalization of the design process, including the use of Building Information Modeling (BIM) and augmented reality tools for cabinet planning, influences hinge specifications earlier in the construction cycle, necessitating closer collaboration between hardware providers and design professionals. Business models are shifting towards offering complete system solutions, including mounting plates and specialized installation tools, rather than just standalone hardware components.

Regionally, Asia Pacific (APAC) stands out as the primary growth engine, fueled by massive housing construction projects, rapid urbanization, and the flourishing furniture manufacturing industries in countries like China, India, and Vietnam. North America and Europe maintain substantial market shares, primarily driven by high renovation expenditure, stringent quality standards, and strong consumer preference for premium, European-style concealed hinges (e.g., 35mm cup hinges). While North America sees consistent demand for robust hardware in large-scale residential and commercial projects, Europe leads in design innovation and the adoption of specialized hinges for customized, high-end furniture. The Middle East and Africa (MEA) and Latin America represent growing opportunities, linked directly to infrastructure development and increasing disposable incomes driving demand for imported or locally manufactured high-quality cabinetry.

Segment trends highlight the dominance of concealed hinges (particularly the soft-close variant) over traditional exposed hinges due to superior aesthetics, adjustability, and functionality. By application, the residential sector remains the largest consumer, but the commercial sector, driven by rapid expansion in hospitality (hotels) and retail fit-outs, exhibits higher growth potential for specialized, heavy-duty hinges. Material-wise, high-grade steel alloys optimized for corrosion resistance and endurance are gaining preference, particularly in moisture-prone environments like kitchens and bathrooms. The distribution channel is increasingly leveraging e-commerce platforms and specialized hardware retail chains to reach professional installers and the expanding DIY consumer base, ensuring wide market penetration and accessibility for various product categories.

AI Impact Analysis on Cabinet Door Hinges Market

Common user questions regarding AI's influence on the Cabinet Door Hinges Market primarily focus on manufacturing efficiency, product quality consistency, and supply chain optimization. Users frequently inquire how AI can minimize defects in precision manufacturing processes, automate complex assembly tasks involving delicate mechanisms, and predict equipment failure in high-volume production lines. There is also significant interest in AI-driven demand forecasting, inventory management, and personalized cabinet design recommendations that dictate specific hinge requirements. The consensus is that while the cabinet hinge itself is a mechanical component, AI significantly enhances the ecosystem surrounding its production, distribution, and utilization, making manufacturing smarter and more responsive to custom orders and sudden market shifts. Key themes revolve around maintaining high tolerances through automated inspection and streamlining logistics from the raw material stage to the installation site.

- AI-driven Predictive Maintenance (PdM): Algorithms analyze machine data (vibration, temperature) to forecast potential failures in stamping, molding, and assembly equipment, minimizing unplanned downtime and ensuring consistent component precision.

- Automated Quality Control (AQC): Vision systems and machine learning models rapidly inspect hinge components for micro-defects, dimensional inaccuracies, and surface finish issues far beyond human capability, raising overall product quality standards.

- Demand Forecasting and Inventory Optimization: AI models process complex market indicators (construction permits, retail sales data, seasonal trends) to improve the accuracy of hinge demand forecasts, reducing stockouts and minimizing carrying costs in the supply chain.

- Generative Design for Hinge Mechanisms: AI assists engineers in optimizing hinge geometry and material usage for maximum strength, durability, and soft-close performance, leading to lighter yet more robust designs.

- Robot-Assisted Assembly: Advanced robotics integrated with AI guidance systems automate the complex multi-step assembly of soft-close mechanisms, ensuring high-speed production and superior repeatability.

- Supply Chain Resilience: AI analyzes logistical bottlenecks, geopolitical risks, and material price fluctuations, enabling proactive sourcing and distribution strategies for global hinge manufacturers.

DRO & Impact Forces Of Cabinet Door Hinges Market

The Cabinet Door Hinges Market is propelled by powerful growth drivers such as the global boom in residential construction and renovation, particularly the surging popularity of modular kitchens requiring high-quality, standardized hardware. This is coupled with ongoing innovation, where manufacturers continuously introduce advanced features like integrated dampening systems (soft-close), multi-dimensional adjustability (6-way adjustments), and specialized mounting solutions (tool-free installation), significantly enhancing the perceived value and performance of the product. Furthermore, the increasing consumer focus on interior aesthetics means that concealed hinges are becoming the baseline expectation, driving volume growth in the premium segment. These drivers create a sustained upward pressure on both quantity and quality demanded in the market.

Conversely, the market faces specific restraints. The intense price competition, especially from mass-produced hinges originating in certain Asian markets, puts severe pressure on the profit margins of established, high-quality international brands. Furthermore, the volatility in raw material prices, particularly steel and zinc alloys, poses a significant risk to manufacturing costs. Technical constraints, such as the complexity of standardizing hinge dimensions across diverse global cabinetry designs and the high initial investment required for implementing advanced soft-close technology in manufacturing, also slightly impede market expansion. The long lifecycle of hinges (often lasting 10-20 years) means replacement cycles are slow, limiting revenue from aftermarket sales compared to initial installation.

Opportunities abound in developing next-generation hinge systems, including the integration of smart technology into cabinetry, potentially requiring hinges with embedded sensors for usage monitoring or electronic locking mechanisms. The expansion into niche markets, such as hinges specialized for heavy-duty commercial applications (e.g., large hotel wardrobes or laboratory storage) and those designed for non-standard materials (e.g., glass doors or thin panel doors), offers diversification potential. Moreover, leveraging e-commerce for direct-to-consumer and professional sales, offering extensive customization options and virtual installation guides, presents a scalable opportunity for market players to bypass traditional distribution hurdles and capture greater market share globally. The current geopolitical landscape encourages regionalization of supply chains, presenting an opportunity for domestic manufacturers in large consumer markets to gain an edge.

- Drivers: Global Construction and Renovation Boom, High Demand for Soft-Close Technology, Aesthetic Preference for Concealed Hinges, Growth of Modular Furniture Industry.

- Restraints: Intense Price Competition from Low-Cost Manufacturers, Volatility in Key Raw Material Prices (Steel/Zinc), Long Product Lifespan Limiting Replacement Cycle, Need for High Precision Manufacturing Investment.

- Opportunities: Integration of Smart Features (Sensors, Electronics), Expansion into Specialized Commercial Hardware, Growth in DIY and E-commerce Sales Channels, Focus on Sustainable Materials and Production.

- Impact Forces: Technological advancements in damping mechanisms significantly enhance user experience (High Impact); Raw material price fluctuations directly influence manufacturing cost and final price point (Moderate Impact); Regulatory standards concerning load-bearing capacity and durability influence product design (Low Impact but Increasing).

Segmentation Analysis

The Cabinet Door Hinges Market is extensively segmented based on key structural and functional parameters, including the product type, material composition, application area, and distribution channel. The complexity of modern cabinetry demands a wide array of hinge solutions, ranging from basic economic options suitable for budget furniture to premium, highly engineered systems designed for customized, luxury installations. Understanding these segments is crucial as different end-user groups prioritize different attributes, such as cost-effectiveness, aesthetic concealment, load capacity, or specialized functionality (e.g., specific opening angles or anti-corrosion properties). The concealed hinge category, specifically the European style (cup hinge), dominates the global landscape due to its superior adjustability and aesthetic advantages, driving standardization across residential and commercial applications.

The segmentation by application reveals the residential sector as the bedrock of demand, fueled by household furniture and kitchen remodeling projects. However, the commercial segment, encompassing offices, hotels, hospitals, and retail fixtures, often demands higher specifications in terms of cyclical durability and fire ratings, representing a critical market for specialized, heavy-duty products. Material differentiation, particularly between various grades of stainless steel, brass, and zinc alloys, is essential for determining the lifespan, corrosion resistance, and eventual cost structure of the hinge. Stainless steel remains paramount for high-moisture environments, whereas zinc alloys often provide cost-effective solutions for standard interior applications.

The market dynamics within these segments are constantly influenced by regional building codes and consumer wealth levels. For instance, North America often favors full overlay hinges, while European markets widely standardize on half overlay or inset options based on continental cabinet construction norms. As global trade facilitates the blending of these styles, manufacturers must maintain flexible production lines capable of addressing varied regional preferences. This detailed segmentation analysis allows companies to tailor their product offerings and marketing strategies effectively, focusing resources on the fastest-growing and highest-margin segments, such as premium soft-close mechanisms sold through specialized distributor networks.

- By Product Type:

- Concealed Hinges (European Style)

- Semi-Concealed Hinges

- Exposed Hinges (Butt Hinges, T-Hinges, Strap Hinges)

- Specialized Hinges (Pantry Hinges, Corner Hinges, Glass Door Hinges)

- By Soft-Close Mechanism:

- Soft-Close Hinges (Integrated Damping)

- Self-Closing Hinges (Spring Loaded)

- Free Swing Hinges

- By Application:

- Residential (Kitchen, Bathroom, Bedroom)

- Commercial (Hospitality, Office, Retail, Healthcare)

- Institutional (Educational Facilities, Public Buildings)

- By Material:

- Stainless Steel

- Zinc Alloy

- Brass and Bronze

- Steel with Plating (Nickel, Chrome)

- By Sales Channel:

- OEMs and Direct Sales

- Distributors and Wholesalers

- Retailers (Hardware Stores, Big Box Stores)

- E-commerce

Value Chain Analysis For Cabinet Door Hinges Market

The value chain for the Cabinet Door Hinges Market initiates with upstream activities centered on the procurement and processing of key raw materials, primarily high-grade steel, zinc, brass, and plastic components used in damping mechanisms. Material suppliers, often global metal processing giants, exert influence based on commodity price volatility and supply consistency. Precision component manufacturing follows, involving complex stamping, die-casting, spring winding, and surface treatment (plating/coating). This stage requires specialized machinery and strict quality control to meet high dimensional tolerances, particularly for concealed soft-close hinges. Leading global hardware companies often invest heavily in highly automated, integrated production facilities to maintain cost efficiency and quality consistency, forming the core value addition point in the chain.

Midstream activities focus on the assembly, packaging, and branding of the final hinge products. Manufacturers aggregate various components, including the hinge cup, arms, mounting plates, and internal damping systems, ensuring robust performance testing. The packaging phase is crucial for protecting the finished goods and providing clear installation instructions, especially for retail and DIY channels. Distribution channels play a vital role, often segmented into direct sales to large Original Equipment Manufacturers (OEMs) who integrate the hinges directly into modular furniture lines, and indirect sales through specialized distributors and wholesalers. These distributors maintain extensive inventories, offering logistical support and crucial technical advice to regional furniture makers and professional installers, thereby bridging the geographical gap between production and consumption.

Downstream analysis focuses on the final point of sale and usage. Direct channels involve manufacturers selling high volumes directly to major furniture producers (e.g., kitchen cabinet makers). Indirect channels leverage large-scale retailers (e.g., Home Depot, Lowe's), specialized hardware boutiques, and increasingly, e-commerce platforms. These platforms provide product visibility, comparative pricing, and access to replacement or specialized parts. End-users—including residential homeowners, commercial builders, and professional carpenters—ultimately drive demand. The aftermarket segment, though smaller, is crucial for replacement parts and upgrades. The overall efficiency of the value chain relies heavily on logistics, inventory management, and the ability of distributors to provide timely delivery of a vast array of SKUs to meet localized cabinet specifications.

Cabinet Door Hinges Market Potential Customers

Potential customers for cabinet door hinges are diverse, spanning multiple industry sectors and consumer segments, yet they primarily coalesce around entities involved in the design, manufacture, installation, or maintenance of furniture and fixtures. The largest single group of buyers consists of Original Equipment Manufacturers (OEMs) in the furniture and cabinetry industry. These are companies that mass-produce kitchen cabinets, wardrobes, office desks, and other storage solutions, purchasing hinges in bulk, often directly from the manufacturer, based on standardized specifications and volume discounts. Their purchasing criteria are heavily weighted towards cost-per-unit, consistency, and guaranteed long-term supply, often preferring integrated solutions (hinge systems) rather than individual components.

A second major customer segment includes professional contractors, builders, and interior design firms. These buyers procure hinges for specific, often bespoke, projects such as high-end custom kitchens, hotel installations, or complex commercial fit-outs. Their demand focuses on specialized features like high load capacity, unique opening angles, specific finishes (e.g., matte black or bronze), and the superior adjustability offered by premium concealed hinges. They typically source through local distributors or specialized trade hardware stores that can offer rapid delivery and technical support. The requirements here emphasize quality, brand reputation, and availability of sophisticated functional hardware that meets specific client aesthetic demands.

Finally, the growing segment of DIY consumers and small-scale renovators constitutes a significant retail customer base. These individuals purchase hinges for repairs, upgrades, or small-scale custom projects, often utilizing retail hardware stores (big-box retailers) and, increasingly, e-commerce platforms. Their decision-making process is highly influenced by ease of installation (e.g., clip-on mechanisms, jig systems), clear instructional content, competitive pricing, and the availability of simple soft-close upgrade kits. Targeting this segment requires strong retail presence and digital marketing efforts focused on installation tutorials and compatibility guides, making them a crucial driver of growth in the aftermarket and replacement category.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 5.2 Billion |

| Market Forecast in 2033 | USD 7.7 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Blum, Hettich, Salice, Grass, Häfele, Kesseböhmer, Ferrari, Accuride, Sugatsune, DTC, Taiming, Siso, Jonathan, Fulterer, Southwest Door & Window, Mepla, Amerock, Richelieu, Federal Lock, Knape & Vogt |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cabinet Door Hinges Market Key Technology Landscape

The technological landscape of the Cabinet Door Hinges Market is dominated by innovations focused on motion control, durability, and simplified installation. The most transformative technology remains integrated dampening systems, commonly known as soft-close mechanisms. These systems utilize specialized hydraulic or spring-based pistons embedded within the hinge cup or arm to decelerate the cabinet door during its closing motion, ensuring silent and smooth operation. Modern iterations of this technology allow for adjustable closing speeds and are increasingly compact, maintaining the sleek profile of concealed hinges. The manufacturing process for these mechanisms relies heavily on precision stamping and specialized oil-dampening components, requiring sophisticated production lines to ensure long-term reliability and leak-free performance under repeated use.

Another critical technological area is multi-dimensional adjustability. Advanced concealed hinges now commonly feature 3-way or 6-way adjustments, allowing installers to precisely align cabinet doors (vertically, horizontally, and in depth) after installation, compensating for slight imperfections in cabinet construction or settling over time. This technology is facilitated by precision-engineered mounting plates and specialized cam mechanisms accessible via screwdriver. Furthermore, clip-on/tool-free installation technologies are gaining prominence, where the hinge arm snaps onto the mounting plate without screws, significantly reducing installation time and complexity for large-scale furniture manufacturers and professional installers. This focus on installation efficiency is a major differentiator in competitive markets.

Material science and surface treatments also constitute a significant technological area. The use of corrosion-resistant materials, such as high-grade 304 or 316 stainless steel, is crucial for hinges deployed in specialized environments (e.g., outdoor kitchens, coastal regions, or laboratories). Enhanced plating techniques, such as PVD (Physical Vapor Deposition) coatings, provide improved aesthetic finishes (e.g., matte black, antique bronze) while offering superior resistance to wear, chemicals, and moisture compared to traditional electroplating. Research and Development efforts are also exploring composite materials for lighter, yet equally durable, hinge components, particularly in the housing and non-load-bearing elements, seeking cost reduction without compromising the core functionality and lifespan of the hinge mechanism.

Regional Highlights

Regional dynamics play a crucial role in shaping the Cabinet Door Hinges Market, driven by differing construction activities, consumer preferences, and manufacturing concentrations. Asia Pacific (APAC) currently holds the largest market share and is projected to exhibit the fastest growth over the forecast period. This growth is intrinsically linked to massive investments in residential infrastructure, increasing urbanization, and the region's position as a global manufacturing hub for furniture and ready-to-assemble (RTA) cabinetry. Countries like China, India, and Southeast Asian nations show skyrocketing demand for both high-volume standardized hinges and increasingly, premium soft-close mechanisms as disposable incomes rise and consumers upgrade their living standards.

- Asia Pacific (APAC): Dominates the market due to robust residential construction, high concentration of furniture manufacturing bases (China, Vietnam), and rapid adoption of modular kitchen concepts. Emphasis is on cost-effective yet increasingly functional concealed hinges.

- North America: Characterized by high renovation expenditure and a strong preference for high-quality, durable, and premium soft-close systems, especially in the US and Canada. The market is driven by customization trends in kitchen and bath design, commanding higher average selling prices.

- Europe: A mature market defined by strict quality standards, leading technological innovation (pioneered by German and Austrian manufacturers like Blum and Hettich), and a strong focus on sustainable manufacturing practices. Demand is high for specialized hinges tailored to unique European cabinet construction norms (e.g., frameless cabinetry).

- Latin America (LATAM): Growth is primarily linked to economic stability and infrastructure projects in countries like Brazil and Mexico. The market is developing, relying on a mix of localized production and imports of mid-range concealed hinges, with price sensitivity being a major factor.

- Middle East and Africa (MEA): Growth is boosted by large-scale hospitality and luxury residential projects (e.g., UAE, Saudi Arabia). Demand is focused on high-end, aesthetically pleasing hardware with specialized finishes suitable for luxury interiors, often sourced from European manufacturers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cabinet Door Hinges Market.- Blum

- Hettich

- Salice

- Grass

- Häfele

- Kesseböhmer

- Ferrari

- Accuride

- Sugatsune

- DTC

- Taiming

- Siso

- Jonathan

- Fulterer

- Southwest Door & Window

- Mepla

- Amerock

- Richelieu

- Federal Lock

- Knape & Vogt

Frequently Asked Questions

Analyze common user questions about the Cabinet Door Hinges market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the adoption of soft-close cabinet hinges globally?

The primary driver is elevated consumer demand for enhanced convenience, reduced noise levels, and superior functionality in modern living spaces, positioning soft-close as a standard expectation for quality cabinetry. Soft-close hinges protect cabinet structures from slamming damage, increasing the longevity of the furniture, which is a key value proposition for end-users and furniture manufacturers alike.

How do concealed hinges differ from exposed hinges, and which type dominates the market?

Concealed hinges (European style) are entirely hidden when the cabinet door is closed, providing a clean, modern aesthetic and offering multi-directional adjustability. Exposed hinges (like butt or strap hinges) are visible. Concealed hinges, particularly the 35mm cup style, overwhelmingly dominate the global market due to their superior aesthetics, functionality, and ease of adjustment, meeting the requirements of modern frameless cabinetry construction.

Which geographical region represents the largest growth opportunity for hinge manufacturers?

Asia Pacific (APAC), particularly driven by urbanization and booming housing markets in countries like China and India, presents the largest growth opportunity. This region combines massive volume demand with rapidly increasing consumer purchasing power, leading to a transition from basic exposed hardware to sophisticated, premium concealed soft-close hinge systems.

What impact does raw material volatility have on the profitability of the cabinet hinges market?

Volatility in prices for steel, zinc alloys, and brass directly impacts the manufacturing costs, subsequently compressing the profit margins of hinge manufacturers, especially those operating on thin margins in the high-volume standardized product segment. Companies often implement hedging strategies and focus on advanced manufacturing efficiency to mitigate these external cost pressures and maintain stable pricing for their end-customers.

What key technological innovations are shaping the future design of cabinet door hinges?

Key technological innovations include the refinement of integrated hydraulic damping for smoother and quieter soft-close performance, the development of tool-free mounting systems (clip-on mechanisms) to simplify installation, and advances in anti-corrosion surface treatments (like PVD coatings) to enhance product durability and aesthetic range. Furthermore, the exploration of smart features, such as integrated sensors for usage monitoring, represents a nascent, high-potential area of development.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager