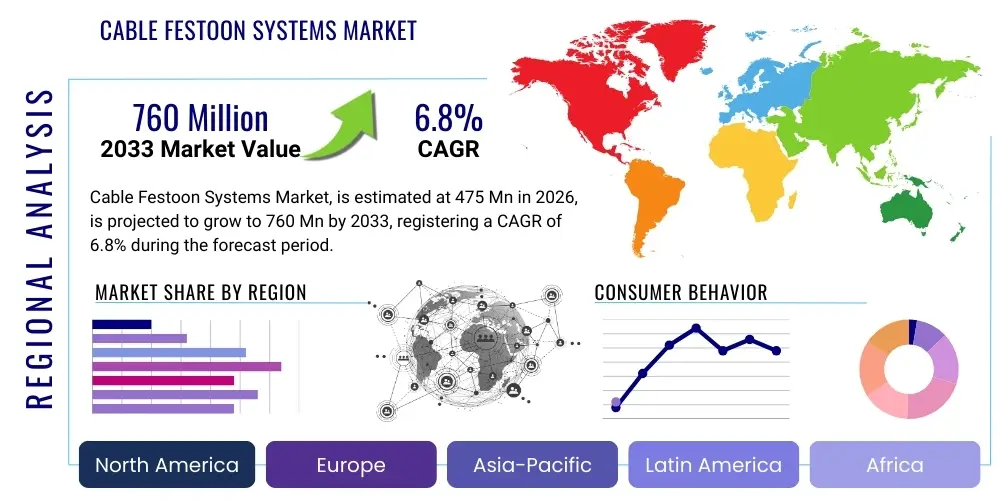

Cable Festoon Systems Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440716 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Cable Festoon Systems Market Size

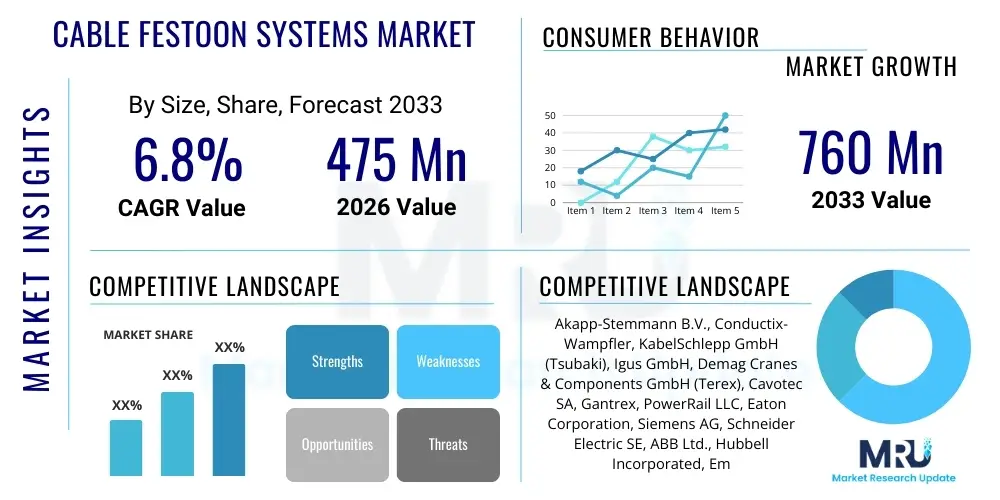

The Cable Festoon Systems Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 475 Million in 2026 and is projected to reach USD 760 Million by the end of the forecast period in 2033.

Cable Festoon Systems Market introduction

Cable festoon systems represent an indispensable category of equipment specifically engineered for the efficient and safe management of power, control, and data cables in dynamic industrial environments. These sophisticated systems are crucial for ensuring uninterrupted operation and reliable performance of various mobile machinery, including cranes, hoists, gantry systems, and conveyor lines, by preventing cable entanglement, damage, and premature wear. Fundamentally, a festoon system provides a flexible electrical and communication umbilical that moves synchronously with the machinery, safeguarding vital connections against the stresses of continuous motion and harsh operational conditions. Their design ingenuity addresses the critical need for an organized and protected method of energy and signal transfer, which is paramount in maintaining productivity and upholding safety standards across diverse industrial applications globally.

The core components of a typical cable festoon system are meticulously designed for durability and seamless integration. These usually include a robust track system, such as C-track, I-beam, or square rail configurations, which serves as the guiding path. Specialized trolleys, fitted with high-quality wheels and bearings, move along this track, securely supporting and carrying the cables. The cables themselves are a critical element, specifically chosen for their high flexibility, resistance to repeated bending cycles, and often, enhanced insulation and shielding properties to ensure reliable power delivery and interference-free data transmission. Additional components like tow trolleys, end clamps, junction boxes, and tension relief devices contribute to the system's overall integrity, ensuring optimal cable sag, proper spacing, and secure termination points. This comprehensive design facilitates a harmonious interaction between static infrastructure and moving equipment, thereby minimizing operational risks and maximizing uptime.

The applications for cable festoon systems are extensive and permeate a multitude of heavy and light industries, underscoring their versatility and critical utility. They are foundational in manufacturing plants for assembly lines and robotic work cells, in logistics and warehousing for automated material handling, and critically in ports and shipyards for powering massive container cranes and ship-to-shore gantry systems. Furthermore, their deployment extends to the automotive sector, mining operations, construction sites, and even the entertainment industry for dynamic stage setups. The overarching benefits derived from adopting these systems include significantly enhanced operational safety through organized cable management, a drastic reduction in costly downtime attributed to cable failures, improved workplace aesthetics, and a substantial extension of cable service life. Market growth is dynamically propelled by the relentless global push for industrial automation, continuous infrastructure development projects worldwide, the increasing imperative to comply with stringent occupational safety regulations, and the ubiquitous demand for highly efficient and robust power and data transfer solutions vital for the modern industrial landscape.

Cable Festoon Systems Market Executive Summary

The Cable Festoon Systems Market is navigating a period of robust expansion, primarily fueled by the accelerating pace of industrial automation and digitalization across global manufacturing and logistics sectors. Key business trends indicate a pronounced industry-wide pivot towards solutions that offer superior durability, enhanced modularity, and greater ease of maintenance. Manufacturers are increasingly focusing on developing systems that can be rapidly customized and integrated with existing operational frameworks, thereby catering to the nuanced and evolving needs of various end-user industries. This strategic emphasis on flexibility and user-centric design is aimed at minimizing installation complexities and reducing the total cost of ownership, making advanced festoon solutions more appealing to a broader spectrum of industrial clients. Furthermore, the drive for operational excellence and efficiency is stimulating innovation in material science and engineering, leading to systems that promise extended operational lifespans and reduced maintenance requirements.

From a regional perspective, the market exhibits distinctive growth patterns influenced by varying levels of industrial development and technological adoption. The Asia Pacific (APAC) region stands out as the primary growth engine, propelled by aggressive industrialization, large-scale infrastructure investments, and the continuous establishment of new manufacturing facilities, particularly in rapidly industrializing nations such as China, India, and Vietnam. North America and Europe, while representing more mature and technologically advanced markets, continue to demonstrate steady demand, driven by modernization initiatives, stringent safety and environmental regulations, and the widespread adoption of Industry 4.0 paradigms. Meanwhile, emerging economies in Latin America, the Middle East, and Africa are showing considerable promise, spurred by significant investments in port infrastructure expansion, burgeoning mining activities, and the nascent but growing industrial diversification efforts within these regions, indicating a broadening global footprint for festoon system applications.

Segmentation trends within the market reveal several important trends shaping product development and market dynamics. The demand for heavy-duty festoon systems, designed to endure extreme environmental conditions and manage substantial cable loads, is particularly strong in sectors like ports, mining, and heavy manufacturing. Conversely, light-duty and medium-duty systems continue to dominate general manufacturing, automotive assembly, and warehousing segments, offering cost-effective and efficient solutions for less demanding applications. A notable technological shift includes the increasing preference for flat cables in certain multi-cable arrangements due to their space-saving design and enhanced efficiency in cable management. Moreover, the integration of advanced data communication cables, including fiber optics, into festoon systems is becoming more prevalent, reflecting the growing need for high-speed, reliable data transmission to support sophisticated, interconnected industrial machinery and smart factory initiatives.

AI Impact Analysis on Cable Festoon Systems Market

The integration of Artificial Intelligence (AI) is poised to significantly transform the Cable Festoon Systems market by addressing common user inquiries and expectations regarding operational optimization, proactive maintenance, and enhanced system intelligence. Users are increasingly seeking solutions that move beyond traditional reactive models, leveraging AI to predict potential failures, optimize cable routing in dynamic environments, and seamlessly integrate festoon systems into broader smart factory ecosystems. The primary concerns users articulate revolve around achieving maximum operational uptime, minimizing unscheduled maintenance, and reducing the overall total cost of ownership by extending asset lifespan. AI's influence is anticipated to manifest through sophisticated data analytics, enabling real-time performance insights and informed decision-making, thereby ushering in a new era of highly efficient and autonomous cable management solutions capable of self-diagnosis and adaptive optimization.

- Smart Diagnostics and Anomaly Detection: AI algorithms can analyze real-time operational data from festoon systems (e.g., trolley speed, cable tension, vibration patterns) to detect subtle anomalies that may precede equipment failure, enabling proactive maintenance interventions before critical breakdowns occur.

- Predictive Maintenance Scheduling: Leveraging machine learning models, AI can forecast component wear and tear, optimizing maintenance schedules based on actual usage and condition rather than fixed intervals, significantly reducing unplanned downtime and associated operational costs.

- Optimized Energy Consumption: AI-driven analytics can identify inefficiencies in cable routing and trolley movement, suggesting dynamic adjustments to minimize energy expenditure, thereby contributing to lower operational costs and enhanced sustainability.

- Seamless Integration with Autonomous Systems: AI facilitates the integration of festoon systems with fully autonomous material handling equipment and robotic processes, enabling coordinated movement, precise cable management, and enhanced safety in complex, highly automated environments.

- Enhanced Safety Monitoring: By continuously monitoring operational parameters and environmental factors, AI can identify potential safety hazards, such as unusual cable behavior or trolley malfunctions, triggering alerts and preventative measures to protect personnel and equipment.

- Real-time Performance Analytics and Reporting: AI platforms provide comprehensive dashboards and reports on system performance, cable health, and operational efficiency, offering invaluable insights for continuous improvement and strategic planning for industrial operators.

- Automated Configuration and Self-Optimization: Future AI advancements could enable festoon systems to self-configure for new routes or loads and adapt their operational parameters dynamically, minimizing manual intervention and maximizing efficiency in diverse industrial applications.

DRO & Impact Forces Of Cable Festoon Systems Market

The Cable Festoon Systems Market's growth trajectory is significantly shaped by a powerful interplay of drivers, restraints, opportunities, and broader impact forces that collectively define its current landscape and future prospects. A paramount driver is the relentless global surge in industrial automation across manufacturing, logistics, and process industries, necessitating reliable and dynamic power and data delivery to mobile machinery. Concurrently, substantial worldwide investments in infrastructure development, particularly in emerging economies, alongside the continuous modernization of existing industrial facilities, further amplify the demand for sophisticated cable management solutions. The increasing implementation of stringent industrial safety regulations, aimed at minimizing workplace accidents and ensuring equipment integrity, also acts as a critical catalyst for adopting standardized and robust festoon systems. Moreover, the inherent need for highly efficient and uninterrupted power and data transfer in dynamic operational environments, where traditional fixed wiring is impractical or unsafe, reinforces the market's fundamental utility and continued expansion across diverse sectors.

Despite these potent growth drivers, the market faces notable restraints that temper its expansion. A significant barrier is the relatively high initial capital outlay required for the procurement and installation of comprehensive festoon systems, which can be a deterrent for smaller enterprises or those with limited investment budgets. Furthermore, the ongoing maintenance costs associated with regular inspection, cable replacement due to wear and tear, and trolley repairs represent recurring operational expenditures that some businesses seek to minimize. The market also contends with intensifying competition from alternative power and data transmission technologies, including advanced wireless solutions for certain applications, and increasingly sophisticated energy chain systems that offer different benefits in terms of cable protection and aesthetic integration. These restraints necessitate continuous innovation in design, materials, and cost-efficiency to maintain competitiveness and expand market penetration against evolving alternatives.

Conversely, the Cable Festoon Systems Market is rich with compelling opportunities for strategic growth and technological advancement. A primary avenue lies in the deeper integration of festoon systems with the burgeoning Internet of Things (IoT) and Industry 4.0 paradigms, enabling smart monitoring, predictive maintenance, and real-time operational analytics to optimize performance and reduce downtime. The immense potential of untapped and rapidly industrializing emerging markets, especially in Asia Pacific and parts of Africa, presents significant expansion opportunities as these regions invest heavily in new industrial infrastructure and automation. There is also a growing demand for highly specialized and heavy-duty festoon systems tailored for extremely challenging environments such, as corrosive marine conditions, high-temperature operations, or explosion-proof requirements in hazardous areas. Furthermore, the continuous development of innovative materials, such as lighter yet stronger composites and advanced, high-flex cables that integrate power with fiber optics, opens new product development pathways, enhancing system durability, versatility, and data transmission capabilities, thereby expanding their applicability to increasingly complex industrial processes.

Segmentation Analysis

The Cable Festoon Systems market is characterized by a sophisticated and multifaceted segmentation, strategically developed to address the highly varied and specific demands of industrial applications across a broad spectrum of sectors. This granular market segmentation is instrumental for manufacturers and suppliers, allowing them to precisely tailor their product offerings, develop niche solutions, and optimize market penetration strategies based on distinct operational needs, technical specifications, and environmental conditions. By dissecting the market into categories such as system type, cable characteristics, application areas, end-use industries, operating environments, and load capacities, stakeholders can gain profound insights into customer preferences and technological requirements. This detailed approach ensures that every solution, from a simple light-duty system for a small workshop to a complex heavy-duty setup for a bustling container port, is optimized for performance, reliability, and cost-effectiveness, fostering innovation and competitive differentiation within the global marketplace.

- By Type

- C-Track Festoon Systems: Widely recognized for their versatility and cost-effectiveness, C-track systems utilize a galvanized or stainless steel track with C-shaped profiles, housing trolleys that carry cables and hoses. They are suitable for light to medium-duty applications and are commonly found in indoor cranes, workshops, and general manufacturing environments due to their ease of installation and maintenance.

- I-Beam Festoon Systems: Designed for heavy-duty applications, I-beam systems employ a robust I-beam girder as their track, providing superior structural integrity for supporting heavier cable loads and operating in more demanding environments. These systems are prevalent in large-scale industrial settings like ports, shipyards, steel mills, and outdoor gantry cranes, offering exceptional durability and resistance to harsh conditions.

- Square Rail Festoon Systems: These systems feature a square or rectangular rail design, offering a compact and often enclosed profile. They are particularly advantageous in applications where space is limited or a cleaner aesthetic is preferred, such as automated storage and retrieval systems (AS/RS), specific automotive lines, and certain specialized machinery requiring precise and confined cable management.

- By Cable Type

- Flat Cables: Preferred for their compact design and efficiency in multi-cable applications, flat cables allow for a higher density of conductors within a smaller space, making them ideal for festoon systems requiring numerous power and data lines. Their uniform bending radius and resistance to twisting enhance longevity.

- Round Cables: Traditional round cables are also extensively used, especially when specific power requirements or individual shielding for various conductors are paramount. They are robust and suitable for a wide range of applications, offering flexibility and durability even in demanding operational scenarios.

- By Application

- Cranes & Hoists: The largest application segment, covering overhead cranes, bridge cranes, and various hoists for material lifting and movement within factories, warehouses, and construction sites.

- Material Handling Equipment: Includes a broad range of machinery such as conveyors, stackers, reclaimers, and transfer carts that require dynamic power and data connections for continuous operation.

- Automated Storage & Retrieval Systems (AS/RS): Critical for automated warehousing, these systems utilize festoons to power stacker cranes and shuttles that move goods within high-density storage facilities.

- Gantry Systems: Large-scale gantry cranes used in manufacturing, construction, and prefabrication industries for heavy lifting and precise positioning tasks.

- Ports & Shipyards: Essential for container cranes (STS, RTG), ship loaders/unloaders, and other port equipment that operates continuously in harsh marine environments.

- Mining Machinery: Robust festoon systems power continuous miners, excavators, and other mobile equipment in underground and open-pit mining operations, often in hazardous conditions.

- Automotive Production Lines: Used extensively in car assembly plants for powering robotic arms, welding equipment, and transport systems along the production line.

- Manufacturing Plants: General manufacturing applications where machinery moves along a fixed path, requiring flexible power and control.

- Entertainment Industry: Specialized applications for moving stage lighting, screens, camera systems, and set pieces in theaters, studios, and live event venues.

- Waste Management Facilities: Employed in recycling plants and waste-to-energy facilities for powering grab cranes and other mobile equipment handling bulk materials.

- By End-Use Industry

- Manufacturing: Includes discrete and process manufacturing across various sub-sectors like machinery, electronics, and general industrial goods.

- Logistics & Warehousing: Central to modern supply chains, enabling efficient storage, retrieval, and movement of goods.

- Construction: Powering mobile equipment on large-scale building and infrastructure projects.

- Ports & Shipyards: Crucial for global trade infrastructure and shipbuilding activities.

- Automotive: Integral to vehicle production and assembly processes.

- Energy & Utilities: Supporting operations in power generation plants, substations, and renewable energy facilities.

- Mining: Providing robust solutions for extractives industries in harsh environments.

- Entertainment: Specialized solutions for dynamic stage and event technology.

- Aerospace & Defense: High-precision manufacturing and specialized testing equipment requiring reliable mobile power and data.

- By Operating Environment

- Standard Industrial: Typical indoor factory or warehouse settings with controlled conditions.

- Hazardous (Explosion-Proof): Designed for environments with flammable gases, vapors, or dust (e.g., chemical plants, oil & gas), requiring intrinsically safe components.

- High Temperature: Engineered to withstand elevated temperatures in steel mills, foundries, or heat treatment facilities.

- Corrosive/Chemical Environments: Utilizing stainless steel or specialized coatings for resistance to acids, alkalis, and other corrosive agents (e.g., chemical processing, marine).

- Outdoor/Weather-Exposed: Robust systems with UV-resistant cables and weather-sealed components for outdoor cranes, ports, and construction sites.

- By Load Capacity

- Light-Duty: Suitable for smaller overhead cranes, trolleys, and light material handling equipment with minimal cable loads.

- Medium-Duty: Designed for standard industrial cranes, conveyor systems, and moderate material handling applications.

- Heavy-Duty: Engineered for large gantry cranes, port equipment, mining machinery, and applications requiring substantial cable weights and robust structural support in challenging conditions.

Value Chain Analysis For Cable Festoon Systems Market

The value chain for the Cable Festoon Systems Market is a meticulously orchestrated sequence of activities that transform raw materials into sophisticated cable management solutions delivered to end-users, encompassing various stages from upstream sourcing to downstream distribution and after-sales support. Upstream analysis focuses on the foundational elements, beginning with the procurement of critical raw materials such as high-grade steel and aluminum for tracks and structural components, copper for electrical conductors, and specialized polymers like PVC, PUR, or TPE for cable insulation and sheathing. These raw materials are then processed and fabricated by specialized component manufacturers into essential building blocks, including sturdy tracks (C-track, I-beam), durable trolleys, high-flex cables, robust connectors, and various mounting hardware and accessories. The quality and availability of these upstream components are paramount, as they directly influence the performance, reliability, and lifespan of the final festoon system, emphasizing the importance of strong supplier relationships and stringent quality control at this initial stage.

Midstream activities primarily involve the design, engineering, assembly, and integration of these diverse components into complete, functional cable festoon systems. This stage often includes significant customization to meet specific project requirements, such as unique track lengths, cable configurations, or environmental adaptations. Original Equipment Manufacturers (OEMs) of cranes and industrial machinery frequently integrate festoon systems into their final products, while specialized festoon system manufacturers and system integrators play a crucial role in designing and assembling bespoke solutions for a wide array of industrial applications. This phase requires significant technical expertise in mechanical engineering, electrical design, and material science to ensure that the assembled systems meet rigorous performance standards, safety regulations, and operational demands, often involving rigorous testing and quality assurance procedures before deployment to the market.

Downstream, the distribution channel is a critical link that connects manufactured festoon systems with their end-users, operating through both direct and indirect sales models. Direct channels typically involve manufacturers or their dedicated sales teams engaging directly with large industrial customers, major project contractors, or OEM partners. This approach facilitates deep technical collaboration, enables highly customized solutions, and often includes comprehensive after-sales services such as installation support, training, and long-term maintenance contracts, fostering strong, enduring client relationships. Conversely, indirect channels leverage an extensive network of authorized distributors, resellers, and local system integrators. These partners are vital for reaching a broader market segment, including small to medium-sized enterprises (SMEs) and geographically dispersed customers, by providing localized sales support, readily available stock, installation services, and rapid response for repairs. The effectiveness of this dual-channel approach lies in its ability to maximize market reach, offer diverse levels of service, and adapt to varying customer preferences and regional market dynamics, ensuring widespread availability and tailored support for all types of industrial clients.

Cable Festoon Systems Market Potential Customers

The potential customer base for Cable Festoon Systems is remarkably broad and diverse, encompassing a wide array of industrial sectors that share a common need for efficient, safe, and reliable management of power and data cables for their mobile machinery. Manufacturing facilities, spanning industries from heavy machinery to consumer goods, represent a core segment. These customers rely on festoon systems to power critical equipment such as robotic welding cells, automated assembly lines, overhead gantry cranes, and various material transfer systems that demand continuous and flexible energy supply. The logistics and warehousing industry is another significant consumer, where festoon systems are integral to the operation of automated storage and retrieval systems (AS/RS), stacker cranes, and large conveyor networks, all designed to optimize inventory management and operational throughput in modern distribution centers. These applications highlight the indispensable role of festoon systems in enabling the seamless movement of goods within complex industrial ecosystems.

Furthermore, critical infrastructure sectors such as ports and container terminals are primary end-users, requiring robust and durable heavy-duty festoon systems for their colossal ship-to-shore (STS) cranes, rubber-tyred gantry (RTG) cranes, and ship loaders/unloaders that operate continuously in harsh marine environments. The construction industry also utilizes these systems for various mobile equipment on large-scale building sites and prefabrication yards, ensuring uninterrupted power to moving platforms and machinery. The mining sector, characterized by its demanding and often hazardous conditions, depends on resilient festoon solutions for powering continuous miners, reclaimers, and other mobile excavation and processing equipment. Additionally, the automotive industry extensively employs festoon systems within its highly automated production lines, ensuring consistent power and data flow to robotic arms, paint booths, and assembly conveyors. Niche markets like the entertainment industry, which relies on dynamic stage setups, moving lights, and visual displays for live events and film production, also benefit from specialized festoon systems for discrete and flexible cable management, further underscoring the universal applicability and critical utility of these systems across a vast spectrum of industrial and commercial operations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 475 Million |

| Market Forecast in 2033 | USD 760 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Akapp-Stemmann B.V., Conductix-Wampfler, KabelSchlepp GmbH (Tsubaki), Igus GmbH, Demag Cranes & Components GmbH (Terex), Cavotec SA, Gantrex, PowerRail LLC, Eaton Corporation, Siemens AG, Schneider Electric SE, ABB Ltd., Hubbell Incorporated, Emerson Electric Co., Metreel (UK) Ltd., STEMMANN-TECHNIK GmbH, VAHLE, Inc., Bär Cargolift, M. K. Engineers, W. G. Eaton Limited, Tecno S.p.a. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cable Festoon Systems Market Key Technology Landscape

The technological landscape of the Cable Festoon Systems Market is characterized by continuous innovation aimed at enhancing product performance, durability, and integration capabilities in increasingly demanding industrial settings. A primary focus lies in the advancement of materials science, particularly for track systems and trolley components. Manufacturers are increasingly utilizing robust and corrosion-resistant materials such as galvanized steel, stainless steel, and specialized engineered plastics to ensure longevity and reliable operation in harsh environments, including those exposed to moisture, chemicals, or extreme temperatures. Furthermore, the development of lighter-weight yet high-strength composite materials is contributing to reduced system inertia and improved operational efficiency, while advanced surface coatings are applied to minimize friction and wear, thereby extending maintenance cycles and reducing overall operational costs for end-users.

Another pivotal area of technological advancement involves the cables themselves, which are the lifeline of any festoon system. Innovations include the development of highly flexible and durable flat and round cables, specifically engineered to withstand millions of bending cycles without degradation of electrical or data transmission properties. These modern cables often incorporate advanced insulation materials, robust outer jackets resistant to oils, UV radiation, and mechanical abrasion, and sophisticated shielding for enhanced electromagnetic interference (EMI) protection. Critically, there is a growing trend towards integrating diverse functionalities within a single cable bundle, combining power conductors with high-speed data transmission lines (e.g., Ethernet, Fiber Optics) and even pneumatic or hydraulic hoses, to provide a consolidated and efficient umbilical solution for complex mobile machinery, supporting the extensive data exchange requirements of Industry 4.0 applications.

Moreover, the integration of smart technologies and digital capabilities is profoundly shaping the future of cable festoon systems. This encompasses the incorporation of intelligent sensors, such as position encoders, accelerometers, and temperature monitors, directly into trolleys and track systems. These sensors gather real-time operational data, which, when coupled with IoT platforms and AI-driven analytics, enables advanced functionalities like predictive maintenance, remote diagnostics, and performance optimization. Features such as self-lubricating trolley wheels, modular designs for easier installation and replacement, and enhanced safety features like anti-collision mechanisms are also becoming standard. These technological strides collectively aim to create more resilient, intelligent, and cost-effective cable management solutions that can seamlessly integrate into smart factories and automated logistics systems, contributing significantly to operational efficiency, safety, and overall productivity in the modern industrial landscape.

Regional Highlights

- North America: This region constitutes a mature yet consistently growing market for Cable Festoon Systems, driven by a strong emphasis on industrial automation, modernization of existing manufacturing infrastructure, and stringent safety regulations. Key demand comes from the automotive, aerospace, logistics, and port sectors, where investments in advanced material handling equipment and smart factory initiatives are prevalent. The adoption of high-quality, reliable, and technologically integrated systems is a significant trend across the United States and Canada.

- Europe: Characterized by highly developed industrial sectors, including advanced manufacturing, automotive, and extensive port operations, Europe presents a stable and technologically forward-thinking market. Demand is propelled by the need for precision engineering, compliance with strict European safety and environmental standards, and the ongoing push towards Industry 4.0. Germany, the UK, France, and Italy are pivotal markets, focusing on durable, efficient, and often customized festoon solutions for their sophisticated industrial applications.

- Asia Pacific (APAC): Emerging as the leading and fastest-growing market globally, the APAC region is experiencing unparalleled expansion due to rapid industrialization, massive infrastructure development projects, and the establishment of new manufacturing hubs, particularly in China, India, and Southeast Asian nations. The booming e-commerce sector fuels demand for logistics and warehousing automation, while extensive port expansions and heavy industrial growth drive the need for robust and scalable festoon systems. This region represents significant opportunities for both established and new market players.

- Latin America: This region exhibits steady growth in the Cable Festoon Systems market, primarily influenced by ongoing investments in mining operations, infrastructure development, and the gradual industrialization of key economies like Brazil, Mexico, and Chile. The focus is often on robust and cost-effective solutions capable of withstanding challenging operational environments. As industrialization progresses, the demand for reliable material handling and power transmission systems is expected to continue its upward trajectory.

- Middle East & Africa (MEA): Representing an emerging market with considerable potential, the MEA region is witnessing growth driven by substantial investments in oil and gas infrastructure, ambitious port expansion projects, and governmental initiatives aimed at industrial diversification. Countries like Saudi Arabia, the UAE, and South Africa are key contributors, with a rising demand for highly durable festoon systems designed to perform optimally in harsh climatic conditions and support large-scale industrial endeavors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cable Festoon Systems Market.- Akapp-Stemmann B.V.

- Conductix-Wampfler

- KabelSchlepp GmbH (Tsubaki)

- Igus GmbH

- Demag Cranes & Components GmbH (Terex)

- Cavotec SA

- Gantrex

- PowerRail LLC

- Eaton Corporation

- Siemens AG

- Schneider Electric SE

- ABB Ltd.

- Hubbell Incorporated

- Emerson Electric Co.

- Metreel (UK) Ltd.

- STEMMANN-TECHNIK GmbH

- VAHLE, Inc.

- Bär Cargolift

- M. K. Engineers

- W. G. Eaton Limited

- Tecno S.p.a.

Frequently Asked Questions

Analyze common user questions about the Cable Festoon Systems market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are cable festoon systems and how do they ensure operational reliability in industrial settings?

Cable festoon systems are dynamic cable management solutions that provide organized, flexible, and protected delivery of power, control, and data to mobile industrial machinery. They work by employing trolleys that move along a track, supporting specialized cables in loops (festoons). This mechanism prevents cable tangling, excessive wear, and damage, thereby ensuring continuous, safe, and reliable operation for equipment like cranes, hoists, and gantry systems in demanding environments, minimizing downtime.

What are the primary benefits of implementing cable festoon systems in industrial settings?

The primary benefits include significantly enhanced operational safety by eliminating loose, hazardous cables and reducing the risk of accidents. They also lead to a drastic reduction in costly downtime by preventing cable damage and entanglement, improving overall system reliability. Furthermore, festoon systems contribute to better workplace organization, extend the lifespan of expensive power and data cables, and offer efficient power and data transmission, thereby boosting productivity and lowering long-term maintenance expenses in dynamic industrial environments.

How is Artificial Intelligence (AI) influencing the Cable Festoon Systems Market and future developments?

AI is profoundly influencing the market by enabling smart diagnostics and predictive maintenance, allowing systems to anticipate component failures and optimize maintenance schedules based on real-time data, thus minimizing unplanned downtime. AI also facilitates optimized energy consumption, enhances safety monitoring through anomaly detection, and supports seamless integration with autonomous industrial systems. Future developments will likely involve self-optimizing systems that adapt to changing operational demands, further improving efficiency, reliability, and cost-effectiveness for industrial operators.

What are the main types of cable festoon systems and their typical applications?

The main types are C-Track, I-Beam, and Square Rail systems, each tailored for specific applications. C-Track systems are versatile and cost-effective for light-to-medium duty, often used in indoor cranes and general manufacturing. I-Beam systems offer robust support for heavy-duty applications like port cranes and mining machinery due to their superior structural integrity. Square Rail systems provide a compact and often enclosed solution, ideal for space-constrained environments such as automated storage and retrieval systems or specific automotive lines, offering precise cable management.

What are the key drivers propelling the growth of the Cable Festoon Systems market globally?

The market's growth is primarily driven by the accelerating global trend towards industrial automation across diverse sectors, which necessitates reliable dynamic power and data transfer solutions. Significant investments in global infrastructure development, especially in emerging economies, and the continuous modernization of existing industrial facilities also act as strong catalysts. Furthermore, the increasing adherence to stringent industrial safety regulations and the inherent demand for highly efficient material handling solutions are crucial factors fueling the expansion of the Cable Festoon Systems market worldwide.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager