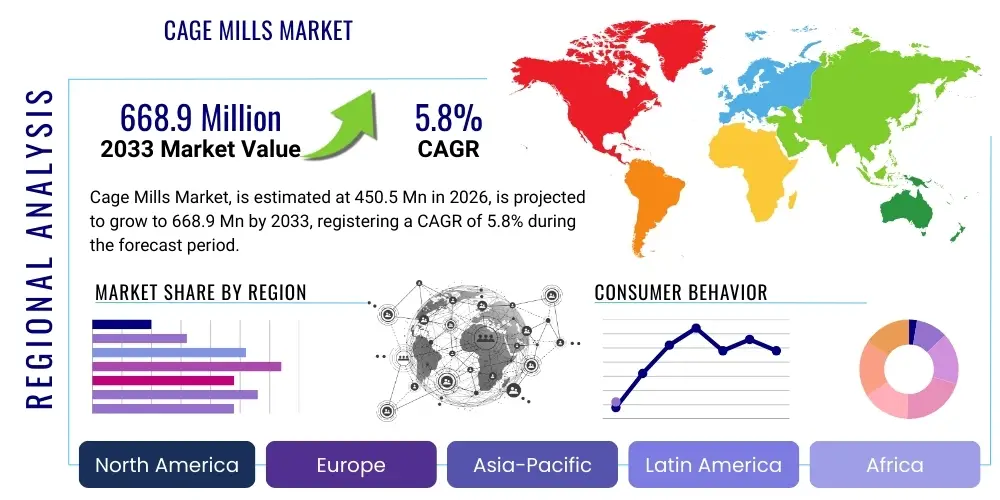

Cage Mills Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442734 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Cage Mills Market Size

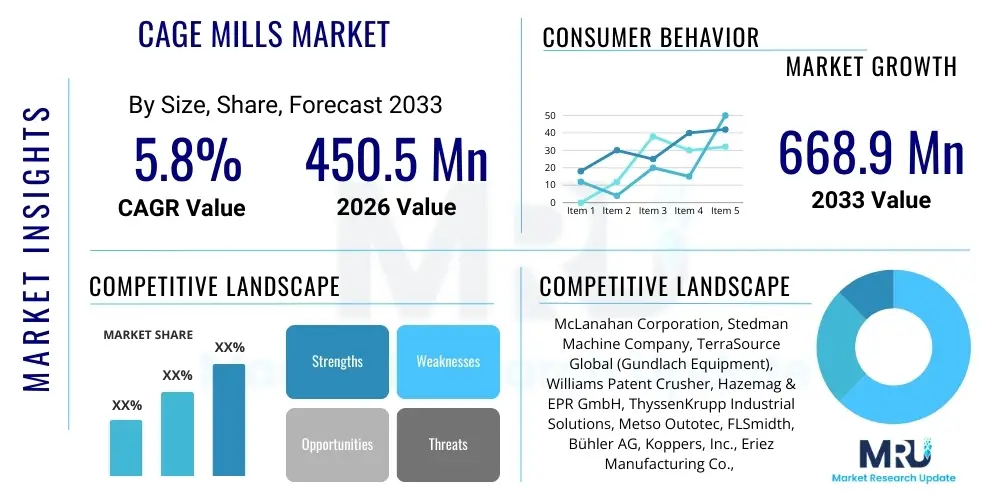

The Cage Mills Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 668.9 Million by the end of the forecast period in 2033.

Cage Mills Market introduction

The Cage Mills Market encompasses heavy industrial machinery used primarily for impact crushing, grinding, and blending various materials, ranging from fertilizers and aggregates to chemicals and industrial waste. Cage mills operate on the principle of high-velocity impact, employing rotating cages with impellers that fracture and reduce material sizes effectively. These machines are highly valued in industries requiring precise particle size control and homogeneous blending, offering superior efficiency compared to traditional hammer mills or roll crushers in specific applications.

Product descriptions typically highlight the configuration of the cages, which can be single-rotor or multi-rotor systems, designed to handle abrasive materials or specific size reduction ratios. Multi-rotor cage mills are particularly sought after for ultra-fine grinding applications and highly efficient material separation, minimizing energy consumption per ton of processed material. Major applications span critical sectors such as phosphate rock crushing for fertilizer production, limestone and shale preparation in the cement industry, and coal processing in the energy sector. Their robust design allows for continuous, high-throughput operation, driving demand across infrastructure and resource extraction domains.

The principal benefits derived from utilizing advanced cage mills include low maintenance requirements due to reduced wear parts compared to compression crushers, exceptional reliability, and the ability to accept wet, sticky, or difficult-to-handle feeds without significant clogging. Driving factors for market expansion include escalating global demand for specialized fertilizers, rapid urbanization necessitating increased infrastructure development (cement and aggregates), and stringent environmental regulations favoring processes that allow for the efficient processing of recycled or waste materials, positioning cage mills as essential equipment in the modern industrial landscape.

Cage Mills Market Executive Summary

The global Cage Mills Market is characterized by robust growth driven primarily by increasing infrastructure spending in emerging economies and the imperative for energy-efficient comminution technologies. Business trends indicate a strong focus on customization, with manufacturers developing specialized rotor configurations and wear materials tailored to specific industrial applications, particularly within the fertilizer and high-purity mineral processing sectors. Strategic collaborations between original equipment manufacturers (OEMs) and major engineering, procurement, and construction (EPC) firms are defining the competitive landscape, ensuring integration of cage mills into large-scale industrial projects globally. Furthermore, the incorporation of IoT sensors and predictive maintenance systems is becoming standard, optimizing uptime and operational efficiency for end-users.

Regionally, the Asia Pacific (APAC) region dominates the market, propelled by massive industrialization, heightened agricultural production requirements, and substantial investments in mining and construction activities, especially in China and India. North America and Europe demonstrate mature market conditions, with growth centered on replacement demand, technological upgrades (e.g., automated feed control), and adoption in environmental applications like waste-to-energy conversion and recycling. Latin America and the Middle East & Africa (MEA) are emerging growth hubs, spurred by the exploitation of previously untapped mineral reserves and governmental initiatives to enhance domestic fertilizer production capabilities, thereby increasing the procurement of advanced crushing equipment.

Segment trends highlight the growing preference for Multi-Rotor Cage Mills due to their superior size reduction capabilities and enhanced throughput, particularly in applications demanding high degrees of material liberation. The application segment is led by Fertilizer Production, where precise granulation and mixing are crucial for product quality. In terms of material, the shift towards High-Chrome Steel and specialized carbide inserts is notable, driven by the need for extended operational lifespan and resistance to highly abrasive feedstocks, contributing significantly to reduced total cost of ownership (TCO) for industrial operators globally.

AI Impact Analysis on Cage Mills Market

User inquiries regarding the influence of Artificial Intelligence (AI) on the Cage Mills Market primarily revolve around operational efficiency, predictive maintenance capabilities, and optimization of energy consumption. Key themes include: "How can AI optimize particle size distribution in real-time?" "What is the role of machine learning in predicting wear and scheduling maintenance for cage mills?" and "Can AI algorithms minimize energy input per ton of crushed material?" Users seek to understand how integrating smart sensors and data analytics platforms can transform the traditional mechanical operation of cage mills into a highly precise, adaptive, and autonomous system, addressing concerns over variable material quality and volatile energy costs.

The consensus view suggests that AI integration will shift cage mill operation from reactive maintenance to proactive performance management. AI-powered diagnostic tools analyze vibration data, current draw, and acoustic signatures in real-time to detect minute anomalies indicative of impeller wear or imbalance, significantly extending equipment lifespan and preventing catastrophic failures. Furthermore, machine learning models can process complex inputs (feed moisture content, hardness, flow rate) to dynamically adjust rotor speeds and material distribution within the mill, optimizing the crushing trajectory to achieve target particle size distribution with minimal energy wastage, thereby enhancing overall operational sustainability.

This computational oversight allows facility managers to operate complex crushing circuits closer to their optimal performance envelope. AI also plays a crucial role in inventory management for critical spares, predicting the precise moment of failure based on historical data patterns and operational stress, ensuring parts are ordered and ready exactly when needed. The integration moves the market toward 'Smart Milling Solutions,' where human intervention is minimized and operational parameters are autonomously governed by advanced algorithms focusing on efficiency and product quality consistency.

- AI-driven Predictive Maintenance: Analyzing vibration and temperature data to forecast component failure (e.g., rotor bars, liners) up to weeks in advance.

- Real-time Optimization: Machine learning algorithms adjust mill parameters (speed, feed rate) dynamically based on material characteristics and desired output fineness.

- Energy Consumption Minimization: Utilizing reinforcement learning to find the most energy-efficient operating points for specific material processing cycles.

- Automated Quality Control: AI vision systems integrated with cage mills to analyze particle shape and size distribution, ensuring adherence to strict product specifications.

- Enhanced Safety Protocols: Monitoring operational stress and identifying potential overload conditions automatically, initiating protective shutdowns.

DRO & Impact Forces Of Cage Mills Market

The dynamics of the Cage Mills Market are significantly influenced by a confluence of accelerating drivers such as sustained global infrastructure development, compelling restraints including high initial capital investment, and substantial opportunities arising from technological advancements in material processing. These forces create a complex operational environment where efficiency and total cost of ownership (TCO) are paramount considerations for end-users. The underlying impact forces revolve around economic cycles, regulatory frameworks governing industrial emissions and waste processing, and the continuous push for higher yields in mining and agriculture sectors. Economic viability, specifically the return on investment through superior material liberation and energy efficiency, remains the central driving impact force governing adoption rates globally.

Drivers: A primary driver is the soaring demand for fertilizers, particularly phosphate, where cage mills excel in preparation and blending stages, ensuring uniform product quality critical for modern agriculture. Concurrently, the increasing need for crushed aggregates and cement components, catalyzed by rapid urbanization in APAC and ongoing reconstruction efforts globally, substantially boosts the procurement of high-capacity crushing equipment. Furthermore, the inherent advantage of cage mills in processing wet, sticky, or mixed materials without significant clogging makes them indispensable in niche applications like municipal waste processing and recycling, supporting circular economy initiatives and driving diversified demand.

Restraints: Significant restraints include the substantial initial capital outlay required for high-capacity multi-rotor cage mills, posing financial barriers for smaller operators or those in developing regions. Additionally, while maintenance frequency is relatively low, the replacement of specialized wear components (such as carbide inserts or high-manganese steel cages) can be costly, influencing procurement decisions when alternative crushing technologies are considered. Market penetration is also occasionally hindered by the perception that cage mills are less effective for extremely hard, large feed sizes compared to primary jaw or cone crushers, limiting their applicability in certain large-scale primary mining operations.

Opportunities: Major opportunities reside in the integration of smart manufacturing technologies, including IoT, AI, and remote diagnostics, enabling optimized performance and extending service intervals, thereby addressing TCO concerns. The burgeoning sector of industrial mineral processing, particularly high-purity silica and specialized clays, which require non-contaminating comminution methods, presents a highly lucrative niche for advanced cage mill systems. Moreover, manufacturers developing models with modular designs that allow for rapid reconfiguration for different materials (e.g., switching from fertilizer blending to aggregate crushing) stand to gain a significant competitive edge by offering flexible processing solutions.

Segmentation Analysis

The Cage Mills Market is systematically segmented based on Type, Application, and Material, providing a granular understanding of product capabilities and end-user requirements across diverse industrial sectors. Segmentation by Type distinguishes between single-rotor and multi-rotor configurations, reflecting variations in required reduction ratios and throughput capacity, with multi-rotor systems often preferred for high-precision, secondary or tertiary crushing stages. Analysis by Application reveals critical demand centers, primarily driven by the fundamental needs of global infrastructure and agriculture, dictating the volume and technical specifications of required equipment.

Further segmentation by Material, such as High-Chrome Steel and Manganese Steel, focuses on the lifespan and wear resistance characteristics of the mill components. This detail is crucial for buyers operating in highly abrasive environments, where the longevity of internal parts directly impacts operational expenditure and maintenance schedules. The continuous evolution in metallurgy aimed at improving component durability is a key element of competitive differentiation within this segment, influencing purchasing decisions towards solutions that minimize downtime associated with liner and cage replacement.

This segmented analysis aids stakeholders in identifying high-growth niches. For example, the increasing demand for ultra-fine materials in specialized chemical manufacturing is boosting the Multi-Rotor segment, while robust infrastructure projects maintain steady demand for larger, high-throughput Single-Rotor mills used for aggregates. Understanding these granular segments allows manufacturers to tailor their R&D efforts and marketing strategies to specific geographical and industrial requirements, maximizing market penetration and securing long-term contracts in demanding sectors like mining and cement production.

- By Type:

- Single-Rotor Cage Mills

- Multi-Rotor Cage Mills

- Fixed-Cage Mills

- Rotating-Cage Mills

- By Application:

- Fertilizer Production

- Mining & Minerals Processing (e.g., Limestone, Phosphate Rock)

- Cement & Construction Aggregates

- Chemical Processing

- Food Processing (e.g., Sugar and Starch)

- Waste Management and Recycling (e.g., Glass and Slag)

- By Material:

- High-Chrome Steel

- Manganese Steel

- Carbide Inserts and Alloys

- Other Specialty Materials (e.g., Ceramic Composites)

Value Chain Analysis For Cage Mills Market

The value chain for the Cage Mills Market begins with the upstream procurement of essential raw materials, dominated by high-quality steel alloys, specialized wear-resistant materials like manganese steel and chrome alloys, and advanced electrical components for motors and control systems. Key upstream activities involve stringent quality control over steel production, heat treatment processes, and precision machining, as the durability and operational lifespan of cage mills are directly dependent on the material integrity of the rotor bars and cages. Suppliers of these specialized components often operate under long-term contracts with major OEM producers, guaranteeing consistent supply and adherence to strict engineering specifications necessary for handling extreme impact forces.

Midstream activities encompass the core manufacturing and assembly processes undertaken by the original equipment manufacturers (OEMs). This phase involves sophisticated fabrication techniques, precision balancing of rotor assemblies to minimize vibration, and the integration of complex electrical and automation systems. Distribution channels are typically a combination of direct sales and a network of authorized regional distributors or agents who provide local sales support, installation services, and crucial aftermarket maintenance and spare parts supply. Direct sales are common for very large, customized installations to major mining or cement companies, ensuring seamless communication between the client's engineering team and the manufacturer's technical staff.

Downstream analysis focuses on the end-users across various industries, including large mining conglomerates, fertilizer producers, cement manufacturers, and specialized recycling plants. The indirect channel plays a significant role in aftermarket services, where independent local service providers, authorized by the OEM, offer ongoing maintenance, optimization consulting, and the supply of high-wear parts. The ultimate value proposition at the downstream level is maximizing operational uptime and achieving precise particle size distribution at the lowest energy cost, making reliable maintenance and swift spare parts availability crucial components of the total value provided by the supply chain.

Cage Mills Market Potential Customers

Potential customers for cage mills are typically large-scale industrial operators requiring efficient, high-impact comminution solutions for mid-to-fine size reduction or high-volume material blending. The primary buyers fall into two main categories: organizations involved in resource extraction and processing (mining, cement, aggregates) and those focused on specialty material production (fertilizers, chemicals). Within the mining sector, customers include major limestone, gypsum, and phosphate rock producers who utilize cage mills for secondary and tertiary crushing to prepare feed materials for subsequent chemical processing or high-pcapacity drying operations.

The second substantial group of customers comprises agricultural chemical companies and fertilizer manufacturers. These end-users rely heavily on the cage mill's ability to precisely blend, granulate, and size materials like potash, urea, and processed phosphates, ensuring the final product meets stringent quality standards for consistency and solubility. Their purchasing decisions are often driven by mill efficiency, blending homogeneity, and the longevity of the specialized wear components, as production downtime in fertilizer manufacturing can result in substantial financial losses during planting seasons.

Emerging segments of potential customers include waste management firms and recycling facilities, specifically those handling industrial slag, electronic waste, or construction and demolition (C&D) debris. These customers require robust cage mills capable of processing heterogeneous, often contaminated, feedstock to liberate valuable components or reduce volume for landfill. Purchasing criteria in this segment emphasize flexibility, ease of cleaning, and the ability to handle non-crushable materials without excessive damage, indicating a shift towards durable and highly adaptable multi-purpose mill designs.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 668.9 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | McLanahan Corporation, Stedman Machine Company, TerraSource Global (Gundlach Equipment), Williams Patent Crusher, Hazemag & EPR GmbH, ThyssenKrupp Industrial Solutions, Metso Outotec, FLSmidth, Bühler AG, Koppers, Inc., Eriez Manufacturing Co., Cemtec Cement and Mining Technology GmbH, Hewitt-Robins, Inc., Custom Built Systems, Inc., P.M.G. Industries |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cage Mills Market Key Technology Landscape

The technology landscape of the Cage Mills Market is rapidly evolving, moving beyond simple mechanical impact towards systems that integrate advanced materials science and digital control for enhanced efficiency and reduced operational expenditure. A significant area of focus is the development of next-generation wear components. Traditional manganese steel is being supplemented or replaced by specialized ceramics, high-chrome white iron, and tungsten carbide inserts. These materials dramatically improve resistance to abrasion and impact, particularly when processing highly siliceous or abrasive ores, resulting in longer intervals between scheduled maintenance and a lower overall consumption of spare parts over the mill’s lifespan. Manufacturers are actively pursuing proprietary alloy compositions tailored for specific applications, such as high-temperature environments in cement processing.

Furthermore, automation and control technology constitute a major technological frontier. Modern cage mills are increasingly equipped with Variable Frequency Drives (VFDs) and sophisticated Programmable Logic Controllers (PLCs) that allow for precise, real-time adjustments to rotor speed and operational torque. This capability is crucial for optimizing energy usage and achieving targeted particle size distributions, especially when the input material characteristics fluctuate (e.g., moisture content or hardness variability). Advanced systems incorporate feedback loops that integrate laser-based sizing sensors and weightometer data, enabling instantaneous adjustments to maintain consistent product quality and throughput efficiency without continuous human oversight.

A third transformative trend is the implementation of advanced connectivity and data analytics, forming the core of Industry 4.0 integration. Key technology includes integrated vibration analysis sensors, thermal monitoring, and acoustic analysis tools designed to predict mechanical failure signatures. This connectivity supports remote diagnostics and condition monitoring services offered by OEMs, ensuring global clients can receive expert technical support irrespective of geographic location. The utilization of these data streams for fleet-wide comparative analysis also allows manufacturers to refine design tolerances and optimize component geometry, leading to continuous incremental improvements in the structural robustness and energy performance of new cage mill models.

Regional Highlights

- Asia Pacific (APAC): This region dominates the global Cage Mills Market, characterized by high growth rates fueled by rapid industrialization, massive infrastructure development, and substantial agricultural sectors in countries like China, India, and Southeast Asia. The demand is heavily concentrated in cement production, aggregate crushing for urban expansion, and the fertilizer industry, particularly for processing phosphate rock and achieving high-quality blending of compound fertilizers. Government initiatives promoting domestic mineral processing and recycling also contribute significantly to procurement volumes, making APAC the key growth engine for the forecast period.

- North America: Representing a mature and technologically advanced market, North America focuses less on new infrastructure build-out and more on replacing outdated equipment with high-efficiency, automated cage mill systems. The market demand is stable, driven by specialized applications in high-purity mineral processing, stringent environmental regulations requiring enhanced waste material processing (e.g., slag and C&D debris), and the integration of IoT and predictive maintenance solutions to minimize operating costs in established mining and chemical sectors.

- Europe: The European market is characterized by a strong emphasis on energy efficiency and sustainable practices. Demand for cage mills is driven by the need for processing recycled materials, specialized chemical manufacturing, and optimization within the cement industry to meet strict carbon emission targets. Innovation is key here, with manufacturers focusing on developing modular, compact designs and integrating advanced materials science to produce mills with the highest energy-to-output ratios, catering to a sophisticated and environmentally conscious industrial base.

- Latin America (LATAM): LATAM is an emerging market with significant untapped potential, primarily driven by the expansion of mining operations (copper, iron ore, phosphate) and a growing need for modern agricultural inputs, particularly fertilizers. Market growth is closely tied to commodity price volatility and foreign direct investment into resource extraction projects. Brazil, Chile, and Argentina are central to this growth, seeking reliable, high-throughput crushing solutions to enhance material liberation in their processing circuits.

- Middle East and Africa (MEA): Growth in MEA is highly localized and project-dependent. The Middle East sees demand stemming from massive construction projects, and the establishment of new petrochemical and industrial complexes, requiring high-volume aggregate processing. Africa's market is primarily fueled by the development of its vast mineral resources, particularly in phosphate and other industrial minerals. The challenge remains logistical complexity and the need for highly robust equipment capable of operating effectively in remote, harsh environments with limited access to specialized maintenance services.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cage Mills Market.- McLanahan Corporation

- Stedman Machine Company

- TerraSource Global (Gundlach Equipment)

- Williams Patent Crusher

- Hazemag & EPR GmbH

- ThyssenKrupp Industrial Solutions

- Metso Outotec

- FLSmidth

- Bühler AG

- Koppers, Inc.

- Eriez Manufacturing Co.

- Cemtec Cement and Mining Technology GmbH

- Hewitt-Robins, Inc.

- Custom Built Systems, Inc.

- P.M.G. Industries

- Impact Crushers International (ICI)

- Haver & Boecker Niagara

- Feeco International, Inc.

- Schenck Process Holding GmbH

Frequently Asked Questions

Analyze common user questions about the Cage Mills market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a multi-rotor cage mill compared to other crushers?

A multi-rotor cage mill is primarily designed for high-velocity impact crushing, fine grinding, and homogeneous blending, offering superior particle size control and energy efficiency compared to traditional compression crushers like jaw or cone mills, especially for moist or sticky materials.

Which industrial application drives the highest demand for cage mills globally?

The Fertilizer Production industry currently constitutes the largest application segment, relying heavily on cage mills for efficient size reduction, granulation, and blending of raw materials such as phosphate rock and potash to ensure consistent product quality for agricultural use.

How is technological advancement reducing the total cost of ownership (TCO) for new cage mill installations?

TCO is being reduced through the adoption of advanced materials like high-chrome steel and carbide inserts, which extend component lifespan, and through the integration of AI-driven predictive maintenance systems that minimize unscheduled downtime and optimize energy consumption.

What are the key advantages of cage mills in processing wet or sticky materials?

Cage mills utilize centrifugal impact forces rather than compression, which effectively prevents material packing and clogging, making them highly advantageous for processing wet feeds, clay-rich minerals, or sticky materials that typically hinder the operation of traditional crushers.

Which geographical region is expected to exhibit the fastest growth in the cage mills market?

The Asia Pacific (APAC) region, driven by continuous infrastructure expansion, rapid urbanization, and significant investments in mining and agricultural sectors in countries like China and India, is projected to be the fastest-growing market during the forecast period.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager