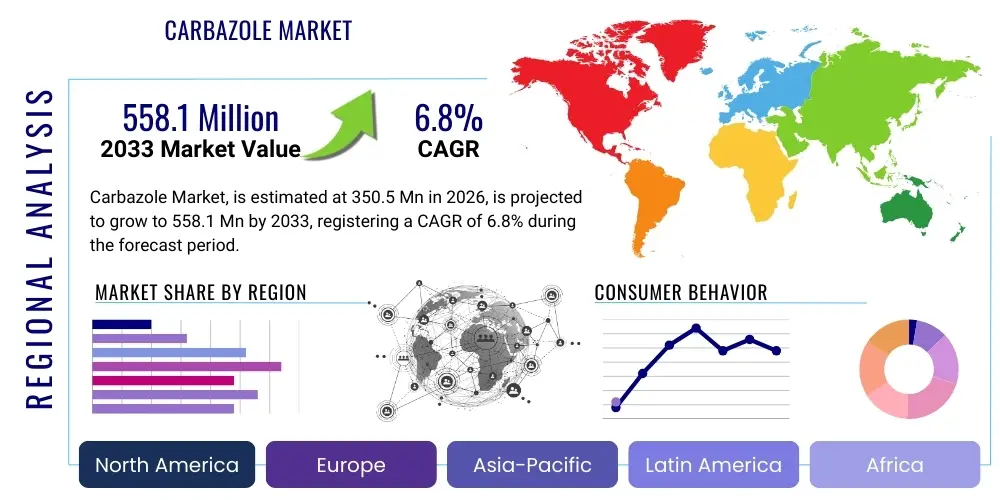

Carbazole Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442287 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Carbazole Market Size

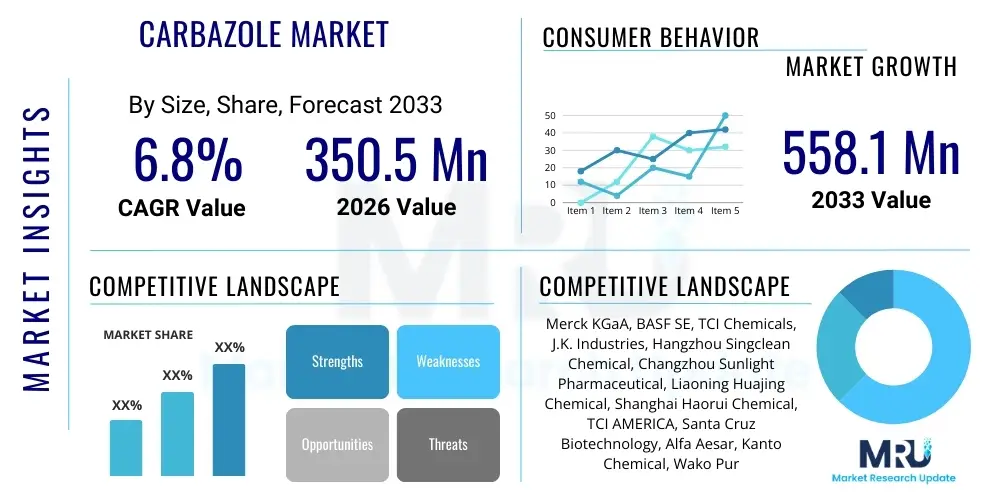

The Carbazole Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 350.5 Million in 2026 and is projected to reach USD 558.1 Million by the end of the forecast period in 2033. This robust growth trajectory is underpinned by the increasing utilization of carbazole derivatives in high-performance materials, particularly within the organic electronics and specialized polymer sectors globally, necessitating significant investment in purification and synthesis technologies to meet stringent end-user specifications.

Carbazole Market introduction

Carbazole is a heterocyclic aromatic chemical compound characterized by a bicyclic structure consisting of two benzene rings fused onto a pyrrole ring. It is primarily derived commercially from coal tar or crude oil distillation processes, serving as a crucial intermediate in the synthesis of a vast array of functional chemicals. The high electron-donating capacity and ease of functionalization make carbazole an indispensable building block in organic chemistry, particularly for applications requiring advanced photophysical and electronic properties. Its derivatives are fundamental components in the manufacturing of high-quality dyes, pigments, specialized pharmaceuticals, and, most prominently in recent years, in materials for organic light-emitting diodes (OLEDs) and photovoltaic cells.

Major applications of carbazole span across several high-value industries. In the pigment and dye industry, derivatives like Carbazole Violet are highly valued for their exceptional lightfastness and chemical stability, crucial attributes for automotive coatings and industrial coloring. Furthermore, carbazole’s significance extends to the pharmaceutical sector, where its core structure is incorporated into various active pharmaceutical ingredients (APIs), particularly those targeting neurological disorders and oncology. The most significant driving force currently is the burgeoning demand from the electronics sector for new materials used in flexible displays, solid-state lighting, and data storage devices, where carbazole derivatives act as host materials or hole-transporting layers (HTLs) due to their superior charge mobility and thermal stability.

The primary benefits driving market expansion include the structural versatility that allows for the creation of customized functional materials, excellent thermal and photochemical resistance in final products, and established large-scale synthesis routes, although purification remains a technical bottleneck. Key driving factors include the rapid global adoption of OLED technology in consumer electronics and television screens, increasing focus on high-performance organic semiconductors for next-generation devices, and regulatory pressures in developed markets favoring safer and more efficient pigments over traditional heavy-metal based alternatives. This transition emphasizes carbazole's role as a sustainable and high-performance chemical intermediate.

Carbazole Market Executive Summary

The Carbazole Market is characterized by intense focus on downstream specialization and technological refinement, shifting business trends away from bulk chemical supply toward specialized, high-purity derivatives tailored for the electronics and pharmaceutical sectors. Global business trends indicate a steady movement toward vertical integration among major players to secure stable access to purified raw materials and control the quality of high-end derivatives such as N-vinylcarbazole and various halogenated carbazoles. Moreover, sustainability initiatives and the push for 'green chemistry' are influencing synthesis methods, driving research into bio-based precursors and more environmentally benign catalytic processes. Mergers and acquisitions are common strategies employed to acquire specialized purification expertise or penetrate niche derivative markets, consolidating market power among leading chemical producers, particularly those operating in the highly regulated European and North American spaces.

Regionally, Asia Pacific (APAC) stands as the undisputed epicenter of both consumption and production, driven overwhelmingly by the colossal manufacturing bases for consumer electronics, automotive industries, and textile production in China, South Korea, and Japan. The region benefits from lower operational costs and the presence of major OLED panel fabricators, fueling unprecedented demand for high-purity carbazole intermediates. Conversely, North America and Europe, while lagging in bulk production, maintain leadership in high-value application R&D, particularly in advanced polymer science, medical compound synthesis, and highly customized electronic materials. Strict environmental regulations in Europe, such as REACH, significantly influence production standards and raw material sourcing, often driving technological innovation in waste management and byproduct utilization, creating opportunities for specialized compliance consultants and advanced purification technology providers.

Segment-wise, the Polymers and Intermediates segment consistently dominates the market, largely owing to the heavy demand for Poly(N-vinylcarbazole) (PVK) in electrophotography, organic photorefractive materials, and insulating films. However, the Dyes and Pigments segment, particularly high-performance organic pigments, is projected to exhibit robust growth, driven by the expanding automotive refinish coatings market and architectural paint sector, which demand superior durability and color stability. A critical emerging trend is the escalating requirement for ultra-high purity carbazole derivatives necessary for electronic applications, which command premium pricing and require sophisticated separation technologies, thus offering significant profitability opportunities for specialized chemical suppliers capable of meeting sub-parts-per-million impurity standards required by semiconductor and display manufacturers.

AI Impact Analysis on Carbazole Market

Analysis of common user questions regarding AI's impact on the Carbazole market reveals a strong interest in three core areas: the acceleration of new derivative discovery, optimization of complex manufacturing and purification processes, and enhanced prediction of raw material supply chain fluctuations. Users frequently inquire whether AI can fundamentally change the speed of pharmaceutical API development using carbazole scaffolds, given the structural complexity and vast combinatorial possibilities. Concerns also revolve around the potential disruption of established synthesis techniques if machine learning algorithms identify radically different, more efficient, or greener synthesis pathways, potentially rendering current intellectual property obsolete. Furthermore, there is significant interest in using predictive analytics to manage the notoriously volatile pricing and availability of coal tar fractions, a key raw material for carbazole production.

AI is beginning to revolutionize the research and development pipeline for advanced carbazole derivatives, moving traditional trial-and-error chemical synthesis towards high-throughput virtual screening and material informatics. Machine learning models are being deployed to predict the electronic band gap, charge carrier mobility, and thermal stability of hypothetical carbazole structures, drastically cutting down the time required to identify candidates suitable for OLEDs or organic solar cells (OSCs). In manufacturing, AI-powered predictive maintenance and process control systems are crucial for optimizing the energy-intensive and time-consuming purification steps, such as fractional distillation and chromatography, which are essential for producing the ultra-high purity material required by the demanding electronics sector. By analyzing real-time sensor data, these systems can minimize batch failure rates, reduce operational costs, and ensure consistent product quality, thereby providing a significant competitive advantage to early adopters in the chemical processing space.

Furthermore, the integration of AI tools for supply chain resilience is becoming paramount. Given the global reliance on complex petrochemical and coal tar supply networks, disruptions due to geopolitical events or environmental factors pose substantial risks. AI algorithms can analyze global commodity markets, regional infrastructure health, and regulatory changes to provide highly accurate forecasts for raw material pricing and logistical bottlenecks. This capability allows manufacturers of carbazole and its derivatives to proactively adjust procurement strategies, manage inventory levels efficiently, and hedge against price volatility. The ability of AI to model complex reaction kinetics and optimize reactor conditions also contributes to overall process sustainability, helping companies meet increasingly strict environmental compliance targets while maintaining profitability margins.

- AI accelerates the discovery of novel carbazole-based compounds for pharmaceuticals and advanced organic electronics.

- Machine learning optimizes energy-intensive purification and fractional distillation processes, enhancing material purity (critical for OLEDs).

- Predictive analytics improves supply chain resilience by forecasting volatility in coal tar and petrochemical raw material sourcing.

- AI-driven material informatics reduce R&D cycles for developing high-performance carbazole polymers and host materials.

- Robotic lab automation, controlled by AI, enables high-throughput synthesis screening of new carbazole derivatives, boosting innovation speed.

DRO & Impact Forces Of Carbazole Market

The Carbazole Market dynamics are defined by a complex interplay of robust demand drivers rooted in technological advancements and persistent constraints related to sourcing and regulatory compliance. Key drivers include the exponential growth in the OLED display market, spanning from smartphones to large format televisions, where highly purified carbazole derivatives are non-negotiable components for hole-transport and host layers, ensuring display efficiency and longevity. Additionally, the increasing focus on advanced polymer materials, such as PVK for specialized electronic components and imaging applications, continues to provide a stable, high-volume demand base. The opportunity landscape is primarily shaped by the ongoing exploration into new applications in renewable energy, specifically in organic solar cells (OSCs) and redox flow batteries, leveraging the electrochemical stability of functionalized carbazoles.

Conversely, significant restraints hinder uniform market growth. The primary challenge remains the volatility and limited availability of high-purity coal tar fractions, which serve as the dominant industrial source for carbazole. Fluctuations in the coal processing industry and the global shift towards cleaner energy sources create supply uncertainty and price instability, affecting profitability for derivative manufacturers. Furthermore, the complexity and high operational costs associated with achieving the ultra-high purity (e.g., 99.99%) required for demanding electronic applications act as a barrier to entry for smaller players and necessitate substantial capital investment in sophisticated separation technologies. Stringent regulatory frameworks, particularly concerning the handling and disposal of byproducts in regions like the European Union, also increase compliance costs and operational overhead.

The impact forces influencing the market are multifaceted, combining technological push with market pull dynamics. The technological impact force is driven by continuous innovation in chemical synthesis, focusing on developing sustainable and cost-effective alternatives to traditional isolation methods, such as catalytic direct C–H functionalization of simpler precursors, which reduces reliance on coal tar. The economic impact force is tied directly to the success of major downstream industries; a strong semiconductor market translates immediately into higher demand for electronic-grade carbazole. Social and regulatory impact forces mandate greater transparency in supply chains and favor companies that can demonstrate minimal environmental footprint, thereby incentivizing investment in green chemistry and closed-loop manufacturing processes. These forces collectively propel the market toward high-value, niche applications rather than bulk commodity sales.

Segmentation Analysis

The Carbazole market is comprehensively segmented based on its grade, primary application area, and the specific derivative synthesized, reflecting the compound's diverse industrial utility. Segmentation by grade is crucial, differentiating between high-purity Electronic Grade material necessary for advanced OLED fabrication and the more standard Technical Grade used primarily in pigment and bulk chemical manufacturing, each commanding vastly different price points and supply chain complexity. Application segmentation highlights the dominance of high-volume sectors like Dyes & Pigments and high-growth sectors such as Electronics & Photonics. Finally, analysis by derivative type focuses on key commercially relevant products, including N-vinylcarbazole (NVC) used in specialized polymers and various halogenated or nitrated carbazoles essential for pharmaceutical intermediates, providing clarity on the underlying chemical demand drivers.

- By Grade:

- Technical Grade

- Electronic Grade (High Purity)

- Pharmaceutical Grade

- By Derivative:

- N-Vinylcarbazole (NVC)

- Polyvinylcarbazole (PVK)

- 3,6-Diiodocarbazole

- Carbazole Dyes (e.g., Pigment Violet 23)

- Other Derivatives (e.g., Alkyl, Halogenated)

- By Application:

- Dyes and Pigments

- Pharmaceuticals

- Polymers and Resins (Plastics, Insulators)

- Electronics and Photonics (OLEDs, OPVs, HTLs)

- Agrochemicals and Fertilizers

- Others (Lubricants, Rubber Chemicals)

Value Chain Analysis For Carbazole Market

The Carbazole market value chain begins fundamentally upstream with the sourcing and processing of crude raw materials, primarily coal tar fractions derived from the coking process in the steel industry or, to a lesser extent, from petroleum refining. Upstream activities involve the initial fractional distillation of coal tar to isolate the crude carbazole fraction. This step is characterized by large-scale commodity operations and is highly susceptible to the global dynamics of the steel and energy sectors. Efficiency at this stage is crucial for managing initial costs, but the resulting product is typically of lower technical grade purity, containing significant amounts of impurities like phenanthrene and anthracene, necessitating further complex purification.

Midstream processing focuses on extensive purification and the subsequent synthesis of high-value derivatives. For technical-grade applications (like pigments), standard crystallization and washing suffice. However, for electronic-grade materials, manufacturers engage in sophisticated, multi-step purification techniques such as zone refining, specialized chromatography, or highly controlled fractional distillation to achieve purity levels exceeding 99.99%. Downstream activities involve the chemical conversion of purified carbazole into specific derivatives, such as the polymerization to PVK or complex multi-step synthesis required for advanced OLED host materials or complex pharmaceutical intermediates. This midstream phase adds the most significant value, relying heavily on specialized chemical expertise and advanced proprietary technologies.

The distribution channel is dichotomous: direct and indirect. Bulk technical-grade carbazole is often distributed indirectly through large chemical distributors and regional agents serving the Dyes & Pigments and polymer feedstock industries. In contrast, electronic-grade and pharmaceutical-grade derivatives utilize a direct distribution model. Key manufacturers establish strong, direct relationships with high-tech end-users (OLED display makers, API synthesizers) to ensure strict quality control, provide technical support, and manage specialized logistics, including temperature-sensitive or high-security shipments. This direct channel is characterized by long-term contracts, stringent quality audits, and high barriers to entry, reinforcing the specialized nature of the high-purity segments of the market.

Carbazole Market Potential Customers

The primary end-users and buyers of carbazole and its derivatives are heavily concentrated in industries that require materials with exceptional optical, electronic, and structural properties. The largest volume consumers belong to the specialty chemical and manufacturing sectors, specifically dye and pigment producers who require carbazole derivatives like Carbazole Violet (PV 23) for high-performance coloration in automotive, plastics, and textile applications, prioritizing color fastness and chemical resistance. These customers typically purchase technical grade carbazole in bulk and require consistent supply and standardized quality metrics, operating on long-term supply agreements to stabilize their input costs in a volatile commodity environment.

A second major customer cluster, representing the highest value segment, comprises manufacturers of advanced electronic devices, particularly those involved in producing OLED displays and organic photovoltaic (OPV) panels. These buyers purchase ultra-high purity Electronic Grade carbazole derivatives, such as those used for creating high-efficiency hole-transporting layers (HTLs) and emissive hosts. Their demands are centered on purity (often measured in parts per million of impurities), stringent thermal stability, and specific electronic characteristics, leading to highly customized, high-price contracts often governed by non-disclosure agreements regarding proprietary chemical formulations. The performance of the final electronic device is directly linked to the purity of the carbazole intermediate, making these customers highly sensitive to quality variance.

Finally, the pharmaceutical and agrochemical industries form another significant segment of potential customers. Pharmaceutical companies use the carbazole scaffold as a core structure for synthesizing various Active Pharmaceutical Ingredients (APIs), including neuroleptics and certain cancer treatments, valuing its bioactivity and structural rigidity. Agrochemical firms utilize certain functionalized carbazole derivatives in the synthesis of specialized crop protection agents and veterinary medicines. These customers require Pharmaceutical Grade materials, characterized by rigorous compliance with Good Manufacturing Practices (GMP), extensive documentation, and audit trails to ensure regulatory approval and patient safety, driving demand for specialized, compliant suppliers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350.5 Million |

| Market Forecast in 2033 | USD 558.1 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Merck KGaA, BASF SE, TCI Chemicals, J.K. Industries, Hangzhou Singclean Chemical, Changzhou Sunlight Pharmaceutical, Liaoning Huajing Chemical, Shanghai Haorui Chemical, TCI AMERICA, Santa Cruz Biotechnology, Alfa Aesar, Kanto Chemical, Wako Pure Chemical, Tokyo Chemical Industry, DOW Chemical (indirect), Mitsubishi Chemical, Sumitomo Chemical, Suzhou Nanocrystal, Furuida Chemical, Puyang Huicheng Electronic Material |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Carbazole Market Key Technology Landscape

The technological landscape of the Carbazole market is primarily defined by the evolution of synthesis and purification methods aimed at achieving higher yields, greater purity, and enhanced structural modification capabilities. Traditional industrial production relies heavily on the isolation of carbazole from crude coal tar using techniques such as acid washing followed by fractional crystallization and distillation. While cost-effective for technical grades, this approach is severely limited in its capacity to produce the ultra-high purity material demanded by the electronics industry. A critical advancement is the application of multi-stage zone refining and sublimation techniques, often conducted under high vacuum, which are crucial for reducing metallic impurities and organic contaminants to sub-ppm levels, directly influencing the performance and lifespan of OLED devices. These advanced purification methods are often proprietary and represent a significant intellectual property advantage for leading specialized suppliers.

In parallel, the market is witnessing substantial innovation in chemical synthesis methodologies, moving beyond basic isolation to sophisticated derivatization and direct synthesis routes. Key technologies include catalytic C–H activation and functionalization protocols, which allow chemists to directly attach functional groups (such as halogens, alkyl groups, or vinyl groups) to the carbazole core in highly selective positions (e.g., C-3, C-6, or N-9). This targeted synthesis approach is vital for creating custom electronic materials with specific HOMO-LUMO energy levels required for next-generation organic electronics, bypassing multi-step traditional syntheses that often generate undesirable byproducts. The development of greener catalytic systems, such as palladium or copper-catalyzed reactions, is also a focal point, aiming to minimize toxic solvent use and enhance process sustainability in line with global environmental mandates.

Another area of technological focus involves the controlled polymerization techniques used for creating Poly(N-vinylcarbazole) (PVK), a well-known hole-transporting polymer. Modern methods emphasize precision polymerization (e.g., controlled radical polymerization) to achieve highly uniform molecular weights and narrow polydispersity indexes, which are essential for materials used in flexible electronics and advanced sensor technologies. Furthermore, the integration of computational chemistry and machine learning platforms (as highlighted in the AI analysis) is becoming a technology enabler, allowing for the rapid modeling and optimization of these complex reaction conditions and purification train designs. This blend of advanced physical chemistry techniques and digital optimization is defining the competitive edge in the high-end carbazole derivative sector.

Regional Highlights

The geographical distribution of the Carbazole market highlights pronounced differences in consumption patterns, production capacity, and regulatory environments, with Asia Pacific (APAC) maintaining a dominant position driven by its extensive manufacturing capabilities across diverse sectors.

- Asia Pacific (APAC): This region is the largest and fastest-growing market globally, primarily due to the concentration of electronics manufacturing hubs (OLED production in South Korea and China), textile processing, and massive domestic pharmaceutical and agrochemical industries. China is both the world's largest consumer and producer of technical-grade carbazole, leveraging abundant coal processing resources. The region's growth is heavily sustained by governmental support for advanced display technologies and the booming demand for affordable consumer electronics, requiring large volumes of carbazole derivatives for polymers and light-emitting materials.

- Europe: Characterized by stringent regulatory environments, particularly the implementation of REACH, the European market focuses intensely on high-value, specialized derivatives, particularly for pharmaceutical intermediates and high-performance organic pigments used in the automotive and aerospace sectors. While large-scale bulk production is limited, Europe is a major hub for R&D and specialized chemical synthesis, prioritizing quality and environmental compliance over high volume, fostering innovation in greener synthesis methods.

- North America: The market here is driven by advanced research in organic photovoltaics, specialized polymer science, and pharmaceutical drug discovery. Consumption focuses on ultra-high purity and pharmaceutical-grade carbazole derivatives, with significant demand originating from research institutions and high-tech start-ups. The North American market emphasizes technological leadership and bespoke chemical production, often importing specific high-purity intermediates rather than relying on domestic bulk production.

- Latin America (LATAM) and Middle East & Africa (MEA): These regions represent emerging markets, primarily serving local demand for Dyes and Pigments in the textile and construction industries, along with growing pharmaceutical manufacturing bases. Market expansion is steady but constrained by limited access to consistent, localized raw material sourcing and reliance on imports for high-end electronic and pharmaceutical grades. Growth is expected to accelerate as industrialization and infrastructure projects increase demand for industrial coatings and coloration materials.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Carbazole Market.- Merck KGaA

- BASF SE

- TCI Chemicals (Tokyo Chemical Industry Co., Ltd.)

- J.K. Industries

- Hangzhou Singclean Chemical Co., Ltd.

- Changzhou Sunlight Pharmaceutical Co., Ltd.

- Liaoning Huajing Chemical Co., Ltd.

- Shanghai Haorui Chemical Co., Ltd.

- TCI AMERICA

- Santa Cruz Biotechnology, Inc.

- Alfa Aesar (Thermo Fisher Scientific)

- Kanto Chemical Co., Inc.

- Wako Pure Chemical Industries, Ltd.

- Mitsubishi Chemical Corporation

- Sumitomo Chemical Co., Ltd.

- Suzhou Nanocrystal Material Technology Co., Ltd.

- Furuida Chemical Co., Ltd.

- Puyang Huicheng Electronic Material Co., Ltd.

- Jilin Provincial Jida Electronic Materials Co., Ltd.

- Acros Organics (Thermo Fisher Scientific)

Frequently Asked Questions

Analyze common user questions about the Carbazole market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the demand for high-purity Carbazole?

The primary driver is the rapid global expansion of the Organic Light-Emitting Diode (OLED) display market, including televisions, smartphones, and automotive lighting, which mandates ultra-high purity carbazole derivatives for highly efficient and long-lasting hole-transporting layers and emissive host materials in display panels.

How is the Carbazole market segmented by grade, and why is purity critical?

The market is segmented into Technical Grade (for pigments/polymers), Electronic Grade (for OLEDs/OPVs), and Pharmaceutical Grade. Purity is critical because impurities, especially metallic ions, can severely reduce the performance, efficiency, and operational lifespan of sensitive electronic components, justifying the high premium for Electronic Grade material.

Which geographical region dominates the production and consumption of Carbazole?

Asia Pacific (APAC), particularly China, South Korea, and Japan, dominates both the production and consumption of carbazole. This is primarily due to the concentration of global electronics manufacturing bases and extensive production capacity of technical grade material derived from local coal tar processing industries.

What are the main supply chain challenges faced by Carbazole manufacturers?

The main challenge is the inherent volatility and inconsistent quality of the primary raw material—coal tar fractions—due to fluctuations in the global steel and energy markets. Additionally, the need for complex, costly, and energy-intensive purification processes to meet high-end electronic specifications poses a logistical and financial challenge.

Beyond dyes and electronics, what is the role of carbazole in the pharmaceutical industry?

In pharmaceuticals, the carbazole scaffold serves as a versatile building block for synthesizing numerous Active Pharmaceutical Ingredients (APIs). Its structure is integrated into molecules used in the treatment of neurological disorders, oncology, and inflammatory conditions, valued for its structural rigidity and inherent bioactivity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager