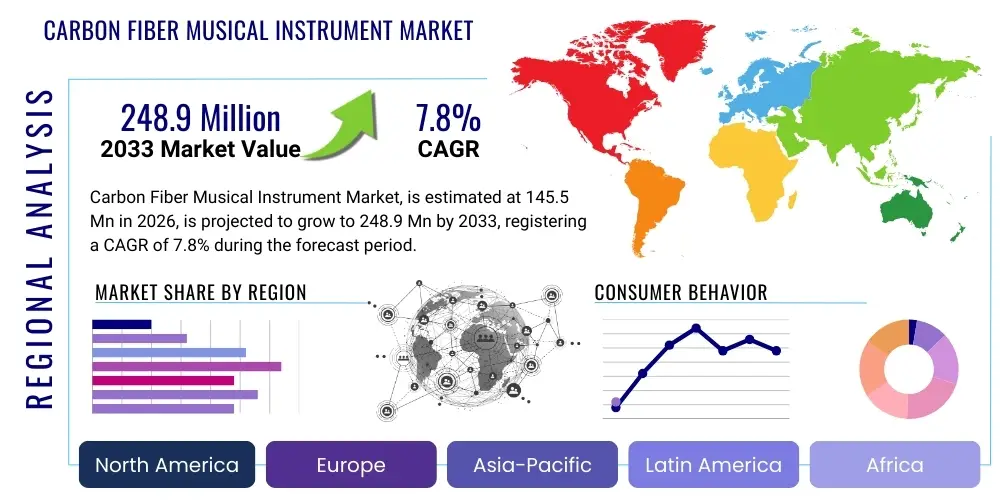

Carbon Fiber Musical Instrument Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443543 | Date : Feb, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Carbon Fiber Musical Instrument Market Size

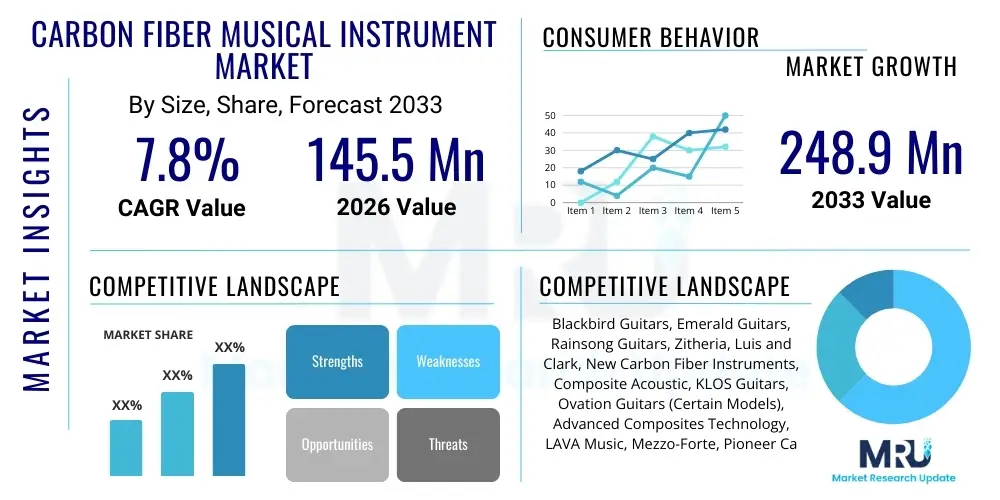

The Carbon Fiber Musical Instrument Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 145.5 Million in 2026 and is projected to reach USD 248.9 Million by the end of the forecast period in 2033.

Carbon Fiber Musical Instrument Market introduction

The Carbon Fiber Musical Instrument Market encompasses the manufacturing, distribution, and sales of musical instruments constructed partially or entirely using carbon fiber reinforced polymer (CFRP) composites. These instruments span a wide range, including string instruments like guitars, violins, cellos, and basses, as well as select percussion and wind instruments. Carbon fiber, known for its exceptional strength-to-weight ratio, durability, and resistance to environmental fluctuations (temperature and humidity), offers significant performance advantages over traditional wood instruments, particularly for touring musicians and outdoor performances.

Product descriptions highlight instruments that maintain acoustic fidelity comparable to high-quality traditional instruments while offering superior resilience and stability. Major applications include professional touring, educational settings requiring robust instruments, outdoor music festivals, and use by hobbyists who prioritize low maintenance and consistent performance. The key benefits driving market adoption are unparalleled durability, stability against warping or cracking, light weight, and often, enhanced projection and sustain.

The driving factors for market growth involve the increasing acceptance of alternative, sustainable, and high-performance materials in premium consumer goods, the rising frequency of outdoor and global music events where climate resilience is crucial, and advancements in composite manufacturing techniques that allow for precise acoustic engineering. Furthermore, the modern aesthetic appeal and reduced maintenance burden associated with carbon fiber instruments attract a growing segment of professional and serious amateur musicians globally.

Carbon Fiber Musical Instrument Market Executive Summary

The Carbon Fiber Musical Instrument Market is undergoing robust expansion, characterized by a fundamental shift in material perception where advanced composites are increasingly viewed not just as alternatives but as superior performance materials for specific instrument categories. Business trends show a strong focus on innovation within specialized niches, particularly high-end acoustic guitars and orchestral instruments like cellos and basses, where the stability and projection provided by carbon fiber are most pronounced. Key manufacturers are investing heavily in patented acoustic designs and lightweight construction methodologies to overcome historical perceptions of carbon fiber instruments lacking warmth compared to wood, thereby expanding the acceptance among discerning professional players.

Regional trends indicate North America and Europe currently dominate the market due to high disposable income, established professional music scenes, and early adoption of innovative composite technologies. However, the Asia Pacific region is rapidly emerging as a high-growth area, driven by expanding music education programs and increasing affluence in countries like China and India, leading to greater demand for durable, student-friendly, and high-quality instruments. Manufacturers are adapting distribution channels, favoring specialty music stores and direct-to-consumer online platforms to manage the specialized nature of these products and educate consumers about the benefits of carbon fiber composites.

Segmentation trends highlight that the String Instrument segment, particularly acoustic guitars, remains the largest revenue contributor, benefiting from significant product diversification and successful marketing campaigns targeting touring professionals. The Hobbyists/Amateurs application segment is experiencing the fastest growth, as carbon fiber instruments become more accessible and valued for their low maintenance requirements. Moving forward, strategic mergers and acquisitions focusing on integrating advanced composite material suppliers into the instrument manufacturing value chain will be crucial for maintaining cost efficiencies and ensuring material quality consistency.

AI Impact Analysis on Carbon Fiber Musical Instrument Market

Common user questions regarding AI's impact on the Carbon Fiber Musical Instrument Market frequently center on themes of customized acoustic design, manufacturing optimization, and personalized consumer recommendations. Users are keen to understand if AI can simulate the complex acoustic properties of rare or aged tonewoods within carbon fiber structures, and how machine learning algorithms might refine the layup process—the precise arrangement of carbon fiber sheets—to minimize material waste while maximizing vibrational characteristics. Key concerns include the potential displacement of traditional luthier skills versus the enhancement of design capabilities, and whether AI-driven design processes can genuinely replicate the subjective 'soul' or unique character often attributed to handcrafted wood instruments.

The overarching expectation is that AI will primarily serve as an advanced tool for optimizing the instrument manufacturing process, offering unparalleled precision in acoustic engineering that traditional methods cannot easily achieve. For instance, Generative Design AI can explore thousands of structural variations for internal bracing patterns or soundboard thickness in carbon fiber guitars, identifying the optimal geometry for specific tonal goals—such as maximizing low-frequency response or achieving superior volume projection. This shift allows manufacturers to move toward hyper-customization based on individual musician preferences regarding tonal profile, playability, and preferred environment, moving beyond standard production models.

Furthermore, AI is expected to revolutionize supply chain management and quality control. Computer vision systems combined with machine learning can automatically inspect carbon fiber prepregs and finished parts for micro-defects invisible to the human eye, ensuring the structural integrity and acoustic consistency of every instrument produced. Predictive maintenance models can also optimize machinery use, reducing downtime and operational costs, which is crucial for maintaining competitive pricing in this specialized composite material market segment.

- AI-driven Generative Design for optimizing internal bracing and soundboard geometries to achieve specific acoustic profiles.

- Machine Learning algorithms predicting optimal carbon fiber layup patterns to minimize material damping and enhance resonance.

- Advanced quality control using Computer Vision and AI for automatic defect detection in composite materials during manufacturing.

- Predictive modeling of instrument performance under various climate conditions, aiding touring musicians in selecting the most stable models.

- Personalized recommendation engines utilizing AI to match musicians with carbon fiber instrument models based on playing style and preferred genre characteristics.

DRO & Impact Forces Of Carbon Fiber Musical Instrument Market

The Carbon Fiber Musical Instrument Market is shaped by significant forces encompassing high-performance requirements (Drivers), the established preference for traditional materials (Restraints), unique technological applications (Opportunities), and external market pressures (Impact Forces). The primary driver is the superior durability and environmental stability of carbon fiber, offering solutions to musicians who frequently face rapid changes in temperature and humidity—conditions highly detrimental to traditional wood instruments. This material property significantly reduces maintenance costs and increases the longevity and reliability of the investment, particularly for professional players and rental fleets. Furthermore, the inherent low weight of carbon fiber improves ergonomics and playability, reducing fatigue during extended performances, which is a powerful selling point for specialized instruments like cellos and acoustic basses.

However, major restraints hinder broader market adoption. The most significant is the deeply entrenched cultural and acoustic preference for traditional tonewoods (like spruce, maple, and mahogany), especially in high-end acoustic and classical instruments. Many musicians and purists perceive carbon fiber instruments as lacking the complex, warm, or nuanced tonal characteristics associated with aged wood. Additionally, the high initial cost of raw carbon fiber material and the specialized, energy-intensive manufacturing processes required to shape and cure complex acoustic components lead to higher retail prices compared to many mid-range wood instruments, creating a financial barrier for amateur and entry-level buyers.

Opportunities for market expansion lie in the application of carbon fiber in hybrid instrument designs, integrating composite elements only where structural stability is paramount (e.g., necks and backs), while retaining traditional wood soundboards where tonal warmth is desired. There is also a substantial opportunity in developing specialized educational and outdoor performance instruments, where durability is prioritized over nuanced classical tone. Impact forces driving market change include increasing global concerns over sustainable sourcing of rare tonewoods, which positions carbon fiber as an environmentally responsible alternative, and the continuous advancement in composite material science, which promises lighter, stronger, and more acoustically refined instruments in the future, gradually eroding the tonal prejudice against synthetics.

Segmentation Analysis

The Carbon Fiber Musical Instrument Market is meticulously segmented based on the type of instrument, the primary application, and the channel through which these products are distributed to customers. This multi-dimensional segmentation allows manufacturers to precisely target marketing efforts and product development toward specific end-user needs, whether focusing on the rugged requirements of outdoor performers or the precise acoustic needs of studio professionals. The string instrument category, encompassing acoustic guitars, violins, and cellos, maintains the largest market share due to the immediate and significant structural benefits carbon fiber offers to these highly tensioned instruments.

Application-wise, professional musicians represent the highest value segment, demanding customizability and performance parity with their wooden counterparts, while the hobbyist/amateur segment drives volume growth, valuing the low maintenance and resilience. Distribution segmentation highlights the reliance on specialty music retail—where expert advice is available to justify the premium cost—but also the growing importance of direct-to-consumer online channels, facilitating niche brands in reaching a global audience without extensive physical retail overhead.

- By Instrument Type:

- String Instruments (Acoustic Guitars, Violins, Cellos, Basses, Ukuleles)

- Percussion Instruments (Drum Shells, Specialty Cymbals, Cajons)

- Wind Instruments (Flutes, Clarinets, Saxophone Necks)

- Keyboard Instruments (Specialty Keyboard Cases/Housings)

- By Application:

- Professional Musicians and Touring Artists

- Hobbyists and Amateur Players

- Educational Institutions and School Programs

- Recording Studios and Orchestras

- By Distribution Channel:

- Online Retail and E-commerce Platforms

- Specialty Music Stores (Brick-and-Mortar)

- Direct Sales (Manufacturer to Consumer)

Value Chain Analysis For Carbon Fiber Musical Instrument Market

The value chain for carbon fiber musical instruments is highly specialized, beginning with the complex upstream analysis focused on sourcing aerospace or high-modulus grade carbon fiber prepregs and composite resins. Upstream activities are dominated by a limited number of specialized material suppliers who provide the critical raw materials—the specific weave and modulus of the carbon fiber directly impacts the acoustic properties and structural integrity of the final instrument. Establishing long-term, quality-assured supply contracts with these raw material providers is paramount, as inconsistencies in the fiber or resin can result in unpredictable acoustic outcomes and significant manufacturing waste.

The midstream phase involves highly technical manufacturing, including specialized tooling, precision CNC machining, and controlled autoclave curing processes, often requiring cleanroom environments to ensure flawless composite bonding. Unlike traditional luthiery, which relies on skilled handcraftsmanship for material shaping, carbon fiber instrument manufacturing heavily leverages automated systems and sophisticated molds to achieve geometric precision critical for consistent tonal output. This specialized production limits the number of manufacturers capable of producing high-quality instruments, often resulting in niche market competition.

Downstream analysis involves distribution channels, which are bifurcated into direct sales and indirect sales via specialty stores. Direct sales allow manufacturers to maintain control over branding, pricing, and specialized customer education necessary for premium composite products, often targeting global niche markets effectively through e-commerce. Indirect channels, particularly specialized music retailers, are vital for providing musicians with a hands-on testing environment and the technical expertise needed to compare carbon fiber instruments against high-end wood alternatives. Effective logistics, ensuring instruments are shipped globally without risk of damage, is also a critical component of the downstream value delivery.

Carbon Fiber Musical Instrument Market Potential Customers

Potential customers for the Carbon Fiber Musical Instrument Market represent a distinct subset of the broader musical community, primarily defined by the need for exceptional reliability, durability, and performance consistency across various environments. The core end-users/buyers are highly mobile professional musicians, especially those engaged in frequent touring, outdoor performances, or educational outreach where instruments are subjected to constant handling and climatic stress. For these buyers, the high initial cost is justified by the elimination of worries concerning cracks, warping, and frequent humidity adjustments associated with wooden instruments, translating into long-term savings and reliability.

A rapidly expanding segment consists of advanced hobbyists and passionate amateurs who appreciate the low maintenance requirements and robust nature of carbon fiber. These buyers often play in less controlled environments—such as homes with variable humidity or taking instruments on camping trips or boats—and seek a reliable instrument that maintains perfect intonation and playability without constant climate monitoring. The educational sector, including university programs and school music departments, also represents a significant customer base, valuing the instruments' ability to withstand rigorous student use and fluctuating institutional environments.

Furthermore, specialized end-users include military bands, extreme environment explorers, and musicians performing in high-humidity regions (coastal areas, tropical climates), where the material’s resistance to moisture and decay is a critical necessity. The buying decision for these customers is driven by performance longevity, resistance to damage, and a preference for modern aesthetics, often bypassing traditional concerns over material authenticity if the acoustic quality meets professional standards.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 145.5 Million |

| Market Forecast in 2033 | USD 248.9 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Blackbird Guitars, Emerald Guitars, Rainsong Guitars, Zitheria, Luis and Clark, New Carbon Fiber Instruments, Composite Acoustic, KLOS Guitars, Ovation Guitars (Certain Models), Advanced Composites Technology, LAVA Music, Mezzo-Forte, Pioneer Carbon Composites, GS Instruments, VIOLINLUX |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Carbon Fiber Musical Instrument Market Key Technology Landscape

The technology landscape in the Carbon Fiber Musical Instrument Market is defined by the sophisticated application of composite science and precision engineering, moving far beyond basic material substitution. A core technological aspect is the utilization of prepreg carbon fiber materials—sheets pre-impregnated with precise amounts of epoxy resin—which ensure consistency and optimal strength-to-weight ratios during the curing process. Crucially, manufacturers employ advanced Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) software to model and simulate the vibrational behavior and sound projection of instrument designs before physical prototyping, allowing for rapid iterations and acoustic optimization that mimics the finest aspects of traditional tonewood resonance.

Manufacturing technology relies heavily on advanced molding techniques, primarily utilizing high-pressure, high-temperature autoclave curing, or Vacuum-Assisted Resin Transfer Molding (VARTM). These processes create seamless, hollow bodies (monocoque construction) that are lighter and inherently stronger than bolted or glued multi-part assemblies. The precise control over the composite structure, including varying the thickness and fiber orientation (layup) across different parts of the instrument body, is crucial for tuning the resonance frequency and damping characteristics to maximize sustain and projection. Specialized coatings and finishes are also a technological focal point, designed to protect the carbon fiber from UV degradation while minimizing interference with the instrument's vibrational properties.

Recent innovations focus on integrating additive manufacturing (3D printing) for creating complex internal bracing structures or precision molds, allowing for acoustic geometries previously impossible with traditional composite layering. Furthermore, proprietary damping technologies and material treatments are being developed to introduce subtle acoustic complexities, often referred to as "tonal warmth," aiming to bridge the perceived gap between the sound of composite instruments and revered vintage wood counterparts. This convergence of high-tech materials and acoustic simulation ensures the market continuously introduces higher fidelity, more robust musical tools.

Regional Highlights

- North America (NA): Represents the largest market share, driven by a high number of professional musicians, strong consumer spending on premium musical equipment, and the presence of several pioneering carbon fiber instrument manufacturers. The region exhibits high acceptance rates for technological innovation in musical gear.

- Europe: A mature market characterized by robust demand from classical orchestral musicians (for instruments like carbon fiber cellos and basses that require high stability) and outdoor/festival musicians. Germany, the UK, and Scandinavia are key revenue hubs due to strong music education sectors and a willingness to invest in durable, professional-grade instruments.

- Asia Pacific (APAC): Expected to register the fastest CAGR. Growth is fueled by massive expansion in middle-class populations, increased spending on music education, and rapid urbanization, which creates a need for durable instruments less affected by regional humidity and temperature extremes (especially in Southeast Asia). China and Japan are leading consumers.

- Latin America (LATAM): Emerging market with demand focused primarily on acoustic guitars and percussion instruments, valued for resilience against varied climate conditions and transportation challenges inherent in large-scale touring across the region. Price sensitivity remains a factor, driving demand for cost-effective manufacturing solutions.

- Middle East and Africa (MEA): A nascent market showing potential in specialty niches, such as instruments used in desert or high-heat environments where wood instability is a critical limitation. Growth is slower but steady, highly dependent on local government investments in cultural infrastructure and music programs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Carbon Fiber Musical Instrument Market.- Blackbird Guitars

- Emerald Guitars

- Rainsong Guitars

- Zitheria

- Luis and Clark

- New Carbon Fiber Instruments

- Composite Acoustic

- KLOS Guitars

- Ovation Guitars (Certain Models)

- Advanced Composites Technology

- LAVA Music

- Mezzo-Forte

- Pioneer Carbon Composites

- GS Instruments

- VIOLINLUX

- CodaBow International

- Müller & Müller GmbH

- Polymer Instruments Inc.

- Graphite Guitar Works

- Sonus Composites

Frequently Asked Questions

Analyze common user questions about the Carbon Fiber Musical Instrument market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary acoustic differences between carbon fiber and traditional wood musical instruments?

Carbon fiber instruments typically offer greater volume, projection, and sustain due to the material's stiffness and consistent density. They are less susceptible to environmental changes, resulting in stable tone and pitch. While historically perceived as lacking the "warmth" of wood, modern composite instruments are engineered to replicate complex harmonic overtones through advanced internal bracing structures and proprietary material layups.

Is the Carbon Fiber Musical Instrument Market experiencing growth due to environmental concerns about tonewood sourcing?

Yes, increasing regulatory scrutiny (like CITES restrictions) and ethical concerns regarding the sustainability and rarity of traditional tonewoods (such as ebony and mahogany) serve as a significant market driver. Carbon fiber offers a high-performance, consistent, and environmentally sustainable alternative, appealing to musicians and organizations committed to responsible material choices.

Which segment holds the largest share in the Carbon Fiber Musical Instrument Market, and why?

The String Instruments segment, particularly acoustic guitars and orchestral string instruments (cellos and basses), holds the largest market share. This is because these instruments highly benefit from carbon fiber’s structural stability, which counteracts the significant string tension, preventing warping, reducing tuning issues, and providing superior durability essential for professional touring.

What is the typical price range for professional-grade carbon fiber musical instruments?

Professional-grade carbon fiber instruments generally occupy the premium price bracket, often comparable to high-end, hand-built wood instruments. Prices typically range from $1,500 to over $10,000, depending on the instrument type and level of composite engineering sophistication. The cost reflects the expense of raw carbon fiber materials and the specialized, low-volume, high-precision manufacturing processes required.

How does carbon fiber material resist extreme temperature and humidity changes compared to wood?

Carbon fiber exhibits an extremely low coefficient of thermal expansion and is non-hydroscopic (does not absorb moisture). This means the material does not expand, contract, or warp significantly when exposed to fluctuations in temperature or humidity, ensuring the instrument maintains its structural geometry, neck angle, and intonation stability far better than traditional porous wood materials.

Detailed Market Overview and Future Outlook

The Carbon Fiber Musical Instrument Market is strategically positioned at the intersection of material science innovation and traditional musical craftsmanship. The market is increasingly characterized by a dichotomy: the high-end professional sector demanding performance parity with vintage wood instruments but with modern durability, and the entry-level/amateur sector prioritizing resilience and low maintenance. Future market growth will be intrinsically linked to the successful demystification of carbon fiber acoustics. Manufacturers are heavily invested in R&D to refine composite recipes, leveraging proprietary resins and specific fiber weave orientations (like spread tow fabrics) to fine-tune vibrational characteristics. This technological pursuit aims to produce instruments that not only survive harsh environments but also offer a tonal richness that appeals universally across genres, from bluegrass and folk to classical ensembles.

Looking ahead, distribution models are expected to evolve, placing greater emphasis on experiential retail that allows musicians to directly compare the sound, feel, and durability of carbon fiber versus wood instruments. Virtual reality and augmented reality tools may be adopted to showcase the structural resilience and internal engineering of composite instruments to online shoppers. Furthermore, the diversification of the product portfolio beyond guitars and bows into niche instruments, such as specialized wind instruments or high-end practice percussion, will unlock new revenue streams. Collaborations between composite engineering firms and renowned luthiers are becoming more common, signaling a merging of technical expertise and artistic acoustic sensibility.

The long-term outlook suggests a sustained positive trajectory, driven by macroeconomic factors such as increasing global musical engagement and microeconomic factors like reduced long-term cost of ownership (due to durability). Regulatory frameworks surrounding intellectual property for composite acoustic designs will also play a crucial role, protecting manufacturers who invest significantly in acoustic modeling and patented manufacturing processes. Successful market penetration hinges on demonstrating that carbon fiber is not merely a substitute, but a material offering unique and superior performance attributes for the modern musician’s dynamic requirements.

Competitive Landscape and Strategic Analysis

The competitive landscape of the Carbon Fiber Musical Instrument Market is fragmented, dominated by a few specialized boutique manufacturers and innovative composite technology companies, rather than the traditional, large-scale instrument makers who remain heavily invested in wood production. Key competitive strategies revolve around differentiating products based on patented acoustic designs and achieving a premium brand perception built on durability and performance consistency. Companies like Rainsong and Emerald focus on acoustic guitars, emphasizing their superior projection and immunity to climate, while firms such such as Luis and Clark dominate the orchestral composite segment (cellos, basses) by targeting high-level institutional and touring groups.

Strategic analysis indicates that mergers, acquisitions, and strategic partnerships are becoming increasingly important. Smaller composite specialists often lack the extensive global distribution networks of larger music companies. Therefore, partnerships that merge advanced composite manufacturing know-how with established sales channels represent a critical path to scale. Furthermore, competition extends beyond material performance into intellectual property rights, with firms aggressively protecting their unique mold designs, bracing patterns, and composite layup sequences to maintain a competitive edge in acoustic quality. The ability to effectively communicate the value proposition—justifying the premium price point through longevity and reliability—is a core competence for leading market players.

Pricing strategy is complex due to the high input costs of aerospace-grade carbon fiber. Successful competitors must achieve operational excellence in composite manufacturing to optimize yields and minimize waste, allowing them to offer instruments at a justifiable premium. Marketing efforts are often concentrated on professional endorsements and direct engagement with musicians through specialized events and trade shows, leveraging testimonials that highlight reliability in real-world touring scenarios. This targeted approach is essential to educate a customer base often skeptical of non-traditional materials, positioning carbon fiber instruments as indispensable tools for the modern, global musician.

The competitive differentiation also lies in specialized warranties and after-sales service, emphasizing the durability advantage. For instance, offering warranties against warping or cracking—common issues with traditional instruments—provides a substantial value-add that competitors using conventional materials cannot match. Technological breakthroughs, particularly in enhancing the low-frequency response and complexity of composite soundboards, are viewed as the next major battleground for market share, pushing companies to continuously iterate on material composition and structural acoustics.

Market Challenges and Mitigation Strategies

The Carbon Fiber Musical Instrument Market faces several persistent challenges, primarily rooted in overcoming consumer bias, managing high production costs, and navigating the specialized knowledge required for manufacturing. The psychological barrier associated with perceived tonal inferiority compared to traditional, naturally resonant tonewoods remains a primary hurdle. Mitigation strategies focus on transparent and scientific acoustic demonstration, utilizing high-fidelity recording and direct comparisons under controlled conditions to prove tonal equivalence or even superiority for specific applications. Targeted endorsements from high-profile artists who have successfully transitioned to composite instruments are also crucial in shifting professional perceptions.

Another significant challenge is the inherent high cost of carbon fiber composites and the specialized, capital-intensive machinery required for precision composite fabrication. To mitigate this, manufacturers are adopting Lean manufacturing principles within their composite shops to reduce material waste (the single largest cost factor) and are exploring automated production techniques to reduce labor overhead. Strategic sourcing and long-term contracts with carbon fiber suppliers help stabilize raw material prices. Furthermore, developing more efficient, lower-temperature curing resins could potentially reduce energy consumption, addressing operational costs.

The lack of standardization in composite instrument construction poses a challenge for repair and maintenance across the broader musical instrument repair industry. Unlike wood instruments where luthier skills are widely available, repairing composite instruments often requires specialized tools and knowledge. The mitigation strategy involves manufacturers offering proprietary repair training programs and detailed maintenance manuals to certified third-party service centers, ensuring customers have access to qualified repair services globally. This infrastructure building is essential for ensuring long-term customer satisfaction and market confidence in the product’s longevity.

Finally, market education is a continuous challenge. Since carbon fiber instruments cater to a niche, high-performance segment, educating the consumer about the technical advantages—stability, durability, and consistent tone—is vital. Mitigation involves extensive digital content creation (videos, webinars, detailed technical specifications) and highly knowledgeable sales staff in specialty retail environments. Clear communication of the total cost of ownership (TCO) benefit, contrasting the initial premium price against the reduced maintenance, repair, and environmental damage costs over decades, effectively validates the investment.

The successful navigation of these challenges relies on innovation, persistent consumer education, and strategic alliances that help distribute the technical expertise required to sustain high-quality composite instrument production. The market is evolving from being purely technology-driven to being acoustically refined, recognizing that material excellence must be paired with genuine musical performance to achieve mainstream success within the professional community.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager