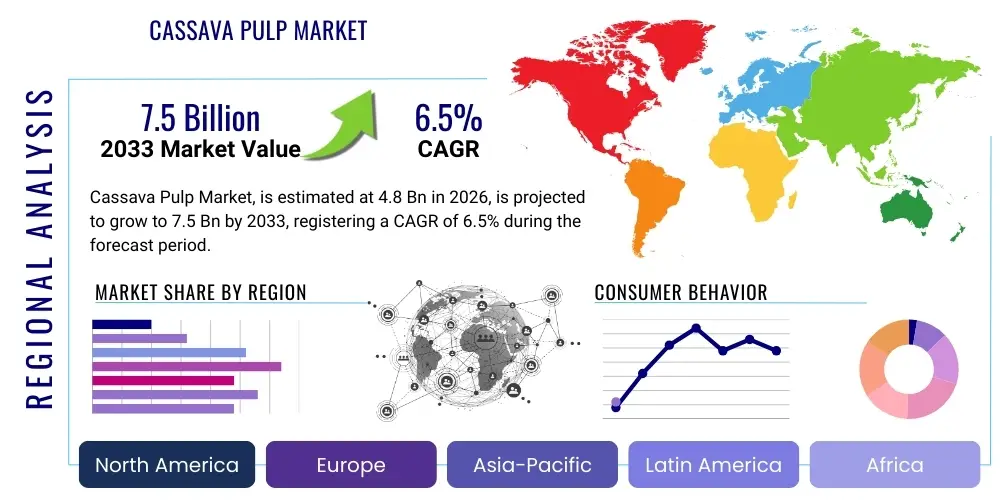

Cassava Pulp Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443512 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Cassava Pulp Market Size

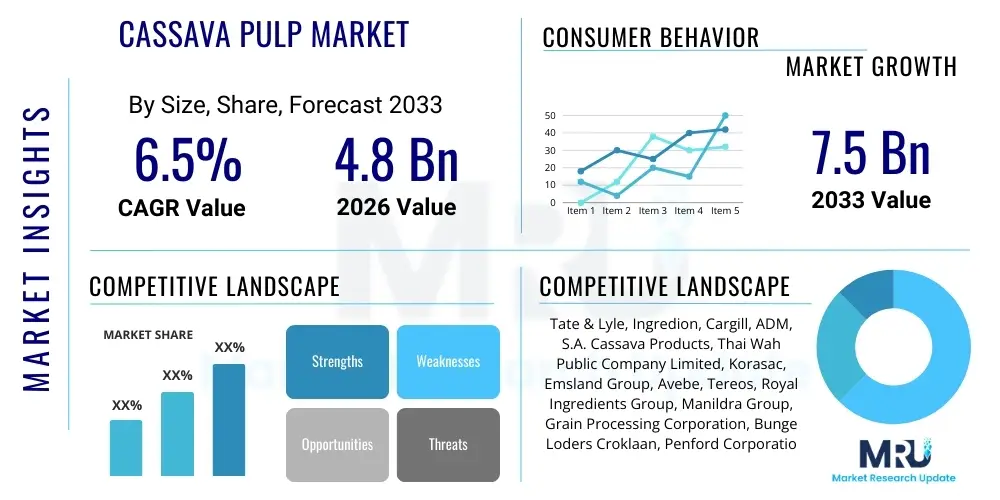

The Cassava Pulp Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 4.8 billion in 2026 and is projected to reach USD 7.5 billion by the end of the forecast period in 2033.

Cassava Pulp Market introduction

The Cassava Pulp Market encompasses the trade and utilization of the fibrous residue obtained after the extraction of starch from fresh cassava roots. This byproduct, often referred to as cassava bagasse or cassava waste, retains significant amounts of fiber, residual starch, and protein, making it a valuable, low-cost raw material, particularly in the animal feed, paper manufacturing, and bioenergy sectors. Traditionally viewed as a waste stream, advancements in drying, detoxification, and valorization technologies have repositioned cassava pulp as an essential industrial commodity that enhances supply chain sustainability for cassava processors globally.

The product's versatility stems from its high energy content and desirable binding properties, which are crucial for applications ranging from livestock feed formulation, where it acts as a bulking agent and low-cost energy source, to the production of eco-friendly packaging materials. Furthermore, the push towards circular economy models and minimizing industrial waste strongly favors the adoption of cassava pulp. Major applications are predominantly found in the Asia Pacific region, driven by large-scale starch processing operations in countries like Thailand, Indonesia, and Vietnam, where efficient management of this residue is paramount for operational profitability and environmental compliance.

Key driving factors accelerating market expansion include the exponential growth in global demand for affordable animal feed alternatives, coupled with increasing governmental mandates supporting sustainable industrial practices and waste reduction. The economic viability of cassava pulp compared to conventional feed ingredients like corn and soybean meal, especially during periods of volatile commodity pricing, solidifies its critical role in various downstream industries. Continuous research into advanced fermentation techniques is further opening opportunities for its utilization in novel biochemical and bioplastic production, transforming it from a simple byproduct into a core component of future bio-industrial value chains.

Cassava Pulp Market Executive Summary

The Cassava Pulp Market is characterized by robust expansion, primarily fueled by synergistic demands from the high-growth animal feed and industrial packaging sectors. Current business trends indicate a strong move toward vertical integration among major cassava starch producers, aiming to capture the value derived from pulp processing and subsequent sales. This integration enhances supply chain reliability and allows producers to offer specialized pulp grades optimized for specific end-user requirements, such as high-fiber materials for paperboard reinforcement or detoxified, pelletized versions for swine and poultry feed. Furthermore, investment in advanced drying and preservation technologies is a key focus, mitigating risks associated with spoilage and transportation, thus expanding the geographic reach of major suppliers.

Regionally, Asia Pacific maintains undisputed dominance, acting as both the largest producer and consumer, underpinned by the substantial output from the region's massive starch industry. However, emerging regional trends highlight increasing processing capabilities in Latin America and Sub-Saharan Africa. These regions are leveraging improved agricultural yields and increasing domestic industrialization to establish reliable local supply chains for cassava pulp, reducing reliance on long-distance imports for feed and paper production. Government policies promoting the cultivation and processing of cassava as a staple crop and industrial raw material are crucial catalysts in these developing markets, ensuring sustainable raw material availability for pulp production.

Segment-wise, the Animal Feed application segment commands the largest market share, driven by the escalating global population and resultant increase in livestock production, particularly in intensive farming operations. Within industrial applications, the Biofuel and Ethanol Production segment is exhibiting the fastest growth trajectory, stimulated by global environmental regulations favoring renewable energy sources and the development of cost-effective conversion technologies utilizing the residual starch and high cellulosic content of the pulp. The market trajectory confirms a shift towards higher-value applications beyond simple bulk filler, positioning cassava pulp as a critical component in future bio-refinery operations.

AI Impact Analysis on Cassava Pulp Market

Analysis of common user questions regarding the impact of Artificial Intelligence (AI) on the Cassava Pulp Market reveals key themes centered around operational efficiency, yield maximization, and quality control prediction. Users frequently inquire how AI can optimize the highly variable processes of cassava cultivation and starch extraction, which directly influence the quantity and quality of the resulting pulp. Specific concerns focus on predictive maintenance for complex machinery (like industrial dryers and centrifuges), AI-driven optimization of drying parameters to preserve nutritional value and minimize energy consumption, and the use of machine learning for forecasting raw material supply stability based on climatic data. The overarching expectation is that AI will transform pulp production from a reactive process based on byproduct management into a proactive, optimized supply chain component, ensuring consistent quality and maximizing the economic value of the residual material.

- AI-Powered Yield Prediction: Utilizing machine learning algorithms to analyze soil conditions, weather patterns, and cultivar performance to predict optimal cassava root yield, ensuring a stable and predictable raw material supply for pulp generation.

- Optimized Processing Parameters: Deployment of AI to adjust parameters in real-time during starch extraction and dewatering processes, maximizing pulp consistency and minimizing residual moisture, thereby reducing spoilage risks and energy costs.

- Predictive Maintenance: AI systems analyze sensor data from industrial drying equipment (e.g., flash dryers) to anticipate mechanical failures, dramatically reducing downtime and ensuring continuous, high-volume production of dry cassava pulp.

- Quality Grading Automation: Implementation of computer vision and analytical sensors integrated with AI to automatically grade cassava pulp based on fiber content, particle size, and cleanliness, ensuring adherence to specific industrial or food-grade specifications.

- Supply Chain and Logistics Optimization: AI algorithms optimize transportation routes and inventory management for the bulky pulp material, reducing logistical costs and improving just-in-time delivery schedules for downstream manufacturers like feed mills and paper factories.

- Market Price Forecasting: Use of advanced predictive analytics to model commodity price fluctuations for competing feed ingredients, allowing producers to strategically price cassava pulp to maximize profitability and market competitiveness.

DRO & Impact Forces Of Cassava Pulp Market

The trajectory of the Cassava Pulp Market is dynamically shaped by a crucial interplay of drivers, restraints, and burgeoning opportunities that collectively form the impact forces defining its growth potential. The primary driver is the pervasive need for cost-effective and readily available carbohydrate and fiber sources in the expanding global animal feed industry, particularly in developing economies where livestock production is accelerating rapidly. Simultaneously, the global mandate towards sustainable industrial practices exerts significant force, compelling starch manufacturers to utilize all byproducts, turning waste streams into profitable resources. This regulatory and economic pressure reinforces the market's positive outlook, ensuring cassava pulp remains a vital component of the circular bioeconomy model.

However, the market faces inherent structural restraints that necessitate strategic mitigation. The most significant challenge is the high moisture content of fresh cassava pulp (often exceeding 80%), which mandates substantial investment in energy-intensive drying technologies to ensure long-term storage and economical transportation. Furthermore, the presence of cyanogenic glycosides in raw cassava necessitates strict detoxification protocols before it can be safely used in high concentrations, particularly for monogastric animal feed applications. These operational challenges increase processing costs and complexity, thereby limiting the ease of entry for smaller processors and requiring standardized processing expertise across the value chain.

The most compelling opportunity lies in the advanced valorization of cassava pulp beyond traditional feed and filler uses. This includes its application in producing sustainable bioplastics, high-performance dietary fibers for human consumption, and bio-ethanol using sophisticated fermentation and hydrolysis techniques that target residual starch and cellulose. These high-value opportunities promise substantially higher profit margins compared to bulk commodity sales, attracting advanced technological investment. The combined effect of strong economic drivers (cost-effectiveness), persistent restraints (processing complexity), and significant technological opportunities defines the potent impact forces compelling market participants to innovate continually and vertically integrate processing capabilities to capitalize on this undervalued resource.

Segmentation Analysis

The segmentation of the Cassava Pulp Market is essential for understanding the diverse end-use applications and the varying quality requirements across industrial sectors. The market is primarily dissected based on Application, Grade, and Processing Method, reflecting the technical specifications and performance characteristics demanded by different buyers. The application segmentation clearly delineates the volume-heavy industrial sectors, such as animal feed and paper manufacturing, from emerging, higher-value sectors like biofuel production and specialized chemicals. This framework allows market participants to tailor their processing methods and product offerings, optimizing for either cost-efficiency in bulk sales or high purity and consistency in niche markets.

Segmentation by Grade—Food Grade and Industrial Grade—is critical as it dictates the stringency of processing standards, detoxification procedures, and quality control measures applied to the pulp. Food-grade pulp (usually processed further into high-fiber flour or functional ingredients) requires rigorous adherence to food safety standards and minimal residual cyanide levels, typically commanding a premium price. Conversely, industrial-grade pulp, utilized in adhesives, paper fillers, and bulk feed, focuses more on consistency in fiber content and cost-effectiveness. Furthermore, analyzing the market by processing method, specifically Wet Milling versus Dry Milling, highlights regional variations in operational scale and technological maturity, influencing the availability and characteristics of the final pulp product.

- By Application:

- Food & Beverages (Functional Fiber Ingredients, Fillers)

- Animal Feed (Ruminants, Swine, Poultry)

- Paper & Packaging (Paperboard, Cardboard Reinforcement)

- Textiles (Sizing Agents)

- Biofuel & Ethanol Production

- Adhesives & Binders

- By Grade:

- Food Grade

- Industrial Grade

- By Processing Method:

- Wet Milling Byproduct

- Dry Milling Byproduct

Value Chain Analysis For Cassava Pulp Market

The Cassava Pulp value chain begins upstream with the cultivation and harvesting of raw cassava roots, predominantly carried out by smallholder farmers in tropical regions. This initial stage is characterized by high variability in yield and quality, which significantly impacts the volume and composition of the resultant pulp. Efficiency in the upstream segment relies heavily on effective agricultural extension services and sustainable farming practices to ensure a consistent, high-quality supply of roots to the processing facilities. Vertical integration, where large starch manufacturers manage or contract substantial farming operations, is becoming increasingly common to stabilize feedstock input and mitigate price volatility inherent in agricultural commodities.

The midstream phase, centered on the starch extraction process (wet or dry milling), is where the cassava pulp is generated as a byproduct. Critical processing steps include mechanical crushing, starch washing, and the crucial dewatering and drying of the residual fiber. This stage requires significant capital investment in energy-efficient equipment, such as screw presses, centrifuges, and flash dryers, to reduce moisture content from over 80% to a stable level of around 10-14%. The quality and subsequent market value of the pulp are largely determined by the efficiency of this drying process and the thoroughness of cyanide detoxification, ensuring product safety and stability for extended storage and transit.

The downstream analysis involves the distribution channel and eventual consumption by end-users. Distribution is multifaceted, involving both direct and indirect sales. Large starch processors often engage in direct B2B contracts with major animal feed manufacturers or paper mills, guaranteeing stable supply volumes and specific quality parameters. Indirect distribution involves commodity traders and specialized industrial distributors who handle logistics, bulk storage, and regional sales to smaller enterprises. The primary end-users—feed manufacturers, paper producers, and biofuel plants—seek consistent supply, competitive pricing, and certified quality, making long-term supply agreements a defining characteristic of successful downstream transactions in the global cassava pulp market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.8 billion |

| Market Forecast in 2033 | USD 7.5 billion |

| Growth Rate | CAGR 6.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Tate & Lyle, Ingredion, Cargill, ADM, S.A. Cassava Products, Thai Wah Public Company Limited, Korasac, Emsland Group, Avebe, Tereos, Royal Ingredients Group, Manildra Group, Grain Processing Corporation, Bunge Loders Croklaan, Penford Corporation, Zhejiang E-Tong Starch Co., Ltd., Shubham Starch Chem Pvt. Ltd., Agrana Beteiligungs-AG, J. Rettenmaier & Söhne GmbH & Co. KG (JRS), Roquette Frères. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cassava Pulp Market Key Technology Landscape

The technological landscape of the Cassava Pulp Market is rapidly evolving, driven by the imperative to reduce energy consumption, enhance product safety, and unlock higher-value applications. Central to this evolution are advanced dewatering technologies designed to efficiently separate water from the fibrous mass immediately after starch extraction. High-efficiency screw presses and Decanter centrifuges are critical in reducing the moisture content substantially before thermal drying, significantly lowering the overall energy footprint of the production process. These mechanical separation techniques are foundational to achieving cost-competitive dried pulp, which is necessary for global trade and long-term storage, mitigating one of the industry's historical constraints.

Thermal processing represents another major technological focus, with modern facilities increasingly adopting sophisticated drying systems such as flash dryers and rotary dryers equipped with heat recovery systems. Flash drying is preferred for its ability to rapidly reduce moisture while minimizing heat damage to residual nutrients and ensuring microbiological stability. Furthermore, detoxification technologies are paramount; this includes controlled fermentation methods or specific heat treatments designed to volatilize and eliminate harmful cyanogenic compounds. The integration of these advanced drying and detoxification protocols ensures that the final cassava pulp product meets stringent international standards for use in animal feed and, increasingly, in human food applications.

Beyond physical processing, the implementation of sensor technology and automation is revolutionizing quality assurance and process control. Near-Infrared (NIR) spectroscopy sensors are now widely used for real-time measurement of key parameters such as residual starch, fiber content, and moisture levels, allowing immediate adjustments in the processing line. This level of precision is vital for producing specialized grades of pulp required for emerging markets like bioplastics and functional fiber ingredients. Moreover, pilot projects focusing on enzymatic hydrolysis and specialized microbial fermentation are opening pathways for converting the residual cellulose and hemi-cellulose in the pulp into valuable platform chemicals and biofuels, marking a significant technological shift toward bio-refinery integration.

Regional Highlights

The global distribution and consumption patterns of the Cassava Pulp Market are highly concentrated, reflecting the geographies of major cassava cultivation and starch processing operations.

- Asia Pacific (APAC): APAC is the global powerhouse for cassava pulp, dominating both production and consumption. Countries such as Thailand, Vietnam, and Indonesia are massive exporters of cassava starch, generating colossal volumes of pulp as a byproduct. The region’s extensive animal feed, paper, and textile industries provide a ready, robust local demand base. Strategic investments in large-scale processing infrastructure and favorable government policies towards commodity exports solidify APAC's leading position, making it the central hub for global pricing and innovation in pulp utilization.

- Latin America: This region, led by Brazil and Nigeria, holds a substantial share in global cassava cultivation. While historically focused on domestic consumption and smaller processing scales, Latin America is rapidly modernizing its starch and pulp processing capabilities. The region is increasingly important as a secondary global supplier, particularly leveraging its strong biofuel industry, where cassava pulp serves as a viable, cost-effective feedstock for ethanol production.

- Middle East and Africa (MEA): Africa is critical due to its massive cassava production capacity, though much of the processing remains decentralized. The market potential here is enormous, driven by rapidly growing domestic demand for animal feed due to expanding industrial farming. The key challenge remains the lack of advanced drying and storage infrastructure, which currently limits its contribution to global trade, focusing primarily on localized feed production.

- North America and Europe: These regions are net importers of cassava pulp, primarily consuming it as a specialty ingredient in high-performance paper, textile sizing, and as a component in certain niche animal feeds. Demand is driven by the search for specialized, non-GMO, and gluten-free fibrous components. While not producers, they dictate high-quality standards and drive demand for advanced, processed grades, including functional fiber derivatives.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cassava Pulp Market.- Tate & Lyle

- Ingredion

- Cargill

- ADM (Archer Daniels Midland Company)

- S.A. Cassava Products

- Thai Wah Public Company Limited

- Korasac

- Emsland Group

- Avebe

- Tereos

- Royal Ingredients Group

- Manildra Group

- Grain Processing Corporation

- Bunge Loders Croklaan

- Penford Corporation

- Zhejiang E-Tong Starch Co., Ltd.

- Shubham Starch Chem Pvt. Ltd.

- Agrana Beteiligungs-AG

- J. Rettenmaier & Söhne GmbH & Co. KG (JRS)

- Roquette Frères

Frequently Asked Questions

Analyze common user questions about the Cassava Pulp market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary commercial use of cassava pulp?

The primary commercial use of cassava pulp, also known as cassava bagasse, is in the formulation of animal feed. Its high fiber content and residual starch make it a cost-effective carbohydrate source and bulking agent for livestock, particularly in poultry and swine diets, after appropriate detoxification and drying processes.

How is the quality of cassava pulp determined for industrial applications?

Cassava pulp quality is predominantly determined by its moisture content, fiber-to-starch ratio, and safety compliance, specifically the residual level of cyanogenic glycosides. Low moisture content (typically 10-14%) is essential for stability, while industrial buyers require consistent particle size and certified detoxification levels for safe integration into production processes.

What technological advancements are crucial for the future growth of the cassava pulp market?

Crucial technological advancements involve energy-efficient dewatering (centrifugation/screw pressing) and drying systems (flash dryers) to reduce processing costs. Additionally, advanced valorization techniques, such as enzymatic hydrolysis and fermentation for bioplastic or functional fiber production, are vital for unlocking high-value market segments.

Which geographical region dominates the global supply and consumption of cassava pulp?

The Asia Pacific (APAC) region, driven by countries with large-scale cassava starch manufacturing like Thailand, Vietnam, and Indonesia, significantly dominates both the global supply and consumption of cassava pulp. This regional stronghold is supported by robust domestic demand from feed and paper industries.

What are the main restraints hindering the market potential of cassava pulp?

The main restraints are the high initial moisture content of the raw byproduct, necessitating substantial energy expenditure for drying, and the presence of cyanogenic compounds, which mandates strict, costly detoxification procedures to ensure safety compliance for feed and food applications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager