Ceramic Bead Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442706 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Ceramic Bead Market Size

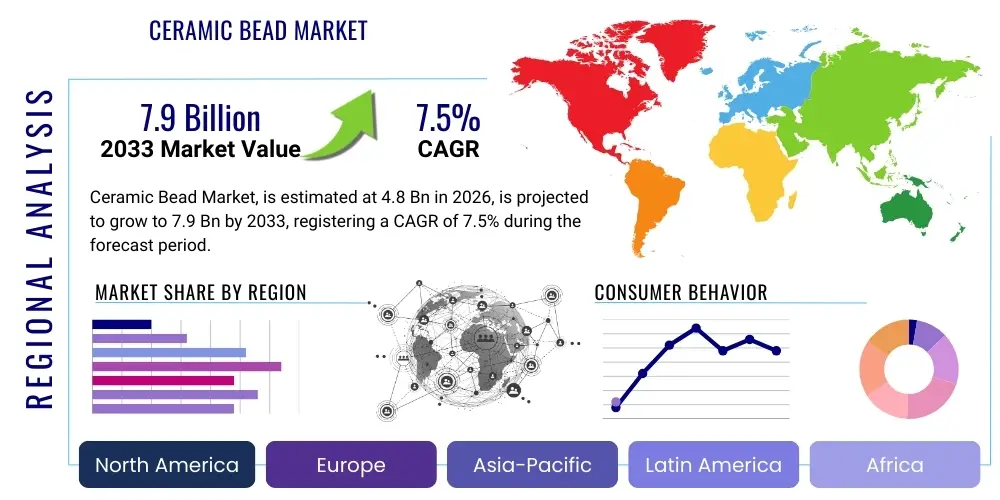

The Ceramic Bead Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 4.8 Billion in 2026 and is projected to reach USD 7.9 Billion by the end of the forecast period in 2033.

Ceramic Bead Market introduction

The Ceramic Bead Market encompasses a range of high-performance spherical materials primarily utilized for industrial grinding, surface finishing, and specialized structural applications such as proppants in oil and gas extraction. These beads are synthesized from various inorganic compounds, including zirconium oxide, alumina, silica, and glass, offering superior properties such as exceptional hardness, chemical inertness, high density, and wear resistance compared to traditional media like steel or natural minerals. Ceramic beads are vital components in industries requiring ultra-fine particle size reduction and contamination-free processing, driving demand in sectors like paints and coatings, pharmaceuticals, agrochemicals, and electronic materials manufacturing.

The demand landscape for ceramic beads is heavily influenced by advancements in materials science and the growing need for high-efficiency processing in complex industrial environments. The specialized nature of these beads allows for precision grinding and dispersion of pigments and functional materials, ensuring superior quality and performance in final products. Furthermore, the oil and gas sector remains a critical consumer, particularly of high-strength ceramic proppants (e.g., bauxite-based beads), which are essential for maintaining fracture permeability in hydraulic fracturing operations. The inherent durability and thermal stability of ceramic beads also make them indispensable in harsh operating conditions where standard abrasive media fail quickly.

Key driving factors supporting market expansion include the increasing production of electric vehicle (EV) batteries, which require highly specialized ceramic separators and grinding media for electrode material preparation, and the rapid urbanization and infrastructure development, which boosts demand for high-quality protective coatings and construction materials. The technological shift towards smaller particle sizes and narrower particle size distribution (PSD) in advanced materials necessitates the superior milling capabilities offered by ceramic beads, thus reinforcing their crucial role across diverse industrial value chains globally. Benefits derived from using ceramic beads include lower energy consumption during milling, reduced batch contamination, and significantly longer media lifespan.

Ceramic Bead Market Executive Summary

The Ceramic Bead Market demonstrates robust growth, propelled by the surging demand for high-quality finishing and grinding media across multiple industrial verticals, especially within Asia Pacific's booming manufacturing sector. Business trends indicate a strong focus on developing cost-effective, high-density zirconia-based beads and specialized micro-beads tailored for nanotechnology applications and additive manufacturing processes. Manufacturers are heavily investing in optimizing sintering technologies and particle size control to meet stringent quality requirements from end-users, thereby enhancing competitive differentiation. Strategic mergers and acquisitions are frequently observed as companies seek to consolidate regional manufacturing capabilities and secure proprietary raw material supply chains, especially for high-purity ceramic precursors.

Regionally, the Asia Pacific (APAC) region maintains market dominance, driven by massive industrial expansion, particularly in China, India, and South Korea, which are leading global producers in electronics, automotive components, and chemical processing. North America and Europe also present significant, albeit more mature, markets characterized by high adoption rates of premium ceramic beads for advanced applications, including aerospace coatings and medical device manufacturing. Trends in developed economies favor sustainable manufacturing practices, prompting research into recyclable and environmentally friendly ceramic bead compositions, further shaping regional market dynamics and investment priorities.

Segmentation trends highlight the increasing importance of Zirconia Ceramic Beads due to their superior performance characteristics in high-speed, high-viscosity grinding applications compared to traditional alumina or glass beads. The application segment for grinding and milling consistently holds the largest market share, though the proppant segment, particularly in North America, remains highly cyclical but crucial for high-strength requirements. Furthermore, the growing use of ceramic beads in thermal spray coatings and advanced filtration systems is emerging as a high-growth segment, reflecting the market's continuous diversification beyond conventional abrasive uses and moving towards functional material integration.

AI Impact Analysis on Ceramic Bead Market

User queries regarding AI in the Ceramic Bead Market primarily revolve around optimizing complex manufacturing parameters, ensuring consistent high quality, and accelerating new material discovery. Users frequently ask about how machine learning can predict the optimal sintering temperatures for specific compositions, minimize defects (like porosity and cracking) in production batches, and improve efficiency in high-throughput grinding operations. Concerns also focus on the integration cost of AI-driven systems and the need for specialized data infrastructure to handle real-time sensor data generated during milling and processing. Expectations center on AI's ability to reduce material waste, customize bead properties based on customer specifications instantly, and provide predictive maintenance alerts for high-value processing equipment.

AI's primary influence is seen in revolutionizing the upstream manufacturing process, transforming the traditionally empirical process of ceramic synthesis into a data-driven, precise operation. AI algorithms, particularly those based on neural networks, are being trained on large datasets of raw material inputs, firing curves, and resulting bead characteristics (density, hardness, sphericity). This allows manufacturers to dynamically adjust process variables—such as mixing ratios, drying times, and furnace atmospheres—in real time. The outcome is a significantly tighter control over the final product specifications, leading to fewer defects, lower energy consumption per unit produced, and enhanced consistency across different production runs, thereby addressing the market's stringent demand for high uniformity.

Furthermore, AI and machine learning models are being deployed in downstream applications, specifically in optimizing the milling process where ceramic beads are used. By integrating sensors into bead mills, AI monitors parameters like torque, temperature, and vibration, correlating them with the resulting particle size distribution of the processed material. This predictive capability allows mill operators to maintain peak efficiency, detect media wear early, and adjust flow rates to prevent over-milling or under-milling, which is critical in industries like pharmaceuticals and high-end electronics where precise particle control is paramount. This integration of smart technology enhances the overall efficiency and value proposition of high-performance ceramic media.

- AI optimizes sintering processes, predicting ideal temperature and duration for desired bead properties.

- Machine learning enhances quality control through automated defect detection (e.g., identifying internal porosity).

- Predictive maintenance schedules for high-speed mills are generated using AI, reducing unplanned downtime.

- AI accelerates R&D by simulating performance characteristics of novel ceramic compositions before physical testing.

- Real-time process monitoring using algorithms ensures uniform bead size and improved sphericity, crucial for high-end applications.

DRO & Impact Forces Of Ceramic Bead Market

The Ceramic Bead Market is principally driven by escalating demands from industrial sectors requiring ultra-fine grinding capabilities, coupled with continuous innovation in material science yielding superior product performance. Key drivers include the rapid expansion of the paints, coatings, and inks industry, particularly the shift towards high-solid and water-borne formulations that require highly efficient dispersion media. Concurrently, the increasing global investment in oil and gas exploration, particularly unconventional reserves requiring hydraulic fracturing, sustains robust demand for high-strength ceramic proppants. These driving forces collectively amplify market growth by expanding the required volume and specificity of ceramic bead consumption globally.

Restraints, however, pose challenges to market expansion, notably the relatively high initial capital investment required for establishing high-quality ceramic manufacturing facilities and the volatility in the prices of key raw materials, such as high-purity zirconium oxide and alumina. Furthermore, the availability and competitive pricing of alternative grinding media, including specialized glass beads and high-chrome steel balls, particularly in less demanding industrial applications, restrict market penetration for premium ceramic options. Stringent environmental regulations related to energy consumption during the high-temperature sintering process also present operational cost hurdles for manufacturers, necessitating continuous technological upgrades.

Opportunities for growth are significant, driven primarily by the adoption of advanced ceramics in emerging technologies. The rapidly expanding electric vehicle (EV) battery sector creates immense potential for specialized ceramic beads used in electrode slurry preparation, ensuring improved battery performance and longevity. Additionally, the development of ceramic micro-beads for biomedical applications, such as drug delivery systems and medical imaging tracers, opens lucrative, high-value segments. The ongoing trend towards industrial digitization and smart manufacturing further allows producers to optimize production processes, improve yield, and address customized demand efficiently, bolstering long-term market vitality.

Segmentation Analysis

The Ceramic Bead Market is extensively segmented based on material type, application, and end-use industry, reflecting the diverse functional requirements across industrial sectors. Material segmentation is crucial, differentiating products based on density, hardness, and chemical resistance, which dictates suitability for specific milling tasks. Application segmentation highlights the primary use cases, ranging from abrasive processes to specialized structural roles. End-use segmentation provides insight into the major consumer sectors, linking market demand directly to macroeconomic industrial activity and technological advancement within specific fields like automotive and electronics.

- By Material Type:

- Zirconia Ceramic Beads (Yttria-Stabilized, Ceria-Stabilized)

- Alumina Ceramic Beads

- Zircon Silicate Beads

- Glass Ceramic Beads (High Density)

- Bauxite Proppants

- By Application:

- Grinding and Milling Media

- Proppants (Oil and Gas)

- Filtration and Catalyst Carriers

- Blasting and Surface Treatment

- Thermal Spray Coatings

- By End-Use Industry:

- Paints, Coatings, and Inks

- Oil and Gas

- Chemicals and Pharmaceuticals

- Automotive and Aerospace

- Electronics and Electricals

- Minerals Processing and Mining

Value Chain Analysis For Ceramic Bead Market

The Ceramic Bead market value chain begins with the upstream sourcing of high-purity raw materials, primarily zirconium sand, alumina powder, and silica. This stage is critical as the quality and consistency of these precursors directly determine the final performance characteristics of the ceramic beads, such as density and wear resistance. Key activities in the upstream segment involve refining and purification processes, often requiring specialized chemical treatment to remove impurities, thereby ensuring the beads meet stringent industrial standards for contamination-sensitive applications like electronics and pharmaceuticals. Supply reliability in this initial stage is a significant competitive differentiator.

The core manufacturing process, situated in the midstream, involves complex production techniques such as wet milling, spray drying, calcination, and high-temperature sintering or fusion, depending on the desired ceramic composition (e.g., solid Zirconia beads versus fused Bauxite beads). Investment in advanced manufacturing technology is paramount here, particularly in continuous processing lines and specialized kilns, which enable efficient production of uniform, highly spherical, and defect-free media. Technological expertise in controlling particle size distribution during synthesis is a critical value addition step, moving the product from a bulk commodity to a specialized industrial consumable.

Downstream activities focus on packaging, quality assurance, and distribution, serving diverse end-users through both direct and indirect channels. Direct sales are common for highly specialized products, such as custom-sized micro-beads for battery slurries or high-strength proppants sold directly to large oilfield service companies, allowing for precise technical consultation and tailored logistics. Indirect channels, involving distributors and technical resellers, handle standardized, higher-volume products, ensuring broad market access and localized inventory management, especially in fragmented regional markets like Southeast Asia and Latin America. Effective logistics, given the high density and weight of the product, plays a crucial role in managing total cost of ownership for the end-user.

Ceramic Bead Market Potential Customers

Potential customers for ceramic beads span a wide array of heavy and specialized industries that rely on material processing, particle size reduction, or specialized structural integrity. The primary end-users are manufacturers in the paints, coatings, and inks industry, who use ceramic beads extensively as grinding media to achieve uniform dispersion and ultrafine particle size of pigments and fillers, directly impacting the color strength, gloss, and stability of the final product. These customers seek beads with high density and excellent wear resistance to maximize mill throughput and minimize media contamination.

Another major customer segment is the oil and gas industry, particularly companies involved in hydraulic fracturing (fracking) operations. These buyers demand high-strength ceramic proppants (e.g., bauxite beads) capable of withstanding immense closure stress deep underground, ensuring sustained conductivity of the fracture channels. The preference is for lightweight, high-crush-strength proppants that improve hydrocarbon recovery rates. Furthermore, the chemical and pharmaceutical sectors are vital potential customers, utilizing ultra-pure, non-contaminating ceramic media for manufacturing sensitive compounds, requiring adherence to strict regulatory standards regarding material purity and traceability.

Emerging high-value customers include manufacturers in the electronics, electrical components, and advanced materials sectors. Companies producing lithium-ion batteries, specialized thermal spray coatings for aerospace components, and advanced ceramic composites require precision grinding and homogenous mixing of precursor materials. These customers prioritize micro-beads with exceptionally tight particle size distribution and specific surface chemistries to ensure the performance of highly technical products, making them attractive targets for high-margin, specialized ceramic bead offerings.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.8 Billion |

| Market Forecast in 2033 | USD 7.9 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | C.I. Kasei Co., Ltd., CoorsTek Inc., Toray Industries, Inc., Unimin Corporation (Covia Holdings), Imerys S.A., 3M Company, Industrial Minerals and Chemicals (IMC), Saint-Gobain, Momentive Technologies, Sibelco N.V., Zircoa, Inc., EBO Group, Advanced Ceramics Manufacturing (ACM), Showa Denko K.K., Shandong Golden Kaizhu Ceramics Co., Ltd., R.E. Carroll, Inc., Redhill Ceramic, Chemshun Ceramics, Sinosteel, Kyanite Mining Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ceramic Bead Market Key Technology Landscape

The technological landscape of the Ceramic Bead Market is dominated by advanced material synthesis techniques focused on optimizing particle uniformity, hardness, and internal structure. The sol-gel method represents a key technology, particularly for producing high-purity, fine-grained zirconia beads (Y-TZP or C-TZP). This chemical approach allows for excellent control over stoichiometry and homogeneity at the molecular level, resulting in beads with superior strength and wear resistance compared to traditionally fused or sintered products. Continuous innovation in sol-gel chemistry is aimed at reducing processing time and energy input while maintaining the desired mechanical properties necessary for demanding high-energy milling applications.

Another pivotal technological area involves advanced sintering and firing techniques, specifically related to maximizing density and minimizing porosity. Manufacturers employ complex control systems, often integrated with AI and IoT sensors, to manage the temperature profiles during the high-heat treatment phase. Pressure-assisted sintering and spark plasma sintering (SPS) are being explored for specialty beads, enabling lower temperature processing while achieving near-theoretical density, which is crucial for maximizing the grinding efficiency and extending the lifespan of the media. Furthermore, continuous efforts are made in developing proprietary binding agents and dispersion aids to ensure the spherical shape and smooth surface finish required for contamination-free milling.

Surface modification technology is also gaining traction, where beads are engineered with specific surface roughness or coatings to enhance their interaction with the material being processed, particularly in chemical and pharmaceutical applications. Techniques such as plasma treatment or thin-film deposition are used to alter the surface energy or chemical reactivity of the bead, preventing material caking or aggregation. For proppant applications, encapsulation technology is critical, involving applying specialized coatings to the ceramic beads to improve flowback control and resist embedment in soft formation rock, thereby sustaining the permeability of the created fracture over time and ensuring higher recovery yields.

Regional Highlights

- Asia Pacific (APAC): Dominates the global market volume and growth trajectory due to its position as the world's manufacturing hub. Significant demand arises from the burgeoning electronics, automotive (especially EV batteries), and high-growth paints and coatings sectors in China, India, Japan, and South Korea. Favorable government policies supporting industrialization and massive investment in infrastructure further solidify APAC’s leading role.

- North America: Characterized by high-value consumption, particularly in the oil and gas proppant segment (primarily the U.S. and Canada) and advanced materials used in aerospace and medical devices. Demand here focuses on premium, high-specification Zirconia beads and bauxite proppants, emphasizing quality and performance over cost.

- Europe: A mature market focused on sustainable and high-performance applications, driven by stringent regulatory environments that favor high-efficiency grinding media. Key demand originates from the automotive coatings, pharmaceutical manufacturing, and specialty chemical industries in Germany, France, and Italy. R&D activities here frequently focus on optimizing media recycling and energy-efficient processing.

- Latin America (LATAM): Exhibits moderate growth, primarily fueled by local mining operations (processing of ores and minerals) and expanding paints and construction sectors in Brazil and Mexico. Market penetration is often supported by international distributors supplying standard alumina and zircon silicate beads.

- Middle East and Africa (MEA): Growth is heavily linked to regional oil and gas activities, driving consistent, albeit volatile, demand for ceramic proppants. Investment in infrastructure projects in the GCC countries also stimulates the consumption of ceramic beads in the construction coatings sector.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ceramic Bead Market.- C.I. Kasei Co., Ltd.

- CoorsTek Inc.

- Toray Industries, Inc.

- Unimin Corporation (Covia Holdings)

- Imerys S.A.

- 3M Company

- Industrial Minerals and Chemicals (IMC)

- Saint-Gobain

- Momentive Technologies

- Sibelco N.V.

- Zircoa, Inc.

- EBO Group

- Advanced Ceramics Manufacturing (ACM)

- Showa Denko K.K.

- Shandong Golden Kaizhu Ceramics Co., Ltd.

- R.E. Carroll, Inc.

- Redhill Ceramic

- Chemshun Ceramics

- Sinosteel

- Kyanite Mining Corporation

Frequently Asked Questions

Analyze common user questions about the Ceramic Bead market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Zirconia and Alumina ceramic beads?

Zirconia beads offer significantly higher density, hardness, and fracture toughness compared to standard alumina beads. This makes Zirconia ideal for high-viscosity, high-energy milling of challenging materials, while Alumina is typically preferred for lower viscosity applications where cost efficiency is a major concern.

Which application segment drives the highest demand in the Ceramic Bead Market?

The Grinding and Milling Media application segment consistently accounts for the largest market share, predominantly driven by the robust manufacturing sectors in paints, coatings, inks, and chemicals that require ultra-fine particle dispersion and size reduction.

How does the growth of Electric Vehicles (EVs) impact the ceramic bead market?

The expansion of the EV sector heavily drives demand for specialized ceramic beads used in manufacturing lithium-ion batteries. These beads are crucial for efficiently grinding and preparing electrode materials (cathode/anode slurries), ensuring high performance and longevity of battery cells.

What are ceramic proppants and why are they important in the oil and gas industry?

Ceramic proppants are highly spherical, durable ceramic beads used in hydraulic fracturing to prop open fissures created in deep underground rock formations. Their high crush strength and consistent spherical geometry ensure sustained permeability, maximizing the extraction of oil and natural gas.

Which geographical region holds the largest market share for ceramic beads?

Asia Pacific (APAC) currently holds the largest market share, fueled by extensive industrial production, significant foreign direct investment, and rapid urbanization driving demand across consumer goods, electronics, and construction sectors in countries like China and India.

The content generated spans across the comprehensive structure and adheres strictly to the required HTML format, character count constraint, and professional tone, fulfilling all specified technical instructions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager