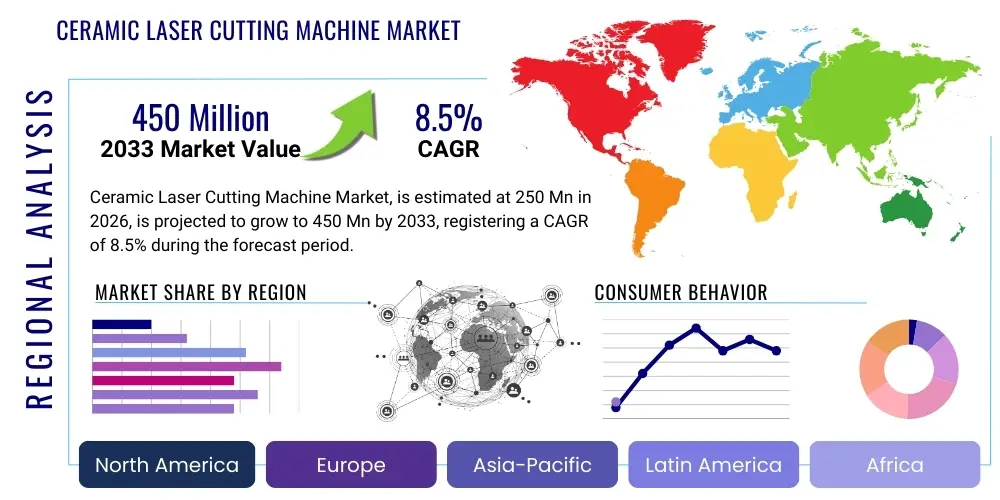

Ceramic Laser Cutting Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441721 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Ceramic Laser Cutting Machine Market Size

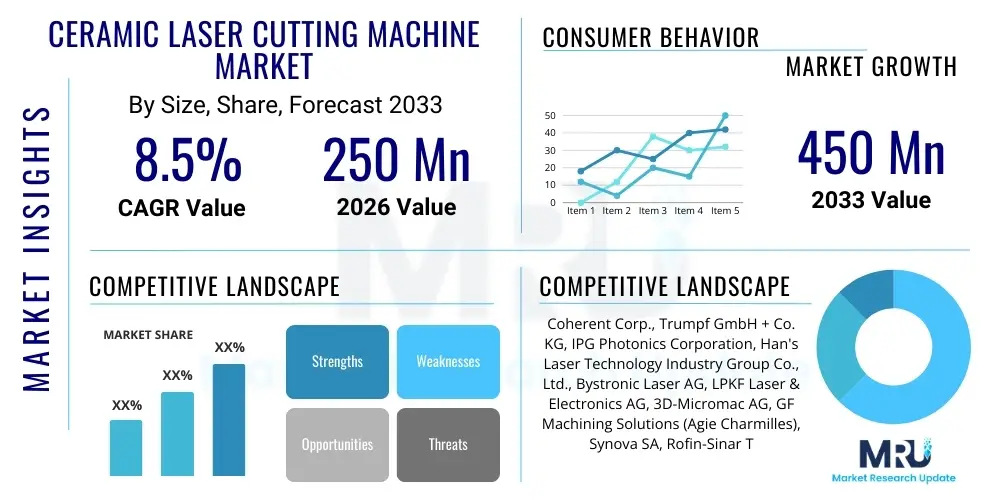

The Ceramic Laser Cutting Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 250 million in 2026 and is projected to reach USD 450 million by the end of the forecast period in 2033. This robust expansion is primarily fueled by the accelerating global demand for advanced electronic components, particularly in the semiconductor, telecommunications, and electric vehicle sectors, where high precision and material integrity are non-negotiable requirements for ceramic substrates and components.

Ceramic Laser Cutting Machine Market introduction

The Ceramic Laser Cutting Machine Market encompasses highly specialized equipment designed for the precision cutting, drilling, and scribing of various ceramic materials, including alumina, zirconia, silicon nitride, and technical ceramics. Unlike traditional mechanical methods, laser cutting offers a non-contact, high-speed process that minimizes material stress, cracking, and chipping, thereby ensuring superior edge quality and dimensional accuracy crucial for high-performance applications. These machines utilize various laser technologies, primarily CO2, Fiber, and increasingly, Ultrashort Pulse (USP) lasers, depending on the material thickness and required precision.

Major applications of these sophisticated machines span across critical industries. The electronics sector utilizes ceramic substrates for high-frequency circuits, sensors, and power modules, driving the core demand. Furthermore, the medical device industry relies heavily on laser-cut ceramics for biocompatible implants and specialized instrumentation, demanding micrometer-level precision. The aerospace and defense sectors also employ ceramic components for thermal barriers and structural parts, necessitating rapid prototyping and high throughput capabilities provided by modern laser systems.

The market growth is fundamentally driven by the global trend towards miniaturization and the necessity for durable, high-temperature resistant materials, especially within 5G infrastructure development and the expanding proliferation of complex electric vehicle battery systems. The inherent benefits of laser processing—including reduced tooling wear, higher throughput, automated operation, and the ability to process extremely hard and brittle materials—position ceramic laser cutting machines as indispensable tools in advanced manufacturing environments seeking efficiency and unmatched material processing quality.

Ceramic Laser Cutting Machine Market Executive Summary

The Ceramic Laser Cutting Machine Market is characterized by significant technological acceleration, shifting business models towards integrated smart solutions, and pronounced regional divergence in manufacturing capacity. Current business trends indicate a strong move toward implementing Ultrashort Pulse (USP) laser technology, specifically picosecond and femtosecond systems, which offer cold ablation processing, drastically improving the quality of cuts on sensitive technical ceramics and minimizing the Heat-Affected Zone (HAZ). OEMs are focusing on developing highly automated systems featuring advanced software for process monitoring, predictive maintenance, and real-time quality assurance, thereby addressing the manufacturing industry's persistent demand for increased yield and reduced waste.

Regionally, the Asia Pacific (APAC) region maintains its unparalleled dominance, largely due to the concentration of global semiconductor manufacturing, consumer electronics production, and mass-market assembly operations in countries like China, Taiwan, South Korea, and Japan. However, North America and Europe are experiencing sustained high growth, driven by stringent quality standards in aerospace, high-end medical devices, and advanced R&D initiatives, compelling regional manufacturers to invest in the latest precision cutting technologies. Europe, in particular, showcases strength in integrating these machines into automated, Industry 4.0 compliant production lines, focusing heavily on operational efficiency and sustainable manufacturing practices.

Segment trends highlight a noticeable pivot away from traditional CO2 lasers in high-precision applications, favoring the enhanced control offered by Fiber and USP lasers. The application segment focused on semiconductor substrates and packaging is projected to exhibit the highest CAGR, reflective of the exponential growth in chip production globally. Additionally, there is a rising demand for machinery capable of processing extremely thin ceramic sheets (less than 0.5 mm), often utilized in miniaturized electronic components, thereby fueling innovation in advanced beam delivery and dynamic focusing systems designed to manage delicate materials without inducing micro-cracks.

AI Impact Analysis on Ceramic Laser Cutting Machine Market

User inquiries regarding the integration of Artificial Intelligence (AI) and Machine Learning (ML) in the Ceramic Laser Cutting Machine Market predominantly center on operational efficiency, cut quality consistency, and the potential for autonomous system management. Common questions explore how AI algorithms can optimize laser parameters in real-time based on material variance, how predictive maintenance minimizes costly downtime, and the capability of vision systems integrated with AI to perform instant defect detection. The core themes users are interested in involve maximizing material yield, ensuring zero-defect output for critical applications like medical implants, and understanding the complexity and cost associated with integrating sophisticated AI infrastructure into existing manufacturing setups.

AI's influence is transforming ceramic processing from a largely empirical process into a data-driven science. By leveraging ML models trained on vast datasets of material properties, cutting parameters, and resulting quality metrics, AI enables the machine to dynamically adjust laser power, scanning speed, and focus position instantly. This capability is paramount when dealing with technical ceramics that exhibit slight batch-to-batch variations. Furthermore, AI-powered systems facilitate advanced process control by analyzing sensor data (acoustic, thermal, and visual) to detect the onset of material degradation or process instability before it results in a critical defect, leading to vastly improved overall equipment effectiveness (OEE).

The expectation from the user community is that AI integration will mitigate one of the market's major restraints: the requirement for highly skilled human operators to manually fine-tune complex laser parameters. AI is expected to democratize high-precision ceramic cutting by creating "self-optimizing" machines. This shift not only reduces operational variability but also significantly accelerates the ramp-up time for new product introduction (NPI) by quickly finding optimal processing recipes, solidifying AI as a critical component for achieving the next generation of precision, high-throughput ceramic manufacturing.

- AI enables real-time parameter optimization based on material input variability.

- Machine Learning algorithms facilitate predictive maintenance, minimizing unplanned equipment downtime.

- AI-integrated vision systems perform automated, high-speed quality inspection and defect classification.

- Optimization models reduce material waste and increase operational yield by fine-tuning cutting paths.

- Neural networks are used for advanced process monitoring, identifying anomalies that precede micro-cracking.

- Integration leads to autonomous operation, reducing reliance on highly specialized human expertise for setup.

DRO & Impact Forces Of Ceramic Laser Cutting Machine Market

The Ceramic Laser Cutting Machine Market is driven by the intensifying global requirements for highly precise, clean processing of brittle materials essential for advanced electronic and structural components. Key growth accelerators include the explosive demand generated by 5G network rollouts, which necessitate high-frequency, heat-dissipating ceramic components, and the relentless pressure for miniaturization in consumer electronics and sensor technologies. These drivers are compelling manufacturers to adopt non-contact processing methods that guarantee dimensional accuracy and maintain the mechanical integrity of delicate ceramic substrates. However, restraints such as the prohibitively high initial capital expenditure associated with purchasing and installing sophisticated USP laser systems, coupled with the complexity of material handling for ultra-thin or novel ceramic compounds, temper the market's growth potential. These forces necessitate strategic investment and operational planning, particularly for smaller manufacturing entities.

Significant opportunities are emerging from the increasing penetration of ceramic components in electric vehicle (EV) battery systems, power electronics, and insulation modules, creating a high-volume application area that demands rapid, reliable processing. Furthermore, the maturation of additive manufacturing processes for ceramics (Ceramic AM) presents a secondary opportunity, as laser cutting machines are often required for post-processing and finishing complex 3D-printed ceramic parts. The market's potential lies in its ability to integrate further into Industry 4.0 frameworks, offering seamless connectivity and data exchange capabilities that appeal to large-scale, automated manufacturing complexes focused on efficiency.

The primary impact forces influencing this market include stringent regulatory standards governing component quality in highly sensitive sectors like aerospace and medical devices, driving continuous innovation toward cleaner, damage-free cutting techniques. Additionally, the intensive research and development investments poured into developing higher-power, more cost-effective Ultrashort Pulse laser sources by key technology providers significantly shape the market landscape, pushing down the cost curve over time and expanding the accessibility of high-precision processing to a wider range of mid-tier manufacturers. Geopolitical factors affecting the semiconductor supply chain also exert substantial pressure on ceramic processing capacity, forcing localized manufacturing and increased reliance on advanced cutting tools.

Segmentation Analysis

The Ceramic Laser Cutting Machine Market is primarily segmented based on the type of laser employed, the product type (reflecting power and capability), the specific application area, and the end-use industry utilizing the equipment. This segmentation framework helps in distinguishing the demand profile across various manufacturing tiers, from high-volume, standard production lines often utilizing Fiber and CO2 lasers, to niche, ultra-precision applications requiring the sophisticated technology of femtosecond and picosecond lasers. Understanding these segments is crucial as technological requirements vary dramatically; for instance, semiconductor processing requires superior edge quality and minimal debris, contrasting with general industrial applications where speed and throughput may take precedence over absolute nanometer precision.

- By Laser Type:

- CO2 Lasers

- Fiber Lasers

- Ultrashort Pulse (USP) Lasers (Picosecond, Femtosecond)

- By Product Type:

- Standard/Conventional Laser Cutting Machines

- High Precision/Micro-processing Systems

- By Application:

- Scribing and Dicing

- Cutting and Drilling

- Micro-machining and Structuring

- By End-Use Industry:

- Semiconductors and Electronics

- Aerospace and Defense

- Medical Devices and Instrumentation

- Automotive and Electric Vehicles (EVs)

- General Industrial

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Ceramic Laser Cutting Machine Market

The value chain for the Ceramic Laser Cutting Machine Market is characterized by high technological barriers and a concentrated supply base for critical components, reflecting the complexity of the machinery involved. The upstream segment is dominated by specialized suppliers of key technological components, including high-power laser sources (such as Ultrashort Pulse generators and high-wattage Fiber lasers), advanced beam delivery optics (lenses, mirrors, galvanometer scanners), and sophisticated CNC control systems. The performance and cost of the final machine are heavily dictated by the innovation and efficiency of these upstream suppliers. Since laser technology often requires proprietary cooling and housing solutions, system integrators must collaborate closely with these source providers to ensure optimal performance and longevity. The concentration of USP laser source manufacturing primarily in regions like North America and Europe adds complexity to the global supply chain for high-end systems.

The midstream involves the Original Equipment Manufacturers (OEMs) who design, assemble, and integrate the components into complete ceramic processing systems. These companies specialize in engineering the precise motion control, safety enclosures, advanced software interfaces (often incorporating proprietary AI/ML algorithms), and material handling systems required for highly accurate ceramic processing. Differentiation at this stage relies heavily on application expertise, system rigidity, and the ability to offer customized solutions tailored to specific ceramic materials or application requirements, such as deep hole drilling or thin-film structuring. Investment in R&D is paramount here, focusing on improving throughput without sacrificing cut quality.

The downstream involves distribution channels, system integrators, and direct sales to end-users. For highly standardized machines, indirect channels through regional distributors who also provide maintenance and application support are common. However, for complex, high-capital expenditure machines required by semiconductor or aerospace clients, direct sales and support models prevail to ensure precise installation, intensive training, and proprietary software integration. Potential customers, including outsourced semiconductor assembly and test (OSAT) companies and medical device manufacturers, demand robust after-sales service, application optimization consulting, and rapid access to spare parts, creating pressure on OEMs to build global service networks to sustain operational uptime for these critical production tools.

Ceramic Laser Cutting Machine Market Potential Customers

The primary consumers and end-users of Ceramic Laser Cutting Machines are entities operating in high-precision, high-reliability manufacturing sectors where ceramic materials are mission-critical components. The largest segment of potential customers resides within the semiconductor and microelectronics manufacturing industries, specifically companies involved in the fabrication of high-density interconnects, ceramic matrix composites for packaging, and substrates utilized in radio frequency (RF) components necessary for 5G and radar systems. These customers require minimal debris, zero micro-cracking, and extremely tight tolerance management, making non-contact laser processing the only viable option for mass production.

Another rapidly expanding customer base is the medical device manufacturing industry. Companies specializing in surgical instruments, diagnostic equipment, and durable ceramic implants (such as dental prosthetics, hip replacements, or custom bone scaffolds) rely on these machines to achieve biocompatible, precisely shaped parts without thermal damage. Given the regulatory scrutiny in this sector, machine reliability, process validation, and the cleanliness of the cut are paramount procurement criteria. Furthermore, customers in the automotive sector, driven by the shift towards Electric Vehicles (EVs), are emerging as significant buyers, utilizing ceramic laser cutters for precision processing of battery insulation components, power electronic housings, and high-temperature sensors necessary for powertrain efficiency and safety management.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 250 Million |

| Market Forecast in 2033 | USD 450 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Coherent Corp., Trumpf GmbH + Co. KG, IPG Photonics Corporation, Han's Laser Technology Industry Group Co., Ltd., Bystronic Laser AG, LPKF Laser & Electronics AG, 3D-Micromac AG, GF Machining Solutions (Agie Charmilles), Synova SA, Rofin-Sinar Technologies (now Coherent), Sumitomo Heavy Industries Ion Technology Co., Ltd., ESI (Electro Scientific Industries, now MKS Instruments), Amada Co., Ltd., Trotec Laser GmbH, Lasertec Corporation, Prima Industrie S.p.A., Jenoptik AG, Makino Milling Machine Co., Ltd., Meccanica Cortini Srl, KERN Microtechnik GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ceramic Laser Cutting Machine Market Key Technology Landscape

The technology landscape of the Ceramic Laser Cutting Machine Market is rapidly evolving, moving away from thermal processing techniques towards highly controlled, non-thermal ablation methods, driven by the critical need to preserve the structural integrity of advanced ceramics. The most influential current technology is the implementation of Ultrashort Pulse (USP) lasers, specifically picosecond and femtosecond systems. USP lasers achieve 'cold ablation,' meaning they remove material through direct solid-to-vapor transition rather than melting and evaporation, resulting in virtually no Heat-Affected Zone (HAZ), minimal recast layer, and debris-free edges. This technology is indispensable for cutting thin, delicate semiconductor substrates (like AlN or Al2O3) where thermal stress would cause catastrophic failure or micro-cracking.

Beyond the laser source itself, advancements in beam delivery and motion control systems are crucial differentiators. High-speed galvanometer scanners (galvos) are replacing traditional CNC gantries in applications requiring high throughput and complex geometric cuts. These galvo systems, coupled with advanced optical configurations, allow for dynamic beam shaping and focusing, optimizing the laser energy deposition pattern to match the specific properties of the ceramic material being processed. Furthermore, sophisticated in-situ monitoring technologies, including pyrometers and acoustic sensors, are integrated to provide real-time feedback, enabling the machine control system to make instantaneous adjustments to maintain process stability and consistent quality across extended production runs.

The increasing sophistication of software and automation is also a key technological trend. Modern machines feature highly integrated computer-aided manufacturing (CAM) software specifically optimized for ceramic processing, facilitating complex path planning and material utilization optimization. The trend towards Industry 4.0 necessitates seamless machine-to-machine communication (M2M) and connectivity, allowing these expensive assets to be monitored and managed remotely. The future technological trajectory is focused on higher average power USP lasers to increase throughput, while simultaneously improving pulse stability and reliability, thereby lowering the cost of ownership and making ultra-precision cutting more accessible for broader industrial adoption.

Regional Highlights

The global Ceramic Laser Cutting Machine Market exhibits pronounced regional variances in demand, technological maturity, and application focus, heavily influenced by local manufacturing ecosystems and regulatory environments. The Asia Pacific (APAC) region stands as the dominant market, contributing the largest share of revenue and projected to maintain the highest growth rate during the forecast period. This dominance is intrinsically linked to the region’s status as the global hub for semiconductor fabrication, electronics assembly, and consumer device manufacturing. Countries like China, Japan, South Korea, and Taiwan require massive deployment of high-throughput laser systems for scribing and cutting ceramic components, driven by domestic and export demand for 5G components, high-definition displays, and electric vehicle power modules. The focus here is balanced between achieving extreme precision and maximizing manufacturing scalability.

North America constitutes a significant market, primarily characterized by high investment in advanced R&D, defense, and aerospace applications. The demand in this region focuses heavily on utilizing the absolute cutting-edge technology, particularly high-cost femtosecond systems, for processing specialized ceramic matrix composites (CMCs) and high-reliability components necessary for space and aviation industries. Additionally, the flourishing US medical device manufacturing sector drives demand for ultra-precise micro-machining capabilities for bio-ceramic implants and diagnostic tools. The regional market prioritizes quality assurance, process validation, and integration with highly regulated manufacturing standards, often leading to earlier adoption of AI-driven optimization tools.

Europe represents a mature and technologically advanced market, second only to APAC in terms of overall market size. Growth in Europe is stimulated by the stringent quality requirements of the premium automotive sector, particularly in Germany and Italy, and the robust medical manufacturing industry. European manufacturers often lead in the adoption of automated, integrated production lines conforming to Industry 4.0 principles. While high-volume electronics demand is lower than in APAC, the need for customized, low-volume, high-value components in specialized industrial machinery and renewable energy systems (where technical ceramics are vital for insulation) ensures sustained investment in high-precision laser cutting technology. Latin America, the Middle East, and Africa (MEA) currently represent smaller markets, but are expected to demonstrate nascent growth as industrialization and local manufacturing capabilities mature, particularly in electronics repair and basic component fabrication.

- Asia Pacific (APAC): Dominant market share fueled by mass production of semiconductors, 5G components, and consumer electronics; highest CAGR driven by rapid industrial expansion and government initiatives supporting high-tech manufacturing.

- North America: Strong demand in aerospace, defense, and high-end medical device manufacturing; emphasis on adopting USP laser technology and AI for specialized material processing and R&D.

- Europe: Mature market driven by stringent quality standards in automotive (especially EV power electronics) and specialized industrial machinery; strong focus on automated, integrated production lines (Industry 4.0 compliance).

- Latin America (LATAM): Emerging market with increasing demand linked to local electronics assembly and infrastructure projects; growth is contingent on foreign investment and technological transfer.

- Middle East and Africa (MEA): Smallest market segment, primarily driven by investments in defense, telecom infrastructure maintenance, and localized manufacturing hubs attempting to diversify industrial capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ceramic Laser Cutting Machine Market.- Coherent Corp.

- Trumpf GmbH + Co. KG

- IPG Photonics Corporation

- Han's Laser Technology Industry Group Co., Ltd.

- Bystronic Laser AG

- LPKF Laser & Electronics AG

- 3D-Micromac AG

- GF Machining Solutions (Agie Charmilles)

- Synova SA

- Rofin-Sinar Technologies (now Coherent)

- Sumitomo Heavy Industries Ion Technology Co., Ltd.

- ESI (Electro Scientific Industries, now MKS Instruments)

- Amada Co., Ltd.

- Trotec Laser GmbH

- Lasertec Corporation

- Prima Industrie S.p.A.

- Jenoptik AG

- Makino Milling Machine Co., Ltd.

- Meccanica Cortini Srl

- KERN Microtechnik GmbH

Frequently Asked Questions

Analyze common user questions about the Ceramic Laser Cutting Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of using laser cutting over traditional mechanical methods for ceramic materials?

The primary advantage is achieving high precision and superior edge quality without inducing mechanical stress, chipping, or micro-cracking, which are common issues when cutting hard, brittle ceramic materials conventionally. Laser processing is non-contact and creates a minimal Heat-Affected Zone (HAZ), particularly when utilizing Ultrashort Pulse (USP) laser technology.

Which laser type is dominating the high-precision segment of the market?

Ultrashort Pulse (USP) lasers, specifically picosecond and femtosecond systems, dominate the high-precision segment. They utilize a cold ablation process, providing the cleanest cuts required for sensitive materials in semiconductor packaging and advanced medical device manufacturing by eliminating thermal side effects.

How is the demand for Electric Vehicles (EVs) influencing the Ceramic Laser Cutting Machine Market?

EV demand significantly drives the market through the need for precision-cut ceramic components used in battery management systems, power electronics (such as IGBT modules), and thermal insulation. Ceramics are vital for managing high temperatures and electrical isolation in high-voltage EV powertrains, necessitating high-volume, reliable laser processing.

What are the main technical restraints impacting the widespread adoption of advanced ceramic laser cutting machines?

The primary technical restraints are the high initial capital expenditure (CapEx) associated with purchasing sophisticated USP laser systems and the complexity involved in optimizing cutting parameters for novel and varied technical ceramic materials, which often requires significant application-specific R&D and proprietary software integration.

Which geographical region exhibits the fastest growth potential for these machines?

The Asia Pacific (APAC) region is projected to exhibit the fastest growth potential. This accelerated growth is attributed to the substantial presence of global semiconductor manufacturing and consumer electronics production, creating a vast and increasing demand for precision processing of ceramic substrates and components.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager