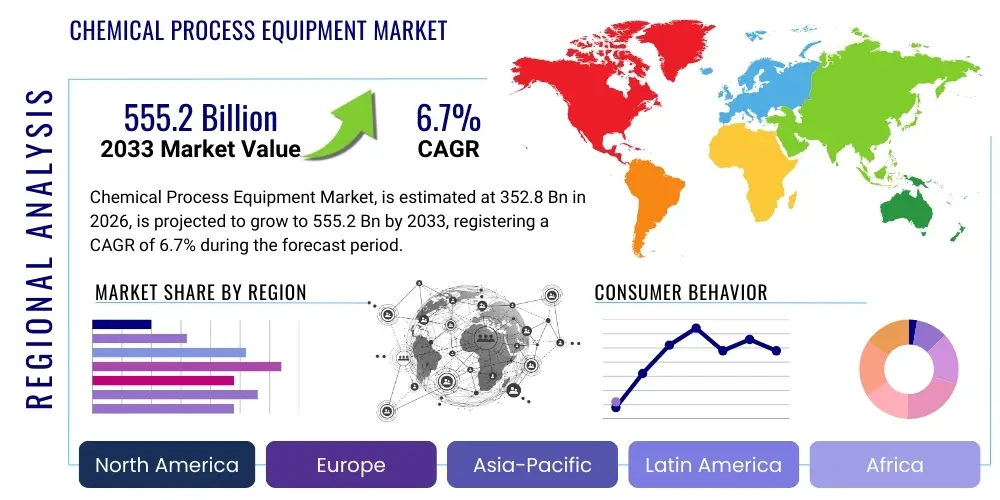

Chemical Process Equipment Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440726 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Chemical Process Equipment Market Size

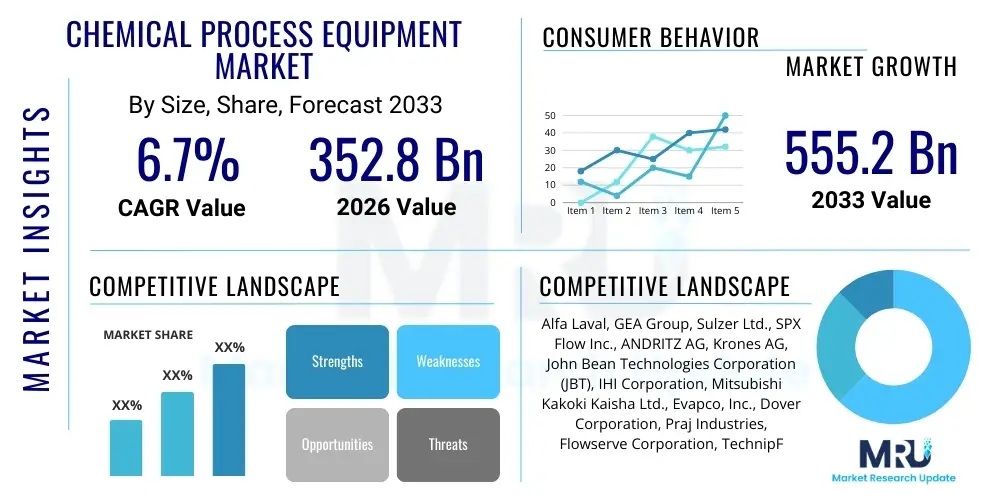

The Chemical Process Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% between 2026 and 2033. The market is estimated at USD 352.8 billion in 2026 and is projected to reach USD 555.2 billion by the end of the forecast period in 2033.

Chemical Process Equipment Market introduction

The Chemical Process Equipment Market encompasses a wide range of machinery, devices, and systems crucial for facilitating chemical reactions, separations, heat transfers, and fluid handling operations across various industries. This equipment is fundamental to transforming raw materials into finished chemical products, intermediates, or byproducts through physical and chemical changes. It includes items such as reactors, heat exchangers, pumps, valves, filters, centrifuges, evaporators, and dryers, all designed to operate under specific conditions of temperature, pressure, and material compatibility.

Major applications for chemical process equipment span diverse sectors including chemicals, petrochemicals, pharmaceuticals, food and beverage, water and wastewater treatment, and metallurgy. This equipment is essential for processes like synthesis, distillation, crystallization, filtration, mixing, and drying, enabling the production of everything from bulk chemicals and specialty polymers to life-saving drugs and processed foods. The benefits derived from advanced chemical process equipment include enhanced operational efficiency, improved product quality and consistency, reduced energy consumption, increased safety standards, and greater scalability in production.

Driving factors for the Chemical Process Equipment Market include the continuous growth and expansion of end-use industries, particularly in emerging economies. Technological advancements leading to more efficient, durable, and sustainable equipment designs also play a significant role. Furthermore, stringent environmental regulations necessitating cleaner production processes and waste reduction, coupled with the rising demand for specialized chemicals and advanced materials, are propelling market growth and innovation. The push for automation and digitalization in manufacturing further contributes to the demand for modern, integrated process solutions.

Chemical Process Equipment Market Executive Summary

The Chemical Process Equipment Market is experiencing dynamic shifts driven by global industrial expansion, technological innovation, and evolving regulatory landscapes. Key business trends point towards an increasing adoption of modular and customizable equipment solutions, driven by the need for flexibility and accelerated project timelines. There is also a strong emphasis on integrating advanced automation and digitalization technologies, such as IoT and AI, to optimize process control, enhance predictive maintenance capabilities, and improve overall operational efficiency. Sustainability initiatives are further shaping the market, with demand growing for energy-efficient equipment and those capable of facilitating green chemistry processes, reducing waste, and minimizing environmental impact across various industries.

Regional trends highlight the Asia Pacific region as a primary growth engine, fueled by rapid industrialization, significant investments in new chemical and pharmaceutical manufacturing capacities, and expanding infrastructure development in countries like China, India, and Southeast Asia. North America and Europe, while mature markets, continue to demonstrate steady demand driven by stringent regulatory compliance, technological upgrades, and a focus on high-value, specialized chemical production. Latin America and the Middle East & Africa are emerging markets, witnessing growth through investments in petrochemical complexes, mining, and water treatment facilities, spurred by local resource development and industrial diversification efforts. Each region's unique economic and regulatory environment influences the type and scale of equipment demanded.

Segmentation trends indicate robust growth in certain equipment categories and end-use sectors. For instance, advanced reactor designs capable of handling complex chemistries and extreme conditions are in high demand across specialty chemical and pharmaceutical industries. The need for efficient separation and filtration technologies is also escalating due to tightening purity standards and environmental regulations. In terms of materials, high-performance alloys and non-metallic composites are gaining traction for their corrosion resistance and durability in harsh operating environments. Furthermore, the pharmaceutical and food & beverage sectors are consistently driving demand for sterile, hygienic, and compliant equipment, emphasizing stainless steel and clean-in-place (CIP) compatible designs. This granular demand dictates specific innovation pathways within the market.

AI Impact Analysis on Chemical Process Equipment Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize the chemical process equipment sector, seeking insights into its potential for enhancing efficiency, safety, and predictive capabilities. Common questions revolve around AI’s role in optimizing process parameters, enabling predictive maintenance to minimize downtime, and improving equipment design through advanced simulations. There is also keen interest in how AI can integrate with existing systems to provide real-time operational insights, leading to more sustainable and cost-effective production. Concerns often include the initial investment costs, the complexity of implementation, data security, and the need for a skilled workforce capable of managing AI-driven systems. Users anticipate AI will drive a paradigm shift towards smarter, more autonomous, and adaptive process environments.

- Enhanced predictive maintenance and fault detection, reducing unplanned downtime.

- Optimization of process parameters and control systems for improved efficiency and yield.

- Accelerated R&D and design of new equipment through simulation and material informatics.

- Real-time monitoring and anomaly detection for increased operational safety.

- Automated quality control and process adjustment, ensuring product consistency.

- Supply chain optimization and inventory management for spare parts.

- Energy consumption reduction through intelligent process scheduling and control.

DRO & Impact Forces Of Chemical Process Equipment Market

The Chemical Process Equipment Market is profoundly influenced by a complex interplay of drivers, restraints, and opportunities, alongside significant impact forces. Key drivers include the relentless expansion of end-use industries, particularly in pharmaceuticals, specialty chemicals, and petrochemicals, which necessitate continuous investment in new and upgraded processing capabilities. Technological advancements, such as process intensification, modularization, and the integration of smart technologies, further propel demand by offering more efficient and sustainable solutions. Moreover, stringent global environmental regulations mandating cleaner production, reduced emissions, and improved resource efficiency compel industries to adopt advanced equipment and optimize existing processes, thereby stimulating market growth. The increasing demand for customized and high-performance equipment tailored to specific chemical applications also acts as a strong driver.

However, the market faces several significant restraints. The substantial capital expenditure required for the procurement and installation of sophisticated chemical process equipment poses a significant barrier, especially for smaller players or in economically volatile regions. Fluctuations in raw material prices, particularly for specialized metals and alloys used in equipment manufacturing, can lead to increased production costs and impact market stability. The complex and evolving regulatory landscape, coupled with diverse international standards, can create compliance challenges and increase time-to-market for new technologies. Furthermore, a shortage of skilled labor proficient in operating, maintaining, and integrating advanced process equipment can hinder market potential and efficient deployment of new systems. The long operational lifespan of existing equipment also somewhat dampens the demand for frequent replacements.

Opportunities within the market are abundant, primarily stemming from the growing adoption of digitalization and automation across industrial sectors. The advent of Industry 4.0, IoT, and AI presents avenues for developing smart, connected equipment that offers enhanced monitoring, predictive analytics, and autonomous operation. The increasing focus on sustainability and green chemistry provides opportunities for manufacturers to innovate in energy-efficient designs, waste reduction technologies, and equipment suitable for biorefineries and circular economy models. Furthermore, the expansion into emerging markets, where industrial infrastructure is still developing, offers significant untapped potential for new equipment sales and service provisions. The demand for modular and compact processing units, facilitating quicker deployment and easier scaling, also presents a lucrative niche for innovation and market penetration. Strategic collaborations and mergers among market players can also unlock new technological capabilities and broaden market reach.

Segmentation Analysis

The Chemical Process Equipment Market is comprehensively segmented across various dimensions to reflect its diverse applications and technological nuances. These segmentations provide a granular view of market dynamics, enabling a better understanding of demand patterns, technological preferences, and competitive landscapes. Analyzing the market through these segments helps identify high-growth areas, specific end-user needs, and opportunities for product innovation and market penetration. Each segment and sub-segment highlights distinct requirements concerning material specifications, operational parameters, and compliance standards, critical for both manufacturers and end-users.

- By Equipment Type

- Reactors (Batch Reactors, Continuous Reactors, Bioreactors, Photoreactors)

- Heat Exchangers (Shell & Tube, Plate, Finned Tube, Air Cooled)

- Pumps & Valves (Centrifugal Pumps, Positive Displacement Pumps, Control Valves, Safety Valves)

- Filtration Equipment (Membrane Filters, Cartridge Filters, Bag Filters, Pressure Filters)

- Mixing Equipment (Agitators, Blenders, Static Mixers, High Shear Mixers)

- Dryers (Fluidized Bed Dryers, Spray Dryers, Vacuum Dryers, Tray Dryers)

- Separation Equipment (Distillation Columns, Evaporators, Centrifuges, Crystallizers)

- Storage Tanks & Vessels

- Material Handling Equipment

- Others (Compressors, Chillers)

- By Material of Construction

- Stainless Steel

- Carbon Steel

- Alloys (Nickel Alloys, Titanium, Hastelloy)

- Non-metallic (Plastics, Ceramics, Glass-lined)

- By End-Use Industry

- Chemicals (Commodity Chemicals, Specialty Chemicals, Agrochemicals)

- Petrochemicals & Refineries

- Pharmaceuticals & Biotechnology

- Food & Beverage

- Water & Wastewater Treatment

- Pulp & Paper

- Power Generation

- Metallurgy & Mining

- Others

- By Operation Type

- Batch Operation

- Continuous Operation

Value Chain Analysis For Chemical Process Equipment Market

The value chain for the Chemical Process Equipment Market begins with upstream activities, primarily involving the sourcing and processing of raw materials. This includes suppliers of various metals such as stainless steel, carbon steel, and specialized alloys like nickel and titanium, which form the core structural components of the equipment. Additionally, manufacturers of non-metallic materials like high-performance plastics, ceramics, and glass linings, essential for corrosion resistance and specific process requirements, are crucial. Component manufacturers, providing specialized parts like seals, gaskets, motors, sensors, and control system elements, also form a significant part of the upstream segment. The quality and availability of these raw materials and components directly impact the final product's performance, durability, and cost-effectiveness.

Moving downstream, the value chain extends to the end-users who integrate this equipment into their chemical processes. These end-users span a wide array of industries including large-scale chemical manufacturing plants, petrochemical refineries, pharmaceutical production facilities, food processing units, and municipal water treatment plants. The integration often involves complex engineering, procurement, and construction (EPC) services, where specialized firms design, build, and commission entire processing units or facilities. Post-installation, the downstream activities include maintenance, repair, and overhaul (MRO) services, as well as the provision of spare parts, ensuring the long-term operational efficiency and safety of the equipment. Technical support and operational training are also critical components delivered to the end-user.

The distribution channel for chemical process equipment involves a mix of direct and indirect sales strategies. Direct sales are common for large, complex, and customized equipment where manufacturers engage directly with major clients, often involving extensive consultation, design, and after-sales support. This approach allows for close collaboration and tailored solutions. Indirect channels typically involve a network of distributors, agents, and engineering procurement construction (EPC) contractors who serve as intermediaries, especially for standardized equipment or when catering to a broader market and smaller clients. These intermediaries often provide local expertise, logistics, and first-line technical support. The choice of distribution channel often depends on the equipment's complexity, the size of the client, and the geographical reach of the manufacturer, balancing efficiency with personalized service delivery.

Chemical Process Equipment Market Potential Customers

Potential customers for the Chemical Process Equipment Market are diverse, encompassing a broad spectrum of industrial sectors that rely on chemical and physical transformations of materials. These end-users are typically large-scale manufacturing enterprises or utility providers with continuous production needs, seeking robust, efficient, and compliant equipment. Key customers include companies engaged in the production of basic and specialty chemicals, where process vessels, reactors, and separation units are fundamental to their operations. Petrochemical refineries also represent a significant customer base, requiring high-pressure and high-temperature equipment for crude oil processing and derivative production. The pharmaceutical and biotechnology industries demand highly specialized, sterile, and precision-engineered equipment for drug synthesis, fermentation, and purification processes, adhering to stringent regulatory standards.

Beyond the core chemical sectors, the food and beverage industry is a substantial consumer, utilizing process equipment for mixing, heating, cooling, separation, and drying in the production of various food products and beverages, with a strong emphasis on hygiene and material compatibility. Water and wastewater treatment plants are also critical buyers, employing filtration, clarification, and disinfection equipment to manage water resources and environmental compliance. Additionally, industries such as pulp and paper, power generation (particularly for flue gas desulfurization systems and water treatment), and metallurgy and mining, which utilize chemical processes for extraction and refinement, also represent significant market segments. The growing demand for sustainable and green technologies is expanding the customer base to include emerging sectors focused on bio-based products and recycling, seeking innovative processing solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 352.8 Billion |

| Market Forecast in 2033 | USD 555.2 Billion |

| Growth Rate | 6.7% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Alfa Laval, GEA Group, Sulzer Ltd., SPX Flow Inc., ANDRITZ AG, Krones AG, John Bean Technologies Corporation (JBT), IHI Corporation, Mitsubishi Kakoki Kaisha Ltd., Evapco, Inc., Dover Corporation, Praj Industries, Flowserve Corporation, TechnipFMC plc, Aker Solutions ASA, Fluor Corporation, Linde Engineering, BASF SE, Chart Industries, ThyssenKrupp AG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Chemical Process Equipment Market Key Technology Landscape

The Chemical Process Equipment Market is continually shaped by advancements in several key technological areas aimed at improving efficiency, safety, and sustainability. A primary focus is on developing advanced materials with superior corrosion resistance, high-temperature stability, and mechanical strength, such as specialized alloys (e.g., Hastelloy, Inconel, Titanium) and non-metallic composites (e.g., PTFE-lined, ceramics, glass-lined steel). These materials enable equipment to operate effectively in increasingly harsh and demanding chemical environments, extending operational life and reducing maintenance requirements. Furthermore, process intensification technologies, including microreactors, compact heat exchangers, and reactive distillation, are gaining traction to achieve higher throughputs, smaller footprints, and lower energy consumption, fundamentally changing how chemical processes are executed.

Another significant technological trend is the pervasive integration of automation, control systems, and digitalization. This includes the deployment of Distributed Control Systems (DCS), Supervisory Control and Data Acquisition (SCADA) systems, and Programmable Logic Controllers (PLCs) for precise process monitoring and control. The adoption of Industry 4.0 principles, such as the Internet of Things (IoT), enables real-time data collection from sensors embedded in equipment, facilitating predictive maintenance, operational optimization, and remote diagnostics. Digital twin technology, creating virtual replicas of physical assets, allows for simulating various operational scenarios, optimizing designs, and training personnel without impacting live production, thereby enhancing efficiency and reducing risks across the equipment lifecycle.

Additionally, advancements in manufacturing techniques, such as additive manufacturing (3D printing), are beginning to impact the market by allowing for the creation of complex geometries and customized components that were previously impossible with traditional methods. This offers opportunities for producing more efficient internal structures for reactors or heat exchangers and rapidly prototyping new designs. Furthermore, there is an ongoing emphasis on developing energy-efficient designs and sustainable technologies, including heat recovery systems, energy-efficient pumps and compressors, and equipment optimized for utilizing renewable energy sources. These technological innovations collectively drive the market towards more intelligent, resilient, and environmentally responsible chemical processing operations, catering to evolving industry demands and regulatory pressures.

Regional Highlights

- North America: A mature market characterized by stringent environmental regulations, a strong focus on high-value specialty chemicals, and significant investment in R&D. Demand is driven by modernization of existing infrastructure and adoption of advanced, energy-efficient equipment.

- Europe: Driven by strict regulatory frameworks for safety and environmental protection, prompting adoption of advanced and sustainable process technologies. Emphasis on innovation in pharmaceuticals, biotechnology, and green chemistry.

- Asia Pacific (APAC): The fastest-growing market due to rapid industrialization, increasing investments in chemical, petrochemical, and pharmaceutical manufacturing facilities, particularly in China, India, and Southeast Asia. Expanding infrastructure and rising disposable incomes fuel demand.

- Latin America: Growth is propelled by investments in petrochemicals, mining, and food & beverage industries. Economic development and increasing industrialization are driving the demand for new and upgraded process equipment.

- Middle East and Africa (MEA): Marked by significant investments in the oil & gas and petrochemical sectors, alongside efforts towards industrial diversification. Demand is influenced by large-scale infrastructure projects and processing capacity expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Chemical Process Equipment Market.- Alfa Laval

- GEA Group

- Sulzer Ltd.

- SPX Flow Inc.

- ANDRITZ AG

- Krones AG

- John Bean Technologies Corporation (JBT)

- IHI Corporation

- Mitsubishi Kakoki Kaisha Ltd.

- Evapco, Inc.

- Dover Corporation

- Praj Industries

- Flowserve Corporation

- TechnipFMC plc

- Aker Solutions ASA

- Fluor Corporation

- Linde Engineering

- BASF SE

- Chart Industries

- ThyssenKrupp AG

Frequently Asked Questions

What is chemical process equipment?

Chemical process equipment refers to machinery and systems used in industrial processes to transform raw materials into finished products through chemical, physical, or biological changes. This includes reactors, heat exchangers, pumps, filters, and mixers, essential for operations in chemical, pharmaceutical, food, and petrochemical industries.

What key factors drive the Chemical Process Equipment Market?

The market is primarily driven by the expansion of end-use industries, technological advancements in equipment design, stringent environmental regulations promoting cleaner production, and increasing demand for specialized chemicals and advanced materials across global markets.

What are the major challenges facing this market?

Major challenges include high capital investment costs for advanced equipment, volatility in raw material prices, the complexity of regulatory compliance across different regions, and a shortage of skilled personnel capable of operating and maintaining sophisticated processing systems.

How is sustainability impacting the Chemical Process Equipment Market?

Sustainability is profoundly impacting the market by driving demand for energy-efficient designs, equipment that facilitates waste reduction, and technologies supporting green chemistry and circular economy principles. This fosters innovation in eco-friendly materials and processes.

What are the key technological trends in chemical process equipment?

Key technological trends include the adoption of Industry 4.0 principles with IoT and AI for process optimization and predictive maintenance, advanced materials for enhanced performance, process intensification for efficiency, and modular designs for flexibility and faster deployment.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager