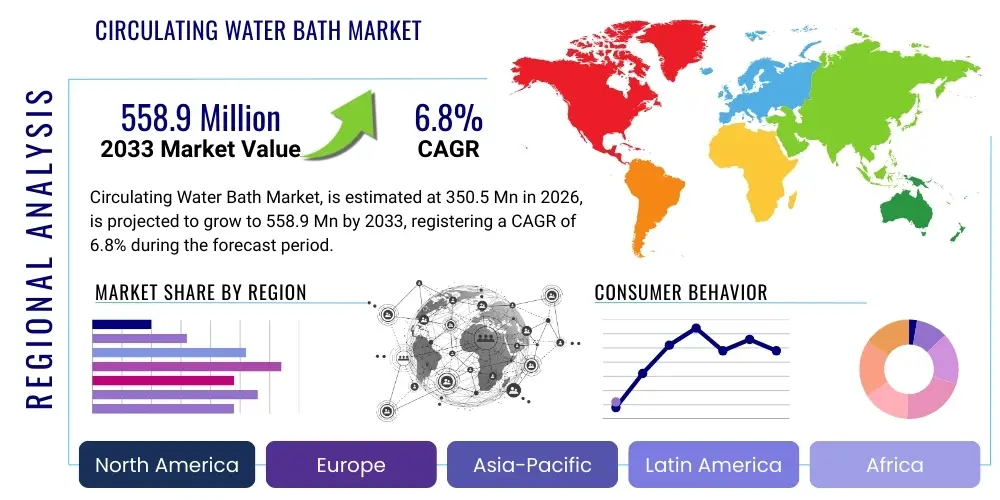

Circulating Water Bath Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442664 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Circulating Water Bath Market Size

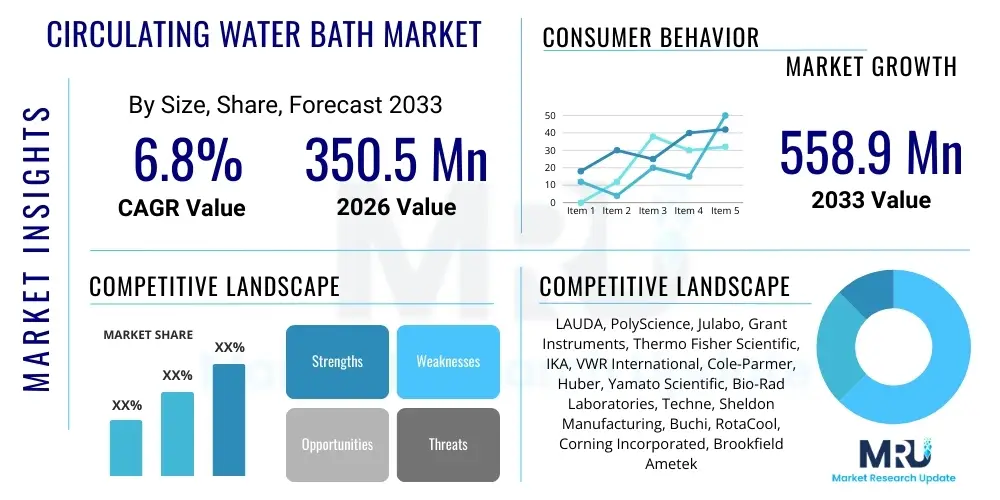

The Circulating Water Bath Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 350.5 Million in 2026 and is projected to reach USD 558.9 Million by the end of the forecast period in 2033.

Circulating Water Bath Market introduction

The Circulating Water Bath Market encompasses specialized laboratory equipment designed to maintain highly precise and stable temperature control for various samples, reactions, and testing procedures. Unlike standard water baths, circulating models, often referred to as circulators or refrigerated/heated circulators, utilize an internal pump mechanism to ensure uniform temperature distribution throughout the reservoir and, critically, to external application systems, such as refractometers, viscometers, jacketed reactors, or electrophoresis units. This capability for external circulation and unparalleled internal temperature uniformity makes them indispensable tools in advanced scientific research, quality assurance, and industrial testing environments where precise thermal management is paramount.

The primary applications of circulating water baths span critical areas in life sciences and material testing. In biotechnology and pharmaceuticals, they are essential for molecular biology applications, including enzyme assays, denaturation studies, cell culture maintenance, and incubation processes requiring temperature accuracy down to 0.1°C or better. Furthermore, in clinical diagnostics and hospitals, these instruments are utilized for sample preparation and controlling reaction kinetics. The core benefit driving market demand is their reliability in maintaining thermal stability over extended operational periods, minimizing experimental variability, and ensuring compliance with stringent regulatory standards, particularly Good Laboratory Practice (GLP) and Good Manufacturing Practice (GMP).

Driving factors for the market include the global expansion of pharmaceutical research and development activities, particularly in emerging economies, coupled with increased funding for academic and governmental research initiatives focused on genomics, proteomics, and drug discovery. Technological advancements, such as the incorporation of advanced microprocessor-based PID controllers and improved energy efficiency through optimized cooling and heating elements, further solidify their crucial role. The continuous need for repeatable and traceable thermal processes across chemistry, materials science, and biological disciplines guarantees sustained market growth.

Circulating Water Bath Market Executive Summary

The Circulating Water Bath Market demonstrates robust growth, largely fueled by burgeoning investments in biopharmaceutical R&D and the increasing complexity of laboratory protocols demanding highly stable thermal environments. Business trends indicate a strong move toward advanced digital integration, including remote monitoring and data logging capabilities, positioning modern circulators as integral components of the smart laboratory ecosystem. Key industry players are focusing on developing compact, energy-efficient units with broad temperature ranges (both heating and refrigeration) to cater to diverse application needs, particularly in high-throughput screening and scale-up processes. Strategic mergers, acquisitions, and partnerships aimed at strengthening regional distribution networks and expanding product portfolios specializing in low-temperature or high-stability applications are prevalent, especially targeting highly regulated sectors like clinical testing and quality control.

Regionally, North America and Europe maintain leading market shares due to established life science industries, high R&D expenditure, and rigorous regulatory frameworks mandating certified temperature control equipment. However, the Asia Pacific (APAC) region is forecasted to exhibit the highest Compound Annual Growth Rate (CAGR), driven by massive government investments in scientific infrastructure in countries like China, India, and South Korea, coupled with the rapid proliferation of contract research organizations (CROs) and domestic pharmaceutical manufacturing capabilities. Emerging markets in Latin America and the Middle East and Africa (MEA) are also showing promising growth, albeit from a smaller base, primarily through increased adoption in clinical diagnostic laboratories and university research centers.

Segment trends highlight the dominance of the Non-Refrigerated Circulating Water Baths segment in terms of volume, attributed to their lower cost and widespread use in fundamental incubation and tempering applications. Conversely, the Refrigerated Circulating Water Baths segment (recirculating chillers/coolers) is experiencing faster value growth, driven by the increasing need for precise sub-ambient temperature control in complex chemical synthesis, material testing, and advanced biological studies, such as protein crystallization. The Pharmaceutical & Biotechnology end-user segment remains the largest revenue generator, demanding premium features such as high stability, extensive safety mechanisms, and validated calibration protocols.

AI Impact Analysis on Circulating Water Bath Market

User queries regarding the impact of Artificial Intelligence (AI) on the Circulating Water Bath Market primarily revolve around how AI can enhance operational efficiency, predictive maintenance, and data integrity in temperature-critical processes. Key themes identified include the expectation of AI-driven optimization of thermal cycles, automated calibration and diagnostics, and the integration of circulators into fully autonomous laboratory workflows. Users are keen to understand if AI can reduce energy consumption by predicting optimal operation modes based on load fluctuations and environmental conditions, and how machine learning algorithms can flag potential temperature deviations before they compromise experimental results. The primary concerns center on the cybersecurity implications of network-connected equipment and the cost barriers associated with adopting AI-enabled instrumentation.

The practical integration of AI focuses less on the core thermodynamic function of the bath itself, and more on the systemic management of laboratory data and equipment performance. AI algorithms are increasingly being used to analyze extensive temperature logs, power consumption patterns, and pump performance indicators to establish a baseline of normal operation. Any deviation from this baseline triggers automated alerts or predictive maintenance schedules, minimizing unexpected downtime and maximizing instrument lifespan. Furthermore, AI facilitates better compliance and auditing by automating the compilation of temperature validation reports, ensuring that regulatory requirements are met with minimal manual intervention and maximum data traceability.

Ultimately, AI technology transforms the circulating water bath from a standalone piece of equipment into an intelligent data node within a laboratory execution system (LES). By enabling sophisticated correlation analysis between thermal stability and experimental outcomes, researchers can gain deeper insights into process reproducibility. This move towards intelligent thermal management ensures that the market evolves toward higher standards of precision, efficiency, and regulatory compliance, addressing user expectations for both operational reliability and enhanced data security in critical scientific applications.

- Enhanced Predictive Maintenance: AI algorithms analyze pump vibrations and heater element resistance to forecast failures, minimizing downtime.

- Automated Protocol Optimization: Machine learning adjusts heating/cooling rates based on external load dynamics for improved energy efficiency and faster thermal stabilization.

- Advanced Data Integrity: AI-driven validation ensures automated logging and anomaly detection in temperature profiles for regulatory compliance.

- Remote Diagnostic Capabilities: Enables remote troubleshooting and calibration assessment using pattern recognition of performance data.

- Integration into Autonomous Labs: Facilitates seamless communication with robotic systems and LIMS for automated workflow execution requiring precise thermal control.

DRO & Impact Forces Of Circulating Water Bath Market

The Circulating Water Bath Market is influenced by a powerful interplay of growth drivers, structural restraints, emerging opportunities, and dynamic impact forces. The core driver is the escalating global expenditure on biopharmaceutical research, particularly in cancer research, vaccine development, and personalized medicine, all of which rely heavily on highly controlled thermal environments for sample preparation and reaction processes. Concurrently, the increasing stringency of global regulatory standards (e.g., FDA, EMA) for laboratory quality control mandates the use of precision instruments with documented calibration and traceability, thereby boosting demand for high-end circulating baths with advanced digital controls and data logging features. These drivers are fundamentally linked to the continuous need for scientific innovation and validated research outcomes across various industries.

However, the market faces significant restraints, notably the high initial capital investment required for advanced refrigerated circulating baths and the specialized maintenance costs associated with complex cooling technologies like cascade refrigeration systems. Furthermore, the inherent energy consumption of continuously operating heating and cooling elements poses both an operational cost burden and an environmental concern, pushing end-users to seek more energy-efficient alternatives. In emerging markets, budget constraints in smaller academic institutions and less established laboratories often lead to the procurement of basic, non-circulating models or low-cost alternatives, limiting the rapid penetration of premium, high-precision circulators. These economic and technical barriers temper the overall market expansion.

Opportunities arise predominantly from the adoption of sustainable technologies, such as the implementation of Peltier-based cooling systems in smaller circulators, offering lower energy consumption and eliminating the need for traditional refrigerants. The expansion of point-of-care diagnostics and miniaturized lab-on-a-chip technologies creates a niche for micro-circulating baths capable of controlling thermal gradients in extremely small volumes. The rapid growth of contract testing and manufacturing organizations (CTMOs) globally presents a major opportunity, as these organizations require scalable, standardized, and highly reliable temperature control solutions for their diverse client services. The primary impact forces shaping the competitive landscape include rapid technological obsolescence dueowing to continuous innovation in PID control algorithms, and intense pricing pressure from Asian manufacturers targeting the mid-range segment.

Segmentation Analysis

The Circulating Water Bath Market is comprehensively segmented based on Type, Capacity, Temperature Range, and End User, reflecting the diverse application needs across different scientific and industrial disciplines. Analyzing these segments provides crucial insights into market dynamics, identifying areas of high growth and technological specialization. The market structure emphasizes the trade-off between basic heating-only applications and complex, wide-range temperature control requirements involving refrigeration. Segment differentiation is key for manufacturers to tailor product offerings—ranging from compact benchtop units used in biological research to large, floor-standing industrial circulators utilized for calibration or pilot-scale reactor cooling.

Segmentation by Type reveals the shift towards refrigerated circulating baths, which offer greater versatility by spanning both sub-ambient and ambient-to-high temperatures, crucial for advanced chemical synthesis and materials characterization. Capacity segmentation (Small, Medium, Large) determines the primary application scale; small capacity baths are preferred in academic and clinical settings for smaller sample volumes, whereas medium to large capacity baths are necessary for pilot plants, external cooling of process equipment, or calibration of sensors requiring large thermal sinks. The ability to meet highly specific temperature control needs drives segment value, particularly where precision and rapid temperature changes are mandatory.

The End User segmentation demonstrates the critical reliance of the Pharmaceutical and Biotechnology sector on these devices due to strict validation requirements and high-stakes research. Conversely, Academic and Research Institutions represent a volume market, driven by educational needs and governmental grants, often favoring robust, user-friendly models. Understanding these segment behaviors allows market participants to develop targeted sales strategies, emphasizing different feature sets—such as safety mechanisms and traceability for regulated industries, versus cost-effectiveness and ease of use for educational environments.

- By Type:

- Refrigerated Circulating Water Baths (Recirculating Chillers)

- Non-Refrigerated Circulating Water Baths (Heated Circulators)

- High-Temperature Circulating Baths (up to 300°C)

- By Capacity:

- Small Capacity (Below 10 Liters)

- Medium Capacity (10 Liters – 20 Liters)

- Large Capacity (Above 20 Liters)

- By Temperature Range:

- Ambient to 100°C

- Sub-Ambient (down to -40°C or -80°C)

- High Temperature (100°C to 300°C)

- By End User:

- Pharmaceutical & Biotechnology Companies

- Academic & Research Institutions

- Hospitals & Diagnostic Centers

- Industrial Laboratories (Chemical, Petrochemical, Food & Beverage)

Value Chain Analysis For Circulating Water Bath Market

The value chain for the Circulating Water Bath Market begins with upstream activities focused on the procurement of specialized raw materials and high-precision components. This includes stainless steel for reservoirs, advanced electronic components such as microprocessors and high-resolution digital displays, sensitive temperature sensors (e.g., PT100), and critical refrigeration components (compressors, heat exchangers) for sub-ambient units. Upstream supplier power is moderate, influenced by global supply chain stability for specialized electronics and refrigerants. Key manufacturing activities involve precision engineering, welding of leak-proof reservoirs, integration of complex PID control systems, and rigorous quality assurance testing, particularly calibration verification, to ensure regulatory compliance and thermal stability specifications are met.

The midstream process involves the manufacturing, assembly, and integration of the core functional systems—heating elements, cooling coils, and high-performance magnetic or turbine pumps that are crucial for efficient fluid circulation and temperature uniformity. Manufacturers often invest heavily in R&D to improve pump efficiency, minimize noise levels, and enhance user interface design. Successful firms differentiate themselves through the proprietary design of their circulation path and controller algorithms, which directly influence performance metrics like ramp time and temperature stability. After manufacturing, intensive quality control and calibration processes, often adhering to international standards (e.g., ISO/IEC 17025), add substantial value.

Downstream distribution channels are segmented into direct sales, serving large pharmaceutical corporations or government tenders, and indirect sales, which utilize specialized scientific equipment distributors and regional resellers. Indirect channels are critical for reaching smaller academic labs and geographically dispersed clinical centers. Distributors offer value-added services such as local installation, initial training, and routine maintenance, leveraging their established relationships with local scientific communities. The movement towards e-commerce platforms and digital marketplaces is increasingly influencing indirect sales, providing researchers with easy access to product specifications, comparisons, and faster procurement cycles, though the highly technical nature of the product still often requires specialized technical support from manufacturer representatives.

Circulating Water Bath Market Potential Customers

The primary cohort of potential customers for circulating water baths resides within the global life sciences sector, encompassing large multinational pharmaceutical companies and emerging biotechnology startups. These entities require high-precision thermal control for critical processes such as drug solubility testing, stability studies, dissolution testing, and maintaining biological reagents at specific, reproducible temperatures for assays. Regulatory adherence is paramount in this segment; therefore, potential buyers prioritize instruments offering extensive data logging, remote monitoring capabilities, and verifiable calibration certificates to support Good Manufacturing Practice (GMP) documentation and audit trails. The increasing need for high-throughput capabilities in drug discovery further drives demand for automated, integrated circulators capable of interfacing with robotic systems.

A secondary, yet equally vital, customer segment includes academic, governmental, and university research institutions globally. These organizations purchase circulating baths for fundamental scientific investigations, student training, and diverse applications ranging from basic chemistry experiments to cutting-edge physics research requiring precise thermal management of detectors or sensitive equipment. Unlike industrial buyers, academic customers often prioritize versatility, robustness, and affordability, leading to higher demand for reliable, mid-range non-refrigerated circulators, though high-end refrigerated units are essential for advanced doctoral and postdoctoral research requiring sub-ambient operations. Procurement cycles in this sector are often tied to grant funding availability and institutional budget allocations.

Finally, industrial laboratories outside the life sciences, including those involved in chemical processing, materials testing (e.g., plastics, polymers), petrochemicals, and food and beverage quality control, represent substantial potential customers. In these settings, circulating baths are used for viscosity testing, tempering samples to standard reference temperatures, calibration of thermometers, and conducting standardized stress tests. For instance, in petrochemical labs, high-temperature circulators are necessary for specific oil and fuel testing protocols. These customers demand durability, high flow rates for industrial heat transfer applications, and instruments built to withstand demanding continuous operation cycles.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350.5 Million |

| Market Forecast in 2033 | USD 558.9 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | LAUDA, PolyScience, Julabo, Grant Instruments, Thermo Fisher Scientific, IKA, VWR International, Cole-Parmer, Huber, Yamato Scientific, Bio-Rad Laboratories, Techne, Sheldon Manufacturing, Buchi, RotaCool, Corning Incorporated, Brookfield Ametek, Remi Group, OptiTemp, AccuTherm |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Circulating Water Bath Market Key Technology Landscape

The technological landscape of the Circulating Water Bath Market is defined by continuous innovation aimed at enhancing thermal precision, energy efficiency, and digital connectivity. Central to modern performance is the utilization of advanced Proportional-Integral-Derivative (PID) controllers. These sophisticated algorithms dynamically monitor and adjust heating and cooling output, minimizing temperature overshoot and maintaining stability typically within ±0.01°C, essential for highly sensitive biochemical reactions. Furthermore, high-performance pump technology, transitioning from traditional magnetic pumps to variable-speed, electronically commutated (EC) motor pumps, ensures consistent flow rates even when circulating to complex external systems with high pressure drops, optimizing external heat transfer efficiency and process uniformity.

In the area of cooling technology, while traditional compressor-based refrigeration remains dominant for ultra-low temperature ranges (below -20°C), there is a significant technological movement towards thermoelectric cooling, specifically Peltier technology, for smaller, benchtop refrigerated circulators operating above 0°C. Peltier systems offer advantages in terms of compact size, silent operation, elimination of ozone-depleting refrigerants, and faster, more precise temperature ramping capabilities. Though Peltier technology currently lacks the cooling power for large-scale or ultra-low temperature applications, its environmental friendliness and digital controllability are driving adoption in academic and smaller diagnostic labs, pushing the industry towards greener instrumentation solutions.

Crucially, the integration of IoT (Internet of Things) and connectivity features is standardizing modern circulators. New instruments are equipped with Ethernet, Wi-Fi, and USB ports, allowing for remote parameter configuration, real-time data logging, and integration with Laboratory Information Management Systems (LIMS). This connectivity supports the principles of the 'Laboratory 4.0' paradigm, facilitating automated compliance documentation, remote diagnostics, and enabling researchers to monitor critical thermal processes outside the lab environment. Touchscreen interfaces and multilingual operating systems are also becoming standard, enhancing user experience and reducing the complexity associated with programming sophisticated thermal profiles.

Regional Highlights

- North America: North America, particularly the United States, holds the largest market share primarily due to the presence of global pharmaceutical and biotechnology giants and substantial R&D funding, both public and private. The stringent regulatory environment necessitates the use of high-end, validated circulating baths with full traceability features. High demand is observed for refrigerated circulators used in complex drug development, clinical trials, and precision manufacturing. The region is also a hub for technological innovation, leading in the early adoption of AI-enabled and IoT-connected laboratory instrumentation.

- Europe: Europe represents the second-largest market, characterized by strong governmental support for academic research and a powerful med-tech industry, particularly in Germany, the UK, and Switzerland. European regulations, such as those related to environmental impact (e.g., F-Gas regulation on refrigerants), drive the demand for energy-efficient and Peltier-based cooling solutions. High-quality standards and long-standing manufacturers ensure a competitive landscape focused on durability and precision, especially catering to specialized areas like high-temperature chemical synthesis and complex materials testing.

- Asia Pacific (APAC): The APAC region is the fastest-growing market, propelled by rapid industrialization, massive investments in scientific infrastructure (especially in China and India), and the relocation of pharmaceutical manufacturing and CRO activities to the region due to lower operational costs. While cost-sensitivity remains a factor, increasing quality demands necessitate the transition from basic water baths to precision circulating models, particularly in sophisticated research centers and export-focused manufacturing facilities aiming for international compliance standards. Japan and South Korea lead in adopting advanced automation and digital integration in laboratory equipment.

- Latin America: The Latin American market experiences moderate growth, largely centered in Brazil and Mexico. Demand is driven primarily by public health initiatives, expanding hospital networks, and increasing university research budgets. The market is often price-sensitive, leading to a strong preference for durable, mid-range non-refrigerated units, though specialized refrigerated models are required in advanced research centers collaborating with US or European entities. Distribution challenges and fluctuating economic conditions present notable restraints in this region.

- Middle East and Africa (MEA): Growth in the MEA region is nascent but promising, supported by significant government investments in diversifying economies away from oil dependency and into scientific research, healthcare, and education, particularly in the UAE and Saudi Arabia. Market demand focuses on diagnostic centers and newly established university research parks. The primary challenge is the dependence on imports and the need for localized technical support and servicing expertise for sophisticated circulating equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Circulating Water Bath Market.- LAUDA Dr. R. Wobser GmbH & Co. KG

- PolyScience (Presto-Cooling Systems)

- Julabo GmbH

- Grant Instruments (Cambridge) Ltd.

- Thermo Fisher Scientific Inc.

- IKA Works GmbH & Co. KG

- VWR International, LLC (Avantor)

- Cole-Parmer Instrument Company, LLC

- Peter Huber Kältemaschinenbau AG (Huber)

- Yamato Scientific Co., Ltd.

- Bio-Rad Laboratories, Inc.

- Techne (Bibby Scientific)

- Sheldon Manufacturing, Inc. (Sheldon Labs)

- Buchi AG

- RotaCool, Inc.

- Corning Incorporated

- Brookfield Ametek

- Remi Group

- OptiTemp, Inc.

- AccuTherm LLC

Frequently Asked Questions

Analyze common user questions about the Circulating Water Bath market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of a circulating water bath over a standard water bath?

A circulating water bath utilizes an internal pump system to actively move the fluid, ensuring highly uniform temperature distribution (stability often below ±0.01°C) throughout the reservoir and enabling precise temperature control of external devices like reactors or sensors, which is critical for reproducible research and calibration.

In which key end-user segment is the demand for refrigerated circulating baths highest?

The demand for refrigerated circulating baths (recirculating chillers) is highest in the Pharmaceutical and Biotechnology sectors. These industries frequently require precise temperature management for complex chemical reactions, protein crystallization, and stability testing that must occur below ambient room temperatures.

How is the Circulating Water Bath Market addressing the need for environmental sustainability?

The market is shifting towards more sustainable cooling technologies, particularly the increased adoption of Peltier-based thermoelectric cooling systems in benchtop models. These systems eliminate the need for traditional, often regulated, hydrofluorocarbon refrigerants, reducing the instrument’s environmental footprint and energy consumption.

What role does digital connectivity (IoT) play in modern circulating water baths?

IoT connectivity enables remote monitoring, automated data logging, and seamless integration with Laboratory Information Management Systems (LIMS). This facilitates improved regulatory compliance, simplifies validation processes, allows for predictive maintenance, and supports the implementation of automated, smart laboratory workflows.

Which geographical region is expected to show the highest growth rate in this market?

The Asia Pacific (APAC) region is projected to exhibit the highest CAGR. This growth is driven by substantial government investments in scientific infrastructure, the expansion of local pharmaceutical manufacturing capabilities, and the proliferation of contract research and testing organizations (CROs/CTMOs) across countries like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager