Cleanroom Storage Cabinet Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442619 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Cleanroom Storage Cabinet Market Size

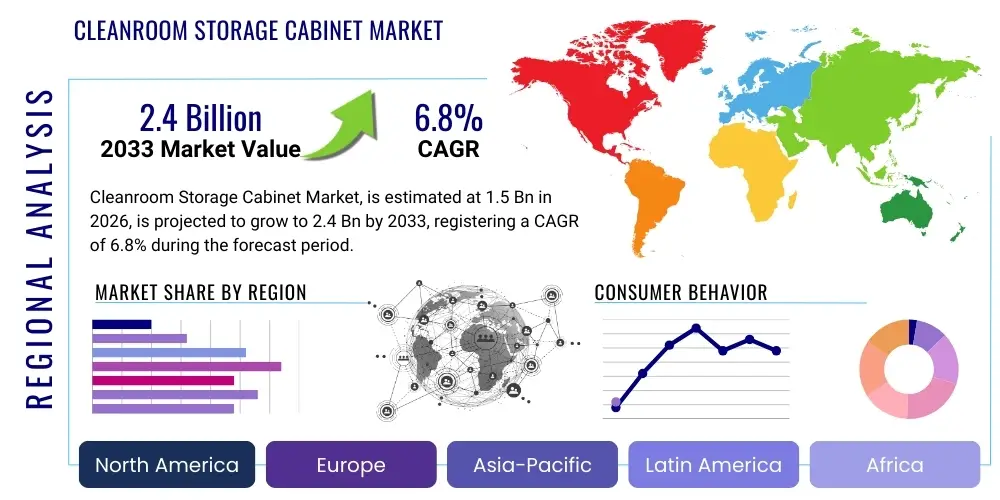

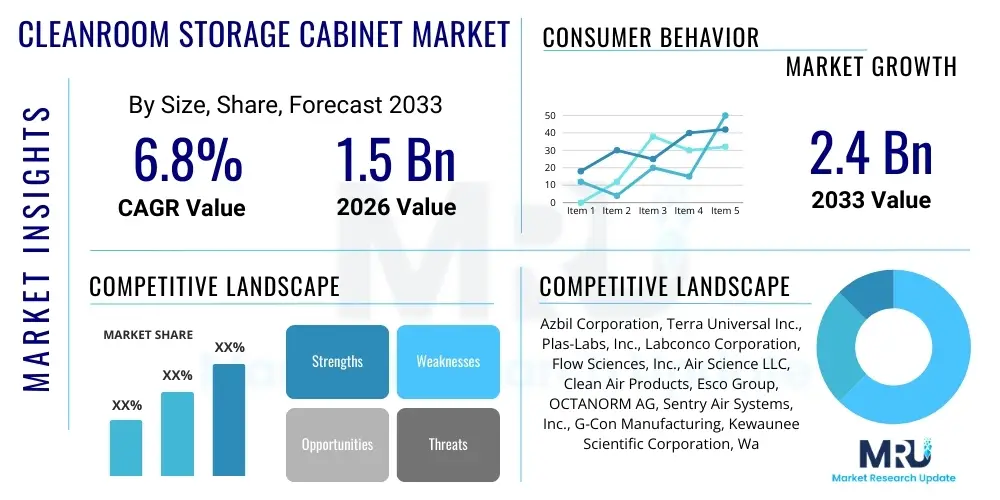

The Cleanroom Storage Cabinet Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.4 Billion by the end of the forecast period in 2033.

Cleanroom Storage Cabinet Market introduction

Cleanroom storage cabinets constitute critical infrastructure within highly regulated environments, fundamentally designed to maintain ultra-low particulate and microbial contamination levels for sensitive materials, tools, and finished products. These specialized units, often constructed from materials like smooth-finish stainless steel (304 or 316L) or chemically inert polymers, are engineered to integrate seamlessly into controlled areas, ensuring compliance with rigorous international standards such as ISO 14644 and various Good Manufacturing Practices (GMP). Their essential function extends beyond mere shelving; they act as certified micro-environments, featuring advanced air handling systems like HEPA or ULPA filtration, precise environmental monitoring, and sometimes inert gas purging capabilities, crucial for protecting high-value components used in pharmaceutical, biotechnology, and semiconductor manufacturing.

The product portfolio encompasses a variety of solutions tailored for specific contamination risks, ranging from static, sealed cabinets utilized for long-term secure storage of less frequently accessed items, to dynamic laminar flow cabinets that actively shower materials with filtered air, guaranteeing continuous particle removal even during access. Major applications span the storage of sterile consumables, sensitive electronic components like semiconductor wafers and photomasks, validated laboratory samples, and critical medical devices prior to final packaging. The cabinets' inherent benefits include minimizing product defect rates by preventing surface contamination, ensuring batch consistency in regulated industries, simplifying audit trails through documented environmental conditions, and significantly reducing the risk of product recall dueoutsourced to environmental compromises.

Market expansion is currently robust, propelled by several driving factors. The exponential global expansion of the pharmaceutical industry, particularly the rise of complex biologics and cell and gene therapies requiring extremely sterile processing and storage, creates an insatiable demand for high-grade, verifiable storage solutions. Additionally, the intensive investment in new and modernized semiconductor fabrication facilities (Fabs) globally mandates specialized desiccator and inert gas cabinets to protect nanoscale components from moisture and oxidation. Furthermore, increasingly stringent global regulatory enforcement—requiring comprehensive validation documentation for all aspects of manufacturing and storage—forces all regulated entities to upgrade their cleanroom infrastructure with certified, modern storage technology that offers automated data logging and real-time parameter control.

Cleanroom Storage Cabinet Market Executive Summary

The Cleanroom Storage Cabinet Market is witnessing a strong growth phase, primarily steered by unwavering global demands for product quality and safety in critical manufacturing sectors. Business trends prominently feature a shift toward modular and scalable cabinet systems that allow for easy integration and reconfiguration within dynamic cleanroom layouts. Manufacturers are increasingly differentiating their offerings through advanced digital integration, incorporating IoT sensors and sophisticated human-machine interfaces (HMIs) for remote diagnostics and centralized environmental control, aligning storage operations with broader Industry 4.0 paradigms. A strong focus on material innovation, specifically the development of anti-microbial coatings and high-durability, non-shedding polymers, aims to satisfy the heightened demand for aseptic conditions in emerging biotechnological applications.

Analysis of segment trends reveals that the stainless steel cabinet segment maintains market supremacy, valued for its superior compatibility with rigorous sterilization procedures and resistance to aggressive chemical agents used in cleanroom cleaning protocols. However, specialized functional segments, particularly Inert Gas Purge Cabinets essential for semiconductor and optics preservation, and Dynamic Pass-Through Units critical for material transfer between cleanroom zones, are exhibiting the fastest growth rates. The Pharmaceutical and Biotechnology sector remains the largest consumer segment, driving the complexity and specification requirements for cabinets, demanding features like validated temperature control and data security compliance, while the burgeoning electronics sector drives demand for highly specialized humidity and oxygen control features.

Regionally, the market dynamics reflect established maturity in North America and Europe, which are characterized by high regulatory compliance standards and substantial market value driven by sophisticated purchasing power for premium products. Conversely, the Asia Pacific region is rapidly emerging as the primary engine for future market expansion. This aggressive growth is directly linked to massive government and private sector investments across East Asia and Southeast Asia in building cutting-edge semiconductor foundries, expanding generic drug manufacturing capacity, and establishing new high-tech medical device assembly hubs. These emerging markets prioritize scalable, high-volume compliant storage solutions, often favoring local sourcing or regional suppliers capable of meeting both international quality standards and competitive pricing structures.

AI Impact Analysis on Cleanroom Storage Cabinet Market

User engagement with the Cleanroom Storage Cabinet Market increasingly centers on the disruptive potential of Artificial Intelligence to elevate storage management from a passive function to a proactive, intelligent system. Common inquiries address how AI algorithms can predict filter replacement cycles based on real-time particle load data, effectively transitioning from time-based maintenance to predictive maintenance, thereby reducing operational risk and cost. Furthermore, stakeholders frequently explore AI’s capacity to optimize material placement within cabinets, minimizing required access time, which is the most significant vector for human-introduced contamination, and ensuring that temperature-sensitive items are consistently placed in locations demonstrating the greatest thermal stability over time, as verified by machine learning analysis of sensor networks.

The prevailing themes of user concern coalesce around data security and system interoperability. Users require assurance that AI-driven monitoring systems comply with strict data integrity regulations, such as FDA 21 CFR Part 11, particularly when these systems autonomously log and validate environmental conditions crucial for batch release decisions. There is also strong market expectation that AI will be leveraged to integrate cabinet data seamlessly with large-scale manufacturing execution systems (MES), facilitating fully automated inventory tracking and quality assurance workflows. The anticipated influence of AI is the transformation of the cabinet into a highly sophisticated, self-auditing control node, capable of subtle anomaly detection that human operators or standard threshold alarms often miss, thereby providing a superior layer of environmental integrity protection for mission-critical materials.

Consequently, the market is poised for significant innovation spurred by AI, moving beyond simple data collection to complex operational optimization. AI will enable prescriptive actions—for instance, autonomously adjusting fan speeds or inert gas flow rates to counteract predicted environmental shifts before they breach acceptable limits, based on established historical patterns and predictive modeling. This shift represents an evolution where cleanroom storage ceases to be a static containment unit and becomes an active, contributing component of the overall contamination control strategy, guaranteeing optimized conditions, minimized manual intervention, and enhanced compliance documentation efficiency throughout the product lifecycle.

- Implementation of predictive maintenance models to anticipate mechanical failures in cabinet filtration and circulation systems, reducing unexpected downtime.

- Integration of machine learning algorithms for real-time particulate and environmental anomaly detection, ensuring immediate alert generation for out-of-spec conditions.

- Optimization of inventory flow and storage allocation through AI-driven demand forecasting, minimizing material exposure time and reducing carrying costs.

- Deployment of computer vision systems combined with AI to verify correct item placement and track consumption automatically, enhancing accountability and reducing manual data entry errors.

- Development of autonomous regulatory compliance auditing features, generating validated reports on storage conditions and material traceability based on logged data patterns.

- AI-driven optimization of power consumption for HEPA blowers and temperature control units, reducing the substantial energy footprint typically associated with maintaining clean environments.

- Enhanced security protocols using AI to monitor and flag unauthorized access attempts or deviations from prescribed access sequences, vital for high-security materials storage.

DRO & Impact Forces Of Cleanroom Storage Cabinet Market

The trajectory of the Cleanroom Storage Cabinet Market is fundamentally shaped by powerful interplay between escalating operational demands from high-technology industries and pervasive, non-negotiable regulatory compliance requirements. The primary drivers include the monumental growth of the global semiconductor industry, which mandates highly specialized, ultra-clean desiccator storage for advanced lithography components, and the explosive expansion of the biopharmaceutical sector, necessitating validated, aseptic storage for novel therapeutics and sensitive biological materials. These drivers are further bolstered by continuous infrastructure modernization efforts globally, where older, less compliant cleanrooms are being systematically upgraded with contemporary storage solutions capable of seamless digital integration and real-time environmental logging, transforming mandatory compliance into a competitive operational advantage.

Conversely, the market faces constraints primarily rooted in the significant financial burden associated with procurement and long-term maintenance. Cleanroom cabinets, particularly those featuring laminar flow, inert gas purging, or ultra-low temperature capabilities, represent a high initial capital outlay, often exceeding the budgets of smaller contract manufacturers or research facilities. Furthermore, the recurrent operational expenses, encompassing regular filter changes, mandatory re-certification (e.g., DOP testing), and energy costs required to maintain precise environmental parameters, act as substantial long-term restraints. Compounding these financial barriers is the challenge of technological integration, as complex, proprietary monitoring systems sometimes struggle to communicate effectively with diverse existing legacy cleanroom management platforms, complicating deployment and data harmonization efforts across large multi-site organizations.

Significant opportunities exist in two key areas: geographic expansion and technological diversification. Geographically, emerging economies in APAC and LATAM, undergoing rapid industrialization and establishing domestic high-tech manufacturing bases, offer untapped demand for scalable cleanroom solutions. Technologically, the opportunity lies in embracing modular construction and integrated service models, where manufacturers offer not just the cabinet but a complete, validated storage ecosystem including installation, SOP development, and long-term remote monitoring services. The paramount impact force influencing the entire market ecosystem is the escalating emphasis on data integrity and traceability (driven by regulations like Annex 1 in Europe), compelling suppliers to develop cabinets that are not just clean, but demonstrably, verifiably compliant throughout every second of their operational life, making advanced sensor technology and secure data logging capabilities mandatory features rather than optional enhancements.

Segmentation Analysis

The Cleanroom Storage Cabinet Market is segmented based on several technical and functional parameters, reflecting the diverse and often highly specific needs of different regulated industries. This granular segmentation allows market participants to precisely understand the requirements stemming from various controlled environments, ranging from ISO Class 9 industrial cleanrooms to highly critical ISO Class 3 pharmaceutical zones. Key segmentation criteria include the type of construction material, which dictates chemical resistance and sterilization compatibility, and the cabinet's operational principle, defining whether it provides active contamination control (dynamic) or passive protection (static). Analyzing these segments provides invaluable insights into end-user preference, regional maturity, and the current pace of technological adoption across the critical manufacturing supply chain.

Functional segmentation is especially crucial, differentiating specialized units like desiccators, which control moisture for electronics, from vertical laminar flow cabinets, which control particulates for biologics. Furthermore, the market is segmented by the primary end-user industry, allowing for distinct analysis of demand drivers. For instance, the semiconductor segment typically prioritizes ultra-low particulate and oxygen control, while the pharmaceutical segment emphasizes aseptic design, robust cleaning compatibility, and extensive environmental data logging capability. Understanding the interaction between these segmentations is paramount for developing targeted marketing strategies and optimizing the supply chain to meet the exacting, often customized, specifications required by global cleanroom operators seeking optimal operational performance and compliance assurance.

- By Material Type:

- Stainless Steel Cabinets (Focus on 304 and medical-grade 316L for high chemical and corrosion resistance)

- Polymer (Polypropylene, High-Density Polyethylene, and specialized ESD-safe Polycarbonate) Cabinets

- Laminated Wood Cabinets (Used in lower-grade industrial or logistics clean areas where cost is a primary constraint)

- Hybrid Material Systems (Combining steel frames with polymer or glass shelving for tailored compatibility)

- By Cabinet Type (Functionality):

- Vertical Laminar Flow (VLF) Storage Cabinets (Active particulate control, common in biotech)

- Horizontal Laminar Flow Storage Cabinets (Often used for specific component protection, less common than VLF)

- Pass-Through Cabinets (Static and Dynamic with interlocks, used for material transfer between zones)

- Static Storage Cabinets (Basic sealed storage for low-risk or packaged materials)

- Desiccator Storage Cabinets (Active humidity control via nitrogen purge or desiccant material, critical for electronics and optics)

- Inert Gas Purge Cabinets (Nitrogen or Argon purging to prevent oxidation of sensitive materials)

- Temperature Controlled Cabinets (Refrigerated or heated storage for specific sample stability)

- By End-User Industry:

- Pharmaceutical and Biotechnology (APIs, sterile packaging, biologics storage)

- Semiconductor and Electronics Manufacturing (Wafers, reticles, critical components)

- Healthcare and Medical Devices (Assembly areas, sterile supply storage, compounding pharmacies)

- Aerospace and Defense (Precision instrument storage, optical components)

- Academic and Research Institutions (Material science, advanced chemistry labs)

- Optics and Photonics (Laser components, high-purity glass)

- By Cleanroom Classification:

- ISO Class 3 (Class 1) - Ultra-critical storage, common in high-end semiconductor lithography.

- ISO Class 5 (Class 100) - Standard for most aseptic processing zones.

- ISO Class 7 (Class 10,000) - General clean assembly and packaging areas.

- ISO Class 8 and 9 (Lower classifications) - Storage of logistics materials and packaging components.

- By Sales Channel:

- Direct Sales (Large project procurement, customized solutions)

- Distributors and Resellers (Standardized units, localized support)

- Original Equipment Manufacturers (OEMs) (Integrated into larger cleanroom facility builds)

- By Region:

- North America (U.S., Canada, Mexico) - Dominant market value due to R&D intensity.

- Europe (Germany, U.K., France, Italy, Rest of Europe) - Strong compliance focus and mature pharma market.

- Asia Pacific (China, Japan, South Korea, India, Southeast Asia, Rest of APAC) - Highest growth rate driven by industrial expansion.

- Latin America (Brazil, Argentina, Rest of LATAM) - Emerging market driven by domestic pharmaceutical capacity.

- Middle East and Africa (GCC Countries, South Africa, Rest of MEA) - Infrastructure investment focused growth.

Value Chain Analysis For Cleanroom Storage Cabinet Market

The intricate value chain of the Cleanroom Storage Cabinet Market commences with the rigorous selection and sourcing of upstream raw materials, a phase dominated by specialized metals and component suppliers. The integrity and compliance of the final product are inextricably linked to the quality of materials procured, necessitating certified, low-carbon stainless steel (316L preferred for pharmaceutical use) known for minimal surface shedding and ease of electropolishing. Upstream also includes highly specialized component manufacturing, focusing on HEPA/ULPA filter media production, precision blower motors, seals, and advanced microprocessors necessary for digital monitoring systems. Relationships here are defined by long-term supply agreements and stringent quality control audits to ensure that input materials meet the exacting non-particulating and chemical resistance standards required for cleanroom use.

The middle segment of the chain is dominated by cabinet manufacturers who specialize in precision sheet metal fabrication, welding techniques that minimize crevices (potential particle traps), and integration of complex air handling systems. This phase also includes critical validation and certification processes, often involving third-party testing to confirm ISO class compliance before shipment. Downstream activities involve reaching the end-user. Distribution channels are highly stratified: large global manufacturers often rely on direct sales teams for complex, customized, multi-unit projects in sectors like semiconductor fabrication, where deep technical expertise and validation support are essential throughout the entire installation and qualification process.

For standardized or replacement units, the indirect channel, comprising regional cleanroom equipment distributors and specialized laboratory resellers, plays a crucial role. These intermediaries offer localized inventory, faster delivery, and critical installation and re-certification services, often bundling the cabinets with other cleanroom equipment like gowning benches and laminar flow hoods. Final value creation occurs at the end-user site, where the cabinets are integrated into facility operations. Post-sales services, including preventative maintenance, recalibration of sensors, and formal re-validation required annually or biannually by regulatory bodies, are essential elements that sustain long-term revenue streams and customer loyalty within this highly compliance-driven market segment.

Cleanroom Storage Cabinet Market Potential Customers

The primary cohort of potential customers for high-specification cleanroom storage cabinets centers around entities operating under mandatory, rigorous regulatory frameworks where contamination control directly impacts product efficacy and public health. Leading this group is the Pharmaceutical and Biotechnology industry, encompassing major multinational drug producers, vaccine manufacturers, and, critically, the growing landscape of Contract Manufacturing Organizations (CMOs) and Contract Development and Manufacturing Organizations (CDMOs). These organizations require cabinets for storage of controlled raw materials, intermediate bulk product, validated media, sterile consumables, and final packaged drugs, demanding fully validated temperature, humidity, and particulate control capabilities to ensure compliance with global GMP standards.

The second major consumer group consists of the global Semiconductor and Electronics Manufacturing sector. Customers in this high-precision field—including wafer fabricators, assembly plants, and advanced display manufacturers—require specialized storage units to protect components from moisture, electrostatic discharge (ESD), and nano-scale particles. Demand here is intense for desiccator cabinets and inert gas purge units (often nitrogen) to maintain environment integrity for photoresist chemicals, lithography masks, and finished integrated circuits (ICs) that are highly sensitive to oxidation and environmental degradation during non-operational periods, with specific requirements often exceeding standard ISO classifications.

Further strategic customer segments include sophisticated Medical Device Manufacturers (especially those producing sterile implants or complex diagnostics), aerospace contractors working with highly sensitive optical or mechanical assemblies, and leading academic and government research institutions conducting cutting-edge material science or genomic research. In all these sectors, the storage cabinet functions as an indispensable quality control barrier. Procurement decisions are typically centralized, driven by Quality Assurance (QA) and Engineering departments, who prioritize verifiable compliance records, extensive manufacturer validation documentation, and cabinet longevity over initial cost, cementing the importance of quality assurance in purchasing criteria.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.4 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Azbil Corporation, Terra Universal Inc., Plas-Labs, Inc., Labconco Corporation, Flow Sciences, Inc., Air Science LLC, Clean Air Products, Esco Group, OCTANORM AG, Sentry Air Systems, Inc., G-Con Manufacturing, Kewaunee Scientific Corporation, Waldner Laboreinrichtungen GmbH & Co. KG, Dafeng Cleanroom Equipment, Lab Furniture and Fume Hoods, Technical Manufacturing Corp. (TMC), M. Braun Inertgas-Systeme GmbH, Bio-Bubble, Inc., Micronova Manufacturing Inc., Stainless Structurals LLC |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cleanroom Storage Cabinet Market Key Technology Landscape

The technology landscape of the Cleanroom Storage Cabinet Market is defined by continuous advancements aimed at achieving higher levels of contamination control, greater energy efficiency, and enhanced data connectivity. The core technology remains centered on sophisticated air filtration and flow dynamics. Leading manufacturers are increasingly utilizing high-efficiency ULPA filters, which boast superior particle retention rates (up to 99.999% retention of 0.12 micron particles) compared to standard HEPA, a requirement driven by the miniaturization trend in microelectronics. This advanced filtration is coupled with proprietary baffling and plenum designs that ensure strictly unidirectional laminar airflow within dynamic cabinets, minimizing turbulence and preventing the reintroduction of particulates onto stored surfaces, a critical engineering challenge in cabinet design.

A second critical technological pillar is the integration of precise environmental control systems. Modern cabinets are equipped with highly accurate, validated sensor arrays for continuous monitoring of temperature, relative humidity, and differential pressure, often exceeding the requirements of the surrounding cleanroom. For highly sensitive applications, this includes closed-loop control systems for nitrogen or other inert gas purging, ensuring that oxygen and moisture levels are maintained below critical thresholds to prevent material degradation. The control interface often utilizes color touchscreen displays and employs secure, encrypted data logging mechanisms to satisfy regulatory demands for historical record keeping and electronic signature compliance (e.g., meeting the stringent criteria of 21 CFR Part 11).

The transition to smart infrastructure, enabled by IoT and advanced communication protocols, represents the third major technology trend. New generation cabinets are designed to be networked, allowing facility managers to remotely monitor the operational status, energy consumption, and performance metrics of hundreds of units simultaneously from a central control hub. This connectivity enables predictive maintenance alerts, software updates, and the seamless export of validation data directly to centralized quality management systems (QMS). Furthermore, manufacturers are investing in specialized anti-static and ESD-safe construction materials and grounding technologies, recognizing the essential need to mitigate electrostatic risk in electronics and precision optics environments, demonstrating a holistic approach to component protection beyond simple particulate control.

Regional Highlights

- North America: North America, particularly the United States, holds the largest market share in terms of value, characterized by early adoption of advanced storage technologies and high-specification custom solutions. The region benefits from extensive research funding, large-scale pharmaceutical R&D operations, and a strong regulatory environment that necessitates continual infrastructure upgrades to maintain compliance. Demand is concentrated on high-end VLF units, inert gas purge cabinets for aerospace materials, and sophisticated temperature-controlled units required for cutting-edge cell and gene therapy manufacturing, driving higher average selling prices and technological complexity.

- Europe: The European market is stable and mature, demonstrating robust demand fueled by strict adherence to EU GMP guidelines, including the critical Annex 1 revisions emphasizing contamination control throughout sterile manufacturing workflows. Countries such as Germany, Switzerland, and Ireland, which host major pharmaceutical and chemical manufacturing hubs, represent the core demand centers. The focus is predominantly on durable, easy-to-clean stainless steel cabinets and dynamic pass-through systems that enhance material flow efficiency while rigidly preventing cross-contamination between classified zones, ensuring high investment in validated, long-lifecycle equipment.

- Asia Pacific (APAC): APAC is the fastest-growing region, projected to surpass all others in capacity expansion due to rapid industrialization in key economies. This growth is predominantly driven by two sectors: government-backed investment in enormous semiconductor fabrication facilities (Fabs) across China, Taiwan, and South Korea, necessitating massive volumes of highly specialized desiccator and nitrogen-purged cabinets; and the rapid expansion of affordable pharmaceutical and generic drug manufacturing capacity in India and Southeast Asia. The market here is characterized by high-volume procurement and a growing preference for regional suppliers offering competitive pricing alongside certified compliance.

- Latin America (LATAM): Growth in LATAM is gradually increasing, propelled by improving economic stability and targeted investments in public health infrastructure and domestic drug production, particularly in Brazil and Mexico. The market generally seeks cost-effective, reliable standard cleanroom storage solutions (ISO Class 7/8), though there is emerging demand for higher-specification cabinets as local pharmaceutical companies strive to meet international export standards and secure necessary certifications (e.g., WHO or FDA pre-qualification).

- Middle East and Africa (MEA): This region is an emerging market with significant long-term potential, primarily concentrated in the Gulf Cooperation Council (GCC) states. Economic diversification strategies in Saudi Arabia and the UAE are leading to the construction of advanced research parks and pharmaceutical manufacturing plants, creating initial high-value demand for new, certified cleanroom equipment from international suppliers. The unique regional challenge involves procuring specialized units designed to mitigate the effects of high ambient temperatures and dust loads found in arid environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cleanroom Storage Cabinet Market.- Terra Universal Inc.

- Azbil Corporation

- Labconco Corporation

- Esco Group

- Flow Sciences, Inc.

- Air Science LLC

- Clean Air Products

- Plas-Labs, Inc.

- Sentry Air Systems, Inc.

- OCTANORM AG

- Kewaunee Scientific Corporation

- Waldner Laboreinrichtungen GmbH & Co. KG

- Dafeng Cleanroom Equipment

- Lab Furniture and Fume Hoods

- Technical Manufacturing Corp. (TMC)

- M. Braun Inertgas-Systeme GmbH

- Bio-Bubble, Inc.

- Micronova Manufacturing Inc.

- Stainless Structurals LLC

- Sheldon Laboratory Systems

- Thermo Fisher Scientific Inc. (through lab equipment offerings)

- Aseptic Enclosures

- Cleatech, LLC

Frequently Asked Questions

Analyze common user questions about the Cleanroom Storage Cabinet market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for advanced cleanroom storage cabinets?

The foremost driver is the increasingly stringent global regulatory framework, such as FDA GMP guidelines and ISO 14644 standards, which mandate verifiable, contamination-free storage conditions for sensitive products, particularly in the rapidly expanding pharmaceutical and semiconductor manufacturing sectors.

How do static and dynamic cleanroom cabinets differ in function?

Static cleanroom cabinets provide sealed storage within the clean environment without active air filtration or circulation. Dynamic cabinets, such as Laminar Flow Storage Units or Dynamic Pass-Throughs, actively filter the internal air using HEPA/ULPA filters to maintain constant unidirectional airflow, actively mitigating particulate contamination during storage or transfer, crucial for protecting highly sensitive materials.

Which end-user industry holds the largest market share for cleanroom storage solutions?

The Pharmaceutical and Biotechnology industry currently accounts for the largest market share. This dominance is due to the absolute necessity of maintaining sterility and preventing cross-contamination for APIs, biological samples, and finished sterile dosage forms throughout the entire manufacturing supply chain, requiring validated, traceable storage conditions.

What role does IoT technology play in modern cleanroom storage cabinets?

IoT integration allows modern cabinets to function as "smart storage," utilizing embedded sensors to continuously monitor and log critical environmental parameters (temperature, humidity, pressure, particle count) in real-time. This enables remote control, automated compliance reporting, and predictive maintenance alerts, vital for maintaining validated storage conditions and optimizing operational efficiency.

What are the key material considerations when purchasing cleanroom storage cabinets?

Key material considerations involve chemical resistance, non-shedding properties, and ease of cleaning. Stainless steel (304 or 316L) is preferred for high-sterility and chemical-heavy applications due to its durability, while high-density polymers are favored in specific lower-corrosion environments or where cost efficiency and ESD protection are prioritized.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager