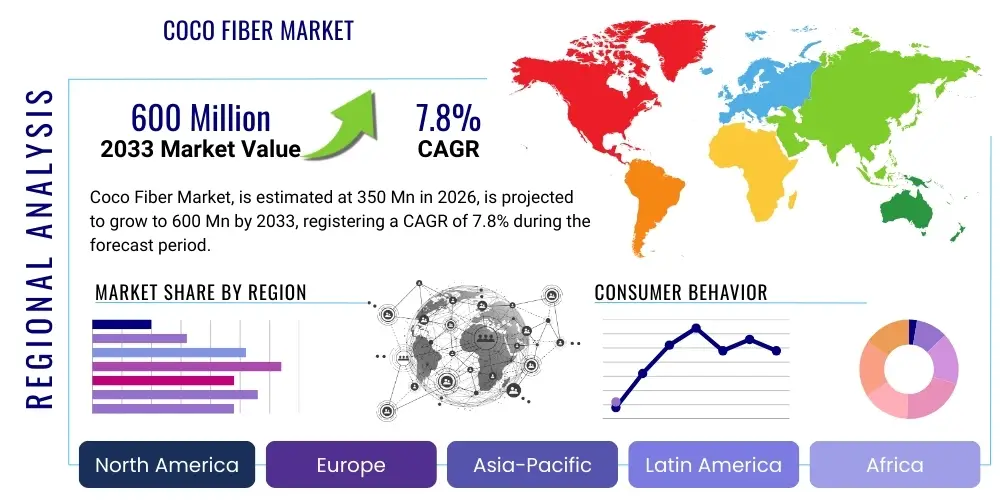

Coco Fiber Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442190 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Coco Fiber Market Size

The Coco Fiber Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 350 Million in 2026 and is projected to reach USD 600 Million by the end of the forecast period in 2033.

Coco Fiber Market introduction

The Coco Fiber market, primarily driven by increasing global focus on sustainable and natural products, encompasses the trade and utilization of coir, a natural fiber extracted from the husk of coconuts. This versatile material finds extensive application across diverse industries, ranging from horticulture and agriculture to automotive, construction, and furnishings. Known for its high lignin content, excellent water retention capabilities, and inherent resistance to rot, mold, and moisture, coco fiber presents an eco-friendly alternative to synthetic materials like peat moss and certain plastics. The market is witnessing robust expansion, especially in regions with high agricultural output and stringent environmental regulations promoting bio-based inputs.

Coco fiber is categorized mainly into brown fiber (extracted from mature coconuts, used in upholstery, matting, and brush making) and white fiber (extracted from immature coconuts, generally used for ropes, fishing nets, and less rigid applications). The increasing demand for soilless growing media, particularly in the booming greenhouse and vertical farming sectors, is a primary catalyst propelling the market forward. Furthermore, its excellent sound absorption and thermal insulation properties are generating significant traction in the construction and automotive interior sectors, positioning coco fiber as a crucial bio-composite raw material.

The key driving factors for market growth include the global shift toward sustainable farming practices, the superior performance attributes of coir in horticulture (e.g., pH neutrality, porosity), and growing consumer awareness regarding the environmental impact of traditional, non-renewable materials. Governments and international organizations are increasingly supporting coir production and utilization through subsidies and initiatives promoting circular economy principles, further solidifying the material’s relevance across multiple high-value industries. The ease of availability in major coconut-producing nations such as India, Sri Lanka, and Indonesia provides a stable supply base essential for long-term market sustainability and investment attractiveness.

Coco Fiber Market Executive Summary

The global Coco Fiber market is characterized by dynamic business trends centered on sustainability, technological refinement, and diversification of end-use applications. Key business trends indicate a substantial move towards advanced processing technologies that reduce water consumption and improve fiber quality, thereby increasing acceptance in highly regulated industries like automotive manufacturing. Strategic alliances between fiber processors and major horticultural supply chain companies are becoming prevalent, aimed at securing consistent, high-grade coir supply. Investment in automation, particularly in fiber separation and treatment facilities, is crucial for market players seeking to enhance operational efficiency and maintain competitive pricing globally. Furthermore, the development of coir composites is opening new avenues for market penetration into infrastructure and industrial packaging.

Regionally, the Asia Pacific (APAC) dominates the production and consumption landscape due to the concentration of major coconut cultivation areas and well-established processing infrastructure, especially in South Asia. However, North America and Europe are exhibiting the highest growth rates, driven by stringent environmental standards favoring biodegradable products and the rapid adoption of hydroponic and controlled environment agriculture (CEA) systems. These Western markets prioritize premium, treated, and certified coir substrates, necessitating robust import and quality assurance mechanisms. Latin America, particularly Brazil and Mexico, is emerging as a significant market, balancing both high-volume production and increasing domestic consumption in agricultural exports.

Segment-wise, the horticulture application segment commands the largest market share, fueled by the accelerating transition from traditional soil methods to coco peat and grow bags. Fiber extracted from the husk remains the dominant product type, but the utilization of coir pith and short fibers in erosion control and filtration systems is growing rapidly. Trends also indicate a segmentation shift where specific grades of coco fiber, optimized for characteristics like low electrical conductivity (EC) and high air-filled porosity (AFP), are becoming specialized products commanding higher price points. The bedding and furnishing segment also shows stable growth, capitalizing on the natural, hypoallergenic properties of coco fiber for mattresses and upholstery filling.

AI Impact Analysis on Coco Fiber Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Coco Fiber market primarily revolve around efficiency gains in processing, enhanced quality control, and predictive analytics for raw material sourcing. Users frequently inquire: "How can AI optimize the retting and drying process to save time and energy?" and "Can AI-driven sensors improve the grading and sorting of coco fiber based on length and micronaire?" There is significant concern about integrating complex AI systems into traditionally low-tech rural processing units. Key expectations include using AI algorithms to forecast regional coconut yields based on climate data, optimizing logistics routes for fiber export, and implementing machine vision systems to automate defect detection in manufactured coir products like mats and ropes. The overarching theme is leveraging AI to transition the industry from manual, labor-intensive operations to standardized, high-precision industrial processes capable of meeting stringent global quality requirements.

The implementation of AI and Machine Learning (ML) models is expected to revolutionize several critical stages of the coco fiber supply chain. In the plantation stage, predictive analytics based on satellite imagery and historical weather patterns can optimize harvesting schedules, ensuring the collection of coconuts at peak maturity for maximum fiber yield and quality. In the crucial retting and drying phases, IoT sensors monitored by AI can precisely control environmental variables like humidity and temperature, significantly reducing processing time, minimizing fiber degradation, and ensuring uniformity across batches. This technological integration addresses a major traditional constraint: the variability inherent in natural fiber processing.

Furthermore, AI-powered automation is poised to enhance the market's competitiveness by optimizing resource utilization. For instance, ML algorithms can analyze energy consumption patterns in defibering units and recommend energy-saving operational parameters. In the quality assurance domain, computer vision systems offer rapid, objective assessment of fiber characteristics (e.g., color, foreign matter content, length distribution) that human inspection cannot match. This level of automated quality control is vital for market players exporting high-value products like specialized hydroponic substrates to technologically advanced markets like Europe and North America, ultimately bolstering consumer confidence and market stability.

- AI-driven optimization of retting and drying cycles to improve processing efficiency and consistency.

- Machine Vision systems automating quality grading of fiber length and cleanliness, ensuring adherence to export standards.

- Predictive analytics for coconut yield forecasting, improving raw material procurement strategies and inventory management.

- Optimization of logistics and supply chain routes using ML algorithms to reduce transportation costs and carbon footprint.

- Implementation of smart sensors (IoT) connected to AI platforms for real-time monitoring of operational parameters in fiber mills.

DRO & Impact Forces Of Coco Fiber Market

The dynamics of the Coco Fiber market are shaped by a complex interplay of Drivers, Restraints, and Opportunities, which collectively constitute the market’s impact forces. The primary driver is the accelerating global adoption of sustainable agriculture, particularly hydroponics and greenhouse farming, which relies heavily on coco peat as a superior, renewable growing medium. Coupled with this is the escalating demand for natural, biodegradable raw materials across construction (insulation, geo-textiles) and manufacturing (automotive interiors, composites). These drivers create a sustained upward pressure on demand, ensuring robust market expansion, especially in developed economies committed to environmental sustainability targets.

However, the market faces significant restraints. The variability in raw material quality, often dependent on unpredictable climate conditions and inconsistent processing methods across small-scale suppliers, poses a challenge to large industrial buyers requiring uniformity. Furthermore, the high initial investment required for modern processing infrastructure, including decortication and drying machinery, acts as a barrier to entry for smaller enterprises. Crucially, logistical challenges associated with shipping voluminous, relatively low-density materials like coir across continents contribute substantially to final product costs, occasionally making synthetic alternatives more economically attractive despite their environmental drawbacks. The risk of contamination, particularly high electrical conductivity (EC) and chloride levels, requires meticulous washing and buffering processes, adding complexity and cost.

The opportunities within the market are vast, predominantly centered on product innovation and geographic expansion. Developing advanced coco fiber composites with enhanced mechanical properties allows for deeper penetration into high-value industrial sectors such as automotive lightweighting and aerospace component manufacturing. Furthermore, capitalizing on the environmental benefits through robust certifications (e.g., RHP, OMRI) can unlock premium pricing segments. Geographically, expanding processing capabilities and market reach into emerging regions in Africa and Latin America, coupled with promoting coir for local infrastructure projects like erosion control and embankment stabilization, presents significant growth potential. Technological advancements in sustainable packaging for coco substrates are also a key opportunity to reduce waste and improve logistical efficiency.

Segmentation Analysis

The Coco Fiber market is systematically segmented based on Product Type, Application, and End-Use Industry, allowing for granular analysis of demand patterns and market potential across various specialized niches. Product segmentation differentiates between raw coir fiber (long fibers used for mattresses, erosion control, and cordage) and coco pith/peat (short fibers and dust used predominantly in horticulture and soil conditioning). Understanding this split is critical as the processing requirements and end-market prices differ significantly between the two. The underlying rationale for this segmentation is the functional disparity of the different parts of the coconut husk, enabling manufacturers to specialize and optimize their production lines.

Application segmentation highlights the distinct purposes for which coco fiber is utilized, defining its value proposition in various sectors. The primary applications are in horticulture (as a substrate, mulch), erosion control (geotextiles), bedding and furniture (filling material), and industrial uses (composites, filtration). Horticulture remains the dominant application due to the exceptional attributes of coco peat in managing moisture and air porosity for plant growth. However, the fastest growth is observed in erosion control and industrial applications, driven by infrastructural development and the search for sustainable, durable geo-textile materials that can replace synthetic polymers in civil engineering projects.

End-use segmentation categorizes the ultimate buyers of coco fiber products, including commercial growers (greenhouses, nurseries), construction companies, automotive manufacturers, furniture makers, and consumers (for home gardening). This structure helps market participants tailor marketing efforts and product specifications to meet the rigorous quality and volume demands of specific industrial clients versus the needs of retail consumers. The rise of large-scale commercial farming operations globally ensures that commercial growers remain the most impactful end-user group, demanding consistent quality and bulk supply. Conversely, the construction and automotive sectors offer high-margin opportunities requiring specialized treatment and certification processes.

- Product Type

- Coir Fiber (Brown Fiber, White Fiber)

- Coco Pith/Peat (Grow Bags, Blocks, Bales, Discs)

- Coir Dust/Short Fiber

- Application

- Horticulture and Agriculture (Soilless Media, Hydroponics, Seed Starting)

- Geo-textiles and Erosion Control

- Bedding and Upholstery (Mattresses, Cushions)

- Filtration and Water Treatment

- Automotive and Industrial Composites

- End-Use Industry

- Commercial Growers and Nurseries

- Construction and Civil Engineering

- Automotive Industry

- Furniture and Bedding Industry

- Residential/Retail Gardening

Value Chain Analysis For Coco Fiber Market

The Value Chain for the Coco Fiber market begins with the upstream processes centered on raw material sourcing and initial processing. Upstream analysis involves coconut cultivation, harvesting, and the acquisition of coconut husks, typically involving smallholder farmers or large plantations. The critical first step is retting, where husks are soaked (traditionally in water, increasingly in mechanical or chemical processes) to loosen the fibers. This process is highly sensitive to environmental factors and directly dictates the quality and usability of the final product. Key upstream activities also include the initial defibering and separation of the long coir fiber from the coco pith and short fibers, usually performed near the cultivation source to minimize transportation costs of bulky raw material.

The downstream analysis focuses on the transformation of the separated materials into usable final products and their subsequent distribution. For coco peat, this involves extensive washing, buffering (to reduce salinity), drying, compression into blocks or bales, and specific packaging (e.g., grow bags). For coir fiber, transformation involves twisting, spinning into yarn, or weaving into mats, ropes, or geo-textiles. Direct channels, involving large processors selling bulk orders directly to major commercial growers or industrial manufacturers (e.g., automotive companies), ensure strict quality compliance and custom specification delivery. These direct relationships are often fortified by long-term contracts guaranteeing supply stability.

Indirect distribution channels leverage wholesalers, distributors, and retail chains, particularly for consumer-grade products such as packaged coco peat blocks for home gardening or pre-fabricated erosion control blankets. These channels provide wide market reach but introduce additional logistical costs and inventory management complexities. The distribution network must navigate the challenge of shipping high-volume, low-density goods efficiently across international borders. Strategic positioning of processing facilities near major ports, coupled with optimizing compression techniques, is essential for maintaining competitive landed costs in key import markets like North America and Europe.

Coco Fiber Market Potential Customers

Potential customers for Coco Fiber products are highly diversified, reflecting the material’s broad utility across industrial, agricultural, and consumer sectors. The most significant segment comprises professional agricultural enterprises, including large-scale commercial greenhouses, hydroponic facilities, and nurseries globally. These buyers seek buffered, low EC coco peat and grow bags as a premium, renewable substrate alternative to rock wool or peat moss, valuing its consistency, superior air-filled porosity, and disease suppression capabilities. Their purchasing decisions are driven by factors like yield enhancement, water retention efficiency, and compliance with organic farming certifications, making quality consistency paramount.

Another rapidly expanding customer base is the civil engineering and construction industry. These customers utilize coco fiber primarily in the form of woven geo-textiles (coir mats) for slope stabilization, erosion control, and soil reinforcement in infrastructure projects (roads, embankments, landfills). They are driven by environmental compliance mandates requiring biodegradable, non-synthetic erosion solutions and the proven durability of coir fibers in challenging outdoor environments. Furthermore, certain construction firms purchase processed coir fiber for use as a lightweight, natural insulation material in building envelopes, appealing to energy-efficient and sustainable architecture projects.

The third major group includes industrial manufacturers, specifically those in the automotive, furniture, and filtration sectors. Automotive manufacturers utilize coir fiber as a component in bio-composites for interior trim panels and seat cushioning, seeking lightweight, sustainable alternatives that meet fire safety and durability standards. Furniture and bedding companies value coir's natural springiness, breathability, and hypoallergenic properties for mattress cores and upholstery padding. Lastly, municipal and industrial water treatment facilities represent a niche but growing customer segment, purchasing coco fiber for use in bio-filtration systems due to its high surface area and ability to harbor microbial communities effective in treating wastewater.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350 Million |

| Market Forecast in 2033 | USD 600 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Geofabrics Australasia Pty Ltd., Formed Fiber Technologies, FibreDust LLC, Coirtex, Allwin Coir, Pelemix S.L., Fibre Family, Dutch Plantin B.V., Cocogreen, Vita-Poli, Kumaran Coir, Classic Coir, Sai Cocopeat Exports, Green Fiber Co., Ben-Con, RIOCOCO, Southern Coco, Botanicoir, Cocopeat India, Sree Balaji Coirs. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Coco Fiber Market Key Technology Landscape

The technological landscape of the Coco Fiber market is undergoing evolution, moving away from traditional manual processing methods towards mechanized and chemically assisted operations focused on improving efficiency, consistency, and reducing environmental impact. A key technological focus is on mechanization of the defibering and separation process using automated decorticating machines, which significantly increase throughput and minimize fiber damage compared to traditional manual separation. Advanced rotary sifters and hydraulic compression baling machines are critical for reducing the volume of coir pith and fiber, making long-distance shipping economically viable. These physical processing technologies are essential for creating products that meet global bulk handling and transportation standards.

Crucially, the treatment and purification phase relies on sophisticated chemical and hydrological technologies. The development of accelerated retting methods, including microbial or enzymatic treatments, is replacing prolonged traditional water retting, thereby reducing the risk of fiber degradation and accelerating the overall production cycle. Furthermore, for horticultural applications, the technology surrounding the washing and buffering of coco peat is paramount. Reverse osmosis and complex ion exchange processes are increasingly utilized to meticulously control the electrical conductivity (EC) and pH levels of the substrate, neutralizing harmful salts (sodium, chloride) and ensuring the final product is chemically stable for sensitive hydroponic crops. This chemical refinement allows coco peat to compete directly with highly engineered synthetic substrates.

In the end-product manufacturing sphere, the adoption of specialized weaving and needling technologies for geo-textiles and erosion control blankets has boosted their performance and lifespan. Automated needle punching machines create durable, high-density coir mats with uniform thickness, essential for civil engineering applications. For industrial composites, technology focuses on surface modification of the fiber, using coupling agents or plasma treatment to enhance compatibility between the natural coir fibers and polymer matrices (thermoplastics or thermosets). This technological advancement is key to unlocking the potential of coco fiber in high-specification sectors like automotive interiors and lightweight panels, ensuring robust mechanical integration and improved performance characteristics.

Regional Highlights

- Asia Pacific (APAC): Dominates the global market, both in terms of production and consumption, due to favorable climate for coconut cultivation and the presence of major processing hubs in India, Sri Lanka, Indonesia, and the Philippines. The region benefits from lower labor costs and established infrastructure for processing raw husks into bulk fiber and coco peat, driving global exports, particularly to Europe and North America.

- North America: Exhibits one of the highest growth rates, driven primarily by the explosion of controlled environment agriculture (CEA), hydroponic farming, and increasing consumer interest in organic gardening supplies. Demand is concentrated on high-quality, certified (RHP/OMRI) buffered coco substrates, often commanding premium prices due to stringent quality import standards.

- Europe: A significant import market characterized by strict environmental regulations and high technological adoption in horticulture. The Netherlands, Spain, and Germany are key consumers, utilizing coco fiber extensively in greenhouses and demanding environmentally traceable and sustainably sourced materials. Growth is also supported by the use of coir geo-textiles in large civil construction projects for environmental mitigation.

- Latin America (LATAM): A region transitioning from being solely a raw material supplier (Brazil, Mexico) to a significant processing and consumer market. Growth is fueled by the expansion of large-scale agricultural exports (e.g., berries, tomatoes) that utilize coco peat for yield optimization, alongside increasing domestic demand for erosion control materials.

- Middle East and Africa (MEA): Emerging market segment focusing on agricultural diversification and water conservation efforts. Coco fiber is highly valued in arid regions for its exceptional water retention properties, making it crucial for landscaping and specialized high-value crop cultivation, particularly in the UAE, Saudi Arabia, and Israel.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Coco Fiber Market.- Geofabrics Australasia Pty Ltd.

- Formed Fiber Technologies

- FibreDust LLC

- Coirtex

- Allwin Coir

- Pelemix S.L.

- Fibre Family

- Dutch Plantin B.V.

- Cocogreen

- Vita-Poli

- Kumaran Coir

- Classic Coir

- Sai Cocopeat Exports

- Green Fiber Co.

- Ben-Con

- RIOCOCO

- Southern Coco

- Botanicoir

- Cocopeat India

- Sree Balaji Coirs

Frequently Asked Questions

Analyze common user questions about the Coco Fiber market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of using coco fiber (coir) over peat moss in horticulture?

Coco fiber offers superior water retention combined with high air-filled porosity, preventing compaction and ensuring optimal root aeration. Unlike peat moss, coir is pH neutral, naturally renewable, and significantly less susceptible to breakdown, offering a longer lifespan as a growing medium. Its environmental profile is also far more sustainable than that of non-renewable peat harvesting.

How is the quality of coco fiber measured, and what is the importance of EC (Electrical Conductivity)?

Coco fiber quality is assessed based on fiber length, uniformity, cleanliness, and chemical parameters like pH and Electrical Conductivity (EC). EC measures the concentration of salts (primarily sodium and chloride) present. For high-value hydroponic crops, a low EC level (typically below 0.5 mS/cm) is crucial, achieved through extensive washing and buffering, to prevent nutrient lockout and salt toxicity to the plants.

Which geographical regions are the leading producers and consumers of coco fiber globally?

Asia Pacific (APAC), particularly India, Sri Lanka, Indonesia, and the Philippines, are the dominant global producers due to high raw material availability and established processing infrastructure. The largest consumers are typically highly developed agricultural markets in North America and Europe, driven by advanced greenhouse and hydroponic farming operations requiring large volumes of consistent, high-grade substrates.

What is the main application of coco fiber geo-textiles in civil engineering and erosion control?

Coco fiber geo-textiles, often woven into mats or blankets, are used primarily for stabilizing slopes, controlling surface erosion, and establishing vegetation cover. Their inherent strength, biodegradability, and high moisture absorption capacity make them highly effective for temporary erosion protection, eventually decomposing to enrich the soil once the vegetation is established.

What technological advancements are driving improved efficiency in coco fiber processing?

Key technological advancements include automated defibering and decortication machinery for increased throughput, advanced hydraulic compression baling to reduce shipping volumes, and specialized washing and buffering techniques (like reverse osmosis) to precisely control the pH and electrical conductivity of coco peat for sensitive hydroponic applications, ensuring quality consistency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager