Cold Mixed Asphalt Additives Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441384 | Date : Feb, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Cold Mixed Asphalt Additives Market Size

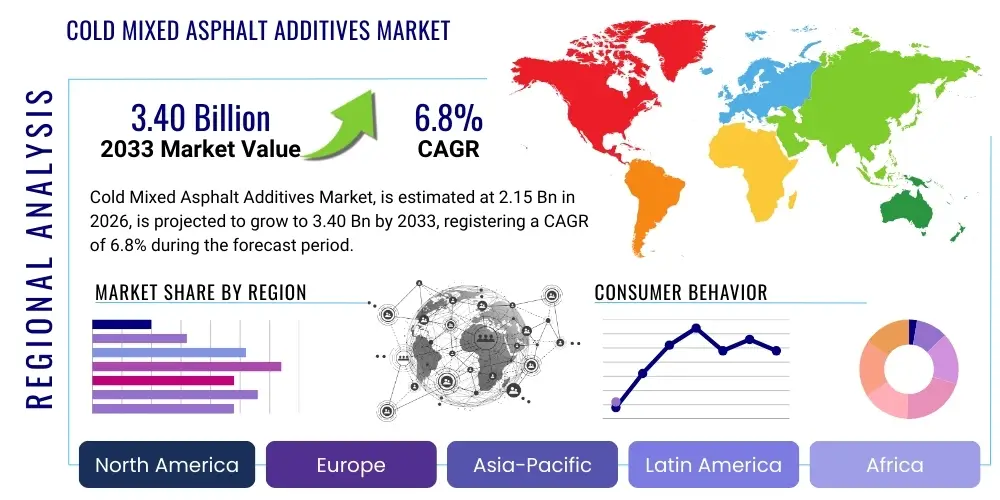

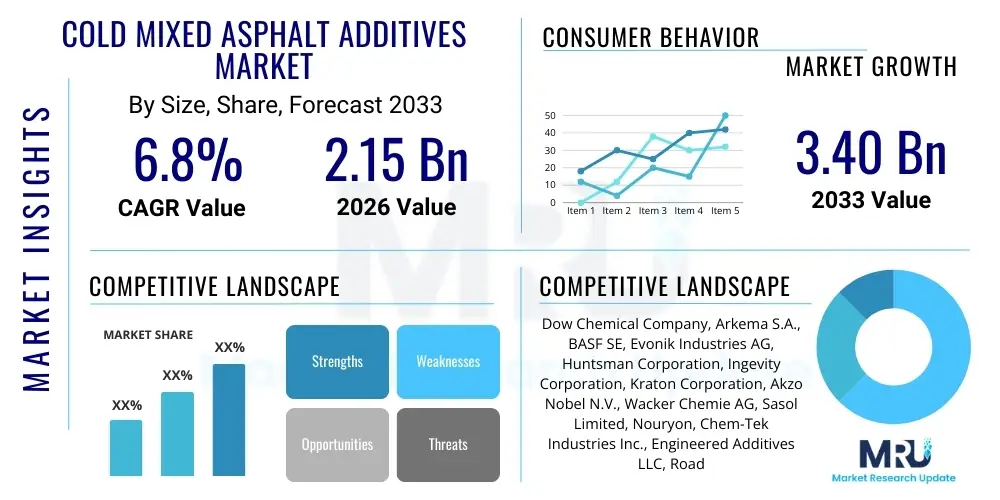

The Cold Mixed Asphalt Additives Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $2.15 Billion in 2026 and is projected to reach $3.40 Billion by the end of the forecast period in 2033.

Cold Mixed Asphalt Additives Market introduction

The Cold Mixed Asphalt Additives Market encompasses specialty chemicals and polymers incorporated into asphalt mixes that are applied and compacted at ambient temperatures. Unlike traditional hot mix asphalt (HMA), which requires high-energy heating, cold mix asphalt (CMA) utilizes emulsification techniques and specific additives to achieve the necessary binding and performance characteristics while significantly reducing energy consumption and greenhouse gas emissions. This shift towards lower-temperature application methodologies is a cornerstone of sustainable infrastructure development, particularly favored for road patching, rural road construction, and applications in remote or environmentally sensitive areas where HMA production is impractical or prohibited.

Product categories within this market typically include emulsifiers, adhesion promoters, anti-stripping agents, and performance modifiers designed to improve the workability, storage stability, and ultimate pavement durability of the cold mix. Emulsifiers play a critical role in dispersing asphalt cement into fine particles within an aqueous phase, allowing for easy mixing with aggregate. Adhesion promoters and anti-stripping agents are vital for ensuring the robust bond between the binder and aggregate, especially in the presence of moisture, which is a common challenge for cold mix technologies. The overall function of these additives is to mimic the rheological and mechanical properties of hot-applied asphalt while eliminating the need for elevated processing temperatures.

Major applications driving the demand for cold mixed asphalt additives include routine pavement maintenance, emergency pothole repair, and the construction of low-volume roads. The primary benefits driving market penetration are the enhanced occupational safety, reduced energy footprint, and the ability to stockpile the treated mix for extended periods, providing logistical flexibility. Key driving factors include increasing governmental focus on sustainable road infrastructure, stringent environmental regulations limiting VOC emissions from traditional asphalt plants, and the inherent cost-effectiveness of cold mix technologies for repair operations, allowing for year-round utility even in colder climates where HMA construction halts.

Cold Mixed Asphalt Additives Market Executive Summary

The Cold Mixed Asphalt Additives Market is experiencing robust expansion driven by global imperatives for sustainable infrastructure development and the increasing lifespan requirements for road networks. Current business trends indicate a strong preference among municipal authorities and public works departments for cold asphalt solutions due to their lower installation costs and reduced environmental impact compared to traditional hot mix alternatives. Furthermore, continuous innovation in additive chemistry is resolving historical performance issues associated with cold mix, specifically concerning early-age strength development and long-term rutting resistance, thereby broadening its applicability beyond temporary repairs into semi-permanent and structural overlays.

Regionally, the Asia Pacific (APAC) stands out as the fastest-growing market, fueled by massive government investments in road construction and rapid urbanization across economies such as China, India, and Southeast Asian nations. North America and Europe, characterized by mature regulatory environments and extensive highway systems, exhibit high demand driven by maintenance and rehabilitation cycles, coupled with regulatory mandates promoting low-emission construction practices. European trends particularly emphasize the use of bio-based and recycled content additives to meet strict circular economy goals, pushing manufacturers toward sustainable raw material sourcing and green chemistry principles.

Segment trends highlight the dominance of emulsifiers and adhesion promoters as essential product types, given the foundational necessity of effective water management in cold mix applications. In terms of application, pavement repair and maintenance remain the core revenue generator, leveraging the cold mix’s ease of use and rapid deployment capabilities. However, the emerging segment of specialized road construction, particularly for secondary and tertiary road networks, is poised for significant growth. Manufacturers are focusing on developing multi-functional additives that combine improved workability with enhanced stripping resistance and freeze-thaw durability, catering to the diverse climatic challenges faced globally.

AI Impact Analysis on Cold Mixed Asphalt Additives Market

User inquiries regarding AI's influence in the Cold Mixed Asphalt Additives Market primarily focus on optimizing material formulations, predicting pavement performance lifetime, and automating quality control during production and application. Key concerns revolve around whether AI-driven systems can efficiently analyze complex rheological data to develop superior, climate-specific additive packages and whether machine learning (ML) algorithms can be integrated into mobile pavement inspection units to predict areas requiring immediate cold patch repair. Users expect AI to minimize human error in mixing ratios and significantly enhance the consistency and quality of stockpiled cold mix, ensuring superior long-term performance and reducing waste, especially concerning the optimal dosage of viscosity modifiers and anti-strip agents in variable aggregate moisture conditions.

- AI-driven formulation optimization minimizes additive usage while achieving target pavement performance specifications, reducing material costs.

- Machine learning models predict the viscoelastic behavior and curing time of various cold mix formulations under different ambient temperature and humidity conditions.

- Predictive maintenance analytics use sensor data from existing infrastructure to identify specific distress patterns, optimizing the timing and location for cold patch application, improving efficiency.

- Automated image processing and computer vision systems ensure consistent aggregate coating and additive dispersion during the mixing process, enhancing quality control.

- AI assists in supply chain management by forecasting regional demand for specific additive types based on seasonal weather patterns and scheduled infrastructure projects.

DRO & Impact Forces Of Cold Mixed Asphalt Additives Market

The dynamics of the Cold Mixed Asphalt Additives Market are shaped by a strong push toward ecological and economic efficiency, balanced against technical challenges inherent in low-temperature applications. A major driver is the substantial global increase in government infrastructure spending, particularly focused on maintaining aging road networks where rapid, cost-effective repair solutions like cold mix are highly valued. Furthermore, increasingly strict environmental regulations—such as those targeting reductions in energy consumption and greenhouse gas emissions associated with hot mix asphalt production—are actively propelling the adoption of cold mixed technologies. The ability of cold mix to be stockpiled and utilized quickly, regardless of the availability of HMA plants, provides significant logistical and emergency response advantages.

Conversely, the market faces significant restraints. A key technical restraint is the generally lower mechanical strength and longer curing time often associated with cold mixed asphalt compared to its hot mixed counterpart, which can limit its use in high-traffic, structurally demanding applications. There are also concerns regarding the potential leaching of certain chemical components of some additives into the environment, although newer bio-based and non-toxic formulations are addressing this. Market adoption is also hindered by the existing entrenched infrastructure investment in HMA plants and the initial resistance from some contractors who perceive cold mix as a purely temporary fix rather than a viable, long-term pavement solution.

Opportunities abound, particularly in the development of high-performance, polymer-modified cold mix additives that significantly enhance early-age strength and long-term durability, thereby expanding the acceptable use cases into main roads and higher-stress areas. The proliferation of bio-based and sustainable additives derived from renewable resources presents a compelling path for manufacturers to meet both regulatory demands and growing consumer preference for green products. The expansion into emerging economies with nascent but rapidly growing road networks, where large-scale HMA production facilities may be scarce, offers substantial growth potential for cold mix solutions. The market impact forces indicate that technological innovation in formulation chemistry and supportive regulatory frameworks are the primary external factors dictating the pace of market penetration against established hot mix methods.

Segmentation Analysis

The Cold Mixed Asphalt Additives Market is extensively segmented based on the function of the additive, the chemical composition, and the specific application area in road construction and maintenance. Segmentation allows market players to specialize in highly effective chemistries tailored to specific aggregate types and climate conditions, optimizing performance and cost-efficiency. The core segmentation by type reflects the chemical role additives play in the mix, ranging from facilitating the initial emulsification process to ensuring long-term adhesion and water resistance, crucial factors for the success of cold mix application. Furthermore, the segmentation by application distinguishes between the high-volume, structural needs of new road construction and the diverse, rapid deployment requirements of maintenance and repair activities.

The product type segmentation is critical for understanding technological advancements, with adhesion promoters and anti-stripping agents gaining prominence due to the necessity of mitigating moisture damage, which is a key failure mechanism in cold mix. The application segmentation demonstrates the strategic importance of the repair segment, which benefits profoundly from the stockpile capability and low-temperature applicability of CMA. As manufacturers develop additives capable of providing performance parity with HMA, the new road construction segment is expected to increase its market share, driven by increasing regulatory support for sustainable construction methods and life cycle cost advantages.

- By Type:

- Emulsifiers (Cationic, Anionic, Non-ionic)

- Anti-stripping Agents and Adhesion Promoters

- Viscosity Modifiers and Rheology Enhancers

- Performance Polymers and Fiber Additives

- Fluxing Agents and Softeners

- By Application:

- Pavement Repair and Maintenance (Pothole Patching, Overlay)

- Low-Volume Road Construction

- Utility Cuts and Trench Restoration

- Shoulder Repair and Parking Lot Construction

- By Chemistry:

- Chemical Modifiers

- Polymer Modifiers

- Bio-based Additives

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Cold Mixed Asphalt Additives Market

The value chain for the Cold Mixed Asphalt Additives Market begins with the upstream sourcing of raw chemical feedstocks, primarily petrochemical derivatives (for polymers and certain emulsifiers) and bio-based sources (for sustainable modifiers). Key activities in this stage involve the purification and synthesis of base chemicals such as amines, fatty acids, and specific polymers. The quality and stable supply of these upstream materials are critical determinants of the final additive performance and cost structure. Major manufacturers often integrate backward or establish long-term supply agreements to mitigate price volatility and ensure the consistency required for high-performance additive formulation.

The midstream segment involves the core intellectual property and manufacturing processes: the blending, modification, and formulation of these raw materials into specialized additive packages. This is where research and development play a decisive role, focusing on customizing emulsifiers and adhesion promoters to suit regional aggregate mineralogy and climatic demands. The distribution channel predominantly involves direct sales to large asphalt emulsion producers and specialized cold mix manufacturers, or through a network of specialized chemical distributors who provide technical support and localized inventory management to smaller road contractors and municipal maintenance yards. The indirect channel involves selling through large construction material suppliers who bundle the additives with other pavement components.

Downstream activities center on the end-user application, which includes mixing the additive-infused emulsion with aggregates at a central facility or increasingly, through in-situ mixing processes. The end-users—primarily public works agencies, road construction companies, and infrastructure maintenance firms—require reliable technical service and guidance on achieving optimal cold mix performance. The effectiveness of the value chain is highly dependent on timely technical support and the ability to quickly adapt additive formulations to new aggregate sources or specific project requirements, ensuring proper curing and long-term durability in the final pavement structure.

Cold Mixed Asphalt Additives Market Potential Customers

The primary customers and end-users of Cold Mixed Asphalt Additives are organizations responsible for the maintenance, repair, and expansion of road infrastructure globally. These include governmental agencies at the federal, state, and municipal levels, such as Departments of Transportation (DOTs) and public works departments, which purchase cold mix or the additives directly for their extensive maintenance operations and low-volume road projects. The preference for cold mix solutions by these governmental bodies is driven by the necessity for rapid response to pavement failures (e.g., pothole repairs) and the cost-efficiency of year-round deployment, especially in regions experiencing extreme temperature variations that prohibit traditional hot-mix paving for large portions of the year.

Another significant customer segment comprises private road construction and paving contractors. These firms utilize cold mix asphalt, formulated with high-quality additives, for specialized tasks such as utility cut restorations, trench backfilling, parking lot construction, and secondary road overlays where logistical constraints make HMA cost-prohibitive. Furthermore, asphalt emulsion producers and cold mix manufacturing plants represent a crucial intermediary customer base, as they purchase the additives in bulk to formulate the final asphalt products sold to the end-users. The decision criteria for these buyers focus heavily on the additive’s performance metrics, including storage stability, stripping resistance, ease of application, and compliance with local environmental and road quality standards.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $2.15 Billion |

| Market Forecast in 2033 | $3.40 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dow Chemical Company, Arkema S.A., BASF SE, Evonik Industries AG, Huntsman Corporation, Ingevity Corporation, Kraton Corporation, Akzo Nobel N.V., Wacker Chemie AG, Sasol Limited, Nouryon, Chem-Tek Industries Inc., Engineered Additives LLC, Road Science, Sinopec Group, Exxon Mobil Corporation, Specialty Chemicals, Tricor Refining, Zydex Industries, Kao Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cold Mixed Asphalt Additives Market Key Technology Landscape

The technological landscape of the Cold Mixed Asphalt Additives Market is characterized by continuous efforts to enhance the water resistance, storage stability, and long-term mechanical properties of cold-applied pavements. A primary technological focus is the advancement of sophisticated polymer modification techniques. These technologies involve introducing specialized elastomers, such as Styrene-Butadiene-Styrene (SBS) or ethylene-vinyl acetate (EVA), into the asphalt emulsion mixture along with tailored stabilizing agents. This process significantly improves the binder’s elasticity, resistance to permanent deformation (rutting), and overall durability, making cold mix suitable for more demanding applications. The effectiveness of these polymer systems relies heavily on the co-application of proprietary emulsifier packages that ensure the polymer remains homogeneously dispersed within the asphalt phase during the mixing and curing stages.

Another crucial area of technological development involves the chemistry of adhesion promoters and anti-stripping agents. Modern additives are increasingly based on advanced chemical structures, such as complex amines and quaternary compounds, designed to chemically react with both the acidic sites on the aggregate surface and the asphalt binder. This strong chemical linkage prevents water intrusion at the interface, thereby mitigating stripping damage and extending pavement life, particularly critical in freeze-thaw environments. Furthermore, the development of specialized fluxing agents that utilize non-volatile, high-flashpoint oils, often bio-based, is essential for achieving optimal workability at ambient temperatures without relying on harmful solvents, aligning with stricter volatile organic compound (VOC) regulations.

The emerging landscape is heavily influenced by green chemistry principles, leading to innovation in bio-based and sustainable additives. Researchers are exploring the use of renewable resources, such as vegetable oils, lignin derivatives, and waste plastics, to create asphalt modifiers that reduce the dependency on petrochemical feedstocks. These bio-additives not only enhance sustainability metrics but are also being engineered to function as multi-purpose agents, combining fluxing and anti-stripping properties. Additionally, advancements in nanotechnology, though nascent, are being explored to incorporate nano-silica or carbon nanotubes to improve the mechanical stiffness and thermal cracking resistance of cold mix pavements through enhanced molecular structure interaction.

Regional Highlights

- Asia Pacific (APAC): APAC is the largest and fastest-growing market segment, primarily driven by massive government expenditure on national highway construction and urbanization projects, particularly in China, India, and Indonesia. The vast infrastructure deficit and the need for cost-effective, easily deployable road repair solutions in remote areas heavily favor cold mix technology. The focus here is on achieving high-volume production with additives that can handle varied local aggregate types and tropical climate challenges, such as monsoon-related moisture damage.

- North America: North America represents a mature yet highly innovative market, characterized by stringent DOT specifications and a high emphasis on long-term pavement performance and safety. Demand is consistently high, driven by the requirement for durable, rapid repair solutions for extensive interstate highway networks subject to severe freeze-thaw cycles. The market is propelled by a strong regulatory push towards sustainability and reduced energy consumption in road construction, favoring polymer-modified cold mix technologies.

- Europe: The European market is defined by strict environmental mandates and a strong focus on circular economy principles. This drives demand for high-performance additives that facilitate the use of high percentages of Reclaimed Asphalt Pavement (RAP) in cold mixes and mandates the use of non-toxic, bio-based additives. Countries like Germany and the UK lead in adopting sophisticated cold mix techniques for urban road maintenance and utility reinstatement, prioritizing low emissions and minimal traffic disruption during application.

- Latin America (LATAM): LATAM is an emerging growth region, where market penetration is accelerating due to the need for road infrastructure expansion in economically sensitive areas and the lack of widespread HMA production facilities. Key drivers include accessibility and lower capital investment required for cold mix production, making the market highly attractive for cost-efficient emulsifiers and basic anti-stripping agents suitable for rural road networks.

- Middle East & Africa (MEA): The MEA region shows potential growth, particularly in the UAE and Saudi Arabia, driven by rapid urban development and infrastructure diversification. The primary requirement in this region is for additives that can effectively handle extremely high ambient temperatures and UV radiation, ensuring the storage stability and long-term durability of the cold mix pavement under severe heat stress conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cold Mixed Asphalt Additives Market.- Dow Chemical Company

- Arkema S.A.

- BASF SE

- Evonik Industries AG

- Huntsman Corporation

- Ingevity Corporation

- Kraton Corporation

- Akzo Nobel N.V.

- Wacker Chemie AG

- Sasol Limited

- Nouryon

- Chem-Tek Industries Inc.

- Engineered Additives LLC

- Road Science

- Sinopec Group

- Exxon Mobil Corporation

- Specialty Chemicals

- Tricor Refining

- Zydex Industries

- Kao Corporation

- Fosroc International Ltd.

- Cargill, Incorporated

- Momentive Performance Materials

Frequently Asked Questions

Analyze common user questions about the Cold Mixed Asphalt Additives market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary performance advantages of cold mixed asphalt additives over traditional hot mix asphalt?

Cold mixed asphalt (CMA) additives offer advantages including significantly reduced energy consumption and lower greenhouse gas emissions during production, enhanced safety due to ambient temperature application, the ability to be stockpiled for extended periods, and year-round utility for pavement repair, particularly in colder climates.

How do anti-stripping agents improve the durability of cold mixed asphalt pavements?

Anti-stripping agents, often complex amines, chemically bond the asphalt binder to the aggregate surface. This robust chemical linkage prevents water from infiltrating the interface, mitigating moisture damage and stripping failure, which is a common vulnerability in cold mix designs, thereby extending the pavement's service life.

Which regional market is exhibiting the highest growth rate for Cold Mixed Asphalt Additives?

The Asia Pacific (APAC) region currently exhibits the highest growth rate, driven by extensive governmental investments in new road infrastructure, rapid urbanization, and the necessity for cost-effective, easily deployed maintenance solutions across developing economies like China and India.

What is the role of polymer modifiers in enhancing cold mix asphalt performance?

Polymer modifiers, such as SBS or EVA, are used to enhance the viscoelastic properties of the cold mix binder. They increase the mix’s elasticity and resistance to permanent deformation (rutting) at high temperatures, while also improving resistance to low-temperature cracking, expanding the application scope to higher-traffic roads.

Are sustainable or bio-based additives becoming prevalent in the Cold Mixed Asphalt market?

Yes, sustainable and bio-based additives derived from resources like vegetable oils and lignin are increasingly prevalent. This trend is driven by stringent environmental regulations in regions like Europe and North America, aiming to reduce reliance on petrochemicals, lower VOC emissions, and support circular economy objectives in construction materials.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager