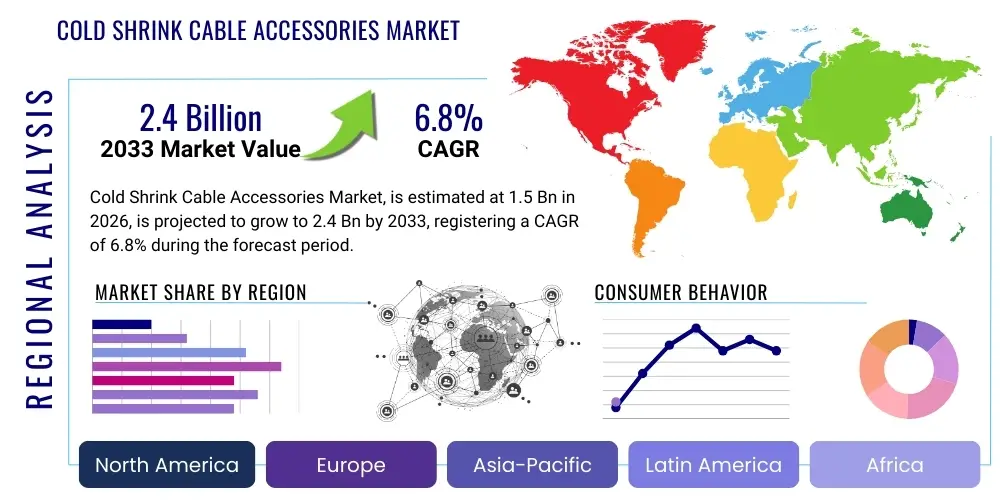

Cold Shrink Cable Accessories Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442907 | Date : Feb, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Cold Shrink Cable Accessories Market Size

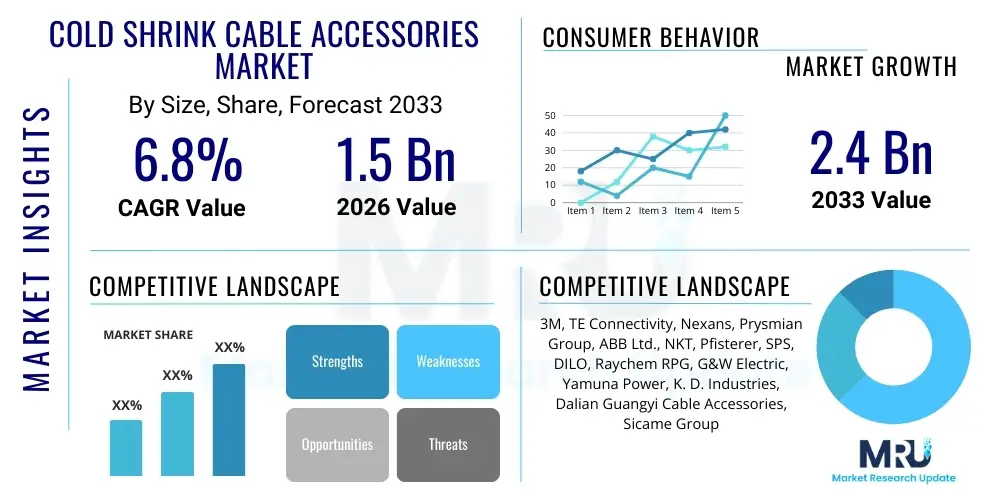

The Cold Shrink Cable Accessories Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.4 Billion by the end of the forecast period in 2033.

The consistent expansion in power transmission and distribution infrastructure globally serves as the fundamental catalyst for the growth trajectory of cold shrink cable accessories. These components, primarily comprising terminations and joints, are essential for ensuring reliable insulation, mechanical protection, and stress control in medium and high-voltage cable systems. The inherent safety advantages, such as installation without the need for heat or specialized tools, significantly reduce installation time and minimize risks associated with open flames, making them the preferred technology over traditional heat shrink alternatives in environments where flammable materials are present or where precise temperature control is challenging to maintain. This technological superiority, coupled with enhanced long-term performance and resistance to environmental factors like UV radiation and moisture ingress, solidifies their position in critical infrastructure projects.

Market expansion is also heavily influenced by the global shift towards renewable energy sources, specifically wind and solar farms, which require extensive underground cable networks for connection to the main grid. Cold shrink technology is particularly well-suited for these applications due to its resilience in harsh outdoor conditions and its ability to accommodate a wide range of cable sizes and insulation materials found in complex renewable energy installations. Furthermore, ongoing modernization projects aimed at replacing aging electrical infrastructure in mature economies, coupled with rapid urbanization and industrialization in emerging markets of Asia Pacific, necessitate reliable and quickly deployable cable accessory solutions. Regulatory mandates promoting safety standards in electrical installations further bolster the adoption rates of these advanced accessories, driving both volume and value growth across various end-user sectors.

Cold Shrink Cable Accessories Market introduction

The Cold Shrink Cable Accessories Market encompasses highly engineered products designed for splicing, terminating, and sealing medium and high-voltage power cables. These accessories utilize pre-expanded elastomeric tubes, typically made from high-quality silicone or EPDM rubber, which are installed over the cable joint or termination point. Installation is achieved by manually removing a removable plastic core, allowing the tube to uniformly shrink onto the cable jacket, providing a tight, void-free seal and excellent electrical insulation without the use of heat guns, torches, or specialized tooling. This simplicity of installation and superior sealing properties make them indispensable in mission-critical applications across various voltage levels, ranging from low voltage applications to complex 35 kV and above high-voltage networks in utilities and industrial settings.

Major applications for cold shrink technology span electric utilities for grid infrastructure, industrial facilities requiring robust power connections (e.g., mining, petrochemicals), and the burgeoning renewable energy sector, including offshore and onshore wind farms, and utility-scale solar installations. The primary benefit these accessories offer is enhanced safety and speed of installation, reducing labor costs and downtime significantly compared to conventional methods. The elastomeric material provides continuous radial pressure, maintaining a secure seal against moisture, contaminants, and thermal cycling, thereby extending the operational lifespan of the cable system. Driving factors include stricter adherence to electrical safety standards, the global push for smart grid development, substantial investments in underground transmission lines, and the necessity of reliable performance in harsh environmental conditions typical of modern infrastructure projects.

Cold Shrink Cable Accessories Market Executive Summary

The global Cold Shrink Cable Accessories Market is experiencing robust growth driven by sustained investment in power distribution infrastructure modernization and the accelerating integration of renewable energy grids. Business trends indicate a strong preference among utility providers for pre-engineered, standardized cold shrink kits, which simplify procurement and installation training, leading to faster deployment times. Manufacturers are focusing heavily on material science advancements, particularly in optimizing silicone rubber compounds to enhance long-term UV and ozone resistance, catering to the increasing demand for accessories suitable for outdoor and exposed installations. Furthermore, strategic partnerships between cable manufacturers and accessory suppliers are becoming common to ensure compatibility and system reliability across the entire power network, fostering innovation aimed at higher voltage applications.

Regionally, the Asia Pacific (APAC) region dominates market expansion, fueled by massive government spending on electrification, rapid industrial growth, and the establishment of new power plants and transmission networks in nations like China, India, and Southeast Asian economies. North America and Europe, while representing mature markets, exhibit steady growth driven by the replacement cycle of aging infrastructure, coupled with rigorous regulatory mandates that favor safe, heatless installation technologies. Segments trends highlight the Medium Voltage (MV) accessories segment as the largest contributor to revenue, primarily due to their ubiquitous use in primary power distribution networks. However, the High Voltage (HV) segment is poised for the fastest growth, propelled by large-scale underground transmission projects and inter-country grid connectivity initiatives. Product standardization and customization capabilities remain key competitive differentiators influencing segmentation uptake.

AI Impact Analysis on Cold Shrink Cable Accessories Market

Common user questions regarding the influence of Artificial Intelligence (AI) on the Cold Shrink Cable Accessories Market frequently revolve around optimizing the manufacturing process, enhancing quality control consistency, and applying predictive analytics to maintenance schedules for installed cable systems. Users are keen to understand how AI algorithms can improve the material formulation process for elastomeric compounds, ensuring optimal performance characteristics such as dielectric strength and elasticity across varying environmental conditions. Key concerns include the integration complexity of AI tools into traditional manufacturing plants and how machine learning (ML) can predict potential points of failure in complex underground cable networks, thereby optimizing the lifecycle management of cold shrink joints and terminations. Expectations center on AI driving cost efficiencies through waste reduction and accelerating new product development cycles to meet higher voltage demands faster, moving the market towards a more intelligent, proactive operational model.

- AI optimizes material blending processes, minimizing batch variation in silicone and EPDM rubber compounds.

- Machine Learning algorithms analyze quality control imaging data, detecting microscopic defects in pre-expanded tubes with higher precision than manual inspection.

- Predictive maintenance platforms use operational data (temperature, load cycles) to forecast potential failure points in cable splices, extending accessory lifespan.

- AI-driven supply chain management improves inventory forecasting for customized cold shrink kits, reducing lead times for critical infrastructure projects.

- Generative design tools utilize AI to model and simulate new accessory designs for ultra-high voltage applications, accelerating R&D efficiency.

DRO & Impact Forces Of Cold Shrink Cable Accessories Market

The market dynamics for cold shrink cable accessories are defined by a powerful convergence of factors where infrastructural requirements, safety standards, and technological adoption play crucial roles. Drivers primarily include substantial global investments in smart grids, the rapid expansion of renewable energy capacity necessitating resilient underground connections, and the intrinsic safety advantage of heatless installation, which dramatically reduces installation risk and complexity. These drivers create a persistent baseline demand for reliable sealing and insulating solutions. Restraints, however, pose moderate challenges, primarily stemming from the relatively higher upfront cost of premium cold shrink solutions compared to traditional heat shrink alternatives, particularly in price-sensitive emerging markets, alongside the necessity for specialized, high-precision installation training to ensure void-free application, which can be a logistical hurdle for large field crews.

Opportunities for market growth are abundant, focusing particularly on developing accessories for increasingly high-voltage applications (up to 132 kV and beyond) required for long-distance power transmission and developing modular, multi-functional kits that integrate advanced sensing capabilities for condition monitoring. The growing acceptance of pre-fabricated kits in the utility sector provides significant scope for standardization and increased production efficiency. The impact forces acting on the market are substantial: regulatory frameworks increasingly mandate safer, more reliable installation methods, favoring cold shrink technology. Simultaneously, the accelerating pace of global electrification in previously underserved regions acts as an enduring external force ensuring continuous demand growth, while competition from advanced polymer technologies necessitates continuous innovation in material science to maintain performance parity and cost effectiveness against competing accessory types.

The overall market trajectory is highly positive, largely insulated by the essential nature of power infrastructure. While economic fluctuations can temporarily slow utility capital expenditure, the fundamental need for maintenance, upgrade, and expansion of power grids remains constant, providing resilience to the cold shrink market. Innovation focused on reducing material costs and simplifying the final steps of installation are critical for mitigating the restraints and capitalizing on the opportunities presented by global electrification trends and infrastructure renewal projects.

Segmentation Analysis

The Cold Shrink Cable Accessories Market is comprehensively segmented based on product type, voltage level, and end-user application, providing a granular view of demand across the power infrastructure landscape. Segmentation by product type primarily includes joints, terminations, and repair kits, each serving distinct functional requirements within the cable network, with terminations holding a significant market share due to their necessity at both ends of every cable run connecting to equipment or overhead lines. The voltage level segmentation (Low Voltage, Medium Voltage, and High Voltage) dictates the technical complexity and material composition of the accessories, where MV applications dominate volume but HV accessories command the highest value per unit due to stringent performance requirements and specialized engineering.

The End-User classification is crucial, delineating demand from key sectors such as Electric Utilities, Industrial (covering heavy manufacturing, mining, oil & gas), and Infrastructure (including transportation networks and data centers). Electric utilities represent the foundational segment, driven by large-scale grid maintenance and expansion programs. However, the industrial sector is increasingly adopting cold shrink technology due to demanding operational environments that necessitate superior sealing properties and resistance to chemicals and abrasive elements. This multi-dimensional segmentation allows manufacturers to tailor product development and marketing strategies precisely, addressing the unique performance criteria and purchasing dynamics specific to each sub-market.

- By Product Type:

- Joints (Splices)

- Terminations

- Repair Kits

- By Voltage Level:

- Low Voltage (Below 1 kV)

- Medium Voltage (1 kV to 35 kV)

- High Voltage (Above 35 kV)

- By End-User:

- Electric Utilities

- Industrial (Manufacturing, Oil & Gas, Mining, Petrochemicals)

- Infrastructure (Railways, Data Centers, Commercial Buildings)

- By Material:

- Silicone Rubber

- Ethylene Propylene Diene Monomer (EPDM) Rubber

Value Chain Analysis For Cold Shrink Cable Accessories Market

The value chain for cold shrink cable accessories begins with the upstream procurement of specialized raw materials, primarily high-grade silicone rubber, EPDM, and various engineered plastics used for the internal support cores. The performance of the final product is highly dependent on the quality and formulation of these elastomeric materials, requiring specialized chemical processing and compounding to achieve necessary dielectric, mechanical, and environmental resistance properties. Key upstream activities include securing stable supplies of chemical feedstocks and continuous research into polymer science to improve flexibility, shrink force, and longevity. The upstream segment is characterized by a limited number of specialized compounders who supply proprietary materials to accessory manufacturers, emphasizing technical specification and consistency.

The midstream involves the core manufacturing process, where the elastomeric compounds are molded, extruded, and pre-expanded onto the removable plastic supporting cores. This stage requires precision engineering and specialized machinery to ensure uniform wall thickness and accurate dimensions, which are crucial for the accessory to provide a void-free seal upon installation. Manufacturing processes are highly standardized and often automated to handle the high-volume production of medium voltage components. Downstream activities involve global distribution, which relies heavily on established electrical wholesale distributors and specialized utility suppliers who manage inventory and provide technical support. Given the critical nature of the product, direct sales channels are frequently employed for large utility contracts and high-voltage projects, where direct technical consultation and project-specific customization are required.

The distribution network balances global reach with localized availability, ensuring that cold shrink kits are accessible quickly for maintenance and emergency repairs. The efficiency of the downstream channel is optimized through rigorous inventory management, as utilities often require accessories certified for specific regional standards. Both direct channels (selling directly to utilities or large EPC contractors) and indirect channels (through distributors and wholesalers) are vital, with indirect channels facilitating broader market penetration across smaller industrial and commercial installations. This robust distribution framework ensures high service levels, which are paramount in the power distribution sector where downtime must be minimized.

Cold Shrink Cable Accessories Market Potential Customers

The primary consumers and end-users of cold shrink cable accessories are broadly categorized into major utility companies, various industrial complex operators, and organizations involved in large-scale infrastructure development. Electric utilities, encompassing state-owned power companies and private power transmission and distribution operators, constitute the largest customer base. These entities continuously require large volumes of terminations and joints for maintaining, upgrading, and expanding their underground and overhead cable networks, spanning suburban distribution loops and major cross-country transmission lines. Their purchasing decisions are heavily influenced by product certification, proven reliability, and long-term warranties, often leading to multi-year framework agreements with approved suppliers.

The industrial sector, including heavy manufacturing plants, mining operations, oil and gas refineries, and petrochemical complexes, represents a highly critical segment. In these environments, power cable accessories must withstand extreme mechanical stress, exposure to chemicals, dust, and corrosive elements. Cold shrink technology is highly valued here for its robust environmental sealing and resistance, ensuring continuous operational integrity where power outages can result in significant financial losses. Furthermore, the simplicity of installation minimizes safety risks in potentially hazardous atmospheres, making it the preferred method for connecting specialized machinery and integrating power systems within expansive industrial facilities.

The infrastructure segment forms the third major customer group, encompassing buyers from transportation systems (metro, railways), major construction projects (airports, tunnels), and the rapidly growing data center industry. Data centers, in particular, require extremely reliable and fast-to-install power connections to manage massive, continuous power loads, favoring the speed and safety of cold shrink solutions. These customers prioritize solutions that offer longevity and minimal maintenance requirements, viewing cold shrink accessories as an integral component of their long-term asset management strategy. The overall customer profile emphasizes reliability, ease of application, compliance with local electrical codes, and cost-effectiveness over the operational lifespan of the installation.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.4 Billion |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M, TE Connectivity, Nexans, Prysmian Group, ABB Ltd., NKT, Pfisterer, SPS, DILO, Raychem RPG, G&W Electric, Yamuna Power, K. D. Industries, Dalian Guangyi Cable Accessories, Sicame Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cold Shrink Cable Accessories Market Key Technology Landscape

The technological landscape of the Cold Shrink Cable Accessories Market is primarily centered on advancements in elastomeric material science and improved geometric design for enhanced electrical stress control. The core technology involves the formulation of specialized silicone or EPDM compounds that offer high dielectric strength, excellent tracking resistance, and superior hydrophobicity, ensuring reliable performance in contaminated or humid environments. Recent innovations focus on developing compounds with a wider operating temperature range and increased mechanical resilience to accommodate the thermal expansion and contraction cycles experienced by power cables under varying load conditions. Furthermore, optimizing the shrinkage force of the pre-expanded tube is critical; too weak, and it fails to create a tight seal; too strong, and it could damage the underlying cable insulation. Manufacturers are utilizing advanced curing processes and molecular structuring to achieve the optimal balance between these properties, thereby extending the accessory’s lifespan and reliability.

A significant technological focus is placed on integrated stress control components within the terminations and joints. For medium and high-voltage applications, managing the electrical stress concentration at the termination point is paramount to preventing premature failure. Cold shrink accessories often incorporate high-K (high permittivity) materials or geometric stress cones designed to evenly distribute the electrical field across the insulation interface. Modern designs utilize computer modeling and finite element analysis (FEA) to perfect the geometric profile of these stress control elements, ensuring optimal electrical performance across diverse cable designs and manufacturing tolerances. The integration of semi-conductive layers and insulation material in a seamless, factory-controlled assembly ensures consistency and minimizes the potential for installer error in the field, a key differentiator from traditional taping methods.

The shift towards modular and customizable kits represents another key technological trend. Manufacturers are developing universal cold shrink designs capable of fitting a broader range of cable dimensions with fewer stock-keeping units (SKUs), simplifying inventory management for utilities and distributors. Furthermore, there is emerging integration of smart features, such as fiber optic temperature sensors or partial discharge monitoring tags, embedded within the cold shrink joints. While still nascent, this convergence of traditional mechanical sealing technology with digital monitoring capabilities promises to transform cable management from reactive repair to proactive, predictive maintenance, aligning the cold shrink accessory market with the broader goals of smart grid development and automated asset management in complex power networks.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, dominating the global market volume due to massive governmental expenditure on rural electrification projects, high population growth necessitating new urban infrastructure, and substantial investment in high-speed rail networks. Countries like China and India are rapidly expanding their transmission and distribution capabilities, prioritizing cold shrink technology for its speed and reliability in large-scale projects, particularly in the medium and high-voltage sectors. The region's increasing adoption of renewable energy, particularly solar farms in Australia and floating solar installations across Southeast Asia, further fuels the demand for robust, environmentally resilient cable accessories.

- North America: The North American market is characterized by stability and high value, driven primarily by the critical need to replace and refurbish aging underground distribution systems. Regulatory pressure to enhance grid reliability and minimize vulnerability to extreme weather events pushes utilities toward safer, non-flame installation technologies like cold shrink. Significant investment under government infrastructure bills is directed towards modernizing the grid, including substation upgrades and deploying smart grid components, ensuring sustained demand for high-quality, certified medium and high-voltage cold shrink terminations and joints, particularly those compliant with ANSI and IEEE standards.

- Europe: Europe represents a mature market focusing on high-specification, sustainable solutions. Growth here is driven by the extensive rollout of offshore wind energy projects and the development of interconnectors for cross-border power sharing, requiring high-voltage (HV) and extra-high voltage (EHV) cold shrink accessories. European regulations, particularly concerning safety and environmental impact, strongly favor technologies that reduce on-site waste and require no volatile organic compounds or heat during installation. Germany, the UK, and Scandinavian countries are key contributors, emphasizing efficiency in installation for complex urban infrastructure projects and specialized industrial applications.

- Latin America (LATAM) and Middle East & Africa (MEA): These regions are emerging markets showing promising growth driven by industrial expansion, particularly in mining (LATAM) and oil and gas infrastructure (MEA). Electrification initiatives in Africa and substantial capital expenditure in Gulf Cooperation Council (GCC) countries on smart city development and diversifying energy sources are creating new large-scale opportunities for cold shrink accessories. The demand is often focused on products that offer resistance to extreme temperatures and dust ingress, making the robust sealing capabilities of cold shrink solutions highly desirable for long-term reliability in challenging environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cold Shrink Cable Accessories Market.- 3M

- TE Connectivity

- Nexans

- Prysmian Group

- ABB Ltd.

- NKT

- Pfisterer

- SPS

- DILO

- Raychem RPG

- G&W Electric

- Yamuna Power

- K. D. Industries

- Dalian Guangyi Cable Accessories

- Sicame Group

- Eaton Corporation

- Furukawa Electric Co., Ltd.

- Orient Cable Co., Ltd.

- R&S Electric Group

- Woongjin Electric Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Cold Shrink Cable Accessories market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of cold shrink cable accessories over heat shrink types?

Cold shrink accessories offer superior safety and speed of installation because they require no external heat source (torch or heat gun), eliminating fire hazards and minimizing installation time. They maintain continuous radial pressure, providing a tighter, more resilient environmental seal and electrical interface over the cable's lifespan, especially important for medium and high-voltage applications.

In which voltage range are cold shrink accessories most commonly utilized globally?

Cold shrink accessories find their most extensive application in the Medium Voltage (MV) range, typically spanning from 1 kV up to 35 kV. This segment covers most urban and industrial primary power distribution networks, where the need for reliable, quick, and safe terminations and joints is highest. Their use is also growing rapidly in the High Voltage (HV) segment.

Which material is predominantly used in the manufacturing of cold shrink cable accessories?

High-quality Silicone Rubber is the predominant material used. Silicone offers excellent dielectric properties, superior UV and ozone resistance, hydrophobicity, and maintains elasticity over a wide temperature range, ensuring the accessory provides a consistent seal and reliable electrical stress control for the duration of the cable system's service life.

How is the demand for cold shrink technology influenced by the growth of renewable energy?

The shift towards renewable energy, such as wind and solar power, drives significant demand as these installations require extensive, reliable underground and protected cable networks. Cold shrink accessories are preferred for their resilience in harsh outdoor conditions (e.g., in wind turbine towers or solar fields) and ease of installation in confined or complex spaces inherent to renewable energy projects.

What are the key certification standards required for cold shrink accessories in the utility sector?

Utilities typically require accessories to comply with international standards such as IEEE (Institute of Electrical and Electronics Engineers), IEC (International Electrotechnical Commission), and country-specific standards like ANSI, CSA, or VDE. Compliance ensures the product meets stringent requirements for electrical performance, mechanical strength, and long-term durability under operational stress.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager