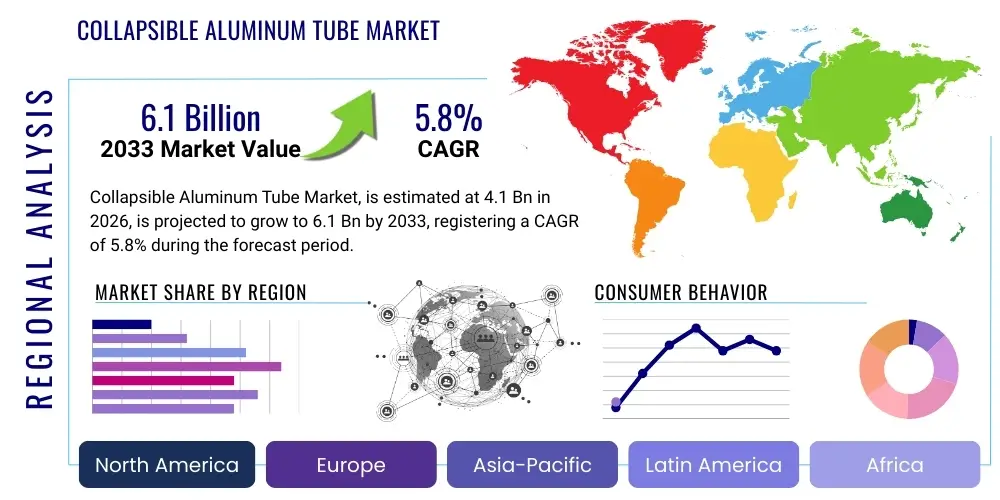

Collapsible Aluminum Tube Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441572 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Collapsible Aluminum Tube Market Size

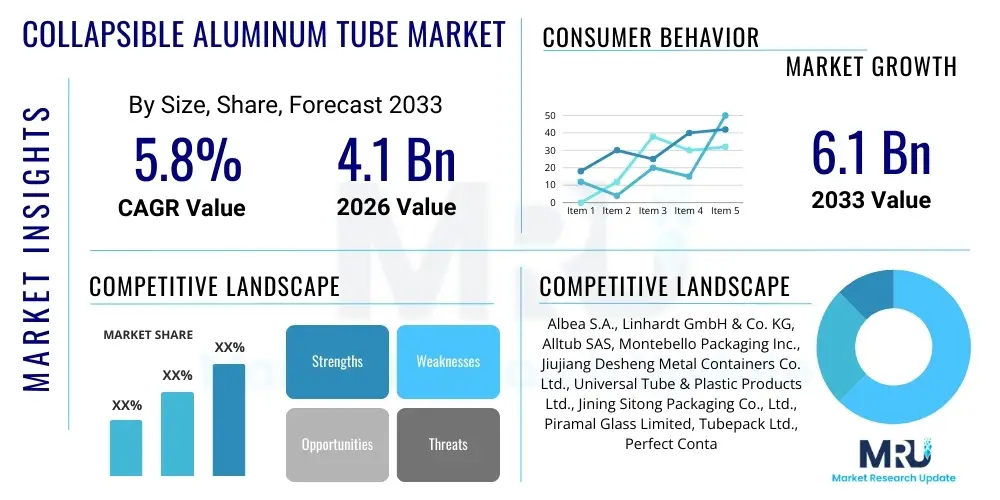

The Collapsible Aluminum Tube Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.1 Billion in 2026 and is projected to reach USD 6.1 Billion by the end of the forecast period in 2033.

Collapsible Aluminum Tube Market introduction

The Collapsible Aluminum Tube Market encompasses the production and distribution of thin-walled aluminum containers primarily used for packaging semi-solid and viscous products. These tubes are characterized by their excellent barrier properties, providing complete protection against light, air, and moisture, thereby preserving the integrity and extending the shelf life of sensitive formulations such as pharmaceuticals, cosmetics, and specialized food items. The manufacturing process typically involves slug impact extrusion, resulting in a seamless, monolithic body that can be easily sealed. This inherent material advantage—being infinitely recyclable—is driving significant adoption across industries increasingly mandated or incentivized to meet stringent sustainability goals. The market structure is highly dependent on global commodity prices for aluminum, sophisticated coating technologies to ensure product compatibility (especially acidic or reactive contents), and high-speed filling line integration.

Major applications of these tubes span highly regulated sectors. In pharmaceuticals, aluminum tubes are the preferred choice for topical creams, ointments, and gels due to their non-reactive nature, sterility capabilities, and precise dosage control achieved through gradual collapsing without drawing air back into the container. Similarly, the cosmetics industry leverages aluminum tubes for high-end products like hair dyes, professional skincare treatments, and specialized toothpastes, valuing the premium aesthetic appeal afforded by sophisticated exterior printing and the brand promise of product safety. The robust growth in global healthcare expenditure, coupled with an aging population requiring increasing quantities of topical medications, serves as a fundamental economic pillar supporting the market expansion.

Key benefits driving market traction include their superior barrier performance compared to many plastics, prevention of product contamination, and the critical environmental advantage of 100% recyclability. Furthermore, the inherent rigidity and subsequent irreversible collapse after squeezing provide crucial anti-counterfeiting benefits, ensuring the consumer knows the product is sealed and unused. Driving factors are multifaceted, involving heightened consumer awareness regarding plastic waste, government regulatory pressures enforcing eco-friendly packaging standards (particularly in the EU and North America), and continuous technological advancements in internal lacquer coatings and advanced printing methods that improve both product compatibility and shelf appeal, making aluminum tubes suitable for a wider range of aggressive formulations.

Collapsible Aluminum Tube Market Executive Summary

The Collapsible Aluminum Tube Market is navigating a dynamic phase characterized by robust demand from the pharmaceutical sector and an intense global shift towards sustainable packaging alternatives, directly benefiting aluminum's high recycling rate credentials. Business trends indicate significant capital investment in high-speed, automated production lines capable of precision coating and advanced digital printing, essential for meeting the stringent quality control standards of major end-users. Fragmentation remains a key structural characteristic, with numerous regional players specializing in specific tube types (e.g., standard cylindrical vs. cantilever or oval shapes) or specific industry requirements (e.g., dental or ophthalmic standards), although consolidation attempts are increasing to achieve economies of scale and geographical coverage. Furthermore, geopolitical stability affects the pricing and availability of primary aluminum slugs, introducing volatility into manufacturer input costs, necessitating sophisticated supply chain risk management strategies.

Regionally, the Asia Pacific (APAC) continues to assert dominance, driven by rapid industrialization, expanding domestic pharmaceutical manufacturing capabilities, and a colossal consumer base demanding affordable cosmetic and personal care products. This region not only represents the largest consumption market but is also emerging as the global manufacturing hub, leveraging lower operational costs and expanding infrastructure. Conversely, Europe is leading the charge in innovation, spurred by the European Green Deal and related packaging directives, which prioritize material circularity. European manufacturers are focusing heavily on developing advanced internal coatings that eliminate trace leaching while optimizing tube wall thickness to reduce material consumption, positioning them at the forefront of premium and specialized aluminum tube production.

Segmentation trends highlight the increasing demand for smaller volume tubes (under 10ml) targeted toward high-value cosmetic and pharmaceutical samples, reflecting strategic marketing shifts by brand owners. By application, the pharmaceutical segment is projected to maintain the highest CAGR due to its non-negotiable requirement for high-barrier packaging and stringent regulatory oversight that often favors aluminum over alternatives. Moreover, technological segmentation shows a rising preference for tubes featuring innovative tamper-evident closures and child-resistant caps, especially within the over-the-counter (OTC) medication space. The shift towards solvent-free or water-based inks for printing is also a notable segment trend, aligning with sustainable production mandates and reducing the environmental footprint of the final packaged product.

AI Impact Analysis on Collapsible Aluminum Tube Market

User queries regarding the impact of Artificial Intelligence (AI) on the Collapsible Aluminum Tube Market primarily center around enhancing operational efficiency, improving product quality control, and optimizing complex supply chains dealing with raw material price fluctuations. Common questions investigate how AI-driven predictive maintenance can reduce downtime on high-speed extrusion lines, a critical factor given the demanding production throughput. Users are also keenly interested in the application of machine vision and deep learning algorithms for instantaneous defect detection—such as minuscule coating flaws, print registration errors, or minor body deformities—which are difficult to detect reliably through conventional methods. Furthermore, significant user concern revolves around utilizing AI for demand forecasting and procurement optimization, specifically to hedge against aluminum price volatility and manage large inventories effectively, thereby maximizing profit margins in a highly competitive manufacturing environment.

The implementation of AI is moving beyond simple automation into strategic optimization within the aluminum tube ecosystem. In the manufacturing phase, AI algorithms are being deployed to monitor parameters such as extrusion speed, internal pressure, and curing temperatures of internal lacquers in real-time, allowing for micro-adjustments that dramatically reduce material waste and energy consumption. This level of precision is crucial for maintaining the demanding specifications required by pharmaceutical clients. Within the business intelligence sphere, AI is enabling market players to rapidly synthesize global regulatory changes, competitor pricing strategies, and consumer purchasing patterns, translating complex data into actionable insights for product development, such as determining optimal tube sizes, coating materials, or regional distribution network enhancements. The integration of AI tools promises a transformation towards 'smart manufacturing,' characterized by enhanced resilience, reduced variability, and superior product consistency, which directly addresses the key pain points of tube manufacturers.

- AI-driven predictive maintenance reduces machinery downtime by forecasting potential mechanical failures on high-speed extrusion lines.

- Machine Vision systems powered by AI enhance quality control, instantly identifying micro-defects in coatings, printing, and tube structure.

- Optimized supply chain management using AI algorithms to predict fluctuations in global aluminum ingot prices for better procurement timing.

- AI assists in dynamic process control (e.g., optimizing lacquer curing times and temperatures) to ensure consistent barrier properties.

- Improved demand forecasting and inventory management, minimizing obsolescence and maximizing manufacturing resource utilization.

DRO & Impact Forces Of Collapsible Aluminum Tube Market

The Collapsible Aluminum Tube Market is propelled by strong structural drivers centered on regulatory support for sustainable packaging and expanding end-user industries, specifically pharmaceuticals and premium cosmetics. Restraints predominantly revolve around the inherent cost volatility of aluminum as a commodity and fierce competition from alternative packaging formats, particularly laminated and barrier plastic tubes, which often offer lower unit costs for certain mass-market applications. Opportunities are abundant in developing advanced functional coatings for challenging new product formulations and leveraging the rapid growth in emerging economies that are investing heavily in local healthcare infrastructure. The impact forces indicate a medium-high level of influence from environmental regulations (a positive driver) and a high degree of market rivalry, demanding continuous innovation and operational excellence from manufacturers.

Key drivers include the global push for sustainability, where the infinitely recyclable nature of aluminum provides a distinct competitive advantage over mixed-material plastic alternatives, making it highly attractive to brands committed to corporate social responsibility (CSR) goals. Furthermore, the specialized needs of the pharmaceutical sector for high-barrier, sterile, and non-reactive packaging remain paramount; aluminum tubes excel in these criteria, especially for formulations containing volatile organic compounds or those requiring long shelf lives. This persistent demand from the robust healthcare industry ensures a steady base revenue stream for the market. Technological advancements, such as improved internal epoxy and phenolic resin coatings, are also driving adoption by expanding the range of products that can be safely packaged in aluminum without material interaction.

Conversely, significant restraints include the fluctuating price of primary aluminum, which can drastically affect manufacturing margins and complicate long-term pricing contracts with major clients. The intense competition posed by sophisticated plastic tubes, which have made substantial advances in barrier technology (e.g., EVOH layers) and often present a lower capital investment for smaller or newer brands, restricts market penetration in cost-sensitive segments. However, the primary opportunities lie in customizing tube properties, such as introducing specialized tamper-evident features, developing tubes with integrated applicators, or employing lightweighting technologies to maintain cost competitiveness while adhering to environmental mandates. Geographical expansion into high-growth markets like Southeast Asia and Latin America, characterized by burgeoning middle classes and increased spending on personal care, offers substantial untapped revenue potential.

Segmentation Analysis

The Collapsible Aluminum Tube Market is systematically segmented based on application, closure type, capacity, and end-use industry, providing manufacturers and analysts with distinct categories for strategic focus. Application segmentation remains the most critical, detailing usage across pharmaceuticals, cosmetics, food, and industrial products, reflecting varying quality and regulatory requirements. Closure type segmentation addresses user convenience and product security, differentiating between standard screw caps, stand-up caps, and specialized child-resistant varieties. Capacity and diameter segmentation are crucial for operational planning, influencing manufacturing line complexity and material usage. Analyzing these segments helps identify niche growth areas, such as the increasing demand for ultra-small volume tubes for clinical trials or high-potency topical medications.

- By Application:

- Pharmaceuticals (Ointments, Creams, Gels)

- Cosmetics & Personal Care (Toothpaste, Hair Dye, Face Creams)

- Food (Condiments, Concentrates, Pastes)

- Industrial & Household (Adhesives, Sealants, Lubricants)

- By Closure Type:

- Standard Screw Caps

- Stand-Up Caps (O-rings)

- Specialty Closures (Child-Resistant, Tamper-Evident)

- By Capacity:

- Below 10 ml

- 10 ml to 50 ml

- 51 ml to 100 ml

- Above 100 ml

- By Diameter:

- 11 mm to 19 mm

- 20 mm to 25 mm

- 26 mm and Above

Value Chain Analysis For Collapsible Aluminum Tube Market

The value chain for the Collapsible Aluminum Tube Market is characterized by a high degree of specialization, starting with the procurement of primary aluminum. The upstream segment involves aluminum ingot producers and specialized slug manufacturers who convert the raw material into slugs of precise dimensions and weight, a critical input for the extrusion process. Midstream activities encompass the core manufacturing process: impact extrusion, neck threading, internal lacquering (coating), base coating, offset or digital printing, and drying/curing. Quality control at this stage is paramount, especially for coating consistency, which dictates product compatibility and barrier efficacy. Efficiency in the midstream is highly dependent on continuous technological upgrades to machinery to handle increasing production speeds and minimize defects.

The downstream activities involve the distribution and filling of the empty tubes. Manufacturers primarily utilize two distribution channels: direct sales to major multinational pharmaceutical or cosmetic companies with proprietary filling capabilities, or indirect sales through specialized packaging distributors who manage inventory and logistics for smaller clients. Direct channels offer higher control and potentially greater margins, especially for custom-designed tubes. The end-users—pharmaceutical companies, cosmetic houses, and food processors—then perform the final, often highly regulated, process of filling, crimping, and sealing the tube. The demand for 'ready-to-fill' tubes that meet rigorous cleanliness and sterility standards heavily influences the relationship between the tube manufacturer and the end-user.

Collapsible Aluminum Tube Market Potential Customers

Potential customers for collapsible aluminum tubes are concentrated primarily within regulated and quality-sensitive industries where product stability and barrier protection are non-negotiable requirements. The largest volume buyers are global pharmaceutical conglomerates and regional generic drug manufacturers, utilizing these tubes for high-value topical treatments such as corticosteroid creams, analgesic gels, and ophthalmic ointments, where contamination risk must be minimized. These customers demand comprehensive documentation regarding materials compliance (e.g., FDA or EMA standards) and manufacturing environment control, prioritizing reliability and consistency above marginal cost savings.

A second major customer segment includes international and local cosmetic and personal care brands, particularly those focused on specialized or high-end products. This includes manufacturers of professional hair colorants (due to the chemical reactivity of dyes), luxury hand creams, and high-fluoride toothpastes. While cosmetic buyers are also concerned with barrier properties, they place a higher emphasis on the aesthetic features of the tube, such as sophisticated matte finishes, intricate multi-color printing, and custom cap designs, viewing the packaging as an integral element of brand identity and consumer appeal. Industrial consumers, covering adhesives, specialty lubricants, and chemical sealants, represent a third, albeit smaller, segment, requiring robust, larger-capacity tubes capable of withstanding industrial storage conditions and providing effective dispensing mechanisms.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.1 Billion |

| Market Forecast in 2033 | USD 6.1 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Albea S.A., Linhardt GmbH & Co. KG, Alltub SAS, Montebello Packaging Inc., Jiujiang Desheng Metal Containers Co. Ltd., Universal Tube & Plastic Products Ltd., Jining Sitong Packaging Co., Ltd., Piramal Glass Limited, Tubepack Ltd., Perfect Containers Pvt. Ltd., Essel Propack (EPL Limited), Constantia Flexibles Group GmbH, Nampak Ltd., Technopack GmbH, Guangzhou L&X Packaging Co., Ltd., China Aluminum Can Co., Ltd., Sun Packaging, Hindustan Tin Works Ltd., Huhtamaki Oyj, and Amcor PLC. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Collapsible Aluminum Tube Market Key Technology Landscape

The technological landscape of the Collapsible Aluminum Tube Market is rapidly evolving, driven by the dual pressures of enhancing product integrity and improving sustainability metrics. Core manufacturing relies on high-speed impact extrusion presses capable of forming seamless tube bodies with precise wall thickness control, essential for lightweighting initiatives. A critical technological focus lies in advanced internal coating application systems, which apply protective layers (typically epoxy phenolic resins or polyamide-imide derivatives) with ultra-uniform thickness. Innovations here are necessary to package highly active or corrosive ingredients, such as certain dental preparations or high-concentration cosmetic actives, preventing chemical interaction with the aluminum substrate and safeguarding product efficacy over extended shelf life.

Another area of significant technological advancement is in exterior decoration and printing. While traditional offset printing remains dominant for high-volume orders, the integration of high-resolution digital printing technologies is gaining traction. Digital printing offers flexibility for shorter production runs, rapid prototyping, and sophisticated personalization or serialization, a requirement increasingly mandated by global pharmaceutical traceability regulations (e.g., U.S. DSCSA and EU FMD). Furthermore, manufacturers are investing heavily in automated quality assurance systems, utilizing sophisticated camera systems and machine learning algorithms to inspect every tube for flaws, ensuring compliance with ISO standards for cleanliness and dimensional accuracy before they are packed and shipped to the filling facility. The development of advanced threading technology for cap closure mechanisms also ensures perfect seal integrity and compliance with child-resistant packaging standards.

Regional Highlights

- Asia Pacific (APAC): APAC is the predominant market, accounting for the largest share in terms of volume and production capacity. This dominance is underpinned by rapid urbanization, significant growth in the regional pharmaceutical and personal care industries (especially in China and India), and the presence of numerous low-cost manufacturing hubs. The demand here is often bifurcated, spanning both mass-market consumer goods and increasingly high-quality, export-oriented pharmaceutical tubes meeting Western regulatory standards.

- Europe: Europe represents a mature but highly innovative market, characterized by strict environmental legislation that strongly favors aluminum's high recyclability. Countries like Germany and France are centers for specialized tube manufacturing, focusing on premium cosmetics and complex pharmaceutical applications. Regulatory initiatives, such as EPR (Extended Producer Responsibility) schemes, incentivize lighter tubes and highly sustainable production processes, driving technological investment in thinner gauge aluminum and water-based printing solutions.

- North America: The North American market is defined by high per capita consumption and a strong preference for high-quality, high-barrier packaging, particularly in the premium pharmaceutical and dental care segments. Demand growth is steady, fueled by an aging population and robust investment in R&D for topical drug delivery systems. Manufacturers in this region focus on reliability, compliance with stringent FDA standards, and offering advanced closure solutions.

- Latin America (LATAM): LATAM is characterized by emerging markets with increasing demand, particularly from the cosmetics and general personal care sectors in Brazil and Mexico. The market is highly price-sensitive but shows increasing appreciation for brand quality, creating opportunities for mid-range aluminum tube manufacturers capable of balancing cost-effectiveness with consistent product quality.

- Middle East and Africa (MEA): This region is experiencing nascent growth, primarily linked to localized expansion of pharmaceutical production and increasing consumer spending on high-end beauty products in the Gulf Cooperation Council (GCC) countries. Supply chains are heavily reliant on imports, though opportunities exist for localized manufacturing to serve rapidly growing regional healthcare markets.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Collapsible Aluminum Tube Market.- Albea S.A.

- Linhardt GmbH & Co. KG

- Alltub SAS

- Montebello Packaging Inc.

- Jiujiang Desheng Metal Containers Co. Ltd.

- Universal Tube & Plastic Products Ltd.

- Jining Sitong Packaging Co., Ltd.

- Piramal Glass Limited

- Tubepack Ltd.

- Perfect Containers Pvt. Ltd.

- Essel Propack (EPL Limited)

- Constantia Flexibles Group GmbH

- Nampak Ltd.

- Technopack GmbH

- Guangzhou L&X Packaging Co., Ltd.

- China Aluminum Can Co., Ltd.

- Sun Packaging

- Hindustan Tin Works Ltd.

- Huhtamaki Oyj

- Amcor PLC

Frequently Asked Questions

Analyze common user questions about the Collapsible Aluminum Tube market and generate a concise list of summarized FAQs reflecting key topics and concerns.Why are aluminum tubes preferred over plastic tubes in the pharmaceutical industry?

Aluminum tubes offer superior barrier properties against oxygen, light, and moisture, crucial for preserving the efficacy and shelf life of sensitive pharmaceutical formulations. They also collapse irreversibly, preventing air intake and contamination, which is critical for dose integrity and stability.

What is the Compound Annual Growth Rate (CAGR) projected for this market?

The Collapsible Aluminum Tube Market is projected to exhibit a Compound Annual Growth Rate (CAGR) of 5.8% between the forecast period of 2026 and 2033, driven largely by sustainability trends and pharmaceutical sector demand.

How does the volatility of aluminum prices affect the market?

Aluminum price volatility poses a significant restraint, as it directly impacts the raw material cost for tube manufacturers, leading to fluctuating production margins and challenging long-term fixed-price contracting with major end-user clients.

Which geographical region holds the largest market share for aluminum tubes?

The Asia Pacific (APAC) region currently holds the largest market share, serving as a primary global manufacturing base and experiencing high domestic demand growth in the personal care and healthcare sectors.

What technological innovations are currently impacting aluminum tube manufacturing?

Key technological innovations include the deployment of high-resolution digital printing for enhanced aesthetic appeal and serialization, and the development of advanced, non-reactive internal lacquer coatings to safely package complex chemical formulations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager