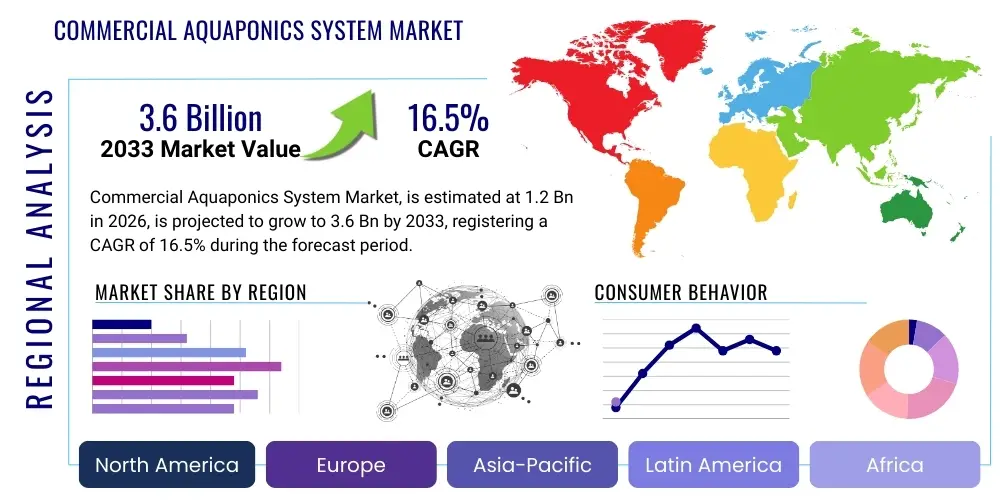

Commercial Aquaponics System Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442183 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Commercial Aquaponics System Market Size

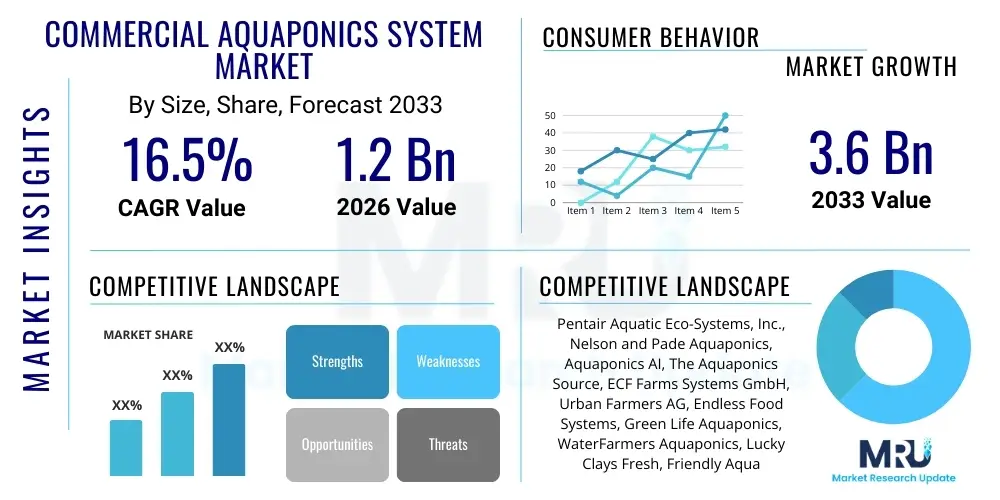

The Commercial Aquaponics System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 16.5% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 3.6 Billion by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the escalating global demand for sustainable food production methods, coupled with the increasing need for locally sourced, fresh produce in urban environments. The rising awareness regarding environmental sustainability, water conservation, and the detrimental effects of conventional agriculture systems are primary factors fueling this rapid adoption across various commercial scales, ranging from small-scale indoor farms to large-scale integrated agricultural enterprises designed for high-volume output and controlled environment food supply.

Commercial Aquaponics System Market introduction

The Commercial Aquaponics System Market encompasses integrated agricultural setups where recirculating aquaculture (raising aquatic animals such as fish, crustaceans, or mollusks) is combined with hydroponics (cultivating plants in water) in a symbiotic environment. The primary product involves the entire system infrastructure, including grow beds, tanks, filtration units, plumbing, pumps, aeration devices, and monitoring technology necessary for large-scale, profitable operations. Major applications span high-density urban farming, controlled environment agriculture (CEA), specialized crop production (e.g., leafy greens, herbs, and high-value fish), and research facilities aimed at optimizing resource efficiency. The paramount benefits include significant water conservation (up to 90% less than traditional farming), elimination of synthetic fertilizers and pesticides, production of two crops simultaneously (fish and plants), and reduced carbon footprints due to localization of food production. Driving factors accelerating market growth include increasing consumer preference for organic and sustainably produced food, regulatory support for water-efficient farming, technological advancements in monitoring and automation, and the inherent resilience of these systems against climate variability, ensuring consistent year-round production irrespective of external weather conditions or soil quality challenges.

Commercial Aquaponics System Market Executive Summary

The Commercial Aquaponics System Market is characterized by robust business trends focusing heavily on vertical integration and technological refinement, particularly the development of modular and scalable systems that can be rapidly deployed in diverse geographical settings, often targeting densely populated urban cores to minimize transport costs and maximize freshness. Key regional trends indicate accelerated adoption in North America and Europe, driven by stringent food safety standards and high disposable incomes enabling investment in premium, sustainable produce. Concurrently, the Asia Pacific region is emerging as a critical growth engine, propelled by population density, limited arable land, and government initiatives promoting food security through innovative farming methods. Segment trends highlight the dominance of the Media-Based Aquaponics segment due to its low complexity and suitability for educational and smaller commercial operations, while the Recirculating Aquaculture System (RAS) technology segment, integrated with hydroponics, is gaining momentum in large-scale installations due to its superior control over environmental parameters and higher production yields per square meter. Overall, the market trajectory is highly optimistic, anchored by the foundational shift toward circular economy principles within the agricultural sector and increasing venture capital interest in AgTech solutions.

AI Impact Analysis on Commercial Aquaponics System Market

User queries regarding AI in the Commercial Aquaponics System Market primarily center on how artificial intelligence and machine learning algorithms can improve operational efficiency, predict disease outbreaks, optimize nutrient cycling, and automate complex labor tasks traditionally managed by human operators. Key themes include the implementation of predictive analytics for maintaining optimal water quality parameters (pH, dissolved oxygen, temperature, ammonia/nitrate levels), questions about reducing energy consumption through smart resource allocation, and expectations regarding fully autonomous nutrient delivery and fish feeding schedules. Concerns often revolve around the initial high capital investment required for integrating sophisticated AI hardware and software, the need for specialized IT skills to manage these systems, and the reliability of machine learning models in dynamic biological environments where unexpected variables frequently occur. Users anticipate that AI will ultimately transition aquaponics from a labor-intensive, experience-driven farming method to a data-driven, highly optimized manufacturing process, leading to greater consistency in yield and quality while lowering overall operational risks associated with environmental fluctuations and biological variability, thereby securing better returns on investment for commercial operators looking to scale their production capabilities globally.

- AI-driven predictive maintenance and failure detection for pumps, sensors, and aeration systems, minimizing operational downtime.

- Optimization of feeding schedules and feed composition using machine learning to maximize Fish Feed Conversion Ratio (FCR) and reduce nutrient waste.

- Real-time water quality monitoring and dynamic nutrient dosing adjustments based on plant uptake rates and fish waste generation.

- Automated disease detection (both fish and plants) through image recognition and thermal scanning, enabling early intervention.

- Climate control optimization in Controlled Environment Agriculture (CEA) aquaponics using neural networks to minimize energy usage for heating, cooling, and lighting.

- Yield forecasting and harvest scheduling algorithms that utilize historical data and current environmental inputs for enhanced supply chain management.

- Robotics integration (controlled by AI) for tasks such as planting, harvesting, and routine system cleaning, addressing labor shortages.

- Data synthesis across multiple system parameters to identify complex correlations, leading to optimized standard operating procedures (SOPs) for biological stability.

DRO & Impact Forces Of Commercial Aquaponics System Market

The dynamics of the Commercial Aquaponics System Market are fundamentally shaped by powerful drivers, systemic restraints, and significant opportunities, collectively forming the critical impact forces determining market direction. The primary drivers include the urgent global necessity for sustainable food production solutions amidst diminishing water resources and arable land, coupled with expanding consumer demand for locally sourced, chemical-free food products. Government subsidies and policy incentives promoting sustainable agriculture also act as potent accelerators. However, the market faces significant restraints, chiefly the high initial capital expenditure required for setting up sophisticated commercial-scale operations, the complexity associated with maintaining the delicate biological equilibrium between fish and plants, and a noticeable shortage of skilled personnel proficient in both aquaculture and hydroponics management. Opportunities lie in technological advancements, particularly the integration of IoT sensors, AI, and modular farming techniques that lower entry barriers and enhance system reliability. The emergence of vertical aquaponics and integration with renewable energy sources further presents avenues for high-density, low-carbon production models. These factors generate high impact forces, pushing the industry toward greater technological sophistication and scalability, while simultaneously requiring operators to mitigate operational complexity through rigorous training and investment in reliable automation technologies to ensure long-term commercial viability and profitability across diverse geographical markets.

Segmentation Analysis

The Commercial Aquaponics System Market is meticulously segmented based on key parameters including the specific system type employed, the primary components utilized, the production technique adopted, and the final application of the produce. This multi-faceted segmentation allows for targeted strategic planning and tailored product development, addressing the diverse needs of farmers ranging from high-tech urban vertical farms to traditional greenhouse installations. The key segments reflect differing levels of operational complexity, capital investment requirements, and suitability for various crop and fish combinations. Understanding these distinctions is crucial for identifying market entry points and assessing competitive advantages, especially as the industry moves toward highly standardized, yet customizable, modular production units designed for rapid deployment and optimized yield efficiency in specific climatic zones. Analyzing segment trends reveals a directional shift towards more controlled and technologically intensive methods, prioritizing resource efficiency and output consistency over traditional methods.

- By Component:

- Rearing Tanks

- Sump Tanks

- Biofilters

- Hydroponics Subsystems (NFT Channels, Media Beds, DWC Rafts)

- Plumbing and Water Circulation Systems

- Aeration and Oxygenation Devices

- Monitoring and Control Systems (Sensors, IoT Devices)

- By System Type:

- Media-Based Aquaponics Systems

- Nutrient Film Technique (NFT) Aquaponics Systems

- Deep Water Culture (DWC) / Raft Systems

- Recirculating Aquaponics Systems (Hybrid/Integrated Systems)

- By Production Technique:

- Indoor Aquaponics (Vertical Farms)

- Greenhouse Aquaponics

- Open Field Aquaponics

- By Produce:

- Fish (Tilapia, Trout, Catfish, Carp, Ornamental Fish)

- Vegetables (Leafy Greens, Fruiting Vegetables)

- Herbs and Microgreens

- By Application:

- Commercial Food Production

- Research and Education

- Home-Based Systems (Non-Commercial, but influencing component demand)

Value Chain Analysis For Commercial Aquaponics System Market

The value chain of the Commercial Aquaponics System Market begins with the upstream analysis, which primarily involves the sourcing of critical raw materials and specialized components. This stage includes suppliers of tank liners (polyethylene, fiberglass), specialized plumbing and piping, biological media (clay pebbles, volcanic rock), high-efficiency pumps, advanced water quality sensors (pH, DO, EC), and fish fingerlings and specialized feed formulations. Key upstream activities are dominated by manufacturing firms specializing in agricultural technology (AgTech) and water treatment solutions, focusing intensely on material durability, energy efficiency, and biological inertness. The quality and cost of high-protein, low-waste fish feed represent a crucial upstream cost factor that directly impacts operational profitability. Innovation at this stage centers on developing smarter, smaller, and more durable components suitable for continuous, high-intensity operations in controlled environments, ensuring reliability.

Midstream activities encompass the system design, construction, integration, and operational management of the aquaponics facility itself. This phase involves specialized engineering and construction firms that design system layouts tailored to specific spatial, climatic, and production objectives (e.g., maximizing leafy green output vs. maximizing fish biomass). Direct distribution channels involve system integrators selling turn-key solutions directly to large commercial operators, providing consultation, installation, and post-setup maintenance contracts. Indirect distribution channels utilize established agricultural equipment suppliers or specialized regional distributors who handle logistics, localized regulatory compliance, and installation services. The complexity of these integrated biological systems mandates robust training and technical support throughout the operational lifespan, distinguishing successful market players from competitors through superior service offerings and specialized biological knowledge transfer to the end-user operators.

Downstream analysis focuses on the harvesting, processing, and final distribution of the dual outputs: fresh fish and produce. This stage requires efficient cold chain logistics and rapid market access due to the perishable nature of the products. Direct channels often include sales directly to restaurants, farmers’ markets, and local community-supported agriculture (CSA) programs, capitalizing on the "locally grown," "sustainable," and "chemical-free" attributes that command premium pricing. Indirect distribution involves selling to specialized organic food retailers, regional supermarkets, and wholesale distributors who can manage large volumes. The effectiveness of the downstream segment is highly dependent on effective branding and certification (e.g., organic, GAP certification) that validates the sustainable production claims, allowing commercial operators to capture higher margins and establish strong consumer trust in the high quality and environmental integrity of their aquaponically grown food items.

Commercial Aquaponics System Market Potential Customers

The primary end-users and buyers of commercial aquaponics systems are highly diversified, encompassing entities ranging from large-scale corporate agricultural investors seeking high returns in controlled environment agriculture (CEA) to niche, specialized food producers focusing on high-value organic or exotic crops. Institutional buyers form a significant customer segment, including governmental organizations investing in food security projects, academic institutions establishing research and educational facilities, and non-profit organizations focused on sustainable community development and localized food supply resilience in challenging environments, such as urban food deserts or arid regions. These customers often prioritize system reliability, water efficiency, and the ability to produce consistent yields regardless of external climate variability, making the sophisticated nature of commercial aquaponics an attractive long-term investment rather than a short-term operational fix.

Furthermore, established traditional aquaculture and hydroponics operators represent a rapidly growing segment of potential customers seeking to transition to integrated aquaponics models. Existing hydroponics farms look to incorporate fish culture to manage nutrient waste organically and generate a secondary income stream, eliminating the need for expensive synthetic nutrient solutions. Conversely, aquaculture facilities increasingly integrate plant culture to naturally clean water resources, reducing water discharge treatment costs and simultaneously creating a profitable byproduct. This segment is characterized by experienced agricultural operators who possess existing infrastructure and supply chain knowledge, requiring modular systems that can be seamlessly integrated into their current operations without necessitating complete rebuilds or excessive disruptions to existing production cycles, making flexible system design a key purchasing criterion for this cohort.

Finally, the food service industry and large-scale retailers are indirectly driving demand, often partnering directly with aquaponics facilities through long-term supply contracts to ensure a consistent, year-round supply of hyper-fresh, certified sustainable produce and fish. Retail chains, particularly those targeting environmentally conscious consumers, utilize the unique selling proposition of aquaponics—chemical-free, minimal water usage—as a major marketing advantage. Therefore, while not direct buyers of the systems themselves, their procurement decisions and preference for certified aquaponic products create stable, high-margin revenue streams for the commercial farm operators, indirectly stimulating continued investment and expansion within the aquaponics system technology market to meet this reliable institutional demand.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 3.6 Billion |

| Growth Rate | 16.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Pentair Aquatic Eco-Systems, Inc., Nelson and Pade Aquaponics, Aquaponics AI, The Aquaponics Source, ECF Farms Systems GmbH, Urban Farmers AG, Endless Food Systems, Green Life Aquaponics, WaterFarmers Aquaponics, Lucky Clays Fresh, Friendly Aquaponics, Living Water Aquaponics, Practical Aquaponics, Urban Organics, Integrated Aqua Systems, Inc., AquaGrow Farms, Superior Fish Systems, Veolia Water Technologies, Japan Aquaponics, AquaSprouts. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Commercial Aquaponics System Market Key Technology Landscape

The technological landscape of the Commercial Aquaponics System Market is rapidly evolving, moving beyond basic filtration and circulation methods to incorporate sophisticated digital and engineering solutions derived from the broader Controlled Environment Agriculture (CEA) sector. Central to this evolution is the deployment of the Internet of Things (IoT), where embedded sensors continuously monitor critical environmental parameters such as pH stability, dissolved oxygen (DO) levels, water temperature, Electrical Conductivity (EC) indicating nutrient concentration, and Ammonia/Nitrate loads. These IoT networks provide real-time data accessibility, enabling operators to make immediate, informed decisions and drastically reduce the reaction time to system fluctuations, thereby preventing catastrophic biological crashes, which is a major historical risk in integrated aquaculture. Advanced water filtration technologies, including specialized mechanical and biological filters like bead filters and moving bed biofilm reactors (MBBR), are also crucial, ensuring the efficient conversion of fish waste into plant nutrients while maintaining pristine water quality for the aquatic life, maximizing the symbiotic efficiency of the entire operational loop and minimizing necessary water exchange rates.

Furthermore, automation and control systems are increasingly becoming standard requirements rather than optional additions in high-volume commercial installations. These systems utilize Programmable Logic Controllers (PLCs) and cloud-based management platforms to automate tedious and high-frequency tasks such as fish feeding, water top-off based on evaporation rates, automated system flushing (backwash), and nutrient supplementation adjustments (for elements not supplied by the fish waste, like iron or calcium). The integration of Variable Frequency Drives (VFDs) for pumps and aeration blowers allows operators to dynamically adjust energy consumption based on current biological load and peak utility hours, significantly improving the overall energy efficiency and lowering the major operational expenditure associated with water circulation and oxygenation. This shift toward intelligent automation is paramount for achieving the necessary scalability and labor optimization required to justify the high initial capital investment characteristic of modern commercial aquaponics ventures across diverse geographical locations.

The convergence of advanced lighting solutions, specifically optimized LED grow lights for indoor and vertical aquaponics, and sophisticated data analytics, including machine learning models, represents the current frontier in technological advancement. LED lighting allows for precise manipulation of the light spectrum (photosynthetic photon flux density - PPFD) to maximize plant growth and nutrient uptake, independent of natural sunlight, dramatically increasing year-round yields in indoor facilities. Concurrently, machine learning algorithms are trained on historical performance data, encompassing inputs like feed usage, water quality trends, and harvest weights, to develop predictive models that forecast growth trajectories, detect subtle signs of biological stress, and recommend optimal intervention strategies. This integration of precise environmental control with predictive intelligence enables system designers to move toward a truly closed-loop, predictive management system, maximizing resource utilization and minimizing the variability traditionally associated with biological farming systems, ensuring commercial viability in competitive markets.

Regional Highlights

- North America: This region stands as a dominant force in the Commercial Aquaponics System Market, driven primarily by the strong consumer demand for locally sourced, organic, and non-GMO food products, particularly in high-density urban centers like New York, California, and the Pacific Northwest. The presence of numerous AgTech startups, coupled with substantial private investment and government grants promoting sustainable agriculture and urban farming initiatives, accelerates technology adoption. Canada, in particular, leverages aquaponics to address challenges related to its harsh winter climate, ensuring year-round, reliable food production. The market here is characterized by highly sophisticated, often vertically integrated, large-scale commercial facilities utilizing advanced Recirculating Aquaculture Systems (RAS) and deep water culture (DWC) techniques for high-yield leafy green production and high-value fish species like trout and striped bass.

- Europe: Europe exhibits robust growth, heavily influenced by strict environmental regulations regarding water usage, fertilizer runoff, and food safety, making resource-efficient aquaponics systems highly attractive. Countries such as Germany, the Netherlands, and Switzerland are leaders, focusing on combining aquaponics facilities with renewable energy sources (solar, geothermal) to achieve net-zero energy operations. The emphasis is often on localized food distribution and cooperative farming models, frequently utilizing high-tech greenhouse structures. Policy support from the European Union, including funding for innovative farming techniques aimed at sustainable resource management and food security, further catalyzes market development, driving the deployment of sophisticated automation and monitoring systems tailored for European operational standards and consumer preferences for artisanal produce.

- Asia Pacific (APAC): APAC is anticipated to demonstrate the fastest growth rate, fueled by soaring population density, shrinking arable land, and urgent food security concerns, especially in rapidly urbanizing nations like China, India, and Southeast Asian countries. Government investment in agricultural modernization and the shift away from traditional, resource-intensive farming are key drivers. Aquaponics systems offer a viable solution for maximizing output per unit of land and water, particularly in coastal or land-constrained areas. While media-based systems are common for smaller, local operations, large commercial investments are increasingly focused on high-tech, integrated vertical farms in major metropolitan areas, utilizing aquaponics to supply fresh, high-quality produce directly to burgeoning middle-class consumers willing to pay a premium for certified safe food.

- Latin America: Growth in Latin America is primarily driven by the need for enhanced water management in arid or semi-arid regions and the desire to reduce reliance on imported produce. Countries like Brazil and Mexico, with strong aquaculture traditions, are integrating hydroponic components to diversify revenue streams and improve environmental sustainability. The market is developing, characterized by a mix of medium-scale commercial ventures and educational projects focused on community empowerment and resilient local food systems. Challenges remain in securing initial capital funding and overcoming infrastructure limitations, but the potential for tilapia and high-value fruit production through aquaponics is significant, particularly with support from international development banks and local agricultural policies.

- Middle East and Africa (MEA): MEA represents a critical future market due to extreme water scarcity and dependence on food imports, making aquaponics a fundamental strategic asset for food sovereignty. Nations in the Gulf Cooperation Council (GCC), backed by significant government funding, are heavily investing in large-scale, climate-controlled aquaponics facilities (often integrated into vertical farms) to ensure local, secure food supply year-round, despite high ambient temperatures and humidity. Focus is placed on energy-efficient cooling and desalination-compatible systems. In Africa, aquaponics is increasingly adopted for humanitarian and small-scale commercial projects, addressing issues of malnutrition and local economic development, often utilizing robust, simple system designs that are easier to maintain in remote or resource-constrained settings, with tilapia and local vegetable varieties dominating production.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Commercial Aquaponics System Market.- Pentair Aquatic Eco-Systems, Inc.

- Nelson and Pade Aquaponics

- Aquaponics AI

- The Aquaponics Source

- ECF Farms Systems GmbH

- Urban Farmers AG

- Endless Food Systems

- Green Life Aquaponics

- WaterFarmers Aquaponics

- Lucky Clays Fresh

- Friendly Aquaponics

- Living Water Aquaponics

- Practical Aquaponics

- Urban Organics

- Integrated Aqua Systems, Inc.

- AquaGrow Farms

- Superior Fish Systems

- Veolia Water Technologies

- Japan Aquaponics

- AquaSprouts

- Manna Aquaponics

- Global Food Technology, Inc.

- HydroCycle Systems

- Backyard Aquaponics

- My Aquaponics

Frequently Asked Questions

Analyze common user questions about the Commercial Aquaponics System market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the typical return on investment (ROI) timeframe for a large-scale commercial aquaponics system?

The ROI timeframe for commercial aquaponics facilities typically ranges from 4 to 7 years, highly dependent on the initial capital expenditure, operational efficiency, local market pricing for the produced fish and vegetables, and successful management of biological risks. Achieving optimal biological balance early and securing premium pricing through direct-to-consumer or specialized retail channels are critical accelerators for early profitability.

Which system type is most preferred for maximizing commercial yields in tight urban spaces?

Deep Water Culture (DWC) or Raft Systems, often integrated into highly vertical structures, are most preferred for maximizing commercial yields in tight urban spaces. DWC offers efficient nutrient delivery, scalability, and robust root support, making it ideal for high-density production of fast-growing leafy greens, significantly leveraging the minimal footprint of urban vertical farms through sophisticated climate control.

How do commercial aquaponics systems address global water scarcity concerns compared to traditional agriculture?

Commercial aquaponics systems are closed-loop recirculating ecosystems, allowing them to utilize up to 90% less water than conventional field agriculture. Water is continuously reused and recycled through the integration of fish and plant tanks, with water loss primarily confined to natural evaporation and transpiration by plants, positioning aquaponics as a fundamental technology for water-stressed regions and long-term climate resilience planning.

What are the primary operational challenges faced by new commercial aquaponics operators?

New operators commonly face challenges related to maintaining the delicate biological equilibrium between the fish population, beneficial bacteria (nitrifying bacteria), and the plant nutrient requirements. Other primary challenges include managing high initial energy costs associated with continuous pumping and aeration, and securing personnel skilled in both biological system management and AgTech monitoring/automation.

What are the key technological advancements driving future growth in the aquaponics market?

Future growth is significantly driven by advancements in artificial intelligence (AI) and IoT sensing technology, which enable precise, automated control over nutrient delivery and environmental parameters. Key advancements also include energy-efficient LED lighting optimized for vertical structures, advanced filtration systems (MBBR), and modular, rapid-deployment system designs that reduce construction time and capital requirements for scalability across diverse geographic locations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager