Commercial Kettles and Braising Pans Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441758 | Date : Feb, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Commercial Kettles and Braising Pans Market Size

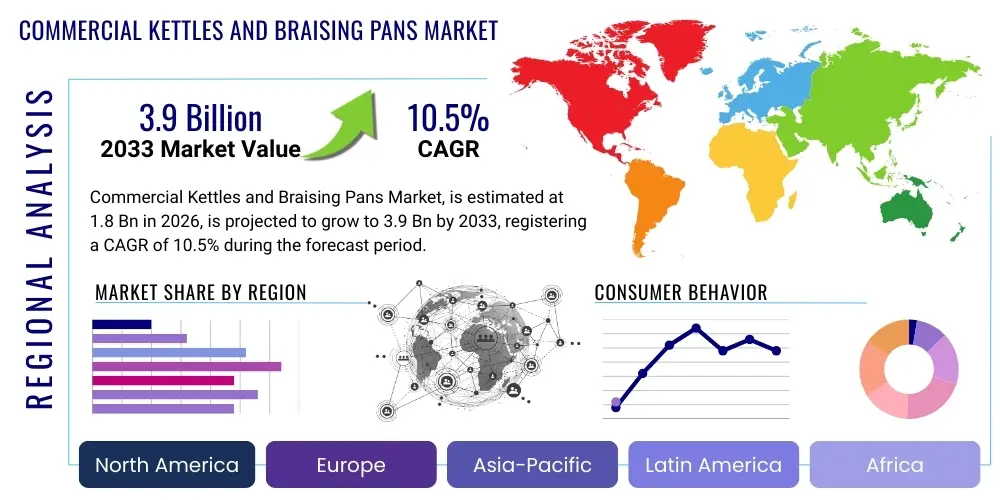

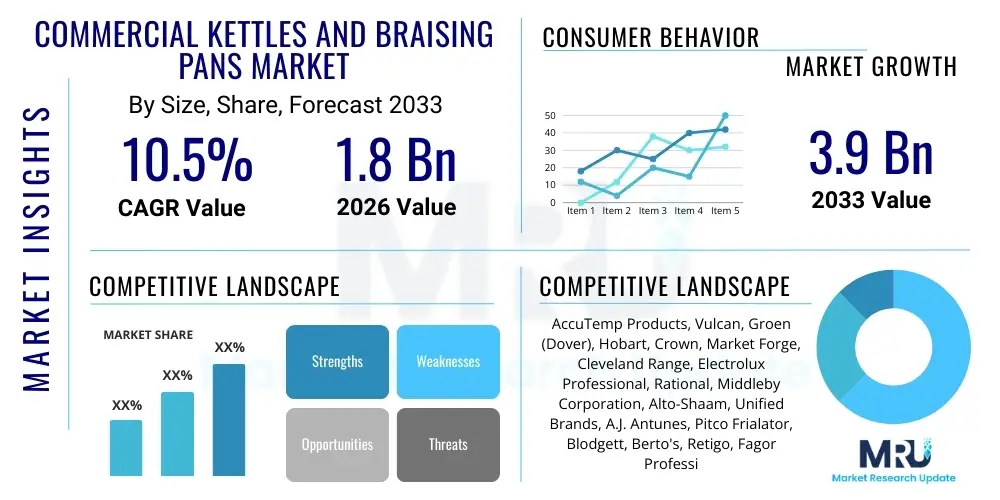

The Commercial Kettles and Braising Pans Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 10.5% between 2026 and 2033. The market is estimated at $1.8 Billion in 2026 and is projected to reach $3.9 Billion by the end of the forecast period in 2033. This substantial growth is fundamentally driven by the increasing global demand for high-capacity, efficient food preparation equipment within the expanding institutional catering, contract food services, and large-scale restaurant sectors. These commercial appliances are essential for operations requiring large batch production, offering significant labor savings and consistent product quality compared to traditional stovetop methods.

Market expansion is also supported by continuous technological advancements, particularly the integration of sophisticated control systems, induction heating technology, and improved energy efficiency standards. Commercial kitchens are prioritizing equipment that adheres to strict safety protocols and reduces operational costs. The transition from manual, open-flame cooking to controlled, jacketed heating systems offered by kettles and braising pans allows for precise temperature management crucial for complex culinary preparations like soups, sauces, stews, and large meat batches. Furthermore, durability and longevity are key purchasing criteria, favoring manufacturers who utilize robust materials like stainless steel and offer comprehensive after-sales service.

Geographical trends indicate robust adoption rates in rapidly urbanizing regions, especially Asia Pacific, where large centralized kitchens and commissary operations are scaling up to support vast delivery networks and organized food services. Simultaneously, replacement cycles in mature markets, such as North America and Europe, are driving demand for advanced, smart-enabled models that integrate seamlessly with kitchen management systems. This dual demand—new installations in emerging economies and modernization in established markets—positions the commercial kettles and braising pans sector for sustained high growth throughout the forecast period.

Commercial Kettles and Braising Pans Market introduction

The Commercial Kettles and Braising Pans Market encompasses heavy-duty, industrial-grade cooking apparatus designed for high-volume food production environments. Commercial kettles, typically utilizing jacketed steam or electric heating, are employed for liquids such as stocks, soups, sauces, and pasta, offering superior heat distribution and precise temperature control. Braising pans, conversely, are versatile, shallow units capable of performing multiple functions including braising, grilling, steaming, frying, and tilting to facilitate product removal. These appliances are critical components in institutional kitchens, catering facilities, hospitals, schools, corporate cafeterias, and large Quick Service Restaurant (QSR) central commissaries, where speed, consistency, and capacity are paramount.

The primary applications of this equipment include mass-production cooking, batch preparation for ready-to-eat meals, and ingredient processing for subsequent distribution. The core benefit these machines provide is enhanced efficiency; a single commercial kettle can replace several traditional stovetops, drastically reducing labor time and improving yield consistency due to automated stirring and temperature maintenance features. Driving factors influencing market growth include the global expansion of organized food service chains, stringent food safety regulations necessitating controlled cooking environments, and the increasing operational complexity of modern commercial kitchens that require multi-functional, space-saving equipment. Furthermore, the rising labor costs globally encourage investment in automated equipment that minimizes manual intervention.

Commercial Kettles and Braising Pans Market Executive Summary

The Commercial Kettles and Braising Pans Market exhibits strong upward momentum driven by several converging business trends, including the rapid automation of back-of-house operations and a critical focus on sustainability and energy efficiency. Business trends highlight a shift towards connected kitchen ecosystems, where kettles and braising pans integrate sophisticated Human-Machine Interfaces (HMI) for recipe programming, diagnostics, and remote monitoring, thereby optimizing operational workflow and reducing ingredient waste. Key manufacturers are aggressively investing in developing compact, multi-functional units that maximize space utilization, particularly appealing to urban food service establishments facing spatial constraints. The emphasis on robust construction materials and longer warranty periods is also driving competitive positioning among market leaders.

Regional trends demonstrate that North America and Europe maintain dominance in terms of technology adoption, showcasing high demand for electric and induction-based models due to superior control and energy efficiency regulations. However, the Asia Pacific region is forecast to register the highest Compound Annual Growth Rate (CAGR), fueled by massive investment in institutional infrastructure, burgeoning organized retail catering, and the establishment of large-scale central kitchens across China, India, and Southeast Asia. Latin America and MEA are focused on foundational growth, prioritizing durable, high-capacity equipment suitable for rapid volume scale-up, often favoring steam or gas-operated systems where utility costs vary significantly.

Segment trends underscore the rising preference for tilting braising pans due to their versatility in handling different culinary tasks and ease of cleaning, significantly reducing downtime. Electric heating methods are gaining market share over traditional gas, specifically in areas with reliable power grids, due to improved temperature precision and safety profiles. Institutional catering remains the largest end-user segment, but the Quick Service Restaurant (QSR) commissary segment is expanding rapidly, demanding customized, high-throughput models for standardized sauce and filling preparation. Overall, the market is characterized by innovation centered on operational intelligence, resource conservation, and maximizing return on investment (ROI) for end-users seeking long-term operational excellence.

AI Impact Analysis on Commercial Kettles and Braising Pans Market

Common user inquiries regarding the impact of Artificial Intelligence (AI) on commercial cooking equipment frequently center on predictive maintenance capabilities, automated recipe execution accuracy, and advanced supply chain integration for ingredients. Users are keen to understand how AI can move beyond simple automation to truly optimize complex cooking processes, ensuring consistency regardless of batch size or operator skill level. The key themes revolve around reducing unplanned downtime through proactive diagnostics (predictive maintenance), optimizing energy consumption based on real-time usage patterns, and achieving perfect product replication by adjusting variables (temperature, stirring speed, cooking time) autonomously in response to ingredient variations or environmental changes. There is also significant user expectation concerning how AI-driven analysis of cooking cycles can inform long-term menu engineering and operational cost reduction strategies.

AI’s influence is shifting these traditional, hardware-centric machines into smart, connected systems capable of self-learning and continuous improvement. The integration of sensors within the kettles and braising pans—measuring factors like viscosity, steam pressure, and heat transfer efficiency—allows AI algorithms to process vast datasets. This analysis results in dynamic adjustments to the cooking parameters, ensuring the desired outcome (e.g., specific sauce consistency or texture) is achieved consistently, minimizing human error and batch rejection rates. This shift transforms the equipment from mere cooking vessels into data-generating assets that contribute to overall kitchen management efficiency and transparency.

Furthermore, AI is crucial for inventory management synergy. By analyzing production schedules and yield rates from the kettles and braising pans, AI systems can automatically trigger reorder points for bulk ingredients, factoring in vendor lead times and forecasted demand variability. This level of integration reduces stockouts, minimizes spoilage, and optimizes working capital. This capability is particularly valuable for large commissaries and institutional feeders that rely heavily on just-in-time inventory strategies, directly translating the efficiency gains of the cooking process into significant supply chain improvements, thereby enhancing overall profitability and operational resilience in the food service sector.

- AI-driven predictive maintenance forecasting equipment failure before occurrence, maximizing uptime.

- Automated, real-time adjustments of cooking parameters (temperature, pressure, agitation) for optimal consistency.

- Recipe optimization algorithms that standardize output quality irrespective of ingredient variability or environmental factors.

- Integration with inventory systems to automate ordering based on production output and stock levels.

- Energy consumption optimization through intelligent scheduling and dynamic power adjustment based on load.

- Enhanced food safety compliance via AI monitoring of critical control points and automated reporting.

DRO & Impact Forces Of Commercial Kettles and Braising Pans Market

The dynamics of the Commercial Kettles and Braising Pans Market are shaped by powerful Drivers promoting expansion, inherent Restraints limiting rapid adoption, and strategic Opportunities paving the way for future innovation, all magnified by pervasive Impact Forces such as global economic stability and regulatory shifts. Key Drivers include the exponential growth of institutional and contract catering, demanding high-throughput cooking solutions, coupled with increasing labor costs that make investment in automated equipment financially justifiable. The constant push for standardized food quality across multi-location chains further necessitates the precision offered by these commercial units. However, major Restraints encompass the significant initial capital investment required for high-capacity, sophisticated units and the physical space constraints often found in urban commercial kitchens. The reliance on specialized utility connections (e.g., high-pressure steam lines or three-phase electricity) can also complicate installation and limit deployment in smaller establishments.

Strategic Opportunities lie primarily in the development of highly flexible, modular, and multi-functional equipment, such as advanced tilting braising pans that can seamlessly switch between sautéing, steaming, and pressure cooking modes. The market can significantly capitalize on the growing focus on energy efficiency through advanced induction heating technologies and superior insulation, appealing to eco-conscious buyers and those seeking lower long-term operating expenses. Furthermore, the integration of IoT (Internet of Things) and connectivity features presents opportunities for remote diagnostics, software updates, and data collection, transforming equipment servicing and operational monitoring into proactive processes rather than reactive repair calls. Emerging markets represent a crucial opportunity for foundational equipment sales as their food service infrastructure rapidly matures.

The dominant Impact Forces influencing the market trajectory are global macroeconomic shifts affecting construction spending and hospitality investment, alongside evolving governmental regulations focused on food safety and energy conservation. Stricter mandates regarding HACCP (Hazard Analysis Critical Control Point) compliance necessitate the use of cooking equipment that provides verifiable temperature logs and controlled environments, directly benefiting manufacturers of modern, digitally controlled kettles and braising pans. The geopolitical stability of key manufacturing and sourcing regions affects material costs (especially stainless steel), exerting considerable pressure on pricing strategies and supply chain resilience. Ultimately, the market benefits from a strong secular trend toward professionalization and industrialization of food preparation, demanding high-quality, high-capacity, and intelligent cooking solutions.

Segmentation Analysis

The Commercial Kettles and Braising Pans Market is segmented based on critical operational and structural characteristics, primarily categorized by Product Type, Heating Mechanism (Operation), Capacity, and End-User Application. This segmentation aids manufacturers in tailoring specific solutions to varied kitchen requirements, from small-scale artisanal production to massive institutional feeding operations. Analyzing these segments reveals shifting preferences toward multi-functional, electric-operated tilting units, reflecting a market demand for versatility and ease of use. The capacity segment is particularly dynamic, with strong growth observed both in compact, less than 40-gallon kettles for specialized restaurants and in ultra-large units exceeding 100 gallons for central commissaries.

The segmentation by Heating Mechanism (Gas, Electric, Steam) determines the unit's thermal efficiency, installation complexity, and operating cost profile. While steam-jacketed kettles remain prevalent in institutional environments due to historical efficiency and large-scale capacity, electric models, especially those utilizing induction technology, are increasingly preferred in modern construction due to their faster response times and localized heat control. End-User segmentation provides insight into consumption patterns, with institutional settings (schools, hospitals) consistently dominating demand, requiring robust, standardized equipment, while the full-service restaurant sector drives demand for more specialized, technologically advanced models suitable for delicate preparations.

Understanding these granular segments is vital for strategic market entry and product positioning. For instance, manufacturers targeting the growing QSR commissary segment must focus on high-speed, high-consistency equipment with automated cleaning features, typically falling within the tilting braising pan category. Conversely, serving the hospital sector mandates focusing on stringent sanitation standards and energy efficiency, often favoring larger, reliable steam kettles. The nuanced analysis of these segments allows for precise forecasting of technological adoption and tailored marketing campaigns.

- By Product Type:

- Tilting Kettles

- Stationary Kettles

- Tilting Braising Pans (Tilt Skillets)

- Stationary Braising Pans

- By Operation (Heating Mechanism):

- Gas Heated

- Electric Heated (Resistance and Induction)

- Steam Heated (Direct Steam and Self-Contained)

- By Capacity:

- Low Capacity (Under 40 Gallons / 150 Liters)

- Medium Capacity (40-100 Gallons / 150-380 Liters)

- High Capacity (Above 100 Gallons / 380 Liters)

- By End-User:

- Full-Service Restaurants (FSR)

- Quick Service Restaurants (QSR) & Commissaries

- Institutional Catering (Healthcare, Education, Corporate)

- Hotels, Resorts, and Hospitality

- Contract Food Services

Value Chain Analysis For Commercial Kettles and Braising Pans Market

The value chain for commercial kettles and braising pans begins with the Upstream Analysis, dominated by raw material suppliers providing high-grade stainless steel (304 and 316), specialized heating elements, and advanced control electronics. Steel procurement costs and quality assurance are critical factors at this stage, directly influencing the final product's durability and price. Component manufacturing, involving the production of jackets, tilting mechanisms, seals, and precise HMI panels, follows, requiring specialized engineering expertise to meet stringent food safety and pressure vessel standards. Efficiency in upstream logistics and long-term contracts with reliable steel providers are key to mitigating supply risk and maintaining competitive manufacturing costs, particularly given the volatility of global commodity markets.

Midstream activities involve the core manufacturing, assembly, and quality testing of the final equipment. Leading companies utilize advanced automated welding techniques and precise temperature calibration processes to ensure regulatory compliance and product reliability. The Distribution Channel is highly specialized, primarily relying on professional commercial kitchen equipment dealers, large national and international distributors, and dedicated consulting firms specializing in kitchen design and fit-out. Direct sales often occur for large institutional or governmental contracts, but the indirect channel, leveraging distributor networks, provides essential localized installation, technical service, and maintenance support crucial for such complex, fixed assets. Specialized distributors often stock replacement parts and provide warranty fulfillment, forming a vital link between the manufacturer and the end-user.

Downstream Analysis focuses on the end-user market, encompassing the installation, commissioning, and long-term operation of the equipment within commercial kitchens. End-users require robust training, rapid maintenance services, and reliable access to spare parts to ensure minimal operational downtime. The product lifecycle often spans 10 to 20 years, making after-sales support a significant element of the total value proposition and a substantial revenue stream for manufacturers and distributors alike. The trend toward connected equipment is further integrating the downstream segment, allowing manufacturers to offer proactive maintenance contracts and performance optimization consultations based on real-time operational data, thus extending the relationship beyond the initial sale.

Commercial Kettles and Braising Pans Market Potential Customers

The primary target audience and End-Users/Buyers of commercial kettles and braising pans are large-scale food production facilities that demand consistency, volume, and operational efficiency far exceeding the capabilities of standard kitchen ranges. These customers fall mainly into the Institutional Catering segment, which includes healthcare facilities (hospitals, nursing homes), educational institutions (universities, K-12 schools), and large corporate campuses. These settings require massive, reliable, and hygienic equipment to feed thousands of individuals daily, making high-capacity, steam-jacketed kettles essential for preparing staple items like soups, purees, and gravies in standardized batches.

Another rapidly growing segment of potential customers is the Quick Service Restaurant (QSR) sector, specifically their central commissaries and ghost kitchens. As QSRs expand globally and rely heavily on standardized ingredients (sauces, chili, fillings) prepared off-site and shipped to individual outlets, they require advanced, automated braising pans and kettles for high-throughput batch cooking with exacting precision. The investment decision in this segment is strongly tied to total cost of ownership, speed of throughput, and seamless integration into automated preparation lines. Contract Catering companies, managing outsourced food services for various clients, are also major buyers, as they need versatile equipment that can adapt to changing menus and high-volume demands across diverse client sites.

Furthermore, large-scale hospitality establishments, including international hotel chains, major resorts, and cruise ship lines, represent significant potential customers. These facilities often operate multiple dining venues requiring vast quantities of consistently prepared base ingredients, driving demand for multi-functional tilting skillets and medium-to-high capacity kettles. The increasing complexity and scale of modern global food delivery systems ensure that any organization focused on producing large, standardized volumes of prepared food, whether for internal consumption or external sale, is a core potential customer for commercial kettles and braising pans.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.8 Billion |

| Market Forecast in 2033 | $3.9 Billion |

| Growth Rate | CAGR 10.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | AccuTemp Products, Vulcan, Groen (Dover), Hobart, Crown, Market Forge, Cleveland Range, Electrolux Professional, Rational, Middleby Corporation, Alto-Shaam, Unified Brands, A.J. Antunes, Pitco Frialator, Blodgett, Berto's, Retigo, Fagor Professional, Ali Group, Convotherm |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Commercial Kettles and Braising Pans Market Key Technology Landscape

The technology landscape within the Commercial Kettles and Braising Pans Market is undergoing a rapid evolution, moving beyond basic heating mechanisms toward smart, highly integrated cooking systems designed for maximum efficiency and precision. A primary technological focus is on advanced heating methodologies, particularly self-contained steam-jacketed kettles that eliminate the need for external boiler systems, simplifying installation and reducing utility complexity. Furthermore, induction technology is gaining prominence, especially in braising pans, offering incredibly fast heating times, superior energy efficiency compared to traditional resistance heating, and highly responsive temperature control, which is essential for delicate preparation tasks while maintaining consistent quality across large batches. The integration of high-resolution digital control panels (HMIs) with intuitive graphical interfaces allows operators to store hundreds of custom recipes and monitor cooking cycles remotely.

Another significant technological advancement centers on automation and ergonomics, directly addressing labor challenges in commercial kitchens. Tilting mechanisms, essential for both kettles and braising pans, are increasingly motorized and controlled electronically, offering precise pouring angles and speeds, minimizing the physical strain on staff and preventing spillage. Furthermore, automated stirrers and agitators, featuring variable speeds and programmable cycles, ensure uniform heat distribution and prevent scorching, critical for products like viscous sauces or delicate custards. These automated tools enhance batch consistency and significantly reduce manual labor associated with constant stirring, thereby increasing throughput efficiency and allowing kitchen personnel to focus on other high-value tasks.

The rise of connectivity through the Internet of Things (IoT) is perhaps the most transformative technological trend. Modern commercial kettles and braising pans are now equipped with Wi-Fi and cloud connectivity, enabling real-time performance monitoring, remote diagnostics for predictive maintenance, and automatic software updates. This connectivity not only reduces service costs and downtime but also allows centralized culinary management teams to track equipment utilization, energy consumption, and product quality consistency across multiple locations globally. Manufacturers are leveraging this data to offer performance-based service contracts and develop more tailored, efficient equipment designs based on real-world usage patterns, ultimately future-proofing the technology investments made by commercial operators.

Regional Highlights

The global Commercial Kettles and Braising Pans Market exhibits significant geographical variations in adoption rates, technological preference, and market maturity, primarily segmented into North America, Europe, Asia Pacific (APAC), Latin America, and Middle East & Africa (MEA). North America, driven by the United States and Canada, remains a dominant market, characterized by mature institutional catering sectors, stringent food safety standards (driving demand for digitally controlled, high-precision equipment), and a strong trend towards chain restaurant expansion requiring large-scale commissary operations. The region demonstrates high demand for innovative electric and smart-enabled equipment with emphasis on energy certification and connectivity features for integrated kitchen management systems, supporting rapid ROI calculation and sophisticated asset management.

Europe represents another key market, distinguished by a strong focus on sustainability, advanced energy efficiency (driven by EU directives), and a preference for multifunctional equipment due to smaller kitchen footprints in densely populated urban centers. Germany, the UK, and France are leaders in adopting high-end, technologically sophisticated braising pans and kettles, often prioritizing ergonomic design and low noise levels. Scandinavian countries show a particular interest in advanced induction heating and self-contained steam systems that minimize environmental impact. The European market is highly competitive, focusing on product durability and extensive after-sales service networks.

The Asia Pacific (APAC) region is projected to be the fastest-growing market globally, fueled by rapid urbanization, significant government investment in institutional infrastructure (healthcare and education), and the exponential rise of organized food services, cloud kitchens, and QSRs. Countries like China and India are seeing mass establishment of central kitchens that require immense capacity, driving demand for high-volume, traditionally steam-heated kettles and robust, cost-effective braising pans. While price sensitivity remains higher in many APAC countries, the demand for equipment capable of handling local high-volume, continuous cooking requirements is soaring, creating substantial opportunities for both local and international manufacturers capable of scaling production quickly.

- North America: Market maturity, focus on smart connectivity, electric heating adoption, and stringent HACCP compliance driving replacement cycles. High capital expenditure capability in institutional and major QSR sectors.

- Europe: Emphasis on energy efficiency (induction/electric), compact, multifunctional designs, and adherence to EU safety and environmental regulations. Strong adoption in hospitality and corporate catering.

- Asia Pacific (APAC): Highest projected growth rate, driven by central kitchen proliferation, institutional sector expansion, and high demand for large-capacity, high-throughput steam and gas-operated systems in developing economies.

- Latin America (LATAM): Developing market characterized by focus on durability and basic functionality. Growth tied to tourism sector expansion and local quick service chain development.

- Middle East & Africa (MEA): Growth stimulated by burgeoning hotel and hospitality sector investments, particularly in the Gulf Cooperation Council (GCC) countries, driving demand for premium, large-scale imported equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Commercial Kettles and Braising Pans Market.- AccuTemp Products

- Vulcan (Illinois Tool Works Inc.)

- Groen (Dover Corporation)

- Hobart (ITW Food Equipment Group)

- Crown (Middleby Corporation)

- Market Forge (Standex International)

- Cleveland Range (Welbilt Inc.)

- Electrolux Professional

- Rational AG

- Middleby Corporation

- Alto-Shaam

- Unified Brands (Standex International)

- A.J. Antunes

- Pitco Frialator

- Blodgett (Middleby Corporation)

- Berto's S.p.A.

- Retigo s.r.o.

- Fagor Professional

- Ali Group S.p.A.

- Convotherm (Welbilt Inc.)

Frequently Asked Questions

Analyze common user questions about the Commercial Kettles and Braising Pans market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving growth in the Commercial Braising Pans Market?

The central factor is the increasing global demand for multi-functional, high-efficiency kitchen equipment within institutional catering and central commissary operations, coupled with rising labor costs which incentivize investment in automated cooking solutions.

How do Commercial Kettles differ fundamentally from standard stock pots?

Commercial kettles utilize a jacketed heating system (steam or electric) for superior heat distribution around the entire vessel, providing precise, uniform temperature control necessary for preventing scorching and ensuring batch consistency at high volumes, a capability standard stock pots lack.

Which heating mechanism is dominating new installations in developed markets?

Electric heating, particularly advanced induction technology, is increasingly dominant in new installations across developed markets like North America and Europe, owing to its superior energy efficiency, rapid heat response, and precise digital temperature management.

What role does IoT connectivity play in modern commercial kettles?

IoT integration enables modern kettles and braising pans to offer remote diagnostics, real-time performance monitoring, automated data logging for HACCP compliance, and predictive maintenance alerts, significantly reducing operational downtime and optimizing performance efficiency.

Which geographical region is expected to show the fastest market expansion?

The Asia Pacific (APAC) region is forecast to experience the fastest market expansion, driven by massive investments in institutional facilities, rapid urbanization, and the proliferation of large centralized kitchens serving expanding Quick Service Restaurant (QSR) chains.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager