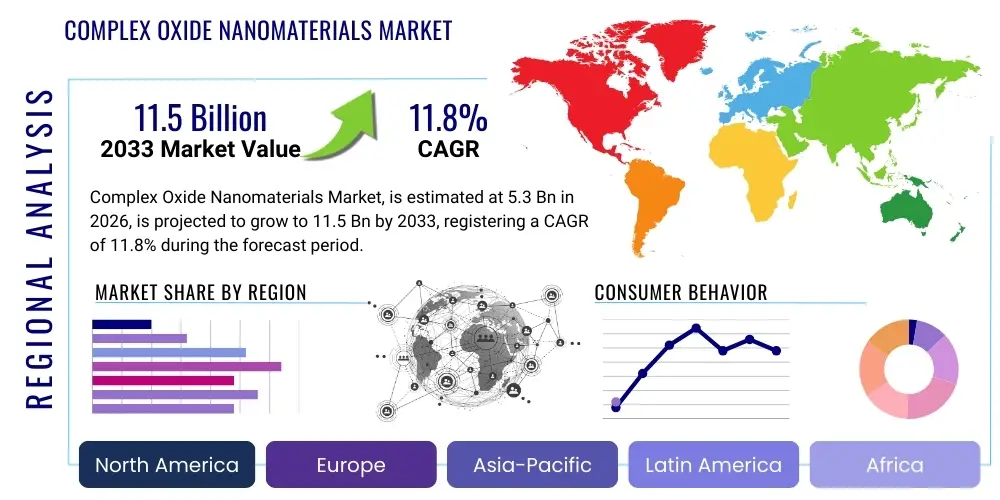

Complex Oxide Nanomaterials Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442219 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Complex Oxide Nanomaterials Market Size

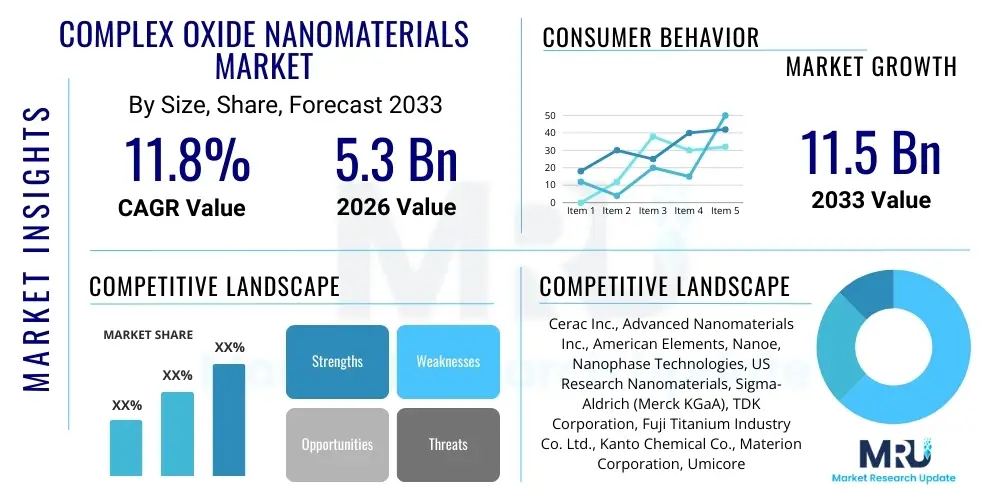

The Complex Oxide Nanomaterials Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 11.8% between 2026 and 2033. The market is estimated at $5.3 Billion in 2026 and is projected to reach $11.5 Billion by the end of the forecast period in 2033.

The substantial growth trajectory is underpinned by the increasing demand for advanced materials with tailor-made functionalities across critical industrial sectors, particularly electronics, energy storage, and biomedical applications. Complex oxide nanomaterials, characterized by their unique crystal structures and tunable electronic and magnetic properties, are becoming indispensable components in next-generation devices such as high-density memory chips, efficient catalytic converters, and robust battery electrodes. Investment in fundamental material science research, coupled with advancements in scalable synthesis techniques like atomic layer deposition (ALD) and hydrothermal processes, are mitigating previous cost barriers and enabling broader commercial adoption globally. The versatility of these materials, encompassing perovskites, spinels, and pyrochlores, allows for highly specialized engineering solutions that are unattainable using conventional bulk materials.

Market expansion is also heavily influenced by global governmental initiatives prioritizing renewable energy infrastructure and energy efficiency. Complex oxide nanomaterials play a crucial role in developing solid oxide fuel cells (SOFCs) and advanced supercapacitors, offering superior charge transfer kinetics and thermal stability compared to organic or simple inorganic counterparts. Furthermore, the push towards miniaturization in consumer electronics and the burgeoning field of quantum computing require materials that exhibit excellent dielectric and ferroelectric properties at the nanoscale, positioning complex oxides as critical enablers for future technological breakthroughs. The Asia Pacific region, driven by massive manufacturing capacities and sustained R&D spending in countries like China, Japan, and South Korea, is anticipated to be the primary engine of market demand throughout the forecast period.

Complex Oxide Nanomaterials Market introduction

The Complex Oxide Nanomaterials Market encompasses materials engineered at the nanoscale (typically 1 to 100 nanometers) that contain two or more different metallic elements combined with oxygen. These materials, including but not limited to perovskites (ABO3 structure), spinels (AB2O4), and garnets, exhibit extraordinary multifunctional properties—such as high dielectric constant, superconductivity, colossal magnetoresistance, and piezoelectricity—that are fundamentally different from their bulk counterparts. They are synthesized using highly controlled techniques like sol-gel processing, chemical vapor deposition (CVD), and pulsed laser deposition (PLD), enabling precise control over composition, morphology, and crystal structure. Major applications span high-performance electronics, including non-volatile memory and advanced sensor technologies; robust energy solutions, such as lithium-ion battery cathodes and catalytic converters; and emerging medical diagnostics and drug delivery systems, leveraging their biocompatibility and magnetic characteristics. The inherent benefits include improved device performance, enhanced energy efficiency, and functional integration across disparate technologies, driving significant market momentum.

The burgeoning demand is primarily fueled by the imperative for enhanced performance in modern electronic devices, necessitating materials capable of operating efficiently at higher frequencies and temperatures. Complex oxide nanomaterials offer unique advantages in areas like spintronics and ferroelectrics, facilitating the development of faster and more power-efficient computing paradigms. Their role as superior catalysts in chemical and environmental applications, particularly for pollutant removal and fuel synthesis, is expanding rapidly due to their high surface area-to-volume ratio and selective chemical reactivity. The development cycle for these materials is highly intricate, requiring substantial capital investment in sophisticated synthesis and characterization equipment, which further underscores the technical expertise required for market participation.

Key driving factors propelling the market include the global transition toward sustainable energy technologies, demanding high-capacity, long-life energy storage solutions where complex oxides are indispensable. Furthermore, the sustained investment in semiconductor technology, particularly in areas requiring advanced thin films for gate dielectrics and interfaces, reinforces the technological need for these specific nanomaterials. While high production costs and scalability challenges present hurdles, the unmatched functional versatility across magnetic, electrical, and optical domains ensures that complex oxide nanomaterials remain at the forefront of advanced materials science innovation, securing their critical role in future technology landscapes.

Complex Oxide Nanomaterials Market Executive Summary

The Complex Oxide Nanomaterials Market is undergoing robust expansion driven by pronounced technological advancements in energy and electronics sectors. Key business trends indicate a strategic focus on collaborative partnerships between material scientists, semiconductor manufacturers, and energy firms to accelerate product commercialization and address scalability issues inherent in nanoscale production. Companies are heavily investing in patented synthesis methodologies to maintain competitive differentiation, particularly in producing highly uniform and stable perovskite structures for photovoltaic and memory applications. Regionally, the Asia Pacific dominates the consumption and production landscape, benefiting from established semiconductor supply chains and aggressive government backing for nanotechnology research, while North America and Europe maintain strong leadership in fundamental R&D and high-value applications like aerospace and defense electronics. Segment-wise, the electronics application category, particularly non-volatile memory (e.g., FeRAM), represents the largest market share due to the relentless demand for higher density and faster access speeds, although the energy segment is projected to exhibit the highest growth rate, fueled by the global electrification movement and advancements in solid-state battery technology requiring highly stable oxide electrolytes and cathodes. The market structure remains fragmented but highly specialized, with a few large chemical and materials companies leading alongside numerous specialized R&D-focused startups.

AI Impact Analysis on Complex Oxide Nanomaterials Market

User queries regarding the impact of Artificial Intelligence on the Complex Oxide Nanomaterials Market predominantly revolve around three critical themes: efficiency in materials discovery, optimization of complex synthesis parameters, and predictive modeling of material properties before physical testing. Users are highly interested in how machine learning algorithms, particularly deep learning models, can be leveraged to screen billions of potential complex oxide compositions virtually, drastically reducing the time and cost associated with conventional trial-and-error laboratory methods. There is significant concern about the need for standardized, high-quality data sets to effectively train these models, given the highly proprietary nature of synthesis data. Expectations are high that AI will not only accelerate the discovery of novel complex oxides with tailored functionalities (e.g., room-temperature superconductivity) but also enable the precise control necessary for industrial-scale manufacturing, thereby lowering production barriers and accelerating market adoption in advanced applications like quantum computing and highly efficient photovoltaics.

- AI accelerates the identification of novel complex oxide compositions with desired electronic or magnetic properties.

- Machine learning optimizes complex synthesis parameters (temperature, pressure, precursor concentration) to achieve desired nanoscale morphology and crystallinity, reducing material defects.

- Predictive modeling using AI minimizes expensive and time-consuming experimental cycles, accelerating time-to-market for new nanomaterial products.

- Integration of AI tools into manufacturing processes enables real-time quality control and dynamic adjustments during large-scale production of oxide thin films and powders.

- Data mining capabilities allow researchers to uncover hidden correlations between structure and function within vast material databases, guiding focused R&D efforts.

DRO & Impact Forces Of Complex Oxide Nanomaterials Market

The Complex Oxide Nanomaterials Market is influenced by a dynamic interplay of growth drivers, inherent constraints, and significant opportunities, collectively shaping its trajectory. The primary drivers include rapid technological innovation in solid-state electronics demanding superior dielectric and ferroelectric properties, coupled with the global pivot towards high-efficiency energy storage systems such as all-solid-state batteries. However, the market faces significant restraints, notably the inherently high cost and technical complexity associated with precise nanoscale synthesis, purification, and large-scale manufacturing of uniform complex oxides, coupled with regulatory uncertainties regarding the environmental impact and occupational safety of advanced nanomaterials. Opportunities abound in emerging sectors like neuromorphic computing, quantum technologies, and advanced catalysis for green hydrogen production. The principal impact forces center on the intensity of R&D investments by governments and private enterprises, the development of cost-effective, continuous synthesis methods, and the growing regulatory push for high-performance, energy-efficient electronic components.

The inherent performance benefits of complex oxide nanomaterials, such as their thermal stability and functional tunability, strongly drive adoption in harsh environment applications like aerospace and high-power electronics. Conversely, the market’s progression is hampered by challenges related to integration, particularly the difficulty in seamlessly incorporating delicate oxide nanostructures into existing silicon-based semiconductor fabrication lines without compromising performance or yielding acceptable defect rates. This integration hurdle necessitates significant capital investment in specialized fabrication tools and highly trained personnel, slowing the rate of widespread industrial uptake beyond niche, high-value markets.

Furthermore, the opportunity landscape is significantly broadened by the potential use of complex oxides in advanced photodetectors and biological imaging agents, capitalizing on their unique optical and magnetic resonance characteristics. The development of next-generation complex oxide thermoelectric materials, capable of efficiently converting waste heat into usable electricity, presents a massive long-term opportunity congruent with global decarbonization goals. These opportunities, while technically challenging, attract substantial venture capital and government grants, reinforcing the market’s innovative core and ensuring sustained long-term growth despite current manufacturing bottlenecks.

Segmentation Analysis

The Complex Oxide Nanomaterials Market is extensively segmented based on material type, structure, application, and synthesis method to provide granular insight into specific market dynamics and growth potential. Segmentation by material structure—including perovskites, spinels, and pyrochlores—reflects the material science foundation and dictates the functional properties relevant to specific end-uses, with perovskites currently leading due to their versatility in solar cells, sensors, and memory devices. Application segmentation details the primary consumption areas, highlighting electronics and energy storage as the most influential segments. This detailed segmentation allows stakeholders to accurately gauge demand trends and tailor their manufacturing and R&D strategies to the most lucrative and rapidly evolving sub-markets within the complex oxide domain.

- By Type/Structure:

- Perovskites (ABO3)

- Spinels (AB2O4)

- Pyrochlore

- Garnets

- Tungsten Bronze

- Others (Ilmenite, Aurivillius phases)

- By Application:

- Electronics (Non-Volatile Memory, Sensors, Capacitors, Spintronics)

- Energy Storage (Li-ion Battery Cathodes/Anodes, Solid Oxide Fuel Cells (SOFCs), Supercapacitors)

- Catalysis and Environmental Remediation

- Medical and Biomedical (Drug Delivery, Imaging Agents, Hyperthermia)

- Aerospace and Defense

- Thermocouples and Thermoelectric Devices

- By Form:

- Nanopowders and Colloids

- Thin Films and Coatings

- Nanowires and Nanotubes

- By Synthesis Method:

- Sol-Gel Process

- Hydrothermal/Solvothermal Synthesis

- Chemical Vapor Deposition (CVD)

- Pulsed Laser Deposition (PLD)

- Molecular Beam Epitaxy (MBE)

- Co-precipitation

Value Chain Analysis For Complex Oxide Nanomaterials Market

The value chain for the Complex Oxide Nanomaterials Market begins with the upstream sourcing and preparation of highly purified raw materials, primarily transition metals (e.g., Fe, Co, Ti, Mn) and rare earth elements (e.g., La, Y), which are critical precursors for the synthesis process. Suppliers must ensure extremely high purity levels, often 99.99% or higher, as trace impurities can significantly alter the electronic and magnetic properties of the resultant nanomaterial. The next stage involves the sophisticated synthesis and processing, where specialized firms utilize complex techniques like PLD, ALD, or hydrothermal methods to precisely control particle size, morphology, and crystal structure—this stage represents the highest value addition due to the inherent intellectual property and technical complexity involved. Quality control and detailed characterization using advanced microscopy techniques (TEM, SEM) are mandatory to ensure functional consistency before materials are integrated into devices.

Moving downstream, the distribution channel is primarily bifurcated into direct sales to large Original Equipment Manufacturers (OEMs) in the semiconductor and automotive sectors, and indirect sales through specialized chemical and materials distributors serving smaller research institutions, universities, and specialized niche manufacturers. Direct channels are prevalent for high-volume, customized thin-film applications (e.g., semiconductor foundry use), where close technical collaboration between the supplier and the OEM is crucial for successful device integration and scaling. Conversely, indirect channels often handle standardized nanopowders and colloidal solutions used in R&D or smaller-scale catalysis applications, emphasizing inventory management and rapid fulfillment.

The final stage involves the integration of the complex oxide nanomaterials into finished products, which includes fabricating cathodes for solid-state batteries, integrating thin films into ferroelectric random-access memory (FeRAM) chips, or incorporating nanoparticles into biomedical contrast agents. This integration requires specialized engineering expertise, particularly concerning interface engineering and stability under operational conditions. The performance of the final device is heavily reliant on the quality and consistency of the complex oxide material, creating strong vertical linkages in the value chain. Effective collaboration across raw material suppliers, synthesis specialists, and end-product integrators is paramount for reducing time-to-market and maximizing the commercial viability of new complex oxide innovations.

Complex Oxide Nanomaterials Market Potential Customers

The primary potential customers for complex oxide nanomaterials are highly specialized manufacturing entities operating in technologically intensive sectors, representing the end-users and large-scale buyers of these advanced materials. Major consumers include semiconductor foundries and memory manufacturers (e.g., producers of non-volatile memory and advanced logic circuits) who utilize complex oxide thin films for high-k dielectrics and functional memory layers due to their superior polarization and energy storage density capabilities. Furthermore, major players in the energy sector, particularly those focused on electric vehicle battery development and stationary grid storage, constitute a substantial customer base, demanding complex oxides for high-stability, high-capacity cathode materials and solid electrolytes in next-generation solid-state batteries. These customers require materials in large, consistent batches, focusing heavily on reproducibility and cost-effectiveness at scale.

The second tier of potential customers includes specialized manufacturers within the chemical and aerospace industries. Chemical companies purchase complex oxide nanopowders for use as highly efficient, selective catalysts in industrial processes such as emissions reduction and chemical synthesis, valuing the high surface area and tunable reactivity offered by these structures. Aerospace and defense contractors utilize complex oxides for their radiation resistance, high-temperature stability, and unique magnetic properties in specialized sensors, lightweight composite structures, and secure electronic systems, where reliability under extreme conditions is non-negotiable and high costs can be justified by superior performance characteristics. These sectors often require highly customized material specifications and stringent certification processes.

Additionally, research institutions and specialized medical technology firms represent a growing niche customer segment. Academic and corporate R&D laboratories procure small, highly specialized batches for exploratory research, particularly in quantum computing and advanced spintronics. Medical device manufacturers use specific magnetic or biocompatible complex oxides (e.g., iron oxides) for advanced applications in targeted drug delivery, magnetic resonance imaging (MRI) contrast enhancement, and hyperthermia treatments for oncology. The customer base is highly educated regarding material properties, often demanding extensive technical support and detailed material characterization data before procurement, highlighting the knowledge-intensive nature of the market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $5.3 Billion |

| Market Forecast in 2033 | $11.5 Billion |

| Growth Rate | 11.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Cerac Inc., Advanced Nanomaterials Inc., American Elements, Nanoe, Nanophase Technologies, US Research Nanomaterials, Sigma-Aldrich (Merck KGaA), TDK Corporation, Fuji Titanium Industry Co. Ltd., Kanto Chemical Co., Materion Corporation, Umicore, Showa Denko K.K., BASF SE, Nanoshel LLC, Saint-Gobain, Alfa Aesar (Thermo Fisher Scientific), QuantumSphere Inc., Nanosynthon, Applied Nanotech Holdings Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Complex Oxide Nanomaterials Market Key Technology Landscape

The technological landscape for complex oxide nanomaterials is defined by the necessity for precision control over stoichiometry, crystallinity, and size distribution, demanding highly specialized synthesis techniques. The Sol-Gel method remains foundational, offering excellent control over chemical composition and homogeneity at relatively low processing temperatures, making it highly suitable for producing high-purity nanopowders and thin films for catalysis and sensor applications. Furthermore, advanced vapor deposition techniques, such as Atomic Layer Deposition (ALD) and Pulsed Laser Deposition (PLD), are critical for semiconductor applications. ALD allows for the deposition of ultra-thin, conformal films with near-atomic precision thickness control, essential for high-k gate dielectrics and advanced memory architectures, while PLD is preferred for creating high-quality, epitaxial thin films exhibiting complex functional properties, often used in fundamental research and prototype development of ferroelectric devices. The choice of synthesis technology dictates the resulting physical properties and ultimately determines the commercial applicability and scalability of the final material.

Beyond synthesis, sophisticated characterization technologies form a vital part of the market’s technological ecosystem. Techniques such as High-Resolution Transmission Electron Microscopy (HR-TEM) and X-ray Diffraction (XRD) are indispensable for verifying crystal structure, phase purity, and identifying defects at the atomic scale, ensuring the synthesized material meets rigorous performance specifications. These characterization methods are particularly crucial when dealing with complex structures like perovskites, which are prone to structural variations that can drastically affect their functionality in devices like solar cells and memory units. The integration of high-throughput screening technologies, often utilizing robotics and automated spectroscopy, is increasingly becoming standard practice to rapidly test and optimize material libraries generated by computational materials science models, thereby accelerating the pipeline from discovery to industrial feasibility.

A significant area of technological focus is the continuous development of cost-effective, scalable manufacturing methods that can bridge the gap between laboratory success and mass production. Technologies like Continuous Hydrothermal Flow Synthesis (CHFS) are gaining traction as they offer a greener and more energy-efficient pathway for producing large volumes of high-quality complex oxide nanopowders compared to traditional batch processes. Furthermore, there is a strong emphasis on developing in-situ monitoring tools that provide real-time feedback during the deposition or synthesis process, enabling dynamic adjustments to maintain tight quality control across large manufacturing runs. This evolution toward highly automated and monitored processes is essential for complex oxide nanomaterials to fully penetrate high-volume markets such as consumer electronics and electric vehicle components, driving down unit costs and solidifying their technological dominance in advanced material applications.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing regional market, primarily driven by massive manufacturing infrastructure in China, South Korea, and Japan. These countries are global hubs for semiconductor production, advanced display technology, and lithium-ion battery manufacturing, making them the largest consumers of complex oxide thin films and high-purity nanopowders. Government policies strongly incentivize nanotechnology research and industrialization, leading to rapid adoption in both consumer electronics and renewable energy projects. Significant R&D is focused on next-generation memory and high-efficiency perovskite solar cells, ensuring sustained market leadership.

- North America: This region is characterized by high R&D intensity, particularly in specialized, high-value applications, including aerospace, defense, and advanced computing. The market here is driven by specialized demands for high-performance ferroelectrics, magnetic materials for spintronics, and complex oxides used in quantum information science. Funding from governmental agencies and leading tech companies maintains North America’s position at the cutting edge of material innovation, focusing on prototype development and system integration rather than large-scale, high-volume production seen in APAC.

- Europe: Europe holds a strong position in environmental and energy applications, driven by stringent European Union regulations pushing for decarbonization. Key areas include the development and utilization of complex oxide catalysts for emissions control and fuel cell technology, as well as advanced materials for smart grids and highly efficient thermoelectric devices. Central and Western Europe boast robust academic research ecosystems and specialized chemical companies that focus on high-pquality, traceable precursor materials and sustainable synthesis routes.

- Latin America (LATAM): The LATAM market remains nascent but is experiencing growth spurred by increasing foreign investment in mineral processing and localized efforts to establish expertise in renewable energy technology. Adoption is slower compared to global leaders, but there is emerging demand in localized sensor development and basic materials research for applications related to mining and environmental monitoring.

- Middle East and Africa (MEA): Growth in MEA is highly localized, driven by energy sector diversification initiatives. Countries like Saudi Arabia and UAE are investing in complex oxide materials for advanced sensor networks, oil and gas monitoring, and solar energy infrastructure, aiming to leverage the materials' thermal stability in high-temperature desert environments. The region relies heavily on imported technology and materials but is building internal research capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Complex Oxide Nanomaterials Market.- Cerac Inc.

- Advanced Nanomaterials Inc.

- American Elements

- Nanoe

- Nanophase Technologies

- US Research Nanomaterials

- Sigma-Aldrich (Merck KGaA)

- TDK Corporation

- Fuji Titanium Industry Co. Ltd.

- Kanto Chemical Co., Inc.

- Materion Corporation

- Umicore

- Showa Denko K.K.

- BASF SE

- Nanoshel LLC

- Saint-Gobain

- Alfa Aesar (Thermo Fisher Scientific)

- QuantumSphere Inc.

- Nanosynthon

- Applied Nanotech Holdings Inc.

- Cabot Corporation

- Evonik Industries AG

- Dupont de Nemours, Inc.

- Arkema S.A.

- Praxair (Linde PLC)

- Sumitomo Chemical Co., Ltd.

- Targray Technology International Inc.

- Toshiba Corporation

- Samsung SDI Co., Ltd.

- Hitachi Metals, Ltd.

- Mitsubishi Chemical Corporation

- Heraeus Group

- Novacentrix

- Advanced Chemical Industries (ACI)

- Graphene Nanochem PLC

- Goodfellow Cambridge Limited

- M Knauer Wissenschaftliche Geräte GmbH

- Nanomaterial Research Corp.

- PChem Associates Inc.

- SkySpring Nanomaterials, Inc.

- Techmer PM, LLC

- Xinte Materials

- Yingkou Tanyun Chemical Research Institute Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Complex Oxide Nanomaterials market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are Complex Oxide Nanomaterials and why are they critical for next-generation electronics?

Complex Oxide Nanomaterials are compounds featuring two or more metals combined with oxygen, engineered at the nanoscale. They are critical for electronics due to their unique multifunctional properties (ferroelectricity, high dielectric constants, and superconductivity), enabling the fabrication of high-density non-volatile memory (FeRAM), efficient thin-film sensors, and advanced spintronic devices superior to traditional silicon components.

Which application segment holds the largest market share for complex oxide nanomaterials?

The Electronics application segment currently holds the largest market share. This dominance is primarily driven by the extensive use of complex oxide thin films in semiconductor manufacturing, specifically for advanced memory technologies, including ferroelectric random access memory (FeRAM), and high-k gate dielectrics necessary for miniaturization and performance enhancement in integrated circuits.

What is the primary restraint hindering the widespread adoption of complex oxide nanomaterials?

The primary restraint is the technical difficulty and high cost associated with achieving large-scale, reproducible synthesis of complex oxides with uniform nanoscale properties. Maintaining precise stoichiometric control and minimizing defect density during mass production, especially for thin-film applications, poses significant manufacturing challenges and capital expenditure requirements, limiting broader industrial scalability.

How are perovskite complex oxides contributing to the energy market?

Perovskite complex oxides (ABO3 structures) are revolutionizing the energy market primarily through their use in highly efficient photovoltaic cells (perovskite solar cells) and as crucial components in next-generation solid-state batteries. They serve as thermally stable, high-performance cathode materials and solid electrolytes, offering superior safety and energy density compared to traditional liquid electrolyte systems.

Which synthesis method is preferred for high-precision deposition of complex oxide thin films in semiconductors?

Atomic Layer Deposition (ALD) and Pulsed Laser Deposition (PLD) are the preferred methods. ALD offers unmatched control over film thickness at the atomic level, crucial for gate dielectrics, while PLD is favored for creating high-quality epitaxial (highly ordered) films used in advanced research and prototype memory devices that require specific crystal orientation for maximum functional performance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager