Concrete Expansion Joint Fillers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441560 | Date : Feb, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Concrete Expansion Joint Fillers Market Size

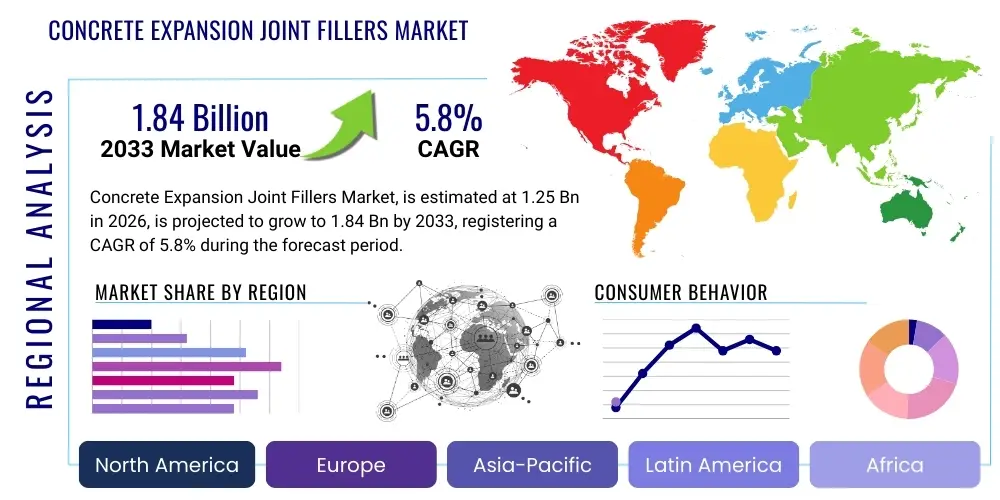

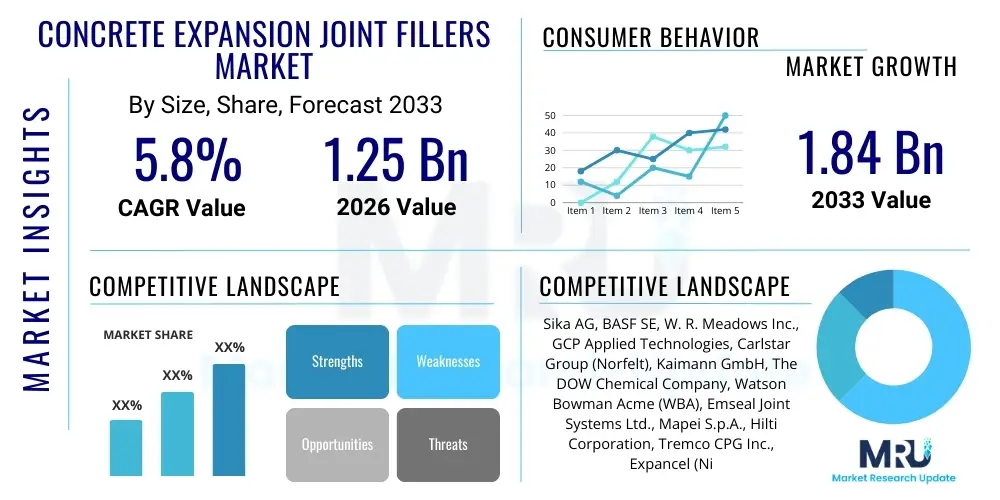

The Concrete Expansion Joint Fillers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.84 Billion by the end of the forecast period in 2033.

Concrete Expansion Joint Fillers Market introduction

The Concrete Expansion Joint Fillers Market encompasses materials designed to occupy the space between adjacent concrete slabs, structures, or components, accommodating thermal expansion and contraction, mitigating stress, and preventing infiltration of debris and moisture. These critical construction elements are formulated from diverse materials, including bituminous compounds, polymer foams (such as polyethylene and polyurethane), rubber, and specialized fiberboard, each selected based on the specific environmental conditions, structural demands, and required longevity of the application. The primary function of these fillers is structural protection, ensuring the integrity and lifespan of concrete infrastructure exposed to varying temperature extremes and dynamic loads.

Major applications of concrete expansion joint fillers span critical sectors such as civil infrastructure (roads, highways, bridges, runways), commercial and residential construction (parking structures, basement floors), and industrial facilities (warehouses, factories, concrete tanks). These fillers are indispensable in projects requiring large expanses of concrete where control of movement is paramount to preventing premature cracking, spalling, and deterioration. The market is propelled by the continuous global investment in infrastructure development, particularly in emerging economies focused on modernizing transportation networks and urban centers.

The core benefits derived from utilizing high-quality expansion joint fillers include enhanced structural resilience, reduced maintenance costs over the asset lifecycle, superior resistance to chemical degradation, and effective waterproofing capabilities. Key driving factors stimulating market expansion include stringent regulatory standards governing the quality and lifespan of infrastructure projects, a global surge in repair and rehabilitation activities for aging public works, and the accelerating pace of urbanization which necessitates robust and long-lasting concrete structures.

Concrete Expansion Joint Fillers Market Executive Summary

The Concrete Expansion Joint Fillers Market is characterized by robust growth, driven primarily by favorable business trends centered on large-scale governmental investment in public infrastructure and a growing emphasis on sustainable and high-performance building materials. Material innovation represents a significant trend, with manufacturers increasingly developing closed-cell foam and elastomeric fillers that offer superior elasticity, durability, and simplified installation processes compared to traditional bituminous products. The competitive landscape is moderately fragmented, featuring both large chemical and construction material conglomerates and specialized regional manufacturers focusing on niche, high-performance applications like chemical-resistant industrial flooring or specialized bridge deck joints. Sustainability mandates are also reshaping the market, driving demand for recycled content and bio-based polymers in filler formulations, aligning with global green building initiatives and reducing the environmental footprint of construction projects.

Regionally, the Asia Pacific (APAC) market is projected to exhibit the highest growth trajectory, fueled by unprecedented infrastructure expansion, particularly in China, India, and Southeast Asian nations investing heavily in high-speed rail, highways, and smart city projects. North America and Europe maintain significant market shares, characterized by a dominant focus on rehabilitation, repair, and maintenance of existing infrastructure assets, alongside the adoption of premium, long-life joint systems designed for extreme weather conditions. Regulatory convergence towards standardized performance specifications across regions is also influencing material choice, favoring internationally certified, durable filler systems.

Segment trends indicate a strong preference for pre-formed foam fillers, particularly polyethylene and polyurethane, due to their ease of handling, lightweight nature, and excellent recovery properties following compression. The application segment for road and bridge construction remains the dominant revenue generator globally, reflecting the necessity of highly durable and weather-resistant joints in critical transportation infrastructure. Furthermore, the specialized industrial and commercial flooring segment is growing rapidly, driven by strict standards for floor flatness and joint integrity in high-traffic warehouses and manufacturing facilities, prompting demand for specialized self-leveling and semi-rigid epoxy fillers.

AI Impact Analysis on Concrete Expansion Joint Fillers Market

User queries regarding the impact of Artificial Intelligence (AI) on the Concrete Expansion Joint Fillers Market frequently focus on how digital technologies can enhance material quality control, optimize logistical challenges, and predict long-term performance failures. Key concerns revolve around the integration of Machine Learning (ML) models for precise mixture formulation, ensuring the perfect balance of polymer composition, density, and elasticity tailored to specific climatic zones and structural loads. Users also anticipate AI-driven systems to improve efficiency in the notoriously complex construction supply chain, facilitating just-in-time delivery of fillers and coordinating installation schedules with large construction phases. The primary expectation is that AI will ultimately lead to higher-performance, longer-lasting joint filler products, reducing the frequency of costly repairs and replacements in major infrastructure projects by accurately simulating real-world degradation factors like thermal cycling and dynamic loading before installation.

- AI-driven optimization of raw material blending, minimizing defects and ensuring uniformity in foam or elastomeric filler production batches.

- Predictive maintenance analytics utilizing sensor data embedded in smart joints to forecast filler lifespan and schedule targeted repairs before structural failure occurs.

- Machine Learning algorithms enhancing quality control by analyzing spectroscopic data of filler materials for instant compliance verification.

- Optimization of supply chain and logistics routes for large infrastructure projects, ensuring timely delivery of customized joint filler sizes and reducing inventory costs.

- Simulation models powered by AI to assess the long-term performance of various filler types under extreme thermal stress and moisture exposure, accelerating R&D cycles.

- Automated visual inspection systems using AI to monitor the installation quality of joint fillers on large job sites, ensuring proper depth, adherence, and finish.

DRO & Impact Forces Of Concrete Expansion Joint Fillers Market

The Concrete Expansion Joint Fillers Market is heavily influenced by a dynamic set of Drivers, Restraints, and Opportunities, collectively managed by powerful Impact Forces that dictate market direction and growth velocity. Key drivers include the massive global investment in infrastructure renewal and expansion, particularly the construction of new roads, bridges, and commercial complexes necessitated by rapid urbanization and population growth in developing nations. Furthermore, the aging infrastructure across developed economies necessitates substantial spending on rehabilitation, where expansion joint replacement is a critical, recurrent maintenance activity. The increasing regulatory pressure to employ durable and environmentally compliant construction materials also acts as a significant market driver, pushing manufacturers toward higher-performance polymer and composite solutions that offer greater resilience against environmental stressors.

Conversely, the market faces notable restraints, primarily related to the volatility and upward trajectory of raw material prices, particularly petrochemical-derived polymers and specialty chemicals essential for producing high-grade elastomeric and foam fillers. This price instability impacts profit margins and makes long-term contract pricing challenging. Moreover, the lack of standardized installation practices in certain geographical areas and the shortage of skilled labor trained in applying specialized joint systems can hinder the adoption of premium products. Economic slowdowns in major construction markets, often influenced by global political stability or recessions, also pose a significant short-term restraint on overall project initiation and material demand.

Opportunities for market players are abundant, focusing primarily on the development of specialized, high-margin products such as fire-resistant joint fillers for tunnel construction, self-healing materials that automatically repair minor cracks, and bio-based or recycled content fillers that appeal to green building standards. The growing demand for specialized, high-performance joint systems in niche applications like cryogenic storage facilities, high-temperature industrial ovens, and highly seismic zones presents avenues for product differentiation and premium pricing. The overarching impact forces—market rivalry, threat of substitutes (e.g., highly sophisticated sealants), bargaining power of large construction contractors, and regulatory pressures—ensure continuous innovation in both material science and application methodology, keeping the market competitive and technologically progressive.

Segmentation Analysis

The Concrete Expansion Joint Fillers Market is segmented across several critical parameters, including Material Type, Product Form, Application, and End-Use Sector, providing a granular view of demand patterns and technological preferences across the global construction industry. Analyzing these segments is essential for stakeholders to effectively target specific high-growth areas, allocate resources for R&D based on material preference, and understand the cyclical nature of demand across civil infrastructure versus commercial construction. The dominance of particular materials like polymer foams in general construction contrasts with the steady demand for bituminous and fiber materials in road rehabilitation projects, necessitating tailored marketing and product strategies.

The Product Form segmentation highlights the evolution from traditional poured or manually installed materials to pre-formed, ready-to-install sheets and strips, which offer significant labor savings and consistency on construction sites. Meanwhile, the Application segmentation clearly demarcates the largest revenue streams, with bridges, roads, and airport runways demanding the most robust and weather-resistant solutions, often at a premium price point compared to standard commercial floor joints. The end-use segmentation reveals the strategic importance of government infrastructure spending as the core driver, although the growth in private industrial and warehousing construction provides a steady, diversified demand base.

- By Material Type:

- Asphalt/Bituminous Fillers

- Polymer Foam Fillers (Polyethylene, Polyurethane)

- Fiberboard/Wood Fillers

- Cork and Rubber Fillers

- Elastomeric Compounds (Neoprene, Silicone)

- Epoxy and Hybrid Fillers

- By Product Form:

- Pre-formed Strips/Sheets

- Poured-in-Place Compounds

- Slab-on-Grade Systems

- By Application:

- Roads, Highways, and Pavements

- Bridges and Overpasses

- Airport Runways and Aprons

- Commercial Buildings (Parking Decks, Basements)

- Industrial Flooring (Warehouses, Manufacturing Plants)

- Water Retaining Structures (Dams, Canals)

- By End-Use Sector:

- Civil Infrastructure (Government & Public Works)

- Industrial Construction

- Commercial & Residential Construction

Value Chain Analysis For Concrete Expansion Joint Fillers Market

The value chain for concrete expansion joint fillers begins with the upstream sourcing of crucial raw materials, predominantly derived from the petrochemical sector (polymers like polyethylene, polyurethane, and rubber), alongside natural materials such as wood pulp for fiberboard or bitumen for asphaltic products. Suppliers in this segment, mainly chemical companies and specialized polymer producers, exert moderate to high bargaining power due to the fluctuating costs of crude oil and the proprietary nature of certain specialized chemical additives required for performance enhancement (e.g., UV stabilizers, anti-aging agents). Efficient procurement and long-term supply contracts are essential for manufacturers to maintain competitive pricing and stable output.

The manufacturing stage involves the processing, compounding, and forming of these raw materials into the final joint filler products, often through extrusion, molding, or casting processes. Value addition at this stage is significant, driven by material science expertise, adherence to strict quality standards (ASTM, AASHTO), and customization capabilities to meet diverse project specifications regarding thickness, width, and expansion capacity. Manufacturers invest heavily in automated production lines and R&D to develop lightweight, durable, and easily installable products, which distinguishes premium offerings from commodity fillers.

Distribution channels are multifaceted, utilizing both direct and indirect routes. Direct distribution involves large manufacturers selling directly to major infrastructure contractors and government agencies responsible for large public works, ensuring immediate control over logistics and installation support. Indirect channels utilize a network of specialized construction material distributors, hardware wholesalers, and local retail outlets, which are crucial for reaching smaller commercial builders and residential contractors. Efficient warehousing and logistics management are paramount due to the bulkiness and regional demand specificity of many joint filler products. Downstream analysis focuses on the end-users—civil engineering firms, specialized concrete contractors, and public works departments—whose specifications and project timelines ultimately drive demand and dictate purchasing volume.

Concrete Expansion Joint Fillers Market Potential Customers

The potential customer base for concrete expansion joint fillers is highly concentrated within the construction and civil engineering ecosystems, categorized primarily by the scale and nature of the construction project being undertaken. Governmental departments and agencies, such as Ministries of Transport, Public Works Departments, and state-level highway authorities, constitute the single largest end-user group globally. These entities are consistently engaged in maintaining, rehabilitating, and expanding critical infrastructure like interstate highways, municipal roads, public bridges, and airport facilities, necessitating massive, continuous procurement of high-performance joint filler systems that comply with rigorous public safety and durability standards.

Large-scale civil infrastructure contractors and engineering, procurement, and construction (EPC) firms represent the second critical segment. These companies execute the actual construction projects under government or private mandates, requiring significant volumes of joint fillers customized for specific structural applications, such as specialized bridge expansion joints or seismic-resistant filler material for dams and tunnels. Their purchasing decisions are heavily influenced by product performance specifications, supplier reliability, and the ease and speed of installation to meet stringent project deadlines.

Furthermore, the industrial and commercial construction sectors form a steadily growing customer segment. This includes developers building large commercial complexes, specialized warehouse facilities, manufacturing plants, and parking structures. These customers demand joint fillers that provide chemical resistance, floor flatness, and robust support for heavy machinery or constant vehicular traffic. Specialized concrete contractors focused on industrial floor treatments and parking deck repairs are key purchasers, often preferring pre-formed, closed-cell foam or specialized epoxy fillers for high-performance applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.84 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sika AG, BASF SE, W. R. Meadows Inc., GCP Applied Technologies, Carlstar Group (Norfelt), Kaimann GmbH, The DOW Chemical Company, Watson Bowman Acme (WBA), Emseal Joint Systems Ltd., Mapei S.p.A., Hilti Corporation, Tremco CPG Inc., Expancel (Nippon Gohsei), Fosroc International Limited, Bostik (Arkema), Trelleborg AB, Owens Corning, 3M Company, MBCC Group, Laticrete International Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Concrete Expansion Joint Fillers Market Key Technology Landscape

The key technology landscape in the Concrete Expansion Joint Fillers Market is rapidly evolving, moving beyond conventional fibrous and bituminous materials toward advanced polymer and composite solutions designed for enhanced durability and sustainability. One significant technological advancement involves the development of high-density, closed-cell polymer foams, particularly based on cross-linked polyethylene (XLPE) and specialized polyurethanes. These advanced foams offer superior water resistance, high recovery rates after compression, and excellent chemical inertness, making them the preferred choice for critical applications like highway expansion and industrial freezer floors where moisture penetration and temperature stability are critical failure points. Manufacturing techniques focus on precise foam density control and lamination processes to create multi-layered, functionally optimized joint strips.

Another crucial technological area centers on the development of elastomeric systems, including pre-compressed foam seals and sophisticated silicone or neoprene extrusion profiles for highly dynamic movement joints, typically found in bridges and parking garages. Innovations here involve formulating materials with exceptional elongation capabilities, UV stability, and adherence properties, often requiring proprietary primer systems to ensure long-term bonding to concrete substrates. Furthermore, the integration of smart materials, such such as those incorporating shape-memory polymers or micro-encapsulated self-healing agents, represents an emerging frontier. Although nascent, these technologies aim to automatically repair micro-cracks that develop over time, significantly extending the service life of the concrete structure and reducing overall maintenance requirements.

Digital technologies are also influencing the application and performance assessment of joint fillers. Building Information Modeling (BIM) platforms are increasingly used to specify and model joint requirements during the design phase, ensuring the correct filler type and size is selected based on anticipated structural movement and thermal analysis. Additionally, sensor technology is beginning to be embedded in high-profile joint systems to monitor actual joint movement, temperature, and moisture levels in real-time. This data feeds back into predictive models, allowing engineers to better understand the performance envelope of different joint filler materials and informing the next generation of product design focused on ultra-high resilience and data-driven maintenance scheduling.

Regional Highlights

The global demand for concrete expansion joint fillers is unevenly distributed, reflecting regional differences in infrastructure investment cycles, construction regulations, and climatic demands. North America, including the United States and Canada, represents a mature market characterized by stringent public infrastructure standards (AASHTO, FHWA). Demand here is heavily skewed towards rehabilitation projects, requiring premium, durable elastomeric, and specialized foam systems capable of withstanding extreme thermal cycles common in the region. Regulatory emphasis on extended service life and reduced lifecycle costs drives the adoption of higher-priced, high-performance joint systems.

Europe, driven by the European Union’s commitment to modernizing transnational road and rail networks, maintains a stable demand. The region shows a strong preference for sustainable and eco-friendly fillers, leading to increased adoption of recycled content polymers and bio-based alternatives, particularly in countries like Germany and Scandinavia. Regulatory frameworks focusing on minimizing volatile organic compound (VOC) emissions are highly influential, pushing manufacturers to develop water-based and solvent-free joint compound formulations. Significant investment in tunneling and complex urban infrastructure projects also requires specialized fire-resistant and high-performance hydrostatic joint fillers.

Asia Pacific (APAC) stands out as the fastest-growing region, powered by rapid urbanization and massive government investments in new mega-infrastructure projects, including highways, ports, high-speed railways, and industrial parks, particularly across China, India, and Indonesia. This region focuses on high-volume production and cost-efficiency, often utilizing commodity fillers like bituminous and standard polyethylene foam, though demand for premium, imported elastomeric systems is increasing in critical structural applications. The Middle East and Africa (MEA) market demonstrates steady growth, highly correlated with large-scale oil and gas infrastructure, tourism development, and public housing initiatives, where fillers must cope effectively with intense heat and high UV exposure.

- Asia Pacific (APAC): Dominates growth due to extensive new construction and urban development projects; key markets include China and India, focusing on infrastructure expansion and capacity building.

- North America: Strong market for high-performance, specialty fillers driven by repair, maintenance, and rehabilitation of aging transportation and commercial infrastructure assets, adherence to rigorous material specifications.

- Europe: Stable growth with a primary focus on environmental compliance, sustainable materials, and specialized applications in dense urban areas and complex tunneling projects.

- Latin America (LATAM): Growth tied to national infrastructure plans and resource development (mining, energy), showing increasing adoption of modern foam fillers over traditional materials.

- Middle East and Africa (MEA): Demand concentrated in high-capital construction projects (e.g., GCC nations), emphasizing materials resistant to extreme heat, sand abrasion, and high salinity environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Concrete Expansion Joint Fillers Market.- Sika AG

- BASF SE

- W. R. Meadows Inc.

- GCP Applied Technologies

- Carlstar Group (Norfelt)

- Kaimann GmbH

- The DOW Chemical Company

- Watson Bowman Acme (WBA)

- Emseal Joint Systems Ltd.

- Mapei S.p.A.

- Hilti Corporation

- Tremco CPG Inc.

- Expancel (Nippon Gohsei)

- Fosroc International Limited

- Bostik (Arkema)

- Trelleborg AB

- Owens Corning

- 3M Company

- MBCC Group (Soprema Group)

- Laticrete International Inc.

Frequently Asked Questions

Analyze common user questions about the Concrete Expansion Joint Fillers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is driving the current growth of the Concrete Expansion Joint Fillers Market?

Market growth is predominantly driven by massive global investment in infrastructure expansion, particularly in high-growth economies in the Asia Pacific, coupled with substantial governmental spending on the repair and rehabilitation of aging transportation networks across North America and Europe. Regulatory mandates favoring durable, long-life construction materials also significantly propel demand.

Which material type is expected to dominate the market share during the forecast period?

Polymer foam fillers, specifically high-density polyethylene and polyurethane, are projected to dominate the market. Their popularity stems from superior performance attributes including high recovery rate, ease of installation, water impermeability, and cost-effectiveness in both civil and commercial construction applications compared to traditional bituminous or fiberboard alternatives.

How do sustainability concerns influence product development in this market?

Sustainability is driving innovation toward green materials. Manufacturers are focusing on developing joint fillers incorporating recycled plastic content, bio-based polymers, and solvent-free formulations (low VOC content) to align with stringent green building certifications and meet the growing demand from environmentally conscious end-users and governmental construction projects.

What is the primary technical challenge facing manufacturers in this industry?

A major technical challenge involves producing joint fillers that maintain performance integrity—specifically elasticity, adhesion, and recovery—across extreme and rapidly fluctuating temperatures. Materials must resist degradation from severe thermal cycling, UV exposure, and moisture ingress while accommodating significant structural movement without failure or spalling, requiring advanced chemical formulations.

Which application segment provides the highest revenue opportunity for joint filler manufacturers?

The Roads, Highways, and Bridges application segment offers the highest revenue potential. These critical infrastructure projects require large volumes of highly specified, durable expansion joint systems and recurrent replacement, positioning the civil infrastructure sector as the most reliable and demanding customer base globally.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager