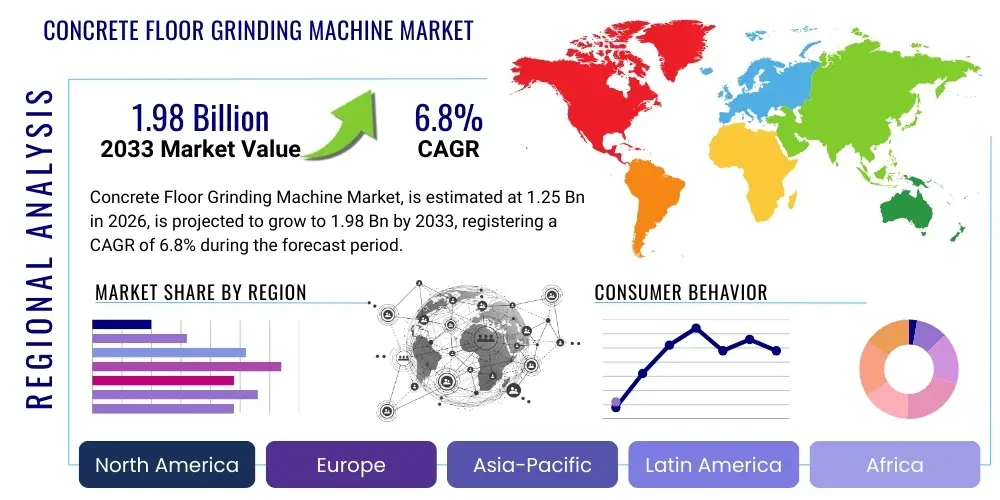

Concrete Floor Grinding Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441282 | Date : Feb, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Concrete Floor Grinding Machine Market Size

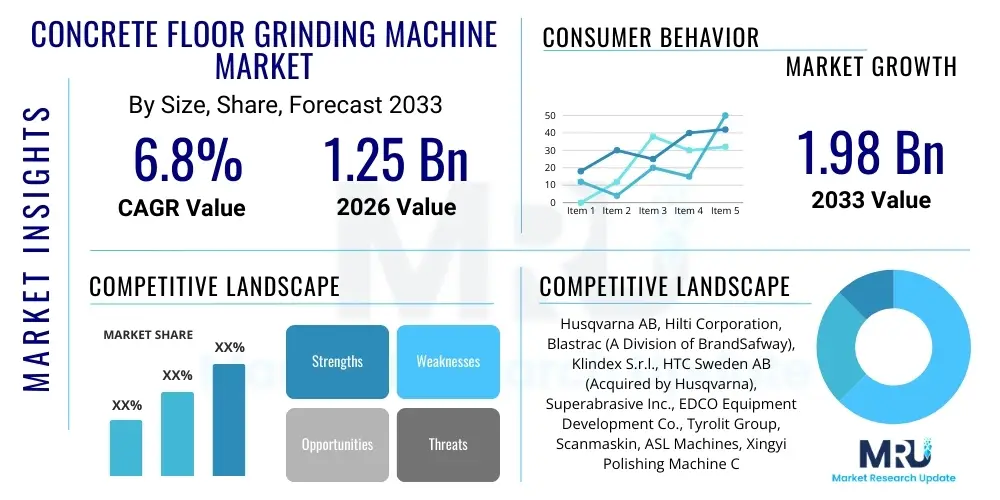

The Concrete Floor Grinding Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.98 Billion by the end of the forecast period in 2033.

Concrete Floor Grinding Machine Market introduction

Concrete floor grinding machines are specialized heavy-duty equipment designed for the preparation, polishing, and restoration of concrete and terrazzo floors. These machines utilize rotating abrasive discs, typically fitted with diamond tooling, to remove surface imperfections, adhesives, epoxies, and coatings, preparing the substrate for further treatment or achieving a high-gloss finish. The primary function involves leveling uneven concrete surfaces, enhancing the floor's aesthetic appeal, and increasing its durability and light reflectivity, which is crucial in industrial, commercial, and institutional settings. The evolution of this equipment has led to the development of sophisticated planetary and rotary models offering varied levels of performance and operator ergonomics, catering to projects ranging from small residential garages to vast industrial warehouses and retail spaces.

The market growth is fundamentally driven by the escalating demand for high-performance flooring solutions, particularly polished concrete, which is increasingly favored for its longevity, low maintenance requirements, and sustainability compared to traditional flooring options. Furthermore, stringent safety regulations concerning floor slipperiness and dust control on construction sites necessitate the use of advanced grinding systems equipped with integrated vacuum technology. Major applications span across industrial facilities, food processing plants, healthcare centers, educational institutions, and large retail chains, where durable, hygienic, and aesthetically pleasing floors are mandatory. The inherent benefits, such as reduced operational costs over the floor's lifecycle and improved indoor air quality through dust minimization, further cement the market's positive trajectory.

Key driving factors include the massive global infrastructural development projects, particularly in emerging economies, coupled with significant refurbishment activities in developed regions focused on modernizing older structures. Technological advancements, such as the integration of remote monitoring capabilities and autonomous operating features, are boosting machine efficiency and reducing labor costs, making professional grinding services more economically viable. The rising adoption of environmentally friendly construction practices also favors concrete polishing, as it minimizes material waste and avoids the use of volatile organic compounds (VOCs) found in traditional sealers and coatings.

Concrete Floor Grinding Machine Market Executive Summary

The global Concrete Floor Grinding Machine Market exhibits robust growth, primarily propelled by favorable business trends centered around infrastructure spending, sustainable building codes, and the increasing preference for polished concrete flooring in commercial and industrial environments. Key business trends include the consolidation among equipment manufacturers focused on offering full-suite floor preparation solutions, and the shift towards rental models, particularly for smaller contractors seeking cost flexibility. Manufacturers are heavily investing in Research and Development (R&D) to improve machine ergonomics, enhance dust suppression capabilities, and integrate IoT (Internet of Things) features for predictive maintenance and optimized performance tracking. The market dynamic is highly competitive, emphasizing efficiency, power output, and versatility across different concrete hardness levels.

Regionally, Asia Pacific (APAC) dominates the market growth trajectory due to rapid urbanization, immense industrialization, and substantial investments in mega-infrastructure projects, particularly in China, India, and Southeast Asian nations. North America and Europe represent mature markets characterized by high adoption rates of advanced, often larger, three-phase grinding machines and strict regulatory compliance regarding environmental and worker safety standards. These regions lead in the adoption of automated and specialized grinding systems, reflecting a focus on labor efficiency and high-quality finishes. Latin America and the Middle East & Africa (MEA) are emerging as high-potential markets, driven by expansion in the retail, hospitality, and logistics sectors.

Segment trends reveal that the three-phase electric machine segment holds the largest revenue share due to their superior power and suitability for large-scale industrial projects. However, single-phase electric and propane-powered machines are gaining traction in smaller commercial and outdoor applications, respectively, offering flexibility and portability. The product type segmentation indicates that ride-on grinders, while commanding a higher initial investment, are increasingly adopted for vast floor areas due to significant improvements in operator comfort and productivity. The application segment remains dominated by industrial and commercial sectors, but the residential remodeling and DIY segment shows a notable acceleration, driven by the availability of user-friendly, smaller machines.

AI Impact Analysis on Concrete Floor Grinding Machine Market

User queries regarding AI's influence in the concrete grinding domain predominantly revolve around automation possibilities, precision improvements, and job displacement concerns. Users frequently ask if AI can enable fully autonomous grinding operations, how machine learning optimizes tooling usage and reduces consumable waste, and whether sensor data analysis can predict floor imperfections requiring specific attention. The core expectations center on AI improving operational efficiency, achieving superior, consistent finishes, and providing predictive maintenance alerts, thereby minimizing downtime and labor costs. The primary concern remains the high initial cost of integration and the need for specialized technicians to manage these advanced, data-driven systems.

The integration of Artificial Intelligence and Machine Learning (ML) is moving the concrete floor grinding market toward 'Smart Grinding Systems.' AI algorithms can process real-time data collected from sensors—including vibration sensors, torque meters, and laser scanners—to dynamically adjust grinding pressure, speed, and direction. This real-time optimization ensures consistent material removal rates, prevents tooling burnout, and adapts automatically to varying concrete hardness across a single floor area, eliminating guesswork and significantly reducing the likelihood of surface damage or unevenness. This level of precision is unattainable with traditional operator-controlled systems, ensuring higher quality outcomes, especially for high-gloss polishing projects.

Furthermore, AI-driven data analytics play a critical role in inventory and operational management. ML models analyze historical wear patterns of diamond tooling based on concrete type, machine usage hours, and environmental conditions. This analysis allows contractors to precisely predict the remaining useful life of consumables, optimizing procurement strategies, reducing inventory holding costs, and preventing unexpected job delays caused by worn-out components. Beyond the machine itself, AI could potentially be used for complex job site mapping, autonomous path planning, and remote diagnostic checks, positioning AI not just as an enhancement, but as a foundational component for next-generation, high-efficiency concrete floor preparation services.

- Autonomous Path Planning: AI enables machines to autonomously map large floor areas and calculate the most efficient grinding path, reducing overlap and increasing productivity.

- Real-Time Parameter Adjustment: Machine learning algorithms process sensor data to automatically adjust grinding pressure and speed based on concrete density and aggregate exposure.

- Predictive Tooling Management: AI analyzes historical usage data to predict diamond tooling wear, optimizing replacement schedules and minimizing consumable waste.

- Defect Detection and Mapping: Image recognition AI identifies and maps specific floor defects (e.g., spalling, cracks, uneven joints) requiring targeted remediation efforts.

- Remote Diagnostics and Monitoring: AI provides remote, predictive maintenance alerts, forecasting potential mechanical failures based on vibration or temperature anomalies, significantly reducing machine downtime.

- Quality Consistency Assurance: ML ensures highly consistent surface roughness and finish levels, critical for meeting strict industry specifications for polished concrete.

DRO & Impact Forces Of Concrete Floor Grinding Machine Market

The Concrete Floor Grinding Machine Market is primarily driven by the escalating global trend toward infrastructure revitalization and the sustained demand for aesthetically superior and highly durable flooring in commercial and industrial environments. Key restraints include the high initial capital investment required for heavy-duty, planetary grinding equipment and the increasing operational complexity associated with integrating advanced digital and IoT features, demanding higher specialized labor skills. Opportunities are vast, centered on the expansion into emerging markets, the development of specialized tooling for unique materials (e.g., highly abrasive surfaces), and the rapid growth of the rental equipment sector, which lowers the entry barrier for small to mid-sized contractors. The collective impact forces favor market expansion, particularly driven by technological innovations that enhance efficiency and adherence to environmental and dust control regulations globally.

Major market drivers include the rapid expansion of the logistics and warehousing sector, which necessitates flat, high-strength polished floors capable of withstanding heavy forklift traffic and continuous use. Furthermore, growing regulatory emphasis on dust control (Silica dust exposure) by bodies like OSHA and similar international agencies mandates the use of specialized dust extractors integrated with grinding machines, pushing contractors toward newer, compliant equipment. The green building movement also strongly supports polished concrete due to its low environmental impact compared to conventional synthetic flooring materials, positioning it as a sustainable alternative favored in LEED-certified construction projects. This environmental and regulatory pressure acts as a significant catalyst for market uplift.

Conversely, the high maintenance costs associated with diamond tooling, which are essential and expendable components, pose a continuous restraint on the market. Economic volatility and cyclical downturns in the construction industry can temporarily suppress demand for new equipment purchases, although the rental segment often mitigates this impact. However, the largest opportunity lies in product differentiation through innovation, specifically the introduction of self-leveling and remote-controlled grinding systems that improve precision and reduce physical strain on operators, addressing the chronic labor shortage in the construction industry. The rapid urbanization across Asia and Africa, coupled with investment in commercial real estate refurbishment, provides geographically focused avenues for sustained market penetration and volume growth, solidifying the positive long-term impact forces.

Segmentation Analysis

The Concrete Floor Grinding Machine Market is segmented based on key operational and structural parameters, including Product Type, Phase Type, Application, and Operation Type. Analyzing these segments provides critical insights into purchasing behaviors, regional demand dynamics, and technological preference shifts within the industry. The segmentation highlights the divergence between large-scale industrial requirements demanding powerful, high-efficiency machinery and smaller commercial or residential needs favoring portable and user-friendly models. This structure allows manufacturers to tailor product development and marketing strategies precisely to the distinct requirements of specialized end-user groups, ranging from professional flooring contractors to general construction companies engaged in concrete restoration and finishing.

The Product Type segmentation delineates between planetary grinders, known for superior flatness and high-quality finishes achieved through multiple rotating heads, and rotary grinders, which are simpler, often cheaper, and suitable for rapid material removal or aggressive stripping tasks. The Phase Type, covering single-phase and three-phase electricity or propane/gas power, determines the machine's power output and suitability for various work environments—single-phase for smaller projects and three-phase for heavy industrial duty where access to powerful electrical infrastructure is available. The Application segment illustrates the primary revenue drivers, with industrial floors (warehouses, factories) and commercial spaces (retail, hospitals) dominating due to the need for continuous performance and strict maintenance standards. Finally, Operation Type differentiates between walk-behind machines, which constitute the bulk of the market, and the rapidly growing ride-on or remotely controlled machines, increasingly popular for large-scale productivity gains.

- By Product Type:

- Planetary Grinders

- Rotary Grinders (Non-Planetary)

- By Phase Type:

- Single-Phase Electric

- Three-Phase Electric

- Propane/Gas Powered

- By Application:

- Industrial (Warehouses, Factories, Logistics Centers)

- Commercial (Retail Stores, Hospitals, Offices)

- Residential

- Infrastructure (Bridges, Roads, Airports)

- By Operation Type:

- Walk-Behind

- Ride-On

Value Chain Analysis For Concrete Floor Grinding Machine Market

The value chain for the Concrete Floor Grinding Machine Market begins with the upstream suppliers providing crucial raw materials and specialized components, including high-grade steel and aluminum for the machine body, specialized motor and gear components (electric or hydraulic), and critically, industrial diamonds and binding matrices required for abrasive tooling production. Efficient sourcing and quality control at this stage are vital, as the performance and durability of the finished grinding machine are directly dependent on the robustness of the components, particularly the motors and the precision of the grinding head assemblies. Strategic partnerships with reliable component manufacturers, especially those specializing in high-torque industrial motors and vacuum system integration, are essential for maintaining production quality and reducing manufacturing lead times.

The midstream stage involves machine manufacturing, assembly, and integration, where core R&D activities related to ergonomics, power transmission efficiency, and advanced dust suppression technologies occur. Manufacturers focus on optimizing machine balance, minimizing operational vibration, and integrating digital control systems (HMI interfaces) to enhance user experience and productivity. This stage also includes the manufacturing of associated consumables like diamond tooling, which often represents a significant, recurring revenue stream. The distribution channel is bifurcated into direct sales to large construction and rental corporations and indirect sales through specialized industrial equipment distributors, agents, and local dealers. Distributors provide essential post-sales support, maintenance services, and local inventory, acting as a crucial link to smaller contractors and end-users.

Downstream analysis focuses on end-users, primarily professional flooring contractors, restoration specialists, and large industrial facilities operating their own maintenance teams. Direct distribution is common for large, expensive ride-on models, ensuring specialized training and support are provided directly by the manufacturer. Indirect channels, particularly the equipment rental market, play a predominant role in lowering the barrier to entry for smaller projects and regional contractors, driving market accessibility. The success of the downstream activities heavily relies on the availability of timely maintenance, technical support, and the provision of continuous training on new equipment features, ensuring high uptime and maximizing customer return on investment. The feedback loop from end-users back to R&D concerning operational issues and desired feature improvements is critical for continuous product development and staying competitive in this specialized machinery market.

Concrete Floor Grinding Machine Market Potential Customers

The primary customer base for Concrete Floor Grinding Machines consists of highly specialized flooring contractors, general construction companies, and rental firms that cater to both commercial and industrial construction and refurbishment projects. Flooring contractors, often specializing in concrete polishing, surface preparation, or epoxy application, represent the largest and most frequent buyers, seeking high-performance, durable machinery to achieve specific surface profile specifications (CSP standards) required for subsequent coatings or finishes. These professionals demand reliability and efficiency, driving demand for heavy-duty, three-phase planetary grinders and associated advanced tooling.

Another significant customer segment includes large industrial and commercial entities, such as multinational corporations managing extensive logistics centers, large retail chains, and hospital networks, which often purchase or lease equipment directly for in-house maintenance and restoration programs. These organizations prioritize machines with integrated dust control and advanced diagnostics, aiming for minimal operational disruption. The growing equipment rental industry also represents a critical customer segment, acting as a powerful intermediary that purchases machines in bulk to supply smaller, project-based contractors, making a wide range of machinery accessible without the substantial capital expenditure required for ownership, especially for single-phase or smaller walk-behind units.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.98 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Husqvarna AB, Hilti Corporation, Blastrac (A Division of BrandSafway), Klindex S.r.l., HTC Sweden AB (Acquired by Husqvarna), Superabrasive Inc., EDCO Equipment Development Co., Tyrolit Group, Scanmaskin, ASL Machines, Xingyi Polishing Machine Co., Ltd., National Flooring Equipment, LAVINA (Superabrasive), Contec GmbH, SPE International, SASE Company, Tomal Company, CPS (Concrete Polishing Solutions). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Concrete Floor Grinding Machine Market Key Technology Landscape

The technological landscape of the Concrete Floor Grinding Machine Market is rapidly evolving, driven primarily by the need for increased efficiency, improved operator safety, and superior surface finish quality. A major shift involves the development of advanced power management systems, moving beyond simple variable speed drives to sophisticated digital controls that maintain optimal torque and rotational speed even under fluctuating loads. This precision control significantly extends the life of diamond tooling and ensures consistent material removal across the entire floor area. Key technologies also include integrated wet and dry grinding capabilities, allowing contractors to adapt quickly to diverse job site requirements and environmental regulations, particularly concerning crystalline silica dust containment. The core innovation remains in the tooling itself, with manufacturers continually developing new bond matrices and diamond grit configurations optimized for specific concrete hardness and desired surface profiles.

Automation and connectivity represent the next frontier. Many leading manufacturers are now incorporating sophisticated Human-Machine Interface (HMI) screens that provide real-time feedback on motor load, vibration levels, and consumption metrics, allowing operators to monitor and adjust machine parameters instantly. Furthermore, the introduction of self-propelled and remote-controlled grinding units minimizes operator fatigue and drastically improves productivity in very large industrial spaces. These remotely operated systems often utilize ultrasonic sensors or GPS localization for programmed path execution, paving the way for eventual fully autonomous operation. Data logging capabilities are becoming standard, enabling contractors to generate digital records of the grinding process, crucial for quality assurance and compliance documentation in highly regulated sectors like pharmaceuticals or food processing.

Dust management technology is arguably the most critical area of focus due to stringent health and safety standards. High-efficiency particulate air (HEPA) filtration systems are now mandatory attachments, and new grinding head designs incorporate advanced shrouding and air flow dynamics to maximize dust capture at the source. The combination of improved magnetic tooling attachment systems and multi-head planetary movement ensures that the grinding machines deliver flatter, more uniform surfaces faster than ever before. These technological advancements not only meet regulatory requirements but also create significant competitive advantages for companies investing in high-end, digitally integrated grinding solutions, improving both the project turnaround time and the final floor quality.

Regional Highlights

Regional dynamics are critical to understanding the differential growth rates and technology adoption patterns across the global Concrete Floor Grinding Machine Market. Each region presents unique characteristics shaped by infrastructural maturity, construction spending levels, labor costs, and adherence to environmental and safety regulations. These factors influence the type of equipment favored, ranging from advanced, high-power systems in Western markets to more cost-sensitive, general-purpose machinery in developing economies. Furthermore, the local availability of rental services significantly impacts the market penetration of large, expensive equipment.

- North America: Characterized by high labor costs and strict OSHA regulations regarding silica dust. This drives strong demand for large, automated, ride-on, and three-phase grinding machines with superior integrated dust extraction systems. The U.S. and Canada lead in the adoption of premium brands and rental fleets, focusing heavily on concrete polishing for retail, institutional, and logistics facilities.

- Europe: A mature market focused on sustainable practices and high-quality finishes. Western Europe (Germany, UK, Scandinavia) adopts advanced planetary grinders and strongly favors electric models for environmental reasons. There is a strong emphasis on machine ergonomics and efficiency to comply with strict worker safety standards, supporting demand for specialized, high-precision equipment.

- Asia Pacific (APAC): The fastest-growing region globally, fueled by rapid urbanization, massive infrastructure development (e.g., roads, smart cities), and burgeoning manufacturing and warehousing sectors (China, India, Southeast Asia). Price sensitivity is higher, but the sheer volume of construction activity drives immense demand for all machine types, including locally manufactured, cost-effective models and imported heavy-duty machines for large industrial parks.

- Latin America (LATAM): An emerging market showing increasing industrialization, particularly in Brazil and Mexico. Market growth is supported by foreign investment in commercial infrastructure. Demand is mixed, with a focus on both affordability and basic performance, driving the sales of robust, mid-range walk-behind machines.

- Middle East and Africa (MEA): Growth is primarily concentrated in the GCC nations (UAE, Saudi Arabia) due to high-value construction and mega-project investments (e.g., NEOM). The hot climate promotes the use of polished concrete for thermal efficiency. Demand is skewed towards powerful three-phase and propane-powered units suitable for large, isolated construction sites and high-traffic areas like airports and convention centers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Concrete Floor Grinding Machine Market.- Husqvarna AB

- Hilti Corporation

- Blastrac (A Division of BrandSafway)

- Klindex S.r.l.

- HTC Sweden AB (Acquired by Husqvarna)

- Superabrasive Inc.

- EDCO Equipment Development Co.

- Tyrolit Group

- Scanmaskin

- ASL Machines

- Xingyi Polishing Machine Co., Ltd.

- National Flooring Equipment

- LAVINA (Superabrasive)

- Contec GmbH

- SPE International

- SASE Company

- Tomal Company

- CPS (Concrete Polishing Solutions)

- Substrate Technology, Inc. (STI)

- Onfloor Technologies

Frequently Asked Questions

Analyze common user questions about the Concrete Floor Grinding Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What factors are driving the growth of the Concrete Floor Grinding Machine Market?

Market growth is driven primarily by increased global investment in infrastructure and warehousing, the rising popularity of durable and low-maintenance polished concrete flooring, and strict governmental regulations mandating advanced dust suppression and worker safety standards in construction.

What is the difference between planetary and rotary concrete grinding machines?

Planetary grinders use multiple counter-rotating heads to achieve superior flatness and finer finishes, ideal for polishing. Rotary grinders use a single large spinning disc and are generally used for aggressive material removal, leveling, or stripping of thick coatings.

How is technological innovation affecting the efficiency of grinding machines?

Technological innovations focus on integrating remote operation, GPS path planning, and AI-driven systems to optimize pressure and speed in real-time. This increases efficiency, reduces operator fatigue, extends tooling life, and ensures consistent, high-quality surface preparation outcomes.

Which application segment holds the largest market share for concrete grinding machines?

The Industrial segment, encompassing large warehouses, factories, and logistics centers, holds the largest market share due to the necessity of flat, high-strength floors capable of handling heavy machinery and continuous, high-volume traffic.

What is the market impact of new regulatory requirements on silica dust control?

Stringent regulations (e.g., OSHA) necessitate the use of grinding machines integrated with high-efficiency vacuum shrouds and certified HEPA filtration systems. This accelerates the replacement cycle for older equipment and drives demand for newer, compliant machinery, strengthening the market overall.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager