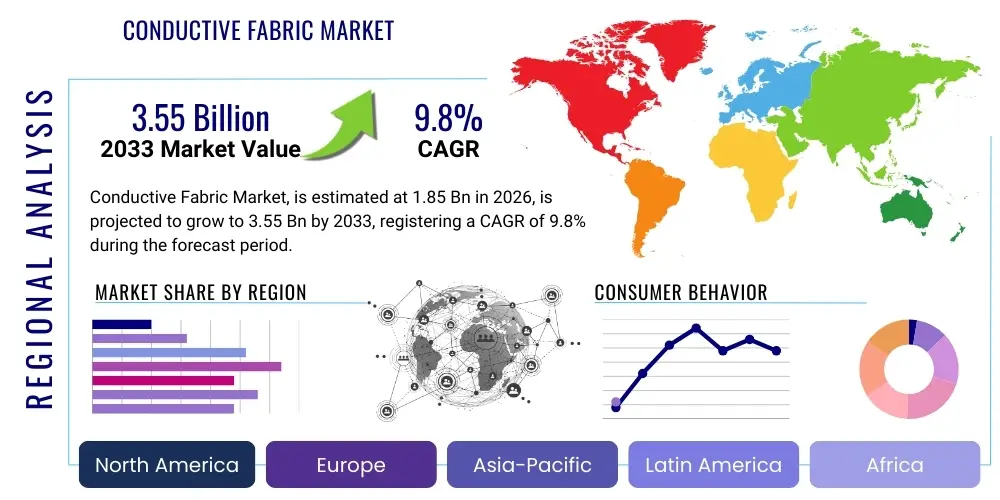

Conductive Fabric Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443516 | Date : Feb, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Conductive Fabric Market Size

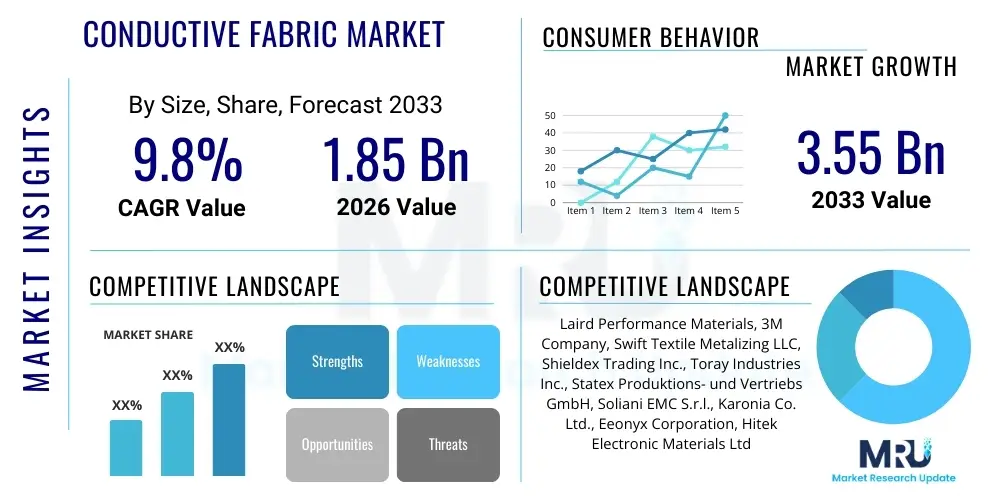

The Conductive Fabric Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.8% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 3.55 Billion by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the escalating demand for advanced electromagnetic interference (EMI) shielding solutions in consumer electronics and the rapidly evolving landscape of smart wearable technology across medical and fitness sectors.

Conductive Fabric Market introduction

Conductive fabrics are textiles engineered to possess electrical conductivity, typically achieved through the integration of metallic fibers, coating processes (such as electroless plating or sputtering), or the incorporation of inherently conductive polymers. These materials bridge the gap between traditional textiles and electronic components, offering unique properties vital for modern technological applications. Primarily, conductive fabrics are utilized for robust electromagnetic interference (EMI) shielding, electrostatic discharge (ESD) protection, and as flexible circuit components in smart textiles and wearables. The market growth is being catalyzed by the proliferation of Internet of Things (IoT) devices, the rollout of 5G networks requiring enhanced shielding capabilities, and increasing investments in advanced defense and aerospace applications where lightweight, flexible shielding is mandatory.

The product portfolio encompasses various forms, including woven, non-woven, and knitted structures, with conductivity imparted usually via copper, nickel, silver, or carbon-based coatings. Major applications span across consumer electronics, medical diagnostics, protective clothing, and automotive sectors. Benefits derived from using conductive fabrics include significant weight reduction compared to traditional metal shielding, superior flexibility and conformability, and the ability to integrate electronic functions seamlessly into apparel. Key driving factors propelling this market include the miniaturization of electronic components, the increasing susceptibility of high-frequency devices to EMI, and governmental mandates requiring effective ESD protection in industrial environments.

Conductive Fabric Market Executive Summary

The Conductive Fabric market is experiencing robust growth fueled by transformative business trends, particularly the convergence of textile manufacturing and electronics integration. Significant investment flows are directed towards enhancing coating durability and improving conductivity while maintaining fabric comfort and washability, crucial for the smart textile segment. Furthermore, strategic partnerships between material suppliers and major consumer electronics manufacturers are streamlining product development cycles, ensuring that new conductive materials meet the stringent performance requirements of next-generation devices, including flexible displays and high-speed data transmission equipment. The shift toward sustainable and non-toxic conductive materials, such as bio-based polymers and advanced carbon structures, is another notable trend influencing current business strategies.

From a regional perspective, Asia Pacific (APAC) currently dominates the market share, primarily due to the high concentration of electronics manufacturing hubs and rapid adoption rates of smart wearables in countries like China, South Korea, and Japan. North America and Europe, however, exhibit higher revenue per unit adoption in niche, high-value sectors such as defense, aerospace, and advanced medical diagnostics, driven by stringent regulatory standards for product safety and electromagnetic compatibility (EMC). Future growth is anticipated to accelerate rapidly in emerging economies across Latin America and the Middle East, correlating directly with increased penetration of 5G infrastructure and rising disposable incomes driving consumer electronics demand.

Segment trends highlight the EMI shielding application segment as the largest revenue generator, a position solidified by the ongoing rollout of complex 5G infrastructure and the need to protect sensitive internal components from electromagnetic noise. Simultaneously, the smart textile segment, although smaller, is projected to record the highest Compound Annual Growth Rate (CAGR). This acceleration is driven by advancements in health monitoring textiles, military applications requiring integrated sensors, and sophisticated interactive apparel. Material-wise, silver-coated fabrics maintain dominance due to superior conductivity, but the lower cost and satisfactory performance of nickel/copper coatings ensure their sustained market presence, particularly in volume-driven industrial and commercial applications.

AI Impact Analysis on Conductive Fabric Market

Common user questions regarding AI's impact on the Conductive Fabric Market frequently revolve around optimizing complex material synthesis processes, enhancing quality control for thin metallic coatings, and facilitating the rapid design iteration of new conductive patterns for flexible electronics. Users are keen to understand how AI-driven simulations can predict the long-term durability, washability, and conductivity retention of these fabrics under varied environmental stresses, thereby reducing physical prototyping time and costs. Furthermore, there is significant inquiry into the role of AI in personalizing smart textile functionality, such as dynamically adjusting sensor sensitivity or optimizing power management in integrated wearable systems. The consensus highlights that AI is anticipated to revolutionize manufacturing efficiency and accelerate material innovation, positioning it as a core technology for future market development.

- AI-driven optimization of electroless plating and sputtering parameters to achieve uniform and durable metallic coating thickness, minimizing material waste.

- Predictive modeling using machine learning to simulate fabric performance (conductivity, flexibility, shielding effectiveness) based on different fiber types and coating compositions.

- Enhanced quality control through computer vision systems identifying micro-defects in woven conductive patterns at high production speeds, ensuring compliance with stringent performance specifications.

- Development of personalized smart textile interfaces by AI algorithms that analyze user biometrics and environmental data, adjusting sensor arrays embedded within the conductive fabric.

- Automated material discovery platforms utilizing AI to identify novel conductive polymers and nano-materials suitable for textile integration, potentially unlocking greener manufacturing alternatives.

- Optimization of supply chain logistics and inventory management for specialty raw materials, ensuring timely production based on demand forecasts provided by AI analytics.

DRO & Impact Forces Of Conductive Fabric Market

The Conductive Fabric Market is significantly influenced by a complex interplay of drivers (D), restraints (R), and opportunities (O). Key drivers include the exponential growth in the wearable electronics and smart clothing sectors, coupled with the critical need for effective EMI shielding in advanced 5G infrastructure and data centers, necessitating lightweight and flexible shielding solutions. However, the market faces significant restraints, suchably the relatively high cost associated with advanced metallic coating techniques like sputtering and PVD, which restricts widespread adoption in cost-sensitive commercial applications. Furthermore, challenges related to the long-term durability, washability, and oxidation resistance of metallic coatings on textiles continue to pose technical hurdles that impede consumer satisfaction and product lifespan. These internal and external pressures create a dynamic environment where technological innovation is essential to overcome limitations and capitalize on emerging application areas.

Opportunities for market expansion are abundant, particularly within biomedical sensing and remote patient monitoring, where conductive fabrics form the foundation of comfortable, continuous data collection devices. The integration of these fabrics into the burgeoning Internet of Things (IoT) ecosystem, especially for smart home applications and environmental monitoring, represents a substantial growth avenue. Moreover, the increasing focus on military and defense applications, requiring sophisticated, camouflage-compatible smart uniforms with integrated communication and power capabilities, presents high-margin opportunities. The overall market is heavily impacted by the rapid pace of miniaturization in electronics, which constantly increases component density and, consequently, the demand for high-performance EMI shielding and reliable flexible interconnectivity.

Segmentation Analysis

The Conductive Fabric Market is segmented based on Material Type, Fabric Type, Application, and End-User Industry, providing a nuanced view of market dynamics and growth pockets. The segmentation highlights the underlying material science competition, particularly between high-conductivity silver coatings and the more cost-effective nickel/copper alternatives, defining performance versus price points across different end-user needs. Analysis by fabric type—woven, non-woven, and knitted—is crucial as it directly impacts flexibility, stretchability, and overall comfort, dictating suitability for wearables versus fixed shielding solutions. The subsequent paragraphs delve into the key segments, illustrating how varying material compositions and fabric structures are tailored to meet specific industry demands, from stringent aerospace specifications to high-volume consumer product integration.

- By Material Type:

- Copper Coated Fabrics

- Nickel Coated Fabrics

- Silver Coated Fabrics

- Gold Coated Fabrics

- Carbon-based Conductive Fabrics (e.g., Graphene, CNTs)

- Others (e.g., Tin, Zinc)

- By Fabric Type:

- Woven Conductive Fabrics

- Non-Woven Conductive Fabrics

- Knitted Conductive Fabrics

- By Application:

- Electromagnetic Interference (EMI) Shielding

- Electrostatic Discharge (ESD) Protection

- Smart Textiles (Heating, Sensing, Lighting)

- Flexible Sensors and Heating Elements

- Conductive Gaskets and Tapes

- By End-User Industry:

- Consumer Electronics (Smartphones, Tablets, Laptops)

- Healthcare and Medical Devices (Remote Monitoring, Electrodes)

- Aerospace and Defense (Avionics Shielding, Smart Uniforms)

- Automotive (Cable Shielding, Interior Sensors)

- Industrial and Manufacturing (Cleanroom Apparel, ESD Mats)

- Telecommunications and IT

Value Chain Analysis For Conductive Fabric Market

The value chain of the Conductive Fabric Market begins with upstream activities involving the sourcing of base textile materials, such as polyester, nylon, and cotton, alongside specialty conductive raw materials like metal powders (silver, copper, nickel) or chemical precursors for electroless plating. The upstream segment is characterized by intense R&D focusing on developing highly durable base polymers and optimizing nanoscale metal particle size for maximum conductivity. Key challenges here include managing the volatility of commodity metal prices and ensuring the purity of chemical inputs used in the deposition process. Innovation is heavily centered on creating environmentally friendly coating chemistries that comply with increasingly strict global regulations regarding heavy metals and solvent usage.

The midstream segment involves the core manufacturing process, where base fabrics are transformed into conductive textiles using advanced techniques such as electroless plating, sputtering (PVD), and chemical vapor deposition (CVD). Fabric manufacturers are responsible for achieving uniform coating coverage, optimal surface resistance, and maintaining the textile's inherent flexibility and comfort. This stage is capital-intensive, requiring specialized machinery and highly controlled environments. Downstream activities involve converting the bulk conductive fabric into final products, such as gaskets, tapes, shielding enclosures, or integrating them into complex smart apparel systems by specialized electronics integrators (OEMs) or apparel manufacturers. The distribution channel is bifurcated into direct sales to large OEMs (especially in defense and aerospace) and indirect sales through specialized technical distributors who provide localized cutting and customization services to smaller application developers and regional manufacturers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 3.55 Billion |

| Growth Rate | 9.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Laird Performance Materials, 3M Company, Swift Textile Metalizing LLC, Shieldex Trading Inc., Toray Industries Inc., Statex Produktions- und Vertriebs GmbH, Soliani EMC S.r.l., Karonia Co. Ltd., Eeonyx Corporation, Hitek Electronic Materials Ltd., Temas Engineering, VTT Technical Research Centre of Finland Ltd., Holland Shielding Systems B.V., Seiren Co., Ltd., Bekaert NV, Technical Absorbents Ltd., Zhejiang Jiashan Huasheng Textile Co., Ltd., DuPont de Nemours, Inc., Swicofil AG, Ametek Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Conductive Fabric Market Potential Customers

The primary consumers of conductive fabrics span several high-growth, technology-intensive industries where controlling electromagnetic interference and ensuring reliable electronic connectivity are critical. Consumer electronics manufacturers constitute a significant customer base, demanding these materials for internal component shielding in smartphones, laptops, and gaming consoles to prevent signal degradation and cross-talk, especially as devices become thinner and operate at higher frequencies. This segment seeks materials that are flexible, highly effective at attenuation, and easily integrated into complex assembly processes. The rapid turnover and volume requirements of the consumer electronics sector make it a key demand driver for mass-produced, cost-effective conductive solutions, particularly nickel- and copper-coated polyester fabrics.

Another major segment comprises the Healthcare and Medical Device industry, which uses conductive fabrics extensively for electrodes in electroencephalography (EEG) and electrocardiography (ECG) monitoring, as well as for remote patient monitoring garments. These buyers require materials that are biocompatible, highly sensitive, soft against the skin for extended wear, and maintain consistent performance after sterilization or washing. Furthermore, the Aerospace and Defense sectors represent high-value potential customers, needing robust conductive fabrics for shielding sensitive avionics against high-altitude electromagnetic pulses (EMP) and for integrating communication and power delivery into military uniforms and protective gear. These applications prioritize maximum performance, reliability, and extreme durability over cost.

Conductive Fabric Market Key Technology Landscape

The technological landscape of the Conductive Fabric market is defined by several sophisticated processes aimed at imparting electrical conductivity to traditional textile substrates without compromising their flexibility, breathability, or physical integrity. Electroless plating remains a foundational technology, involving the chemical deposition of metallic ions (commonly silver, copper, or nickel) onto the surface of the textile fibers. Advancements in this area focus on using multi-layered deposition to improve corrosion resistance and washability, ensuring conductivity is maintained throughout the product lifespan. This method is highly scalable and generally cost-effective, making it popular for high-volume EMI shielding applications and general ESD protection clothing, but controlling the uniformity and adherence of the thin metal layer remains a continuous technological challenge that research is addressing through optimized pretreatment processes.

Physical Vapor Deposition (PVD), particularly sputtering, represents a higher-end technology utilized when exceptional shielding effectiveness or very thin, uniform coatings are required, common in military and specialized medical applications. PVD allows for precise control over the coating thickness and purity, often resulting in superior conductivity compared to chemical methods, though the process is more capital-intensive and less suitable for highly porous or complex 3D textile structures. A rapidly emerging technological front involves the integration of nanoscale materials, such as Carbon Nanotubes (CNTs) and Graphene, directly into the textile matrix or as part of a polymeric coating. These materials offer the advantage of inherent conductivity combined with extremely low weight and superior mechanical properties. While commercialization of high-performance graphene-based conductive fabrics is ongoing, this area promises revolutionary advancements in flexible electronics and self-powering textiles, driving future high-performance market growth and addressing the industry’s demand for flexible, next-generation materials.

In addition to coating techniques, the market leverages advancements in smart weaving and knitting technologies that strategically embed conductive yarns alongside traditional fibers during the textile formation process. This "hybrid integration" allows for precise circuit placement directly within the fabric structure, facilitating the production of truly washable and durable smart garments. Furthermore, research into flexible, non-toxic, and environmentally benign conductive polymers is crucial, aiming to replace heavy metal coatings in consumer goods. These inherently conductive polymers offer superior flexibility and better integration potential with soft electronics, pushing the boundaries of continuous health monitoring and human-machine interface textiles.

Regional Highlights

- Asia Pacific (APAC): APAC holds the largest market share due to its dominance in global electronics manufacturing, particularly in China, South Korea, and Taiwan. The region benefits from lower labor costs, robust infrastructure for high-volume production, and high domestic demand for consumer electronics and smart wearables. The region is also a major center for research and development in advanced textile technology and low-cost coating processes, driving rapid market growth and innovation adoption.

- North America: North America is a critical market characterized by early adoption of advanced technology and high-value applications, particularly in aerospace, defense (where high-performance, MIL-SPEC conductive fabrics are essential), and medical devices. Stringent regulatory environments regarding electromagnetic compatibility (EMC) necessitate high-quality EMI shielding solutions, leading to higher average selling prices and a focus on premium, durable silver and nickel/copper-coated fabrics.

- Europe: The European market is growing steadily, propelled by strong regulatory emphasis on environmental safety (REACH compliance) and worker protection (ESD apparel). Europe is a hub for high-end smart textile research, with significant activity in integrated e-textiles for fashion, sports, and advanced industrial protective clothing. Germany, the UK, and France are key contributors, focusing on materials with high sustainability profiles and superior aesthetic integration.

- Latin America (LATAM): This region is an emerging market for conductive fabrics, driven primarily by increasing investment in telecommunications infrastructure (5G rollout) and growing manufacturing capacity in automotive electronics. While currently smaller, the market offers significant potential as local manufacturing increases and domestic demand for shielded consumer devices rises, leading to higher reliance on imports or localized assembly of shielded components.

- Middle East and Africa (MEA): Growth in MEA is concentrated in sectors related to defense modernization and smart city initiatives, which require sophisticated telecommunication and security systems demanding effective EMI shielding. The adoption of smart protective clothing for oil and gas and industrial workers also contributes to demand, though overall market penetration remains lower compared to developed regions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Conductive Fabric Market.- Laird Performance Materials (DuPont)

- 3M Company

- Swift Textile Metalizing LLC

- Shieldex Trading Inc.

- Toray Industries Inc.

- Statex Produktions- und Vertriebs GmbH

- Soliani EMC S.r.l.

- Karonia Co. Ltd.

- Eeonyx Corporation

- Hitek Electronic Materials Ltd.

- Temas Engineering

- VTT Technical Research Centre of Finland Ltd.

- Holland Shielding Systems B.V.

- Seiren Co., Ltd.

- Bekaert NV

- Technical Absorbents Ltd.

- Zhejiang Jiashan Huasheng Textile Co., Ltd.

- DuPont de Nemours, Inc.

- Swicofil AG

- Ametek Inc.

Frequently Asked Questions

Analyze common user questions about the Conductive Fabric market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of conductive fabric in electronic devices?

The primary function of conductive fabric in electronic devices is Electromagnetic Interference (EMI) shielding. By forming a highly conductive enclosure or gasket, the fabric effectively attenuates external electromagnetic signals, protecting sensitive internal components from signal degradation and ensuring overall device stability, crucial in high-frequency environments like 5G devices.

Which material coating is most prevalent in high-performance conductive fabrics?

Silver coating is the most prevalent material for high-performance applications due to its exceptionally high electrical conductivity and excellent shielding effectiveness across a broad frequency range. While it is more expensive than nickel or copper, silver-coated fabrics are preferred in defense, medical sensing, and premium consumer electronics where performance is paramount.

How does the growth of smart wearables influence the conductive fabric market?

The proliferation of smart wearables significantly drives the conductive fabric market by creating demand for flexible, skin-contacting textiles that can function as electrodes, heating elements, or data transmission pathways. These fabrics must be comfortable, washable, and highly durable, pushing manufacturers toward advanced material integration, particularly knitted and woven conductive structures.

What are the main technical challenges facing conductive fabric manufacturers?

The primary technical challenges include ensuring the long-term durability and washability of the metallic coating without losing conductivity, preventing metal oxidation (especially copper and nickel), and maintaining the textile's physical comfort and breathability after the conductive treatment process. Developing sustainable and cost-effective high-performance coating methods is also a continuous hurdle.

Is Conductive Fabric used in the automotive industry, and if so, how?

Yes, conductive fabric is increasingly utilized in the automotive industry, primarily for cable and harness shielding to protect sophisticated sensor systems and infotainment electronics from vehicle electromagnetic noise. It is also explored for use in flexible heating elements and integrated pressure sensors within smart car seats and interior cabin structures to reduce overall vehicle weight.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager