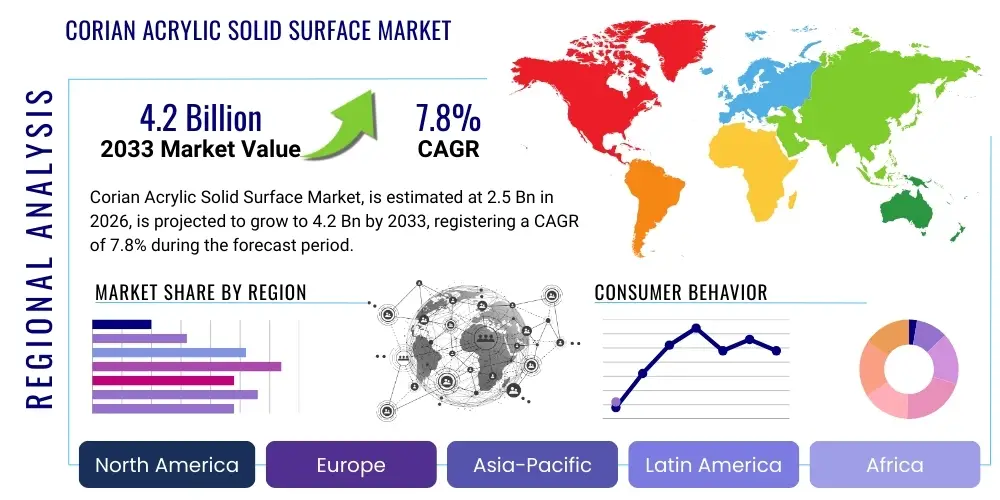

Corian Acrylic Solid Surface Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441992 | Date : Feb, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Corian Acrylic Solid Surface Market Size

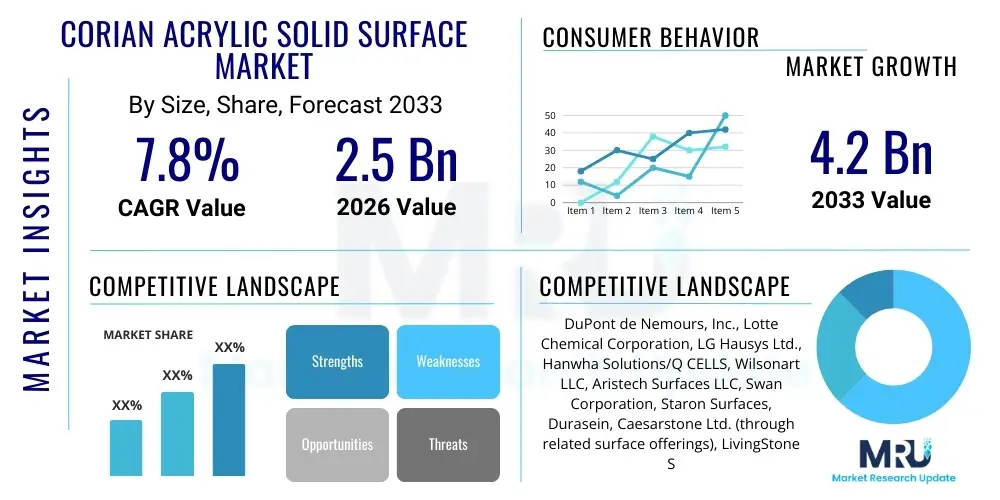

The Corian Acrylic Solid Surface Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. This robust growth trajectory is underpinned by increasing global demand for aesthetically pleasing, highly durable, and hygienic surface materials across commercial and residential sectors. The market expansion is particularly evident in high-growth construction markets in Asia Pacific and among sophisticated consumers in North America and Europe who prioritize specialized, non-porous materials for kitchen countertops, bathroom vanities, and specialized architectural applications. Furthermore, the rising awareness regarding antimicrobial properties and ease of maintenance in post-pandemic environments is driving the adoption of acrylic solid surfaces over traditional materials.

The market is estimated at USD 2.5 Billion in 2026 and is projected to reach USD 4.2 Billion by the end of the forecast period in 2033. This valuation reflects not only volume growth but also continuous advancements in material composition, leading to premium pricing for specialized products offering enhanced characteristics such as superior thermoformability, UV resistance, and integrated smart technology capabilities. Strategic investments by key manufacturers in expanding production capacity and diversifying color palettes and patterns are crucial factors influencing this upward financial trajectory.

Corian Acrylic Solid Surface Market introduction

The Corian Acrylic Solid Surface Market encompasses the global trade and utilization of synthetic surfacing materials primarily composed of acrylic resins, pigments, and mineral fillers, such as alumina trihydrate (ATH). Although Corian is a proprietary brand name established by DuPont, the term is often used generically to describe the broader category of acrylic solid surfaces known for their seamless appearance, excellent reparability, and non-porous nature. These attributes make them highly suitable for applications demanding superior hygiene and aesthetic integration, moving beyond traditional laminate or natural stone options.

Major applications of acrylic solid surfaces span critical sectors including residential construction, commercial interiors, healthcare facilities, hospitality venues, and specialized industrial environments. In residential settings, they are predominantly utilized for kitchen countertops, integrated sinks, bathroom vanities, and shower surrounds due to their mold and mildew resistance and seamless joints that prevent bacterial accumulation. Commercially, they are crucial for public-facing areas such as reception desks, transaction counters, retail display fixtures, and food service areas where durability and ease of cleaning are paramount operational requirements. The inherent flexibility of the material, allowing for thermoforming into complex three-dimensional shapes, further expands its architectural utility.

The primary driving factors fueling the market include the global increase in construction and renovation activities, particularly the modernization of healthcare infrastructure requiring high levels of sanitation. Furthermore, consumer preferences are shifting towards sustainable and low-maintenance interior finishes. The benefits of acrylic solid surfaces—such as longevity, color stability, non-toxicity, and the ability to be seamlessly repaired and renewed—position them favorably against competing materials, solidifying their status as a premium surfacing solution in modern architectural design and interior decoration globally.

Corian Acrylic Solid Surface Market Executive Summary

The global Corian Acrylic Solid Surface Market is characterized by robust growth, driven primarily by favorable business trends centered on urbanization and technological integration in construction practices. The market is consolidating around key manufacturers who are investing heavily in innovative composite formulations to enhance environmental sustainability and functional properties, such as advanced stain resistance and thermal stability. A significant business trend involves strategic partnerships between material suppliers and architectural design firms to integrate solid surfaces earlier into the project lifecycle, ensuring tailored material specifications meet evolving aesthetic and performance requirements across large-scale commercial and institutional projects. Furthermore, digital fabrication techniques, including CNC milling, are streamlining installation processes, reducing waste, and making customized designs more cost-effective, thus broadening market penetration.

Regionally, the Asia Pacific (APAC) stands out as the highest-growth segment, fueled by massive infrastructure development, increasing residential housing projects, and a rapidly expanding middle class with disposable income to invest in high-end interior finishes. North America and Europe remain mature, high-value markets characterized by a strong emphasis on premium product segments, green building standards, and the renovation sector. In these regions, stringent health and safety regulations, particularly in medical and food preparation environments, mandate the use of non-porous, easily sanitized materials, providing a continuous baseline demand for acrylic solid surfaces. The regional dynamic is also influenced by local manufacturing capabilities and the proximity of distribution networks to minimize logistical costs associated with bulky construction materials.

Segment trends indicate that the 100% pure acrylic surface segment is gaining prominence due to its superior thermoforming capabilities and UV stability, making it preferred for outdoor applications and complex interior designs, despite a higher price point compared to modified acrylics. In terms of application, the commercial sector, encompassing hospitals, hotels, and institutional settings, dominates the market share due to the large surface area requirements and the critical need for hygienic surfaces. However, the residential segment is showing the fastest expansion rate, largely attributed to increased remodeling activities and the growing desire among homeowners for durable, customized, and aesthetically unified kitchen and bathroom designs that acrylic solid surfaces uniquely facilitate. Material innovation focused on recycling content and low-VOC emissions is crucial for segment growth, appealing to environmentally conscious consumers and developers.

AI Impact Analysis on Corian Acrylic Solid Surface Market

Common user inquiries regarding the influence of Artificial Intelligence (AI) on the Corian Acrylic Solid Surface market center predominantly on three core areas: the automation of design and specification processes, the optimization of complex manufacturing and fabrication workflows, and enhancements in supply chain efficiency and predictive maintenance. Users are keenly interested in how AI tools, such as generative design algorithms, can rapidly produce aesthetically optimized layouts that integrate seamless solid surface elements, minimizing material waste and speeding up project timelines. Concerns often revolve around the initial investment required for sophisticated AI-driven fabrication machinery and the potential displacement of traditional artisan skills. The expectation is that AI will primarily drive precision in thermoforming and complex curve generation, improve color consistency through automated quality control, and utilize predictive modeling to forecast raw material demand and manage volatile commodity pricing, ultimately leading to lower fabrication costs and higher material throughput.

- AI-driven Generative Design: Utilizes algorithms to rapidly create complex, optimized solid surface designs for countertops, facades, and integrated sinks, reducing design cycle time and material waste.

- Automated Quality Control: Deploys computer vision systems to detect minute surface imperfections, color variations, and dimensional errors during the casting and finishing processes, ensuring superior product consistency.

- Predictive Maintenance: AI analyzes operational data from manufacturing equipment (mixers, curing ovens, CNC machines) to anticipate failures, maximizing machine uptime and reducing unexpected production stoppages.

- Supply Chain Optimization: Machine learning models forecast demand for key raw materials (ATH, acrylic resins) based on market signals, optimizing inventory levels and mitigating risks associated with supply chain volatility.

- Personalized Customer Experience: AI assists customers and designers in visualizing personalized color, pattern, and texture combinations in real-time virtual environments, enhancing specification accuracy.

- Energy Efficiency Optimization: AI algorithms monitor and adjust curing temperatures and energy consumption in large-scale manufacturing plants, driving down operational costs and enhancing sustainability.

DRO & Impact Forces Of Corian Acrylic Solid Surface Market

The market dynamics of the Corian Acrylic Solid Surface sector are governed by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively constitute the critical Impact Forces shaping market trajectory. The primary driver is the accelerating global trend toward hygienic and non-porous surfaces, particularly in commercial and healthcare construction, catalyzed by global health crises which raised standards for sanitation. Complementary drivers include the superior aesthetic versatility and design flexibility offered by acrylics, such as their seamless jointing capability and thermoformability, which are highly valued by architects and interior designers aiming for bespoke, unified interior concepts. This is coupled with the general resilience of the renovation and remodeling sector, which continues to drive demand for durable and modern surfacing solutions.

Conversely, the market faces significant restraints. The high raw material cost, specifically for 100% pure polymethyl methacrylate (PMMA) resins and high-grade alumina trihydrate (ATH), contributes to a higher final product price point compared to mass-market alternatives like laminates or certain natural stones. Furthermore, the intense competition posed by next-generation engineered materials, particularly quartz surfaces, which often offer superior scratch and heat resistance, acts as a substantial restraint. Market perception regarding the susceptibility of acrylics to scratching and heat damage, despite ongoing material improvements, necessitates targeted marketing and user education to mitigate this restraint effectively.

Opportunities for expansion are primarily vested in geographical expansion into emerging economies with rapidly developing construction industries, such as Southeast Asia and parts of Africa, where market penetration is currently lower. Product innovation presents another crucial opportunity, focusing on developing solid surfaces with enhanced functionalities, such as integrated antimicrobial additives, self-cleaning coatings, or surfaces capable of incorporating wireless charging technology. Furthermore, leveraging the circular economy through improved recycling programs for solid surface offcuts and end-of-life products offers a path to attract environmentally conscious developers and secure long-term market sustainability. These DRO factors manifest as powerful impact forces, compelling manufacturers to focus on cost efficiency, material science innovation, and aggressive market education to maintain competitive advantage against alternative surfacing materials.

Segmentation Analysis

The Corian Acrylic Solid Surface market is extensively segmented based on material composition (type), application sector, and distribution channel, providing a granular view of demand patterns and competitive positioning. The segmentation by material type, differentiating between 100% Pure Acrylic and Modified Acrylic (often blended with polyester resins), is critical as it dictates the material’s performance characteristics, cost, and thermoformability limits. Analyzing these segments helps stakeholders tailor their product offerings to specific end-user requirements, such as selecting pure acrylic for complex, curved architectural features or modified acrylics for more cost-sensitive, flat surface applications. The dominance of the commercial application segment underscores the high volume demand generated by large-scale projects like hospitals and airports, contrasting sharply with the fragmented but high-growth residential remodeling market.

Segmentation by end-user application—covering residential, commercial, industrial, and institutional sectors—reveals that commercial environments prioritize durability, hygiene, and low maintenance, while the residential sector focuses heavily on aesthetic appeal, customization, and longevity. The commercial segment’s reliance on seamless integration for hygiene protocols makes acrylic solid surfaces an indispensable choice. Geographic segmentation is equally vital, highlighting the mature consumption patterns in North America and Europe versus the high-velocity expansion in Asia Pacific, necessitating regionally specific marketing and supply chain strategies tailored to local building codes and economic dynamics. These segments define market opportunities and risks, providing a framework for strategic resource allocation.

- By Type:

- 100% Pure Acrylic

- Modified Acrylic

- By Application:

- Residential (Kitchen Countertops, Bathroom Vanities, Integrated Sinks)

- Commercial (Hospitals and Healthcare Facilities, Hospitality and Hotels, Retail and Public Spaces, Office Interiors)

- Industrial and Institutional (Laboratories, Educational Institutions)

- By End-Use Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, U.K., France, Italy, Spain)

- Asia Pacific (China, India, Japan, South Korea)

- Latin America (Brazil, Argentina)

- Middle East & Africa (MEA)

Value Chain Analysis For Corian Acrylic Solid Surface Market

The value chain for the Corian Acrylic Solid Surface market begins with the upstream processes focused on the meticulous procurement and processing of key raw materials. The two primary components are acrylic resins, specifically high-purity polymethyl methacrylate (PMMA) or blends for modified surfaces, and the mineral filler, which is predominantly alumina trihydrate (ATH). Upstream activities involve highly specialized chemical processing to ensure resin consistency and the refining of bauxite ore to produce the required grade of ATH. Cost fluctuations in petrochemical feedstock directly influence the cost of acrylic resins, making raw material sourcing a critical point of value creation and vulnerability. Strategic relationships with chemical suppliers are essential for manufacturers to maintain competitive pricing and ensure the consistent quality required for high-performance surfaces.

The midstream segment of the value chain is dominated by manufacturing processes, where the raw materials are combined using casting or continuous sheet extrusion methods. This involves precise mixing, pouring, curing, sanding, and finishing. Value is added through technological advancements in manufacturing, such as continuous casting techniques that minimize internal stress and enhance sheet consistency, alongside sophisticated color blending and pattern injection processes. Quality control at this stage is crucial, as defects such as porosity or inconsistent coloring can significantly devalue the final product. Downstream activities involve global and regional distribution, specialized fabrication, and final installation. Manufacturers typically rely on certified fabricators who possess the necessary expertise and equipment (e.g., CNC machines, thermoforming ovens) to handle, cut, and seamlessly join the material according to architectural specifications, adding immense value through customized design execution.

Distribution channels are multifaceted, utilizing both direct and indirect routes. Direct sales are often reserved for large commercial projects or institutional clients where technical support and customized orders are necessary. However, the majority of the product moves through indirect channels, including specialized material distributors, wholesalers targeting the construction industry, and retail outlets that cater to residential homeowners and small-to-mid-sized contractors. Partnerships with professional installer networks and certified fabricators are essential for maintaining quality control and brand reputation, as the final appearance and performance of the solid surface material heavily depend on expert installation. The effectiveness of the value chain hinges on seamless integration and communication between manufacturers and certified fabricators, ensuring efficient delivery of complex, custom solutions to the end-user.

Corian Acrylic Solid Surface Market Potential Customers

The primary consumers and end-users of Corian Acrylic Solid Surfaces are diverse, encompassing professional specifiers, institutional buyers, and high-end residential clients who prioritize durability, hygiene, and aesthetic flexibility. Architects and interior designers constitute a cornerstone of the potential customer base, as they actively specify materials for commercial and residential projects based on performance criteria, design vision, and compliance with building codes. These professionals are drawn to the material's seamless appearance and thermoforming capabilities, allowing for innovative, curved designs that cannot be achieved with stone or laminate, making them high-value decision-makers in the procurement process. Specialized industry consultants, particularly those focused on healthcare and hospitality design, are also key influencers due to their mandates for non-porous and easily sanitized surfaces.

Institutional buyers represent large-volume potential customers, notably facility managers and procurement officers in hospitals, universities, and airports. For healthcare environments, the non-porous nature of acrylic solid surfaces minimizes microbial growth and simplifies stringent cleaning protocols, driving consistent demand for materials used in operating theaters, patient rooms, and laboratories. Similarly, the hospitality sector, including luxury hotels and cruise lines, utilizes these surfaces extensively for high-traffic areas such as bars, reception desks, and bathrooms, valuing their renewability and resistance to wear and tear. These institutional customers often seek long-term relationships with suppliers that can guarantee consistent material supply and specialized technical support for large, complex installations.

In the residential sector, the prime potential customers are affluent homeowners undertaking major kitchen or bathroom remodeling projects, often working through general contractors or specialized remodeling firms. These buyers seek premium, customized solutions that elevate the home's value and aesthetic appeal. DIY enthusiasts or smaller contractors also constitute a segment, particularly utilizing modified acrylic products for budget-conscious projects. Targeting these residential customers requires extensive retail presence, compelling showroom displays, and detailed consumer education regarding the material’s benefits over competing countertop materials. Ultimately, the market caters to anyone needing a durable, seamless, and hygienic surface solution where design integrity and low maintenance are paramount purchasing factors.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.5 Billion |

| Market Forecast in 2033 | USD 4.2 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | DuPont de Nemours, Inc., Lotte Chemical Corporation, LG Hausys Ltd., Hanwha Solutions/Q CELLS, Wilsonart LLC, Aristech Surfaces LLC, Swan Corporation, Staron Surfaces, Durasein, Caesarstone Ltd. (through related surface offerings), LivingStone Solid Surface, GIMAT Solid Surfaces, Lion Chemtech Co., Ltd., Axia Materials, Formica Group, Megapoxy, Mystera Solid Surface, CHR Solid Surface, Avonite Surfaces, and Greenlam Industries Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Corian Acrylic Solid Surface Market Key Technology Landscape

The technology landscape governing the Corian Acrylic Solid Surface market is primarily focused on enhancing material performance, simplifying complex fabrication, and improving manufacturing sustainability. One of the most critical technologies is Thermoforming, which allows the solid sheets to be heated and molded into seamless, curved, or complex architectural shapes that are impossible with most traditional surfacing materials. Continuous innovation in thermoforming techniques, including vacuum forming and pressure forming, allows fabricators to achieve tighter radii and more intricate geometries, significantly expanding the creative scope for designers. Complementary to this is advanced CNC (Computer Numerical Control) machining, which ensures high-precision cutting, inlay work, and edge profiling, reducing manual labor and improving consistency across large projects.

Another significant technological focus lies in material science, specifically the development of improved composite formulations. This includes research into optimizing the ratio and type of mineral fillers (ATH) and acrylic resins (PMMA) to enhance critical properties like scratch resistance, thermal stability, and UV resistance, making the material suitable for more demanding applications, including exterior cladding. Furthermore, manufacturers are increasingly incorporating Digital Printing Technology directly onto or beneath the solid surface sheet during curing. This allows for the creation of intricate, high-resolution patterns, textures, and graphic images that are permanently sealed within the material, offering unprecedented customization options that mimic natural stone or wood grains without compromising the non-porous properties of the acrylic surface.

Sustainability is also a major technological driver. Manufacturers are adopting advanced processes to reduce volatile organic compound (VOC) emissions during casting and curing, aligning with increasingly stringent environmental regulations, particularly in Europe and North America. Efforts are also underway to increase the proportion of recycled content, both post-industrial and post-consumer waste, incorporated into new solid surface formulations without sacrificing performance attributes. Technologies related to integrated functionalities are emerging, such as embedding translucent materials for backlighting effects, or integrating wireless charging coils beneath the surface, transforming the material from a passive cover into an interactive element, thereby securing its relevance in future smart interior designs and competitive market positioning.

Regional Highlights

The global demand for Corian Acrylic Solid Surfaces is geographically diverse, with distinct growth patterns and market characteristics across major regions, necessitating tailored strategies for market penetration and supply chain management.

- Asia Pacific (APAC): Represents the fastest-growing market globally, driven by massive urbanization, infrastructure investment, and rising disposable incomes in economies like China, India, and Southeast Asian nations. The region is seeing rapid adoption of acrylic surfaces in large-scale commercial real estate, high-end residential complexes, and a dramatic expansion of healthcare facilities demanding hygienic interior solutions.

- North America: A mature, high-value market characterized by robust demand in both the residential renovation sector and specialized commercial applications (healthcare, retail). Focus remains strongly on premium, 100% acrylic products, sustainable formulations, and design-led specifications. Strict building codes related to fire safety and hygiene also underpin stable demand.

- Europe: Exhibits steady, incremental growth, heavily influenced by green building standards (e.g., LEED, BREEAM) and stringent environmental regulations (e.g., REACH). Western European countries like Germany and the UK lead in adopting sustainable, low-VOC acrylic surfaces, while strong aesthetic traditions drive demand for unique, custom-fabricated designs across the hospitality and institutional segments.

- Latin America (LATAM): An emerging market showing potential, primarily concentrated in major urban centers like São Paulo and Mexico City. Growth is linked to foreign investment in commercial infrastructure and a nascent trend toward modernization in residential interiors, though adoption rates are often constrained by economic volatility and higher import costs.

- Middle East and Africa (MEA): Growth is tied to large government-backed infrastructure projects, particularly in the GCC states (UAE, Saudi Arabia) focused on tourism, hospitality, and luxury residential developments. The demand here is centered around premium products that can withstand high temperatures and offer aesthetic opulence for grand interiors and hotel lobbies.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Corian Acrylic Solid Surface Market.- DuPont de Nemours, Inc.

- Lotte Chemical Corporation

- LG Hausys Ltd. (now part of LG Hausys Holdings)

- Hanwha Solutions/Q CELLS (Hanwha Advanced Materials)

- Wilsonart LLC

- Aristech Surfaces LLC

- Swan Corporation

- Staron Surfaces

- Durasein

- Caesarstone Ltd. (maintains related product portfolios)

- LivingStone Solid Surface

- GIMAT Solid Surfaces

- Lion Chemtech Co., Ltd.

- Axia Materials

- Formica Group

- Megapoxy

- Mystera Solid Surface

- CHR Solid Surface

- Avonite Surfaces

- Greenlam Industries Ltd.

Frequently Asked Questions

Analyze common user questions about the Corian Acrylic Solid Surface market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between 100% pure acrylic and modified acrylic solid surfaces?

The primary difference lies in the resin composition and performance characteristics. 100% pure acrylic surfaces use high-grade PMMA resin, offering superior thermoformability, better UV resistance (making them suitable for some outdoor applications), and greater longevity, though they are generally higher priced. Modified acrylic surfaces blend PMMA with polyester resins, which reduces the cost and slightly lowers the thermoforming capability and UV stability, making them suitable for flat, indoor, cost-sensitive applications.

How do acrylic solid surfaces contribute to hygienic environments, particularly in healthcare settings?

Acrylic solid surfaces are inherently non-porous, meaning they do not absorb liquids, moisture, or support the growth of mold, mildew, or bacteria. Crucially, they can be fabricated with seamless joints, eliminating crevices where pathogens might accumulate, a feature highly valued in hospitals, laboratories, and food preparation areas where strict sanitation is mandatory.

Is the Corian Acrylic Solid Surface Market growing faster than natural stone or quartz surfacing markets?

While quartz has experienced rapid growth due to its superior scratch and heat resistance, the acrylic solid surface market maintains competitive growth, largely driven by its unique attributes: renewability, seamless fabrication, and extreme design flexibility (thermoforming). Acrylic's growth is particularly strong in institutional and complex architectural projects where these specialized features outweigh the minor material trade-offs compared to stone-based composites.

What are the key sustainability trends impacting the manufacturing of acrylic solid surfaces?

Key sustainability trends involve reducing VOC emissions during manufacturing, increasing the incorporation of recycled content (both post-industrial and post-consumer waste) into new sheets, and improving the material's end-of-life recyclability. Manufacturers are increasingly prioritizing low-carbon footprint production methods and transparency in material sourcing to align with global green building certification standards.

Which geographical region holds the highest growth potential for acrylic solid surfaces through 2033?

The Asia Pacific (APAC) region is projected to exhibit the highest growth potential through 2033. This forecast is underpinned by rapid urbanization, substantial government investment in infrastructure and healthcare facilities, and a growing middle class that is increasingly adopting premium, imported, or domestically manufactured modern surfacing materials for both residential and commercial projects.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager