Coriolis mass flow meters Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443216 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Coriolis mass flow meters Market Size

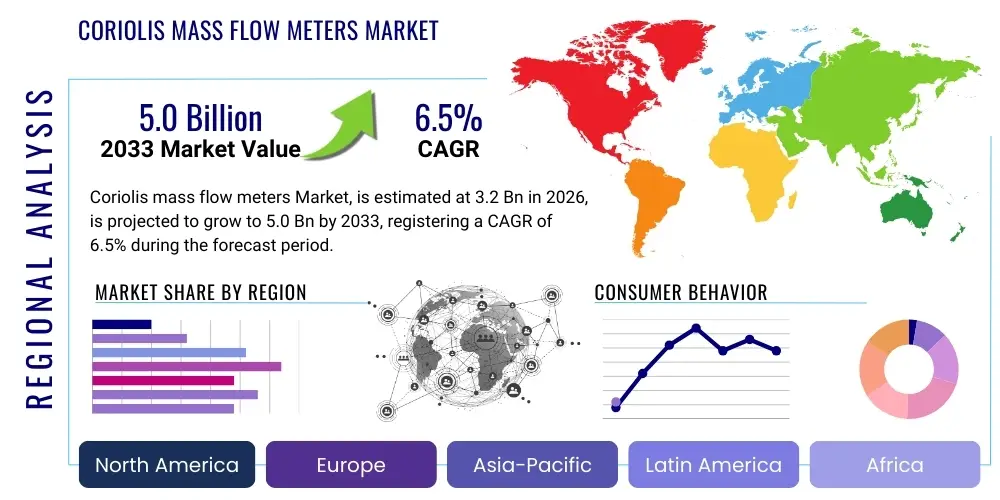

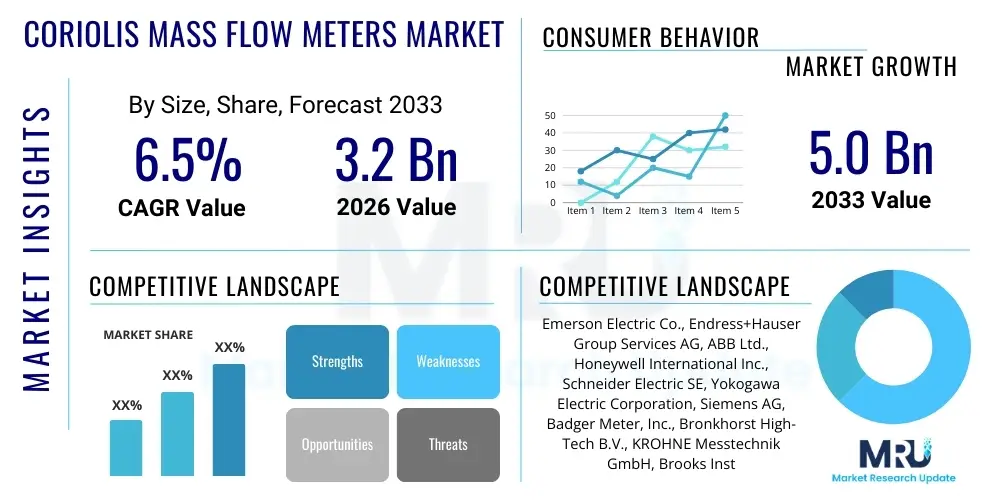

The Coriolis mass flow meters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 3.2 Billion in 2026 and is projected to reach USD 5.0 Billion by the end of the forecast period in 2033.

Coriolis mass flow meters Market introduction

Coriolis mass flow meters represent a sophisticated class of flow measurement devices distinguished by their ability to measure mass flow rate directly, independent of changes in fluid density, temperature, pressure, or viscosity. Utilizing the Coriolis effect—the inertial forces generated when a mass moves radially in a rotating frame of reference—these meters vibrate a tube containing the flowing fluid, detecting the resulting phase shift caused by the fluid's inertia. This fundamental principle allows for unparalleled accuracy and reliability, especially in applications requiring precise measurement of complex or multi-phase fluids, positioning them as essential tools across critical industrial processes where volumetric measurement is insufficient or subject to significant error.

The core advantage of Coriolis technology lies in its high accuracy and capability for multi-variable measurement, often providing readings for mass flow, density, temperature, and volume flow simultaneously. This versatility makes them invaluable in stringent regulatory environments, such as custody transfer applications in the oil and gas sector, where minute measurement errors can result in substantial financial losses. Furthermore, the robust design and lack of internal moving parts contribute to minimal maintenance requirements and a longer operational lifespan compared to traditional flow measurement technologies. Their superior performance characteristics have driven substantial adoption across industries struggling with highly corrosive, abrasive, or non-homogeneous media.

Major applications driving the demand for Coriolis mass flow meters span pivotal industrial sectors, including chemical processing, petrochemical refining, pharmaceutical manufacturing, and the food and beverage industry. In chemical plants, these meters ensure precise mixing and batch control, optimizing reaction yields and product consistency. In the food and beverage sector, they are crucial for monitoring ingredients like syrups, fats, and highly viscous dairy products, maintaining strict quality control and regulatory compliance. The persistent global drive toward process optimization, energy efficiency, and stringent environmental monitoring mandates continued technological advancements and market expansion for Coriolis flow measurement systems.

Coriolis mass flow meters Market Executive Summary

The Coriolis mass flow meters market is characterized by robust growth, primarily fueled by the accelerating requirement for high-precision measurement in critical process industries and the stringent regulatory frameworks governing custody transfer operations globally. Key business trends indicate a strong move toward advanced digital integration, where Coriolis meters are increasingly incorporated into Industrial Internet of Things (IIoT) ecosystems, providing real-time diagnostic data and predictive maintenance capabilities. This integration enhances operational uptime and minimizes costs associated with unscheduled downtime, thereby solidifying the return on investment despite the higher initial capital expenditure associated with this technology. Furthermore, manufacturers are focusing on developing specialized meters capable of handling extreme temperatures and pressures, catering specifically to demanding upstream oil and gas operations and high-temperature chemical reactions.

Regionally, the Asia Pacific (APAC) market is anticipated to exhibit the fastest growth trajectory, driven by rapid industrialization, large-scale infrastructure projects, and significant investments in chemical and pharmaceutical manufacturing, particularly in countries like China and India. North America and Europe, while mature markets, continue to hold substantial market share, buoyed by the strict adherence to environmental regulations and the continuous modernization of existing industrial infrastructure, particularly within the petrochemical and natural gas sectors. The adoption rate in emerging economies is accelerating as quality standards improve and industries transition away from less accurate volumetric measurement methods, recognizing the long-term operational advantages offered by mass flow technology.

Segment-wise, the market sees dominant demand from the Oil and Gas sector due to the critical nature of hydrocarbon measurement, including fiscal metering and pipeline monitoring. However, the Pharmaceuticals and Food & Beverage segments are demonstrating significant expansion, reflecting increased global demand for consumer safety and product quality assurance, which mandates highly accurate ingredient dosing and batch control. Technological segmentation highlights the prominence of bent-tube designs, though straight-tube meters are gaining traction in hygienic and sanitary applications dueving to their easier cleanability and reduced pressure drop. The overall trend points toward consolidation among leading players focusing on expanding their service offerings and software solutions to complement the core hardware sales, ensuring comprehensive process management for end-users.

AI Impact Analysis on Coriolis mass flow meters Market

Common user questions regarding AI's influence on Coriolis mass flow meters often center on how these advanced analytical capabilities can further enhance measurement accuracy, facilitate predictive maintenance, and integrate flow data into broader operational intelligence systems. Users are keenly interested in determining if AI can compensate for external disturbances or aging effects on the meters, potentially extending calibration cycles and reducing operational expenses. Furthermore, there is significant inquiry into using machine learning algorithms to identify subtle anomalies in flow patterns that might indicate developing process problems long before conventional alarms are triggered, moving process control from reactive to truly proactive management. The central theme revolves around leveraging AI to maximize the value derived from the high-fidelity data generated by Coriolis meters.

The integration of Artificial Intelligence (AI) and Machine Learning (ML) algorithms is poised to revolutionize the operational landscape of Coriolis mass flow meters, transitioning them from passive measurement tools to active components in smart industrial infrastructure. AI algorithms can analyze vast historical and real-time flow, density, and temperature data generated by the meters to build predictive models regarding meter health, calibration drift, and process efficiency. For instance, ML can detect subtle patterns in vibration frequencies or density readings that signal the early onset of tube erosion or fouling, allowing maintenance teams to intervene precisely when required, thereby optimizing asset utilization and minimizing catastrophic failures.

Beyond asset management, AI significantly enhances measurement confidence and process optimization. By analyzing correlated variables, AI can dynamically correct minor measurement biases caused by non-ideal installation environments or slight variations in fluid properties not explicitly factored into the meter’s base calibration curve. This level of autonomous self-correction pushes the boundaries of real-world accuracy, making Coriolis meters even more reliable for highly sensitive applications like high-value batch control or complex blending processes. Moreover, AI-driven digital twins, utilizing high-accuracy Coriolis data, allow operators to simulate operational changes, test new recipes, and optimize system throughput virtually before implementing changes in the physical plant, drastically reducing risk and time-to-market.

- Enhanced Predictive Maintenance: AI analyzes sensor data (e.g., vibration, diagnostics) to predict meter failure or calibration drift, maximizing uptime.

- Automated Calibration Verification: ML models cross-validate flow data against process parameters, flagging potential inaccuracies without manual intervention.

- Anomaly Detection: Algorithms identify subtle, non-linear deviations in flow patterns, detecting early signs of leaks, cavitation, or component wear.

- Process Optimization: AI integrates Coriolis data into overall process models to optimize blending ratios, reaction times, and energy consumption dynamically.

- Digital Twin Integration: High-fidelity Coriolis data feeds into digital twin models for accurate simulation and virtual commissioning of process changes.

- Improved Signal Processing: AI techniques filter out noise and interference, further increasing the signal-to-noise ratio and measurement stability.

DRO & Impact Forces Of Coriolis mass flow meters Market

The market for Coriolis mass flow meters is influenced by a powerful combination of drivers stemming from industrial demands for high precision and technological superiority, offset by significant restraints primarily related to cost and complexity, yet mitigated by substantial opportunities arising from global regulatory changes and digital transformation. This dynamic interplay defines the competitive landscape and adoption patterns across diverse industrial segments. The principal driver remains the inherent capability of these meters to provide direct mass flow measurement, which is critical for custody transfer and stoichiometry in chemical reactions, offering a distinct and essential advantage over traditional volumetric flow technologies that require density compensation.

Key drivers include the rigorous global regulatory environment, particularly concerning safety, emissions, and fiscal metering in the oil and gas and chemical sectors, which necessitate the exceptional accuracy Coriolis meters deliver. Furthermore, the increasing global consumption of high-value specialty chemicals, pharmaceutical products, and complex food ingredients requires highly accurate batch control, pushing manufacturers toward advanced mass flow solutions. Restraints primarily involve the high initial procurement and installation costs compared to simpler flow meters (like magnetic or vortex meters), which can be prohibitive for smaller operations or non-critical applications. Additionally, the complex physics and advanced electronics involved in calibration and maintenance sometimes demand specialized technical expertise, presenting a barrier to entry in regions with underdeveloped technical labor pools.

Opportunities for market expansion are significant, particularly centered on the integration of smart features, including IIoT connectivity, wireless capabilities, and advanced onboard diagnostics, enhancing the value proposition and operational efficiency. The increasing global focus on renewable energy, particularly biofuel production and carbon capture technologies, presents new, complex fluid measurement challenges ideally suited for Coriolis technology. The primary impact force shaping the market is technological obsolescence risk avoidance; industries increasingly recognize that investing in high-accuracy, future-proof Coriolis technology minimizes risks associated with inaccurate measurements and regulatory non-compliance, thereby justifying the higher capital outlay over the operational lifetime of the plant.

- Drivers: Demand for high-accuracy measurement in custody transfer; Stringent regulatory requirements across processing industries; Versatility in handling multi-phase and viscous fluids; Increased focus on process efficiency and inventory control.

- Restraints: High initial investment cost and complexity of installation; Susceptibility to external vibration or pipeline noise in certain environments; Requirement for specialized technical knowledge for maintenance and calibration.

- Opportunities: Integration with IIoT and Industry 4.0 platforms; Expansion into hygienic and sanitary applications (Food & Pharma); Growth in alternative energy sectors (e.g., LNG, Hydrogen, Biofuels); Development of smaller, lower-cost sensors for niche applications.

- Impact Forces: Technological Advancements in Sensor Design (High); Regulatory Scrutiny on Fiscal Metering (High); Price Sensitivity in Non-Critical Applications (Medium); Competition from Alternative Flow Technologies (Medium-Low).

Segmentation Analysis

The Coriolis mass flow meters market is comprehensively segmented based on various technical, application, and geographical parameters, reflecting the diverse industrial requirements and operational scales. Understanding these segments is crucial for strategic planning, as distinct end-user industries prioritize different flow meter specifications, such as tube design, material composition, and communication protocol capabilities. The market is primarily analyzed based on the type of medium measured (liquid or gas), the tube design utilized (bent tube or straight tube), the material of construction (stainless steel, Hastelloy, or titanium), and the end-user industry application (Oil & Gas, Chemicals, Water & Wastewater, etc.).

The dominant application segment remains Oil and Gas, driven by mandatory custody transfer regulations and the need for accurate measurement of crude oil, refined products, and natural gas, often under harsh environmental conditions. However, the fastest growth is anticipated in segments prioritizing sanitary design, such as Pharmaceuticals and Food & Beverage, where straight-tube meters are preferred due to their easy draining and cleaning characteristics, minimizing contamination risk. Material segmentation is dictated by the chemical compatibility with the fluid being measured; while stainless steel is standard for general industrial use, specialized alloys like Hastelloy and Titanium are necessary for highly corrosive media prevalent in chemical manufacturing.

Furthermore, segmentation by sensor type or connectivity highlights the shift towards digital field devices. Flow meters equipped with advanced communication standards (like HART, Foundation Fieldbus, or PROFINET) and built-in diagnostic capabilities are experiencing increased demand as industries globally adopt digitalization initiatives. This enables seamless integration into Distributed Control Systems (DCS) and SCADA systems, facilitating remote monitoring and enhanced operational control, thereby justifying the higher cost of advanced units compared to legacy analog output meters.

- By Medium Measured:

- Liquid Flow Meters

- Gas Flow Meters (Gas-Phase & LNG)

- By Design Type:

- Bent Tube Coriolis Meters

- Straight Tube Coriolis Meters

- By Application:

- Custody Transfer/Fiscal Metering

- Process Control and Monitoring

- Batch Control and Blending

- By End-User Industry:

- Oil and Gas (Upstream, Midstream, Downstream)

- Chemical and Petrochemical

- Pharmaceutical and Biotechnology

- Food and Beverage

- Water and Wastewater Treatment

- Power Generation and Utilities

- By Material:

- Stainless Steel

- High-Performance Alloys (e.g., Hastelloy, Titanium)

Value Chain Analysis For Coriolis mass flow meters Market

The value chain for the Coriolis mass flow meters market is intricate, beginning with the highly specialized sourcing of materials and concluding with complex installation and post-sales servicing, necessitating close collaboration across various specialized entities. The upstream segment is characterized by the procurement of high-grade, often corrosion-resistant, exotic materials such as high-nickel alloys (e.g., Hastelloy C) and specialized stainless steels (e.g., 316L, Duplex), which are critical for constructing the measurement tubes that withstand high pressures, temperatures, and aggressive chemicals. Manufacturing requires highly precise machining and welding techniques to form the sensitive tubes and coils, ensuring structural integrity and measurement accuracy, representing a significant technological bottleneck and barrier to entry for new competitors.

The midstream phase involves the core manufacturing process, which includes the assembly of the sensing elements, electronics, and housing, followed by rigorous calibration processes. Calibration is a critical and expensive step, often requiring dedicated primary standard facilities (water and gas flow rigs) to certify the meters' accuracy against traceable standards, which underscores the high investment required in R&D and quality control. Distribution channels are varied but often rely on specialized third-party distributors or integrators who possess the necessary application knowledge to match the meter specifications precisely to the end-user’s operational requirements. Direct sales models are typically employed for large, strategic accounts in the Oil & Gas sector, ensuring direct access to technical support and custom engineering.

Downstream activities focus heavily on installation, commissioning, and aftermarket services. Due to the high value and precision of Coriolis meters, proper installation—including minimizing pipeline stress and ensuring adequate flow conditioning—is paramount to achieving specified accuracy. Post-sales support, including periodic recalibration, diagnostics, and repairs, forms a significant revenue stream and competitive differentiator. Companies that offer comprehensive, geographically dispersed service networks and remote diagnostic tools are better positioned to capture and retain high-value customer segments, particularly in industries where operational downtime is extremely costly. The prevalence of indirect channels, specifically system integrators, is high, as they embed Coriolis meters within larger automation and control packages for complex plant deployments.

Coriolis mass flow meters Market Potential Customers

The primary consumers, or end-users, of Coriolis mass flow meters are organizations operating process-intensive facilities that handle high-value materials, dangerous substances, or products requiring stringent quality control and high measurement precision. These customers recognize that the elevated accuracy and reliability offered by Coriolis technology significantly mitigate operational risks, reduce material losses, and ensure regulatory compliance, far outweighing the initial capital expense. Key buyers reside within the core heavy industries globally, necessitating reliable, multi-variable measurements for optimizing complex chemical reactions, hydrocarbon processing, and critical utility management.

Within the Oil and Gas sector, potential customers include major national and international oil companies, pipeline operators, storage terminal management firms, and refineries. Their procurement decisions are heavily influenced by the need for certified custody transfer accuracy (often dictated by standards like API and OIML) and the robust performance required in harsh environments, such as offshore platforms or remote pipeline stations. Furthermore, the midstream segment focusing on Liquefied Natural Gas (LNG) transport and storage represents a high-growth customer base due to the complex temperature and density variations inherent in LNG processing, which Coriolis meters handle effectively.

Another crucial customer segment is the Pharmaceutical and Biotechnology industry, including large pharmaceutical manufacturers and contract manufacturing organizations (CMOs). These buyers use Coriolis meters extensively for highly accurate dosing of active pharmaceutical ingredients (APIs), solvent mixing, fermentation processes, and ensuring product sterility. Their purchasing decisions prioritize sanitary design, compliance with cGMP (current Good Manufacturing Practices), and traceability. Similarly, high-volume food and beverage manufacturers, particularly those dealing with viscous or high-solid content liquids (like chocolate, dairy cream, and syrups), constitute a robust customer base, leveraging the meter’s ability to measure mass directly, unaffected by air entrapment or changes in viscosity.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.2 Billion |

| Market Forecast in 2033 | USD 5.0 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Emerson Electric Co., Endress+Hauser Group Services AG, ABB Ltd., Honeywell International Inc., Schneider Electric SE, Yokogawa Electric Corporation, Siemens AG, Badger Meter, Inc., Bronkhorst High-Tech B.V., KROHNE Messtechnik GmbH, Brooks Instrument (ITW), Clark-Reliance Corporation, Alicat Scientific, Inc., SICK AG, Thermo Fisher Scientific Inc., Baker Hughes Company, General Electric (GE), FCI Fluid Components International, Vögtlin Instruments GmbH, Faure Herman. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Coriolis mass flow meters Market Key Technology Landscape

The technological landscape of Coriolis mass flow meters is dominated by continuous advancements in sensor design, digital signal processing, and material science, all aimed at enhancing accuracy, reducing susceptibility to external disturbances, and broadening application scope. Current technology utilizes sophisticated drive and pick-off coil mechanisms to sustain and measure the tube's resonant frequency and phase shift with extreme precision. Recent innovations include the development of multi-variable measurement capabilities where a single meter can simultaneously deliver highly accurate readings for mass flow, density, temperature, and derived variables like concentration or volume flow, streamlining process instrumentation and reducing installation complexity. This convergence of sensing capabilities into a single device provides considerable economic and operational benefits to end-users.

A critical area of technological focus is the optimization of tube geometry and materials to minimize pressure drop and improve cleanability, especially vital for sanitary applications. Straight-tube designs, for instance, are leveraging advanced titanium or Hastelloy tubing coupled with highly sensitive sensor arrays to provide high accuracy in hygienic processes where bent tubes could pose cleaning challenges. Furthermore, the electronics and software embedded within these meters are undergoing rapid transformation. Modern Coriolis meters feature powerful digital signal processors (DSPs) capable of filtering out process noise, compensating for external pipe vibration, and conducting self-diagnostics in real time, dramatically improving measurement stability and confidence under varying field conditions. This processing power enables advanced features like built-in batch control and concentration measurement without external computing.

Connectivity and integration form the third pillar of the current technology landscape. Virtually all new high-end Coriolis meters are equipped with comprehensive digital communication protocols, including Ethernet/IP, Modbus TCP, PROFINET, and HART, facilitating seamless integration into Industry 4.0 environments. The meters are designed to serve as smart field devices, storing calibration histories, diagnostic reports, and configuration parameters, supporting remote access, monitoring, and firmware updates. This technological evolution ensures that Coriolis meters are not just instruments for measuring flow but integral components of a plant’s digital backbone, enabling data-driven decision-making and enhancing overall operational visibility, thereby maintaining their premium position in the flow measurement ecosystem against competing technologies like ultrasonic or differential pressure meters.

Regional Highlights

- North America: A technologically mature market, North America is dominated by high regulatory standards, particularly within the oil and gas (custody transfer and shale exploration) and chemical industries. Growth is driven by the replacement of older infrastructure and the rapid adoption of IIoT-enabled smart metering solutions. The U.S. remains the largest consumer, valuing high-accuracy fiscal metering and regulatory compliance above cost considerations.

- Europe: Europe maintains a strong market position, characterized by stringent environmental regulations and significant investments in pharmaceutical and specialty chemical manufacturing, particularly in Germany and the UK. The emphasis here is on precision, energy efficiency, and adherence to complex EU-wide standards (e.g., MID for fiscal metering).

- Asia Pacific (APAC): The fastest-growing region globally, fueled by massive industrial expansion, urbanization, and government initiatives promoting advanced manufacturing in China, India, and Southeast Asia. The demand is escalating in the petrochemical, water treatment, and food processing sectors as quality control standards improve and industries scale up production capacity.

- Latin America: Growth is primarily driven by large-scale upstream and midstream oil and gas projects in countries like Brazil and Mexico, requiring accurate measurement for resource exploitation and export. Market adoption is tempered slightly by economic volatility but shows strong potential in high-value mining and refining operations.

- Middle East and Africa (MEA): This region is a vital market due to its concentration of major hydrocarbon production and export facilities. Demand is almost exclusively concentrated in the oil and gas sector, with meters required for high-volume, critical custody transfer points and loading/unloading terminals. Investment is sensitive to global oil price fluctuations but remains strong for mission-critical applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Coriolis mass flow meters Market.- Emerson Electric Co.

- Endress+Hauser Group Services AG

- ABB Ltd.

- Honeywell International Inc.

- Schneider Electric SE

- Yokogawa Electric Corporation

- Siemens AG

- Badger Meter, Inc.

- Bronkhorst High-Tech B.V.

- KROHNE Messtechnik GmbH

- Brooks Instrument (ITW)

- Clark-Reliance Corporation

- Alicat Scientific, Inc.

- SICK AG

- Thermo Fisher Scientific Inc.

- Baker Hughes Company

- General Electric (GE)

- FCI Fluid Components International

- Vögtlin Instruments GmbH

- Faure Herman

Frequently Asked Questions

Analyze common user questions about the Coriolis mass flow meters market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of a Coriolis mass flow meter over volumetric flow meters?

Coriolis meters measure mass flow rate directly, which is independent of fluid properties like density, temperature, pressure, and viscosity changes. Volumetric meters require separate measurements and compensation for these variables, making the Coriolis meter inherently more accurate and reliable, particularly in custody transfer and batch control applications.

In which industrial applications are straight-tube Coriolis meters preferred over bent-tube designs?

Straight-tube Coriolis meters are primarily preferred in sanitary, hygienic, and abrasive fluid applications, such as in the Food & Beverage and Pharmaceutical industries. Their design minimizes pressure drop and allows for easier cleaning (CIP/SIP capabilities) and complete draining, thus reducing contamination risks and preventing material buildup.

How does the integration of IIoT impact the operational lifespan and maintenance of Coriolis mass flow meters?

IIoT integration, facilitated by advanced digital communication and diagnostics, enables real-time remote monitoring and predictive maintenance. This allows operators to identify subtle deviations indicating meter health issues, schedule maintenance precisely, extend calibration cycles, and significantly reduce unscheduled downtime, thereby maximizing the meter's operational lifespan and efficiency.

What are the key financial considerations when adopting Coriolis mass flow technology?

While Coriolis meters have a high initial capital expenditure (CAPEX) compared to traditional flow technologies, the long-term financial benefits include reduced product loss, minimized maintenance costs due to lack of moving parts, superior accuracy for fiscal metering, and lower total cost of ownership (TCO) over the asset lifecycle, especially in high-value fluid applications.

Are Coriolis flow meters suitable for measuring multi-phase fluids, such as fluids containing entrained gas?

Modern Coriolis meters are highly capable of handling complex multi-phase fluids, including liquids with entrained gas or suspended solids, provided the gas void fraction (GVF) remains below certain tolerance limits (typically less than 5%). They excel by accurately measuring the density and mass flow rate, providing crucial process insights even under non-ideal flow conditions where other technologies fail.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager