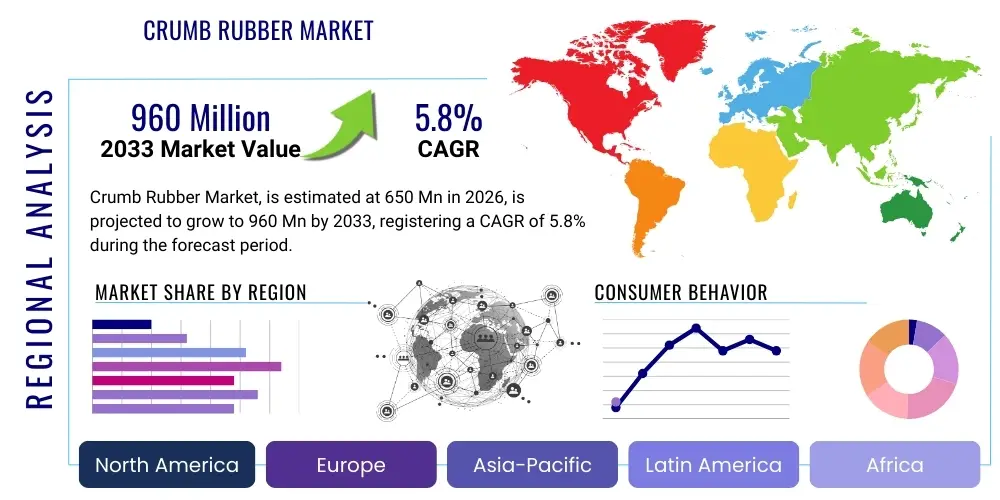

Crumb Rubber Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442135 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Crumb Rubber Market Size

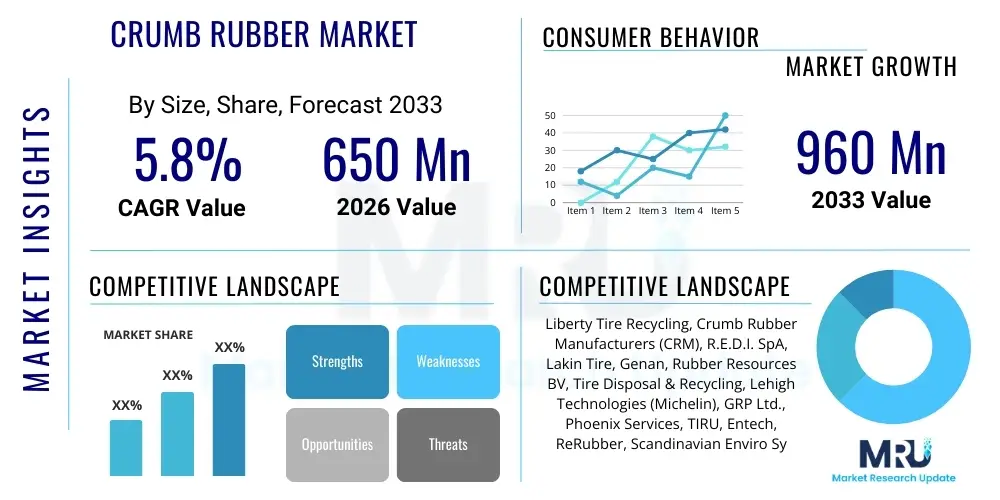

The Crumb Rubber Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 650 Million in 2026 and is projected to reach USD 960 Million by the end of the forecast period in 2033. This growth trajectory is fundamentally supported by increasing global emphasis on sustainable resource management, particularly the robust regulatory frameworks governing end-of-life tire (ELT) disposal, compelling industries across construction and automotive sectors to adopt recycled rubber materials.

Crumb Rubber Market introduction

The Crumb Rubber Market encompasses the production and utilization of fine-particle rubber granules derived primarily from recycled scrap tires, known as End-of-Life Tires (ELTs). Crumb rubber is manufactured through mechanical processes such as ambient grinding, cryogenic grinding, or wet grinding, which reduce whole tires into small particles, separating the rubber from steel and fabric components. This material serves as a highly sustainable, cost-effective, and versatile raw material, crucial for promoting the circular economy within the rubber and infrastructure industries. Key specifications such as particle size (mesh size) dictate its suitability for diverse applications, ranging from fine powders used in compounding to larger granules utilized in civil engineering projects.

Major applications of crumb rubber span across several critical sectors, including civil engineering, automotive manufacturing, and sports surfacing. In infrastructure, Crumb Rubber Modified (CRM) asphalt significantly enhances road longevity, reduces cracking, and minimizes traffic noise, making it a preferred material for sustainable road construction projects globally. Furthermore, it is extensively used in molded products, such as mats, speed bumps, and railway crossing pads, owing to its superior durability and resilience. The versatility of crumb rubber extends to its application as infill material for artificial turf fields, providing shock absorption and stabilizing the synthetic grass fibers, thus improving athletic performance and safety standards.

The market expansion is largely driven by a combination of stringent environmental regulations and the inherent benefits of the product itself. Governments worldwide are implementing stricter mandates regarding landfill bans for ELTs, forcing tire manufacturers and waste management companies to prioritize recycling solutions. Crumb rubber offers significant benefits, including reducing reliance on virgin rubber, lowering material costs for manufacturers, and providing excellent physical properties such as enhanced resistance to abrasion, ozone, and weathering. These factors, coupled with increasing consumer and corporate demand for sustainable construction materials, are the primary propellers of market growth throughout the forecast period.

Crumb Rubber Market Executive Summary

The global Crumb Rubber Market is experiencing robust expansion, fundamentally driven by the escalating pressure for sustainable waste management solutions and accelerated infrastructure development across emerging economies. Key business trends indicate a strong move toward advanced processing technologies, such as improved devulcanization methods, which enhance the quality and versatility of crumb rubber, enabling its adoption in higher-value applications like premium automotive parts and specialized rubber products. Strategic partnerships between tire recycling organizations, chemical manufacturers, and asphalt producers are becoming crucial for optimizing supply chain efficiency and ensuring consistent quality material availability, thereby transforming what was once a waste product into a valuable industrial commodity.

Regional trends reveal Asia Pacific (APAC) as the dominant and fastest-growing region, primarily fueled by massive infrastructural investments in countries like China, India, and Japan, coupled with rapidly increasing vehicle fleets that generate substantial volumes of ELTs. North America and Europe demonstrate mature markets characterized by established regulatory frameworks and high technological adoption rates, particularly in using Crumb Rubber Modified (CRM) asphalt for road networks and specialized applications in athletic surfacing. Emerging economies in Latin America and the Middle East & Africa (MEA) are also showing promising growth, albeit starting from a smaller base, driven by urbanization and the implementation of initial tire recycling infrastructure projects designed to meet sustainable development goals.

In terms of segment trends, the utilization of crumb rubber in the infrastructure sector, particularly road construction (CRM asphalt), remains the largest and fastest-growing application segment due to governmental prioritization of durable and environmentally friendly roadways. Furthermore, the market for fine mesh crumb rubber (powder) is expected to exhibit above-average growth, spurred by its increasing incorporation into new tire manufacturing as a partial substitute for virgin rubber and its use in high-performance polymer modification. The market structure continues to favor large-scale recyclers that can manage the complex logistics of ELT collection and possess the capital for advanced processing machinery, ensuring product consistency necessary for industrial use.

AI Impact Analysis on Crumb Rubber Market

User queries regarding AI’s influence on the Crumb Rubber Market frequently revolve around maximizing feedstock utilization, optimizing energy consumption during processing (especially cryogenic grinding), and ensuring the quality consistency of the final crumb rubber product, which is critical for downstream applications like asphalt modification. Users are keenly interested in how Artificial Intelligence can streamline the complex logistics of ELT collection and sorting, identifying different rubber types automatically to improve yield and purity. Furthermore, a significant area of user concern and expectation is the application of AI-driven predictive maintenance systems to minimize downtime in high-wear mechanical grinding operations and the use of machine learning algorithms to accurately model and predict the optimal mixing ratios of crumb rubber in modified asphalt concrete mixtures, thereby guaranteeing performance standards and reducing material waste.

- AI-driven optimization of End-of-Life Tire (ELT) collection logistics, predicting supply fluctuations and managing optimal routing for lower carbon footprints.

- Machine learning algorithms enhance quality control through computer vision systems, rapidly classifying rubber feedstock by tire type and removing contaminants (steel, fiber) before processing.

- Predictive maintenance analytics are deployed on grinding and shredding machinery, minimizing operational downtime and extending the lifespan of high-capital equipment in recycling plants.

- AI models optimize energy usage in energy-intensive processes like cryogenic grinding by dynamically adjusting cooling rates and particle size parameters based on real-time data input.

- Integration of AI in pavement management systems to model the long-term performance and optimal concentration of Crumb Rubber Modified (CRM) asphalt mixtures under varying climatic conditions.

- Enhanced market forecasting and pricing models for recycled rubber commodities, based on real-time scrap tire availability and virgin rubber price volatility.

DRO & Impact Forces Of Crumb Rubber Market

The Crumb Rubber Market is fundamentally driven by a confluence of regulatory push and technological pull factors, creating significant market momentum. A primary driver is the widespread implementation of strict environmental legislation globally, particularly in Europe, North America, and major parts of Asia, which prohibits the landfilling or uncontrolled dumping of End-of-Life Tires (ELTs). This regulatory pressure mandates recycling and recovery, effectively creating a guaranteed feedstock supply for crumb rubber production. Simultaneously, the growing demand for sustainable infrastructure development, particularly road construction using Crumb Rubber Modified (CRM) asphalt, acts as a powerful demand-side driver, as it offers superior road performance, reduced maintenance costs, and a strong environmental narrative.

However, the market faces notable restraints that temper its growth potential. Chief among these is the volatile cost associated with the collection and processing of ELTs, particularly the high energy consumption of mechanical grinding, which can erode profit margins, especially when coupled with fluctuating steel and fuel prices. Furthermore, the perceived inconsistency in quality, particularly regarding mesh size purity and the presence of textile or steel remnants, often creates reluctance among high-specification manufacturers, hindering broader adoption in specialized rubber compounding applications. Overcoming these logistical and quality control challenges requires significant capital investment in advanced processing technologies, which remains a barrier for smaller market participants.

Opportunities for exponential market growth lie in continuous technological advancements, particularly in devulcanization techniques (e.g., microwave or chemical methods) that restore the chemical properties of recycled rubber closer to virgin material. This technological breakthrough opens up new, high-value avenues for crumb rubber utilization, allowing its re-incorporation into high-performance products, including new tires and complex automotive components. Additionally, the increasing global focus on green building certifications and circular economy procurement policies presents a significant opportunity for expanding crumb rubber use in molded products, specialized construction materials, and railway applications, ensuring the market’s transition from merely a waste management solution to a key component of sustainable industrial supply chains. These dynamics result in potent impact forces characterized by environmental mandates driving supply and infrastructure needs driving sustained, high-volume demand.

Segmentation Analysis

The Crumb Rubber Market is meticulously segmented based on production process, mesh size, and end-use application, reflecting the varied requirements of industrial buyers across different sectors. Understanding these segments is critical for manufacturers to tailor product specifications—such as cryogenic vs. ambient ground rubber—to specific functional needs, ensuring optimal performance in applications ranging from finely tuned polymer blends to large-scale civil engineering projects. The segmentation highlights the market's versatility and its critical role in diverting substantial volumes of waste materials into productive, high-performance commercial outputs, addressing both sustainability goals and functional material requirements simultaneously.

- By Type/Process:

- Ambient Grinding Crumb Rubber

- Cryogenic Grinding Crumb Rubber

- Wet Grinding Crumb Rubber

- By Mesh Size:

- Less than 30 Mesh

- 30 to 50 Mesh

- 50 to 80 Mesh

- Greater than 80 Mesh (Crumb Rubber Powder)

- By Application:

- Crumb Rubber Modified (CRM) Asphalt and Roadways

- Sports Surfaces (Artificial Turf Infill, Running Tracks, Playgrounds)

- Molded and Extruded Products (Mats, Tiles, Railway Crossings)

- Automotive Parts (Tire Manufacturing, Gaskets, Bumpers)

- Construction and Building Materials (Waterproofing, Sealants)

- By End-User Industry:

- Infrastructure and Construction

- Automotive and Transportation

- Sports and Recreation

- Manufacturing and Compounding

Value Chain Analysis For Crumb Rubber Market

The value chain for the Crumb Rubber Market begins significantly upstream with the critical phase of End-of-Life Tire (ELT) collection and logistics. This phase involves extensive networks of scrap tire collectors, processors, and recycling centers responsible for sorting, separating, and transporting discarded tires. Effective upstream management is paramount, as inconsistencies in feedstock quality or unreliable supply streams directly impact the efficiency and cost structure of the downstream processing facilities. Due to the bulkiness and dispersed nature of ELTs, efficient transportation and aggregation represent substantial operational costs and logistical complexities that must be managed effectively to maintain competitive pricing for the final crumb rubber product.

The core processing stage involves transforming whole tires into crumb rubber, utilizing specialized machinery for shredding, granulating, and refining (including magnetic separation for steel wire removal and air classification for fiber separation). This manufacturing step is capital-intensive, requiring high-precision equipment, particularly for producing fine mesh crumb rubber via cryogenic methods. The distribution channel subsequently moves the processed material to various industrial consumers. Distribution is predominantly indirect, utilizing bulk shipping and specialized industrial distributors who handle large volumes of aggregated material. Direct sales often occur between major crumb rubber manufacturers and large-scale industrial buyers, such as national asphalt paving contractors or multinational tire compounding companies, particularly for customized or high-specification grades.

Downstream analysis focuses heavily on the integration of crumb rubber into high-volume end applications. For instance, in the infrastructure sector, crumb rubber is utilized by asphalt blending plants to produce Crumb Rubber Modified (CRM) asphalt, which then flows to civil engineering contractors. In the manufacturing sector, it is sold to rubber compounders and molders who incorporate it into final products such as floor mats, playground tiles, or automotive gaskets. The efficiency of the downstream segment is highly dependent on standardization and certification; consistent mesh size, purity, and availability are crucial for encouraging broader industrial adoption and ensuring product performance in demanding applications like road construction and new tire manufacturing processes.

Crumb Rubber Market Potential Customers

The primary customers for crumb rubber are large industrial entities heavily involved in infrastructure development, construction, and high-volume manufacturing. Government agencies and municipal bodies, acting through their contracted paving and civil engineering firms, represent a massive segment, particularly those focused on sustainable development and requiring high-performance roadways. These buyers seek large volumes of medium mesh crumb rubber suitable for asphalt modification, valuing consistency, price stability, and documented environmental compliance. Secondary buyers include athletic facility developers and municipal recreation departments, which require granular crumb rubber for infill in synthetic turf systems and safety surfacing in playgrounds, prioritizing impact attenuation and material safety certifications.

Another significant customer base resides in the rubber compounding and general manufacturing industries. These customers use finer mesh crumb rubber powder as a functional filler or reinforcing agent in new rubber products. This includes original equipment manufacturers (OEMs) in the automotive sector that incorporate recycled content into non-critical components like floor mats, mud flaps, and acoustic barriers, driven by corporate sustainability mandates and cost reduction strategies. The purchasing criteria for this segment are stringent purity levels, extremely fine mesh sizes (80 mesh or finer), and guaranteed consistency to ensure compatibility with high-speed mixing and molding processes without compromising the final product's integrity.

Furthermore, specialized construction and building material companies constitute a growing market segment, utilizing crumb rubber in products requiring excellent durability, sound dampening, or waterproofing characteristics. This includes manufacturers of roofing membranes, sealants, railway vibration dampeners, and specialized industrial flooring. These buyers often purchase customized blends or larger Tire-Derived Aggregate (TDA) materials, emphasizing the rubber's inherent resistance to weathering, ozone, and chemical degradation. Ultimately, the purchasing decisions across all segments are converging toward lifecycle cost reduction and verifiable sustainability metrics provided by the crumb rubber supplier.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650 Million |

| Market Forecast in 2033 | USD 960 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Liberty Tire Recycling, Crumb Rubber Manufacturers (CRM), R.E.D.I. SpA, Lakin Tire, Genan, Rubber Resources BV, Tire Disposal & Recycling, Lehigh Technologies (Michelin), GRP Ltd., Phoenix Services, TIRU, Entech, ReRubber, Scandinavian Enviro Systems AB, Ecore International, Resource Tire, Kirkby Tyres Ltd, Tyromer Inc., Rubbermaid Commercial Products, Delta-P RVS. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Crumb Rubber Market Key Technology Landscape

The technological landscape of the Crumb Rubber Market is defined by the core processes used to efficiently break down and refine End-of-Life Tires (ELTs) into high-quality particulate material. Ambient grinding, which uses specialized shredders and granulators at normal temperatures, is the most common and cost-effective method, producing rougher, higher-mesh-size crumb rubber suitable for large-scale applications like Tire-Derived Aggregate (TDA) or basic infill. Conversely, cryogenic grinding involves freezing the tires using liquid nitrogen, making the rubber brittle, and then shattering it into extremely fine powder. While more expensive due to the energy demands of cooling, this method yields superior, ultra-fine mesh rubber (often 80 mesh and smaller) critical for inclusion in new rubber compounding and high-specification polymer modification, offering properties closest to virgin material.

A significant area of innovation is devulcanization technology, which aims to break the sulfur cross-links in the vulcanized rubber structure without significantly degrading the polymer chains. Current methods include thermochemical, microwave, and mechanical devulcanization. Successful devulcanization allows the crumb rubber to be chemically reactive, enabling its substantial incorporation into new tire compounds or specialized elastomers, thereby maximizing its value and closing the loop entirely on tire recycling. The development of commercially viable, large-scale devulcanization processes represents a transformative opportunity, potentially overcoming the primary limitation of crumb rubber—its inability to be completely re-processed like a thermoplastic.

Beyond the core processing, the integration of advanced separation and quality assurance technologies is crucial. High-efficiency magnetic separators and sophisticated air classification systems are continuously improved to eliminate minute impurities (steel fragments and textile fibers) that compromise the integrity of downstream products, especially in rubber modified asphalt where contaminants can cause premature failure. Furthermore, blending and mixing technologies used in the downstream segment, such as specialized mixers for wet-process CRM asphalt, are vital for ensuring homogeneous dispersion of the rubber particles into the hot asphalt binder, a process requiring precise temperature and shear rate control to achieve the desired visco-elastic performance enhancements in the final road pavement.

Regional Highlights

Regional dynamics are critical drivers of the Crumb Rubber Market, highly correlated with vehicular density, regulatory stringency, and infrastructure spending patterns. Asia Pacific (APAC) dominates the global market, not only in terms of production capacity but also in consumption volume. This dominance is attributed to the unprecedented growth in vehicle fleets across countries like China, India, and Southeast Asia, leading to massive generation of ELTs. Simultaneously, vast government expenditures on new roads, highways, and residential infrastructure in these rapidly urbanizing economies provide a continuous and escalating demand for Crumb Rubber Modified (CRM) asphalt and construction materials. Regulatory shifts favoring recycling over landfilling, though often recent, are rapidly institutionalizing the circular economy for tires.

North America and Europe represent mature markets characterized by stringent, long-standing environmental regulations that have largely eliminated landfilling of whole tires, ensuring a stable and predictable supply of feedstock. In North America, the focus is heavily on high-specification road construction (wet-process and dry-process CRM), while Europe leads in the adoption of crumb rubber for high-quality sports surfaces, including FIFA-certified artificial turf infill and specialized playground safety tiles. Technological innovation, particularly in devulcanization and fine mesh production (cryogenic grinding), is concentrated in these regions, driven by higher labor costs and the need for premium, specialized rubber compounds for automotive and industrial manufacturing.

Latin America (LATAM) and the Middle East and Africa (MEA) are emerging as significant, high-growth markets. In LATAM, countries like Brazil and Mexico are witnessing significant regulatory enforcement on tire disposal, leading to rapid investment in local recycling infrastructure. The demand here is primarily driven by urban development projects and the need for durable materials to withstand varied climates. The MEA region, particularly the GCC countries, is seeing an influx of infrastructure mega-projects, coupled with efforts to diversify waste management practices away from traditional disposal methods. Although market penetration is currently lower than in developed regions, the rapid pace of development and the need for resilient construction materials signal strong long-term growth potential for crumb rubber in these areas.

- Asia Pacific (APAC): Market leader driven by infrastructure boom and high ELT generation from massive automotive markets in China and India; focuses on large-scale CRM asphalt projects.

- North America: Mature market with strong regulatory support; high adoption of CRM asphalt and focus on technological innovation in high-purity, fine mesh crumb rubber.

- Europe: Emphasizes recycling consistency and high environmental standards; significant demand for crumb rubber in sports surfacing, noise reduction barriers, and specialized industrial moldings.

- Latin America (LATAM): Rapidly developing recycling infrastructure spurred by regulatory enforcement; growth centered around urban and transportation infrastructure development in key economies like Brazil.

- Middle East & Africa (MEA): Emerging market driven by substantial investment in infrastructure mega-projects (e.g., in Saudi Arabia, UAE) and the strategic imperative for sustainable waste diversion solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Crumb Rubber Market, encompassing major recyclers, specialized processors, and integrated solution providers.- Liberty Tire Recycling

- Crumb Rubber Manufacturers (CRM)

- Genan

- R.E.D.I. SpA

- Lakin Tire

- Lehigh Technologies (Michelin)

- Rubber Resources BV

- GRP Ltd.

- Tire Disposal & Recycling

- Phoenix Services

- TIRU

- Entech

- ReRubber

- Scandinavian Enviro Systems AB

- Ecore International

- Resource Tire

- Kirkby Tyres Ltd

- Tyromer Inc.

- Delta-P RVS

- Weathershield Recycling

Frequently Asked Questions

Analyze common user questions about the Crumb Rubber market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Crumb Rubber and what are its primary sources?

Crumb rubber is recycled rubber material derived primarily from End-of-Life Tires (ELTs). It is manufactured by grinding or shredding scrap tires to remove steel and fiber, resulting in granular or powdered rubber. This process diverts millions of tires from landfills annually, supporting the circular economy.

How is Crumb Rubber Modified (CRM) asphalt superior to traditional asphalt?

CRM asphalt offers enhanced durability, increased resistance to rutting and fatigue cracking, and improved performance across extreme temperatures. The addition of crumb rubber also significantly reduces traffic noise and increases the overall lifespan of road pavement, reducing long-term maintenance costs for infrastructure.

What are the main technical challenges facing the broader adoption of crumb rubber?

Key technical challenges include ensuring high purity levels (minimal textile or steel contamination) and maintaining consistent particle size (mesh size), which is crucial for high-specification applications. Furthermore, the limited chemical compatibility of vulcanized crumb rubber with new polymers remains a hurdle, though devulcanization technologies are aiming to resolve this.

Which processing method yields the highest quality crumb rubber powder?

Cryogenic grinding, which utilizes extreme cold (typically liquid nitrogen) to embrittle the rubber, yields the highest quality, ultra-fine crumb rubber powder (often 80 mesh and finer). This method produces cleaner, more uniformly shaped particles preferred for high-value applications like rubber compounding and automotive part manufacturing.

What is the regulatory outlook driving the Crumb Rubber Market growth?

The market is strongly driven by governmental regulations imposing stringent bans on landfilling whole tires and mandates promoting sustainable construction materials. Extended Producer Responsibility (EPR) schemes, which hold tire manufacturers accountable for end-of-life management, are a major catalyst for reliable feedstock supply and market expansion.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Polymer Modified Bitumen Market Size Report By Type (SBS Modified Bitumen, Plastomer Modified Bitumen, Crumb Rubber Modified Bitumen, Others), By Application (Road Construction and Paving, Roofing, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Modified Bitumen Market Statistics 2025 Analysis By Application (Road Construction & Paving, Roofing), By Type (SBS Modified Bitumen, Plastomer Modified Bitumen, Crumb Rubber Modified Bitumen), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Polymer Modified Bitumen Market Statistics 2025 Analysis By Application (Road Construction and Paving, Roofing), By Type (SBS Modified Bitumen, Plastomer Modified Bitumen, Crumb Rubber Modified Bitumen), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Recycled Tire Crumb Rubber Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (6-14 Mesh, 10-30 Mesh, 30-50 Mesh, 50-80 Mesh, 80-200 Mesh), By Application (Synthetic Turf, Playground Surfacing, Rubber Modified Asphalt, Molded Products, Rubber and Plastics, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager