Cryogenic PPE Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440865 | Date : Feb, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Cryogenic PPE Market Size

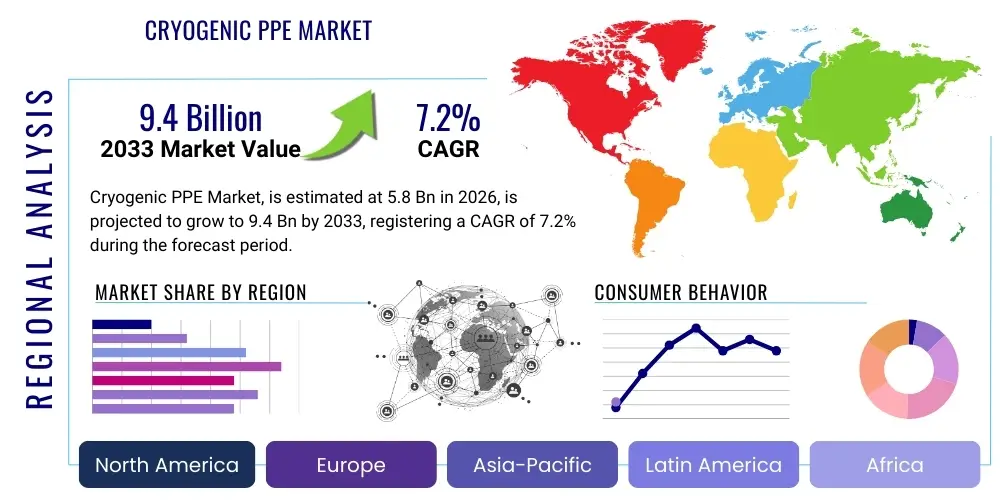

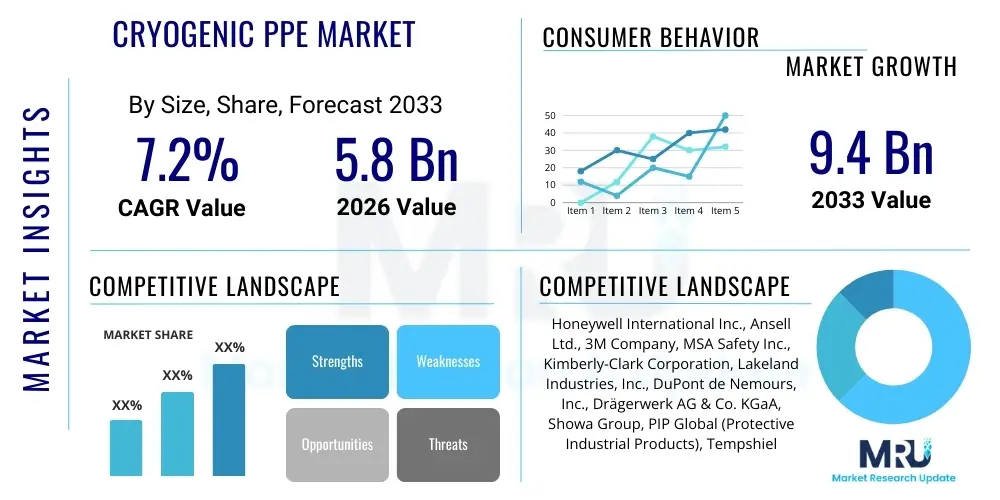

The Cryogenic PPE Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2026 and 2033. The market is estimated at USD 5.8 Billion in 2026 and is projected to reach USD 9.4 Billion by the end of the forecast period in 2033.

Cryogenic PPE Market introduction

The Cryogenic Personal Protective Equipment (PPE) Market encompasses a specialized range of safety gear designed to protect individuals working with extremely low temperatures, typically below -150°C (-238°F), associated with cryogenic liquids and gases such as liquid nitrogen, liquid oxygen, and helium. These critical applications span various industries where direct contact or proximity to cryogens poses severe risks, including frostbite, cold burns, and tissue damage. The demand for robust and reliable cryogenic PPE is intrinsically linked to the expanding use of cryogenics in scientific research, industrial processes, and advanced medical procedures, necessitating stringent safety protocols and specialized protective solutions.

Products within this market include insulated gloves, aprons, face shields, safety glasses, boots, and full body suits, all engineered with advanced multi-layer materials to provide superior thermal insulation and protection against splashes and contact with cryogenic fluids. These materials often incorporate waterproof yet breathable fabrics, composite fibers, and specialized linings to ensure both safety and a reasonable degree of comfort for the wearer. Major applications for cryogenic PPE are diverse, ranging from the safe handling and storage of biological samples in healthcare and biotechnology, such as in IVF clinics and biobanks, to the industrial processing and transportation of liquefied natural gas (LNG), industrial gases, and various chemicals. Additionally, sectors like aerospace, electronics manufacturing, and advanced materials research heavily rely on these protective measures to safeguard personnel against the extreme conditions encountered in their operations.

The primary benefits of utilizing cryogenic PPE include preventing severe cold injuries, ensuring compliance with evolving occupational safety standards, and significantly mitigating operational risks in cryogenics-intensive environments. The market's growth is predominantly driven by increasing awareness of workplace safety, the proliferation of cryogenic technologies across new industrial and medical applications, and the continuous innovation in material science leading to more effective and comfortable protective gear. Furthermore, the expansion of global LNG infrastructure, the burgeoning biotechnology and pharmaceutical sectors, and the escalating demand for cryopreservation techniques are key factors propelling market expansion, underscoring the indispensable role of cryogenic PPE in safeguarding human health and operational integrity.

Cryogenic PPE Market Executive Summary

The Cryogenic PPE Market is experiencing robust expansion, propelled by stringent global safety regulations and the escalating adoption of cryogenic technologies across diverse industries. Key business trends indicate a strong focus on advanced material innovation, with manufacturers investing heavily in developing lighter, more flexible, and highly insulated protective gear that offers enhanced dexterity and comfort without compromising safety. There is a noticeable shift towards integrated PPE solutions that combine multiple protective elements into a single garment, streamlining safety protocols and improving user acceptance. Furthermore, strategic partnerships between PPE manufacturers and technology providers are becoming more common, aiming to embed smart functionalities like temperature monitoring and connectivity into cryogenic protective wear, catering to the evolving demands for real-time safety management and predictive maintenance in hazardous environments.

Regional trends reveal significant growth opportunities, particularly in emerging economies within Asia Pacific and Latin America, driven by rapid industrialization, increasing investments in LNG infrastructure, and expanding healthcare sectors. North America and Europe, while mature markets, continue to lead in technological advancements and adoption of premium, high-performance cryogenic PPE, supported by stringent regulatory frameworks and a strong emphasis on worker safety. The Middle East and Africa region is also demonstrating promising growth, primarily fueled by massive oil and gas projects requiring extensive cryogenic operations. These regional dynamics highlight a globally expanding market with localized drivers, emphasizing the need for tailored product offerings and distribution strategies to effectively penetrate diverse geographical landscapes and address specific industrial requirements.

Segmentation trends indicate that insulated gloves and aprons consistently dominate the market due to their direct interface with cryogenic materials and high wear-and-tear rates, necessitating frequent replacement and upgrades. However, the demand for full body suits and specialized footwear is also rising, especially in applications requiring prolonged exposure or full-body protection against splashes and spills. In terms of application, the healthcare and biotechnology sector remains a significant consumer, driven by extensive use of cryopreservation techniques for biological samples and pharmaceuticals, alongside the burgeoning market for cell and gene therapies. The oil and gas sector, particularly the LNG segment, presents another substantial growth avenue, fueled by increasing global energy demands and the expansion of liquefaction and regasification terminals. Material advancements, such as the increasing use of composite fibers and multi-layer laminates, are also shaping segment growth, offering superior protection and durability.

AI Impact Analysis on Cryogenic PPE Market

Common user questions regarding AI's impact on the Cryogenic PPE Market often revolve around how artificial intelligence can enhance safety, improve material design, and optimize manufacturing processes. Users are keen to understand if AI can predict equipment failures, personalize PPE for better fit and comfort, or streamline supply chains for specialized cryogenic gear. There's also curiosity about AI's role in training and remote monitoring of personnel in cryogenic environments. The overarching themes suggest an expectation that AI will bring unprecedented levels of precision, predictive capability, and efficiency to a market historically reliant on static material properties and manual safety protocols, ultimately leading to safer and more cost-effective solutions for extreme cold protection.

- AI-driven predictive maintenance can analyze usage patterns and environmental data from embedded sensors in smart PPE to forecast wear and tear, indicating when specific components or entire garments require replacement, thereby preventing potential safety failures before they occur.

- Generative design algorithms, powered by AI, can rapidly explore novel material compositions and garment structures, optimizing for properties like thermal insulation, flexibility, breathability, and durability, leading to the development of next-generation cryogenic PPE with superior performance characteristics.

- AI-enhanced manufacturing processes, including robotics and automation, can improve the precision and consistency of multi-layer fabric assembly and stitching, reducing human error and waste, which is particularly critical for the complex construction of cryogenic protective garments.

- Intelligent inventory management systems leveraging AI can optimize the stocking and distribution of specialized cryogenic PPE, ensuring that the right sizes and types of equipment are available exactly when and where they are needed, minimizing stockouts and operational delays in critical applications.

- AI can facilitate advanced training simulations and virtual reality environments for personnel working with cryogens, providing immersive and realistic scenarios for practicing safe handling procedures and emergency responses, thereby improving preparedness without actual risk.

- Real-time monitoring systems integrated with AI can track worker physiological data (e.g., body temperature) and environmental conditions, issuing immediate alerts for potential cold stress or exposure risks, enabling proactive interventions and significantly enhancing worker safety in hazardous cryogenic zones.

- Natural Language Processing (NLP) can analyze vast amounts of incident reports, safety guidelines, and material specifications to identify recurring risks, suggest improvements in PPE design, and refine safety protocols, leading to data-driven decision-making for enhanced protection.

DRO & Impact Forces Of Cryogenic PPE Market

The Cryogenic PPE Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities that collectively shape its growth trajectory and competitive landscape. A primary driver is the global increase in industrial safety regulations and standards, particularly from bodies like OSHA and EN, which mandate the use of specialized protective equipment in environments involving extreme cold. This regulatory push forces industries to adopt compliant solutions, ensuring worker safety and avoiding hefty penalties. Furthermore, the burgeoning demand for liquefied natural gas (LNG) globally, driven by energy transition efforts and geopolitical factors, necessitates extensive cryogenic operations in production, transportation, and regasification, directly fueling the demand for high-performance cryogenic PPE. The expansion of the biotechnology and healthcare sectors, with their reliance on cryopreservation for biological samples, cell therapies, and pharmaceuticals, also serves as a substantial driver, creating a consistent need for advanced protective gear.

Despite robust growth drivers, the market faces several notable restraints that could temper its expansion. High initial investment costs associated with advanced cryogenic PPE, which often utilizes specialized, multi-layer, and high-performance materials, can be a significant barrier for small and medium-sized enterprises (SMEs) or organizations with limited budgets. Moreover, a lack of widespread awareness regarding the specific risks associated with cryogenic exposure and the benefits of proper PPE, particularly in developing regions, can hinder adoption rates. Challenges related to material flexibility and wearer comfort also pose a restraint; while protection is paramount, rigid or bulky gear can impede dexterity and lead to user reluctance or improper usage, compromising safety in the long run. The complexity of certifying and validating new cryogenic PPE materials and designs further adds to development costs and time-to-market.

Opportunities within the Cryogenic PPE market are abundant and promising, largely revolving around technological innovation and market expansion. The emergence of smart PPE, which integrates sensors for real-time temperature monitoring, connectivity, and data analytics, presents a significant opportunity to enhance safety and operational efficiency. Such innovations can provide predictive insights into equipment integrity and worker well-being, moving beyond traditional passive protection. Furthermore, the continuous expansion into new cryogenics applications, such as space exploration, quantum computing, and advanced superconductivity research, creates novel niches and specialized demand for bespoke cryogenic PPE solutions. Strategic partnerships between PPE manufacturers, material science companies, and technology firms can accelerate research and development, leading to the creation of more effective, lightweight, and comfortable protective gear. The growing emphasis on sustainability also offers opportunities for developing eco-friendly cryogenic PPE materials and manufacturing processes, appealing to environmentally conscious industries and consumers. Lastly, global initiatives aimed at improving occupational health and safety standards continue to open new markets and reinforce existing ones, creating a stable environment for sustained growth.

Segmentation Analysis

The Cryogenic PPE market is meticulously segmented to reflect the diverse product types, applications, materials, and end-use industries that define its operational landscape. This comprehensive segmentation allows for a granular understanding of market dynamics, enabling manufacturers and stakeholders to identify specific growth areas, tailor product development, and refine market entry strategies. By dissecting the market along these critical dimensions, it becomes possible to analyze purchasing patterns, technological preferences, and the unique safety requirements across various user groups, thus providing a holistic view of the market's structure and potential. Each segment represents distinct demands and challenges, driving specialized innovation and competitive differentiation within the broader cryogenic safety industry.

- By Product Type: This segment categorizes PPE based on the specific body part or area it is designed to protect.

- Gloves & Aprons: Essential for direct handling of cryogenic liquids, offering critical hand and torso protection against splashes and contact.

- Face Shields & Head Protection: Safeguard the face and head from accidental splashes, flying debris, and radiant cold, often integrated with safety glasses.

- Footwear: Specialized insulated boots designed to protect feet from spills and prolonged exposure to cold surfaces, ensuring thermal integrity.

- Body Suits & Garments: Full-body protection suits for environments requiring extensive coverage, often multi-layered and insulated for complete thermal safety.

- Eye Protection: Goggles and safety glasses providing basic eye protection against splashes and vapor hazards.

- Others (e.g., respiratory protection, specialized sleeves): Includes less common but equally critical items like respiratory masks for cryogen vapors or protective sleeves for specific arm protection.

- By Application: This segment classifies the market based on the primary industry or purpose where cryogenic PPE is utilized.

- Healthcare & Biotechnology: Extensive use in cryopreservation, biobanking, in-vitro fertilization (IVF), and handling of biological samples and pharmaceuticals.

- Oil & Gas: Primarily in liquefied natural gas (LNG) production, transportation, storage, and regasification terminals, protecting workers from extreme cold.

- Chemicals: Used in the manufacturing, storage, and transportation of industrial gases and other cryogenic chemicals.

- Food & Beverage: Applications in flash freezing, food preservation, and transportation of cryogenically treated food products.

- Electronics: For cooling sensitive electronic components, superconductor research, and specialized manufacturing processes involving extreme cold.

- Aerospace & Defense: In rocket fuel handling (liquid oxygen, liquid hydrogen), spacecraft cooling, and specialized defense applications.

- Others (e.g., Research & Development, Metallurgy): Includes various scientific research, academic laboratories, and industries using cryogens for material testing or processing.

- By Material: This segment distinguishes PPE based on the primary protective materials used in their construction.

- Composite Fibers: Advanced multi-layer fabrics often incorporating proprietary blends of synthetic fibers for superior thermal insulation and flexibility.

- Laminated Fabrics: Materials constructed from multiple layers of different fabrics bonded together, offering enhanced barrier properties against liquid cryogens and extreme cold.

- Leather: Traditionally used for its durability and cut resistance, often combined with insulating layers for cryogenic applications, particularly in gloves.

- Others (e.g., GORE-TEX, specialized polymers): Includes proprietary high-performance fabrics and polymer blends designed for specific cryogenic protection levels and environments.

- By End-Use Industry: This segment provides a broader categorization of the types of organizations or sectors that are the ultimate consumers of cryogenic PPE.

- Industrial: Encompasses manufacturing, heavy industries, oil & gas, chemicals, and other sectors where large-scale cryogenic processes are prevalent.

- Research & Development: Includes academic institutions, private research laboratories, and R&D divisions within corporations focused on scientific discovery and innovation involving cryogens.

- Medical: Pertains specifically to hospitals, clinics, biobanks, pharmaceutical companies, and biotechnology firms utilizing cryogenic techniques for patient care, diagnostics, and drug development.

Value Chain Analysis For Cryogenic PPE Market

The value chain for the Cryogenic PPE market is intricate, encompassing various stages from raw material procurement to end-user consumption, each adding value and ensuring the final product meets stringent safety and performance standards. Upstream analysis reveals a reliance on specialized material suppliers who provide high-performance fabrics, insulating layers, waterproof membranes, and advanced fibers such as composite blends, laminated textiles, and specialized polymers. These suppliers are critical as the quality and characteristics of their materials directly dictate the thermal protection, durability, flexibility, and comfort of the final PPE. Research and development activities, often collaborative between material scientists and PPE manufacturers, play a significant role at this stage, focusing on innovation to enhance protection capabilities and address specific cryogenic challenges, like ultra-low temperature resistance and cryogen splash protection. Ensuring a consistent supply of these specialized materials, often from a limited number of expert providers, is a key consideration for manufacturers.

In the midstream segment, manufacturers acquire these raw materials and undertake the complex process of designing, cutting, stitching, and assembling the multi-layered cryogenic PPE. This stage involves sophisticated manufacturing techniques, quality control protocols, and rigorous testing to ensure compliance with international safety standards such as EN 511, EN 388, and CE marking. Manufacturers often invest heavily in advanced machinery and skilled labor to handle specialized fabrics and ensure the integrity of critical seams and insulation layers. Product differentiation is primarily achieved through superior design, ergonomic features, material innovation, and the integration of smart technologies. Brands with strong reputations for reliability and durability tend to capture larger market shares, driven by industrial buyers who prioritize safety and longevity over initial cost.

Downstream, the finished cryogenic PPE products reach end-users through a combination of distribution channels. Direct sales channels are common for large industrial clients, government agencies, and major research institutions, where manufacturers can offer customized solutions, bulk pricing, and direct technical support. Indirect channels, however, form the backbone of broader market reach, involving a network of specialized industrial distributors, safety equipment suppliers, and online retail platforms. These distributors often maintain inventories, provide local sales support, and offer comprehensive product catalogues catering to various industries. The effectiveness of these channels depends on their ability to provide technical expertise, timely delivery, and compliance knowledge to end-users across diverse geographical regions. The market’s success hinges on efficient logistics and a robust supply chain that can respond to fluctuating demands from industries ranging from healthcare and biotech to oil & gas and aerospace, ensuring that critical safety equipment is always available.

Cryogenic PPE Market Potential Customers

The potential customers for the Cryogenic PPE market are diverse and span across numerous industrial, scientific, and medical sectors where the handling, storage, or transportation of extremely cold substances is a routine or critical operation. These end-users are characterized by their stringent safety requirements and the imperative to protect personnel from severe cold burns, frostbite, and other hazards associated with cryogenic liquids and gases. Key purchasing decisions are often driven by regulatory compliance, worker safety initiatives, operational risk mitigation, and the need for durable, high-performance equipment that can withstand extreme conditions. Understanding the specific operational contexts and safety cultures of these varied customers is essential for manufacturers and distributors to effectively market and supply appropriate cryogenic PPE solutions that meet their unique demands.

Within the industrial sector, major customers include companies involved in the production and distribution of industrial gases such as liquid nitrogen, oxygen, argon, and helium, as well as the rapidly expanding liquefied natural gas (LNG) industry. These entities require robust cryogenic PPE for operators working at liquefaction plants, regasification terminals, and in the maintenance of cryogenic storage tanks and pipelines. The chemical processing industry and certain manufacturing sectors, particularly those involved in advanced materials or electronics, also represent significant customer bases due to their use of cryogens for various cooling and processing applications. For these industrial customers, the emphasis is often on durability, robust protection, and the ability of PPE to integrate seamlessly with existing safety protocols and heavy-duty work environments.

The healthcare and biotechnology sectors constitute another major segment of potential customers, including hospitals, biobanks, pharmaceutical companies, research laboratories, and fertility clinics. These institutions extensively utilize cryopreservation techniques for storing biological samples like stem cells, blood, tissues, and vaccines, as well as in procedures such as in-vitro fertilization (IVF). For medical and biotech customers, the priority lies in sterile, comfortable, and highly reliable cryogenic PPE that allows for precise handling of sensitive materials while providing maximum protection. Additionally, academic and government research institutions, aerospace and defense contractors handling cryogenic propellants, and food processing companies utilizing flash-freezing technologies are all critical end-users, each with specialized needs for high-quality cryogenic PPE to safeguard their personnel and ensure operational continuity in challenging ultra-cold environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 5.8 Billion |

| Market Forecast in 2033 | USD 9.4 Billion |

| Growth Rate | 7.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Honeywell International Inc., Ansell Ltd., 3M Company, MSA Safety Inc., Kimberly-Clark Corporation, Lakeland Industries, Inc., DuPont de Nemours, Inc., Drägerwerk AG & Co. KGaA, Showa Group, PIP Global (Protective Industrial Products), Tempshield, Riverstone Holdings LLC (Cryo-Gloves), SureFit, GVS S.p.A., Ergodyne, National Safety Apparel, Kappler, Inc., Bullard, Paulson Manufacturing Corp., MCR Safety |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cryogenic PPE Market Key Technology Landscape

The Cryogenic PPE market is continuously evolving, driven by advancements in material science, manufacturing processes, and smart technologies aimed at enhancing protection, comfort, and usability. At the core of this landscape are multi-layered fabric constructions, which combine various materials to create an effective thermal barrier against extreme cold while also offering protection against splashes of cryogenic liquids. These constructions often integrate a waterproof outer layer, a highly insulating inner layer composed of proprietary fibers or aerogels, and a comfortable, breathable lining. Research in advanced insulation techniques focuses on reducing bulk without compromising thermal performance, leveraging nanotechnology and vacuum insulation panels to achieve superior protective properties in thinner, more flexible garments, thereby improving wearer mobility and dexterity which is crucial for intricate tasks in laboratory or industrial settings.

Beyond passive protection, the technology landscape is increasingly incorporating smart PPE solutions. These innovations involve embedding sensors directly into garments to monitor critical parameters such as internal temperature, external temperature, and even worker physiological data like heart rate or body temperature. Connectivity features, often leveraging Bluetooth or Wi-Fi, enable real-time data transmission to central monitoring systems or mobile devices, allowing for immediate alerts in case of potential exposure or cold stress. This shift towards proactive safety management allows for predictive maintenance, anticipating when PPE might need replacement based on usage patterns and environmental stressors, and provides invaluable data for optimizing safety protocols and training. The integration of augmented reality (AR) and virtual reality (VR) also represents a nascent but promising technological trend, offering immersive training simulations for safe cryogenic handling without actual risk, thereby improving worker preparedness and reducing incident rates.

Furthermore, advancements in ergonomic design and material composites are pivotal in shaping the modern cryogenic PPE market. Manufacturers are increasingly utilizing 3D scanning and computer-aided design (CAD) to develop anatomically contoured garments that offer a superior fit, which not only enhances comfort but also improves the effectiveness of the thermal barrier by reducing air gaps. The use of specialized coatings and treatments on outer fabrics improves durability, abrasion resistance, and chemical splash protection, extending the lifespan of the PPE. Ongoing research into novel materials that combine properties such as inherent flame resistance with cryogenic protection, or materials that are inherently antimicrobial, further pushes the boundaries of what cryogenic PPE can achieve, making it safer and more versatile across a wider array of hazardous environments and ensuring compliance with the highest safety standards in an ever-demanding industrial world.

Regional Highlights

- North America: This region stands as a significant market for Cryogenic PPE, driven by stringent occupational safety regulations, substantial investments in research and development, and a robust healthcare and biotechnology sector. The presence of major players in the oil and gas industry, particularly in LNG production and export in the United States and Canada, fuels consistent demand. High awareness regarding workplace safety and the early adoption of advanced protective technologies contribute to its leading position, with a strong focus on high-performance, durable, and smart PPE solutions.

- Europe: Europe represents a mature but dynamic market, characterized by strict regulatory frameworks set by the EU and national bodies, emphasizing worker protection in industries like chemicals, industrial gases, and medical cryopreservation. Countries like Germany, France, and the UK are key contributors, driven by advanced manufacturing bases, significant biotechnology investments, and a proactive approach to adopting new safety standards. Innovation in material science and ergonomic design is a key regional trend, alongside a growing demand for eco-friendly and sustainable PPE options.

- Asia Pacific (APAC): The APAC region is projected to be the fastest-growing market for Cryogenic PPE, primarily due to rapid industrialization, burgeoning investments in LNG infrastructure, and expanding healthcare and research sectors in countries like China, India, Japan, and South Korea. Increasing awareness of industrial safety, coupled with evolving regulatory landscapes, is driving significant market expansion. The region also sees substantial manufacturing activity, leading to a rising demand for protective gear in cryogenic applications across diverse industries.

- Latin America: This region demonstrates steady growth, fueled by developing industrial sectors, increasing foreign direct investment in oil and gas exploration, and a growing emphasis on improving occupational safety standards. Countries such as Brazil, Mexico, and Argentina are key markets, with demand primarily stemming from industrial gas production, petrochemical operations, and emerging healthcare facilities adopting cryopreservation techniques. The market here is sensitive to economic stability and the enforcement of safety regulations.

- Middle East and Africa (MEA): The MEA region presents significant growth potential, largely driven by massive investments in the oil and gas sector, particularly the expansion of LNG production and export facilities in countries like Qatar, Saudi Arabia, and the UAE. The region's hot climate often necessitates specialized PPE designs that balance thermal protection with heat stress mitigation for workers. Increasing industrialization efforts and a growing awareness of international safety standards are further contributing to the demand for cryogenic PPE across various nascent industries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cryogenic PPE Market.- Honeywell International Inc.

- Ansell Ltd.

- 3M Company

- MSA Safety Inc.

- Kimberly-Clark Corporation

- Lakeland Industries, Inc.

- DuPont de Nemours, Inc.

- Drägerwerk AG & Co. KGaA

- Showa Group

- PIP Global (Protective Industrial Products)

- Tempshield

- Riverstone Holdings LLC (Cryo-Gloves)

- SureFit

- GVS S.p.A.

- Ergodyne

- National Safety Apparel

- Kappler, Inc.

- Bullard

- Paulson Manufacturing Corp.

- MCR Safety

Frequently Asked Questions

What is Cryogenic PPE and why is it essential?

Cryogenic PPE, or Personal Protective Equipment, comprises specialized gear like insulated gloves, aprons, face shields, and full body suits designed to protect individuals from the extreme cold temperatures (below -150°C) of cryogenic liquids and gases. It is essential because direct contact or proximity to cryogens can cause severe injuries such as frostbite, cold burns, and tissue damage. This equipment acts as a crucial thermal barrier, ensuring worker safety and compliance with stringent occupational health and safety regulations in industries like healthcare, biotechnology, oil & gas, and advanced research.

Which industries are the primary consumers of Cryogenic PPE?

The primary consumers of Cryogenic PPE are diverse and include the healthcare and biotechnology sectors for cryopreservation and sample handling; the oil and gas industry, particularly for liquefied natural gas (LNG) operations; chemical manufacturing and industrial gas production; and specialized applications in electronics, aerospace, and food processing for flash freezing. Additionally, academic and private research laboratories, where experimental work involves extreme cold, are significant end-users. These industries rely on cryogenic PPE to protect personnel from the inherent hazards of ultra-low temperature environments.

What are the key technological advancements shaping the Cryogenic PPE Market?

Key technological advancements are significantly transforming the Cryogenic PPE Market. These include the development of advanced multi-layered materials utilizing proprietary composite fibers, aerogels, and laminated fabrics for superior thermal insulation and reduced bulk. The integration of "smart PPE" with embedded sensors for real-time temperature monitoring and worker physiological data, along with connectivity features, is enhancing proactive safety management. Furthermore, advancements in ergonomic design, 3D printing for customized fits, and sustainable material alternatives are contributing to more comfortable, durable, and environmentally conscious protective solutions, pushing the boundaries of traditional cryogenic safety gear.

What are the main growth drivers and restraints for the Cryogenic PPE Market?

The Cryogenic PPE Market is primarily driven by escalating global industrial safety regulations, increasing demand from the expanding LNG sector, and rapid growth in healthcare and biotechnology applications reliant on cryopreservation. Technological advancements in material science also contribute significantly to market expansion by enabling more effective and comfortable products. However, significant restraints include the high initial investment costs associated with advanced, specialized PPE, limited awareness of cryogenic hazards in some regions, and challenges in developing materials that offer optimal flexibility and dexterity without compromising protection, which can impact user adoption and overall market growth.

How is the Cryogenic PPE Market segmented and what are the key segments?

The Cryogenic PPE Market is segmented by product type, application, material, and end-use industry. Key product types include insulated gloves & aprons, face shields & head protection, footwear, and full body suits, each addressing specific protection needs. Major applications span healthcare & biotechnology, oil & gas, chemicals, and electronics, reflecting diverse industrial requirements. Material segmentation highlights the use of composite fibers, laminated fabrics, and specialized polymers for advanced protection. End-use industries such as industrial, research & development, and medical also define crucial market segments, each with unique demands for specialized cryogenic protective equipment.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager