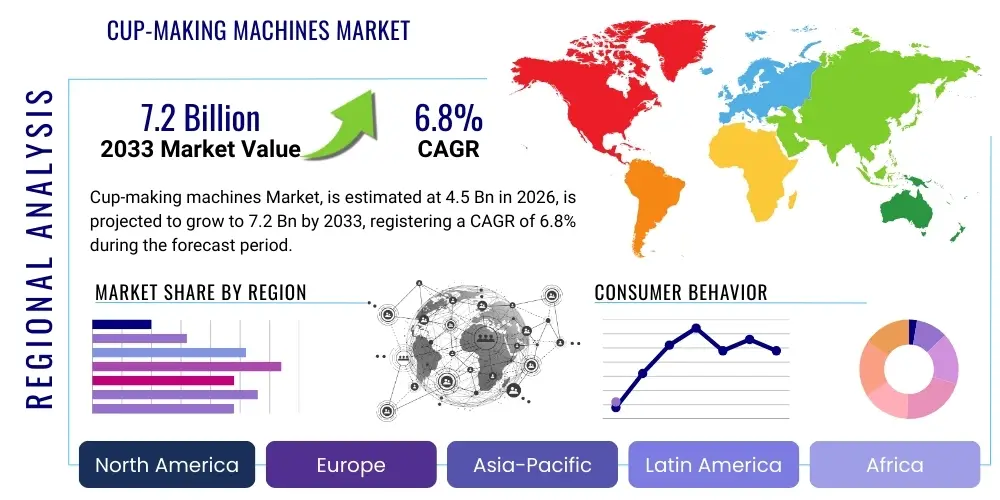

Cup-making machines Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441942 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Cup-making machines Market Size

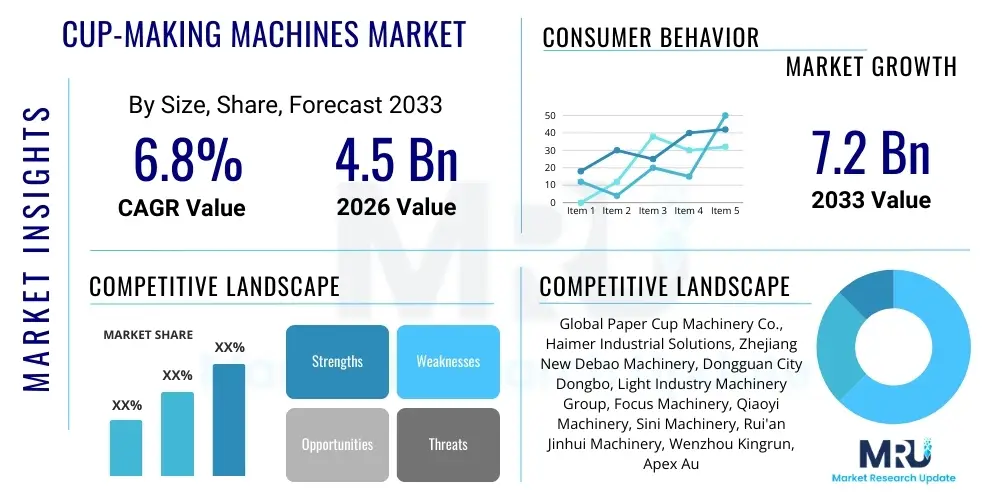

The Cup-making machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 7.2 Billion by the end of the forecast period in 2033.

Cup-making machines Market introduction

The Cup-making machines Market encompasses the manufacturing, sales, and service of automated and semi-automated industrial machinery designed for the high-volume production of disposable cups from various materials, primarily paper, plastic (PP, PET), and biodegradable composites. These sophisticated machines handle processes ranging from paper feeding, printing, die-cutting, forming, ultrasonic sealing, and rim rolling, culminating in finished cups ready for packaging. The fundamental objective of these machines is to deliver high efficiency, precision, and hygiene required by modern food service and packaging industries. Product descriptions vary significantly based on the output material and speed requirements, with fully automatic, high-speed paper cup machines dominating the market due to increasing demand for sustainable and single-use packaging solutions globally.

Major applications of manufactured cups span the entire spectrum of the Fast-Moving Consumer Goods (FMCG) and hospitality sectors. Key end-user segments include quick-service restaurants (QSRs), coffee chains, institutional cafeterias, office environments, healthcare facilities, and specialized industrial packaging uses. The widespread adoption of takeaway and delivery services, particularly post-2020, has significantly amplified the necessity for reliable, efficient, and sanitary cup production capabilities. This continuous operational demand pushes manufacturers towards developing faster, more flexible machines capable of handling diverse cup sizes and complex printing requirements.

The core benefits driving this market include enhanced production efficiency, reduction in labor costs, consistency in product quality, and the capability to rapidly switch between different product specifications (e.g., hot drink cups vs. cold drink cups). Key driving factors are primarily centered around global urbanization, the robust expansion of the organized food service industry in developing economies, stringent hygiene standards necessitating disposable options, and a paradigm shift towards eco-friendly materials like bamboo pulp and PLA-coated paper, which requires specialized machinery adaptations for complex thermal bonding processes.

Cup-making machines Market Executive Summary

The Cup-making machines Market is experiencing robust expansion driven by structural shifts in global consumer behavior, notably the pervasive culture of convenience and the massive growth of the e-commerce enabled food delivery segment. Business trends indicate a strong pivot toward automation, focusing on machines offering faster setup times, reduced material waste, and integrated quality control systems powered by machine vision. Manufacturers are increasingly prioritizing modular designs that allow for easy integration of specialized components for handling compostable materials, reflecting the dominant environmental trend. Furthermore, strategic mergers and acquisitions among machinery manufacturers and material suppliers are optimizing the supply chain, facilitating the development of integrated packaging solutions, and addressing the growing need for turnkey production lines in emerging markets.

Regional trends demonstrate accelerated growth in the Asia Pacific (APAC) region, spearheaded by China, India, and Southeast Asian nations. This growth is fueled by massive population bases, rapid urbanization leading to increased QSR penetration, and government initiatives promoting food safety standards. North America and Europe, while mature markets, emphasize technological upgrades, seeking machines capable of higher energy efficiency and compliance with strict environmental regulations, particularly concerning plastic alternatives. Latin America and the Middle East & Africa (MEA) represent significant opportunities, characterized by foundational infrastructure development and the early stages of adopting high-speed automatic production capabilities, moving away from older, semi-automatic systems.

Segment trends highlight the dominance of Automatic Paper Cup-making Machines due to global sustainability mandates and consumer preferences shifting away from traditional plastics. Within the material segment, machines optimized for producing Biodegradable and Compostable Cups are witnessing the highest growth trajectory, demanding innovations in sealing technology and heating elements. The application segment remains dominated by the Food Service industry, but the Institutional and Retail sectors are growing steadily, demanding specialized smaller-batch machines for niche packaging requirements. Overall, the market trajectory is defined by a dual focus: maximizing output speed while simultaneously adapting to environmentally sensitive materials and complex customization demands.

AI Impact Analysis on Cup-making machines Market

Common user questions regarding AI's influence on the Cup-making machines Market typically revolve around operational efficiency, predictive maintenance capabilities, and enhanced product quality control. Users frequently inquire about the feasibility of integrating AI to reduce material wastage, how machine learning algorithms can optimize production scheduling for complex orders, and whether AI can diagnose faults proactively before catastrophic equipment failure. There is significant interest in AI-driven vision systems for real-time inspection of printing and sealing integrity, ensuring zero-defect output and minimizing costly recalls. The primary expectation is that AI will transform cup manufacturing from a reactive maintenance process to a highly predictive, self-optimizing system capable of dynamic calibration based on real-time material properties and ambient conditions.

The integration of Artificial Intelligence and Machine Learning (ML) is fundamentally shifting the operational paradigm within the cup manufacturing industry. AI algorithms analyze vast streams of data collected from sensors embedded throughout the production line—monitoring parameters such as temperature stability, pressure application, sealing strength, and material feed rate. This analytical capability allows machines to dynamically adjust operational settings (e.g., heating element intensity or cutting speed) in micro-seconds, ensuring consistent output quality regardless of minor fluctuations in raw material quality or ambient temperature. This level of optimization drastically reduces the standard deviation in product specifications and minimizes expensive downtime associated with manual recalibration.

Furthermore, AI is instrumental in implementing sophisticated predictive maintenance regimes. By recognizing subtle anomalies in machine vibrations, motor current signatures, or pneumatic system responses, ML models can accurately forecast component failure several weeks in advance. This transition from scheduled maintenance to condition-based maintenance maximizes machine uptime, reduces inventory holding costs for spare parts, and extends the overall lifecycle of highly specialized machinery components. As machinery becomes more complex, especially with the addition of modules for handling multi-layer or sustainable materials, AI’s role in managing these intricate systems is becoming indispensable for achieving optimal Total Equipment Effectiveness (TEE).

- AI-driven predictive maintenance reducing unplanned downtime by up to 30%.

- Machine vision systems utilizing Deep Learning for zero-defect quality inspection and pattern recognition.

- Optimization of material usage by ML algorithms, minimizing raw material waste during cutting and forming.

- Dynamic speed and temperature control based on real-time feedback loops and material variance analysis.

- Automated production scheduling and resource allocation managed by optimization algorithms.

- Enhanced energy efficiency through AI monitoring and regulation of high-power components like heaters and vacuum pumps.

- Faster troubleshooting and remote diagnostics facilitated by integrated AI support systems.

- Personalized cup customization and printing quality verification in high-speed environments.

- Simulation and digital twin technology leveraging AI for virtual commissioning and process optimization.

DRO & Impact Forces Of Cup-making machines Market

The market dynamics for Cup-making machines are characterized by a strong interplay of escalating demand (Drivers) countered by high capital investment requirements and technological complexity (Restraints), while evolving sustainability mandates present significant avenues for innovation (Opportunities). The primary impact forces include rapid global urbanization and rising disposable incomes fueling QSR expansion, which acts as a fundamental growth driver. Conversely, the increasingly severe regulatory landscape regarding single-use plastics forces rapid technological adaptation, placing immense pressure on manufacturers to overhaul existing machine designs. Overall, the market is highly elastic to consumer environmental awareness and governmental policy shifts regarding packaging materials.

Major market drivers include the explosive growth of the global food delivery and takeaway segment, which necessitates huge volumes of disposable cups. Furthermore, heightened global awareness regarding hygiene and food safety, especially in institutional settings and emerging economies, reinforces the use of single-service disposable packaging. The rapid expansion of organized retail and global coffee chains into Tier 2 and Tier 3 cities worldwide creates continuous, localized demand for new cup manufacturing facilities. Technological advancements, such as the introduction of faster servo-driven machines and integrated printing capabilities, also act as a driver by improving production efficiency and cost-effectiveness for manufacturers.

Restraints largely center on the high initial capital expenditure required for acquiring advanced automatic machinery and the subsequent high maintenance costs associated with complex, high-precision equipment. Fluctuation in the price of key raw materials, such as paperboard and plastic resins, can create supply chain instability and affect the profitability of cup manufacturers, thereby temporarily dampening machine investment. Moreover, the shortage of highly skilled technical personnel required for operating and maintaining advanced CNC and servo-driven cup machines, particularly in developing regions, poses an operational restraint. However, the most significant long-term restraint is the global legislative push to ban or severely restrict single-use plastics, requiring significant R&D investment for machinery compatible with diverse sustainable substrates, a transition that is slow and costly.

Opportunities are abundant in the development and marketing of specialized machinery capable of handling 100% compostable and biodegradable materials (e.g., PLA, bamboo fibers, and water-based barrier coatings). The growth of customized and promotional cup packaging demands flexible machinery capable of quick format changes and high-quality digital printing integration. Geographically, untapped potential exists in building localized manufacturing hubs in regions like Sub-Saharan Africa and specific parts of Latin America, minimizing import dependencies and logistical costs. The deployment of Industry 4.0 concepts, including comprehensive IoT integration, remote monitoring, and AI-driven process optimization, offers substantial opportunities for market leaders to differentiate their product offerings based on intelligence and efficiency.

Segmentation Analysis

The Cup-making machines Market is intricately segmented based on Type, Material Compatibility, Automation Level, and Application, providing a granular view of demand across various end-user industries and technological requirements. Segmentation by Type predominantly distinguishes between machinery optimized for paper cups versus plastic cups, reflecting the divergent processing technologies required for thermal bonding versus ultrasonic sealing. The automation level is crucial for determining production scale, separating high-volume automatic lines from smaller, semi-automatic units favored by nascent or niche producers. Analyzing these segments is essential for understanding targeted investment areas and identifying market saturation points versus high-growth potential niches, such as machines optimized for bio-plastic processing.

- By Automation Level:

- Fully Automatic Cup-making Machines (High-speed, continuous operation)

- Semi-Automatic Cup-making Machines (Manual feeding or unloading required)

- By Material Compatibility:

- Paper Cup Machines (PE-coated, PLA-coated, Water-based barrier coatings)

- Plastic Cup Machines (PP, PET, PS, PVC)

- Biodegradable/Compostable Cup Machines (Dedicated machinery for specialized bio-polymers and pulp)

- By End-User Application:

- Food Service (QSRs, Cafes, Restaurants)

- Institutional (Hospitals, Offices, Schools)

- Industrial Packaging (Containers for processed food, pharmaceutical uses)

- Retail and Consumer Goods (In-store brand promotion, smaller retail units)

- By Output Capacity (Cups/Minute):

- Low Capacity (Under 80 cups/min)

- Medium Capacity (80 - 150 cups/min)

- High Capacity (Above 150 cups/min)

Value Chain Analysis For Cup-making machines Market

The value chain for the Cup-making machines Market is complex, stretching from upstream raw material providers (metals, electronics, specialized components) through machine design and assembly, culminating in distribution and extensive downstream support. Upstream analysis focuses on specialized component suppliers, including high-precision CNC parts manufacturers, advanced servo motor and drive suppliers, ultrasonic welding equipment providers, and industrial automation software vendors. The quality and reliability of these components are paramount, directly influencing the speed, accuracy, and longevity of the final cup machine. Robust relationships with providers of specialized steel alloys and precision bearings are crucial for ensuring the high operational uptime demanded by end-users.

Midstream activities involve the machine manufacturers themselves, who focus heavily on R&D for next-generation technology, particularly around energy efficiency, material flexibility (handling new sustainable substrates), and software integration (HMI interfaces, IoT capabilities). Fabrication, assembly, stringent quality testing, and compliance certification (e.g., CE, UL standards) form the core of this segment. Competition here is intense, driven by innovation in speed and efficiency metrics (e.g., cups per minute per square meter of factory floor space). The core value addition lies in the proprietary design of the forming and sealing stations, which dictates the quality and integrity of the final cup product.

Downstream analysis covers distribution channels and post-sales service, which are critical differentiators in this market. Distribution channels typically involve a mix of direct sales teams for large strategic clients (global packaging giants) and specialized regional distributors or agents who handle sales, installation, and localized technical support for SMEs. The indirect channel relies heavily on these regional partners to navigate local regulatory requirements and provide rapid response to maintenance issues. Excellent post-sales service, including spare parts availability, remote diagnostics, and preventative maintenance contracts, is vital, as machine downtime translates directly into significant production losses for the customer.

Cup-making machines Market Potential Customers

The primary potential customers for Cup-making machines are highly specialized entities focused on high-volume production of disposable and semi-disposable beverage and food containers. These end-users are broadly categorized into large-scale commercial packaging manufacturers who supply cups to global QSR chains and supermarket brands, and smaller, localized packaging enterprises serving regional food service industries and institutional buyers. Specifically, global quick-service restaurant (QSR) chains often mandate specific cup formats and materials, driving demand for tailored, high-speed machinery capable of meeting standardized global specifications. The expansion of major coffee house franchises, particularly in emerging Asian markets, generates continuous procurement requirements for automatic paper cup machinery optimized for hot beverages and specialized lid-fitting tolerances.

A rapidly growing segment of potential customers includes specialized manufacturers focusing exclusively on sustainable packaging solutions. These companies require advanced machinery capable of processing novel, difficult-to-handle materials like high-barrier PLA, recycled fibers, and complex multi-layer biodegradable laminates, often necessitating advanced ultrasonic or laser sealing techniques rather than traditional heat sealing. Furthermore, large institutional purchasers, such as centralized hospital supply chains and major corporate catering services, indirectly drive the market by creating stable, high-volume contracts for cups, thereby necessitating continuous capacity expansion and equipment upgrades among their packaging suppliers. The purchasing decision is heavily influenced by factors such as machine reliability, energy efficiency, ease of material changeover, and the total cost of ownership (TCO) over a typical ten-year lifespan.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 7.2 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Global Paper Cup Machinery Co., Haimer Industrial Solutions, Zhejiang New Debao Machinery, Dongguan City Dongbo, Light Industry Machinery Group, Focus Machinery, Qiaoyi Machinery, Sini Machinery, Rui'an Jinhui Machinery, Wenzhou Kingrun, Apex Automation, MegaTech Systems, Precision Robotics Ltd., EcoPak Solutions, Automated Packaging Inc., Wenzhou New World, Ruian Gaogong, Haining Jingxin, Hangzhou Dingtai. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cup-making machines Market Key Technology Landscape

The technological landscape of the Cup-making machines Market is rapidly evolving, driven primarily by the pursuit of higher production speeds, enhanced operational flexibility, and seamless integration of smart manufacturing principles (Industry 4.0). The shift from traditional cam-driven mechanisms to advanced servo motor technology represents the most significant recent advancement. Servo-driven systems allow for highly precise control over individual machine movements, such as paper feeding, heat sealing, and bottom cutting, resulting in reduced noise, higher energy efficiency, and instantaneous format changeovers. This precision is critical when handling delicate or non-standard sustainable materials that require specialized sealing parameters, which conventional mechanical systems struggle to manage consistently.

Another crucial technological development involves the implementation of advanced sealing and bonding technologies to address the challenges posed by biodegradable and compostable materials. As polyethylene (PE) coatings are phased out in favor of polylactic acid (PLA) or water-based barrier coatings, machine manufacturers are developing sophisticated ultrasonic welding techniques and customized hot air systems. These methods ensure robust seam integrity without compromising the material’s structural properties or environmental profile. Furthermore, integrated digital printing and inspection systems are becoming standard, allowing for personalized, high-resolution graphics to be applied in-line, reducing reliance on pre-printed stock and enhancing supply chain agility for customized orders.

The rise of the Industrial Internet of Things (IIoT) is transforming cup machine operation and maintenance. Modern machines are equipped with hundreds of sensors that continuously transmit operational data to centralized cloud platforms. This connectivity enables sophisticated features such as remote diagnostics, real-time performance monitoring (OEE tracking), and proactive predictive maintenance scheduling. Manufacturers are leveraging this data to offer Machine-as-a-Service (MaaS) models, focusing on operational uptime rather than just equipment sale. This technological shift maximizes productivity for the end-user while providing valuable insights back to the machine developers for iterative design improvement, cementing the market’s move towards fully automated, intelligent production lines.

Regional Highlights

- Asia Pacific (APAC): This region dominates the global market, both in terms of production capacity and consumption. Rapid urbanization, increasing disposable income, and the massive expansion of the QSR sector in China, India, and Southeast Asia are the primary catalysts. The demand here is largely centered on high-speed, cost-effective automatic paper cup machines. Investment in new manufacturing plants, often backed by government incentives, makes APAC the highest growth region. There is a dual focus: maximizing output speed while simultaneously gearing up for the localized adoption of sustainable packaging mandated by regional governments.

- North America: A mature yet highly quality-conscious market characterized by stringent hygiene regulations and a leading focus on environmental sustainability. Demand here is driven by replacement cycles for older machinery and the urgent need for equipment compatible with advanced biodegradable materials. Manufacturers in this region prioritize precision, integration of AI-driven quality control, and superior energy efficiency to reduce operational footprints. The high concentration of global food chains dictates machine requirements for highly consistent and standardized products.

- Europe: The European market is highly sensitive to legislative changes, particularly the European Union’s directive against single-use plastics (SUPD). This regulatory pressure creates immediate demand for new machinery capable of processing non-plastic alternatives, driving innovation in sealing and material handling technology. Western Europe focuses on high-precision, low-volume specialized machines, while Eastern Europe represents a strong growth area for newer, efficient automated lines replacing aging infrastructure to meet Western quality standards.

- Latin America (LATAM): This region is characterized by substantial untapped potential and an ongoing shift from semi-automatic to fully automatic production methods. Market growth is closely tied to the expansion of international QSR franchises and increased investment in local food processing infrastructure. Key markets include Brazil and Mexico. Price sensitivity remains a factor, driving demand for machines offering a strong balance between initial cost and long-term operational efficiency.

- Middle East & Africa (MEA): Growth in the MEA region is accelerating, linked to infrastructural development, tourism growth, and the professionalization of the local food service industry, particularly in the Gulf Cooperation Council (GCC) countries. The demand is often for turnkey solutions, encompassing printing, forming, and packaging capabilities. The presence of major logistics hubs and growing populations supports the establishment of local or regional cup manufacturing facilities, reducing reliance on long-distance imports.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cup-making machines Market.- Global Paper Cup Machinery Co.

- Haimer Industrial Solutions

- Zhejiang New Debao Machinery

- Dongguan City Dongbo

- Light Industry Machinery Group

- Focus Machinery

- Qiaoyi Machinery

- Sini Machinery

- Rui'an Jinhui Machinery

- Wenzhou Kingrun

- Apex Automation

- MegaTech Systems

- Precision Robotics Ltd.

- EcoPak Solutions

- Automated Packaging Inc.

- Wenzhou New World

- Ruian Gaogong

- Haining Jingxin

- Hangzhou Dingtai

- Shanghai Printpack Technology

Frequently Asked Questions

Analyze common user questions about the Cup-making machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for fully automatic paper cup machines?

The predominant factor is the global surge in demand from the Quick Service Restaurant (QSR) sector and takeaway food services, coupled with increasing governmental pressure to adopt paper-based, sustainable packaging alternatives over traditional plastics. High-speed automation is essential for meeting large-scale, consistent production quotas.

How are new sustainable packaging materials impacting the design of cup-making machinery?

The shift towards materials like PLA, bio-plastics, and water-based coatings necessitates significant redesigns, primarily focusing on advanced sealing technologies, such as ultrasonic welding and optimized hot air systems, to ensure cup integrity while accommodating the unique thermal properties of these environmentally friendly substrates.

Which geographical region exhibits the fastest growth rate in the cup-making machines market?

Asia Pacific (APAC), specifically led by emerging economies like China, India, and Southeast Asia, demonstrates the highest projected CAGR. This is attributed to rapid urbanization, expanding middle classes, and massive foundational investments in local manufacturing and food service infrastructure.

What role does Industry 4.0 play in modern cup-making operations?

Industry 4.0, integrating IoT and AI, enables predictive maintenance, real-time performance optimization (OEE tracking), and remote diagnostics. This intelligence maximizes machine uptime, reduces material waste, and allows for dynamic adjustment based on continuous sensor feedback, enhancing overall operational efficiency.

What are the key financial considerations when investing in a high-speed cup-making machine?

Key financial considerations extend beyond the initial capital expenditure (CAPEX) to include the Total Cost of Ownership (TCO), focusing on energy consumption, maintenance contract costs, the lifespan of precision parts, and the machine's efficiency in minimizing raw material wastage throughout its operational cycle.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager