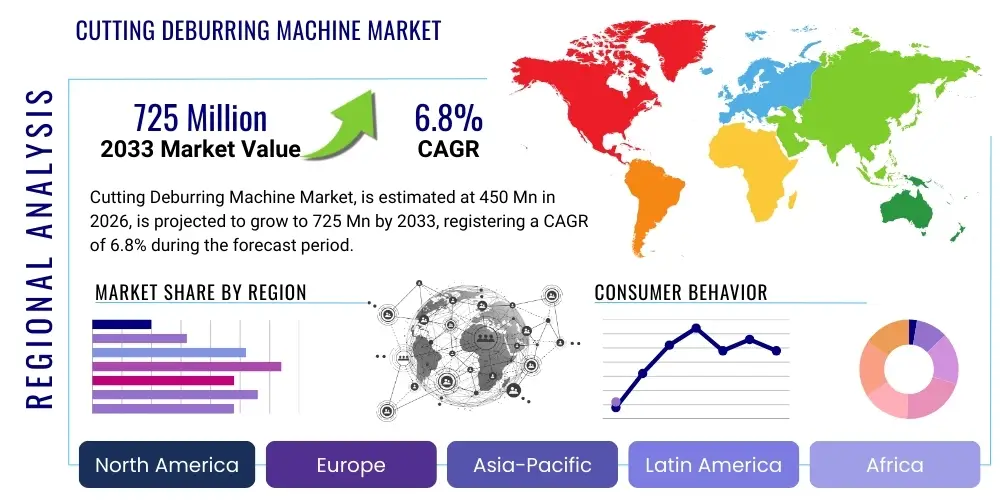

Cutting Deburring Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442558 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Cutting Deburring Machine Market Size

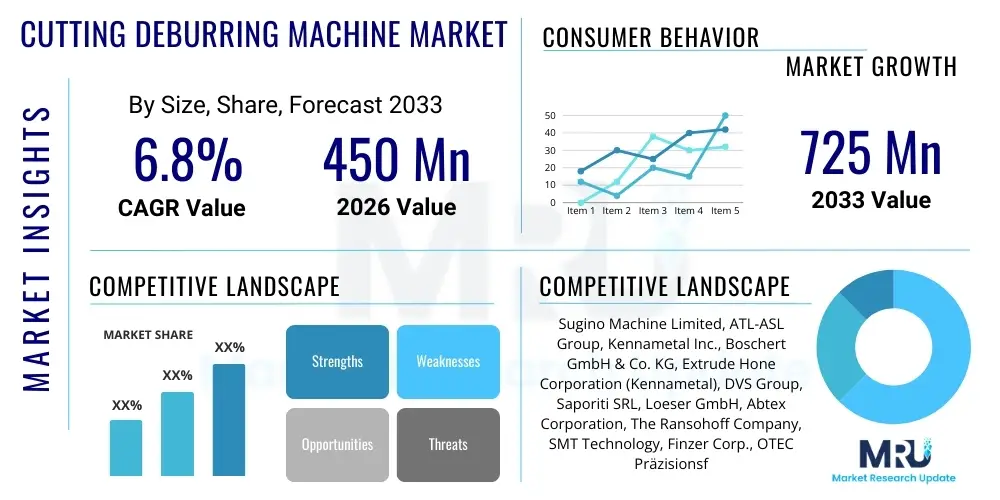

The Cutting Deburring Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 725 Million by the end of the forecast period in 2033.

Cutting Deburring Machine Market introduction

The Cutting Deburring Machine Market encompasses specialized industrial equipment designed to simultaneously cut raw materials and remove sharp edges, burrs, and imperfections resulting from machining processes. These machines are essential components in high-precision manufacturing environments where component quality, surface finish, and operational safety are paramount. The product range includes automated CNC cutting machines integrated with specialized deburring modules utilizing technologies such as thermal energy, abrasive flow, electropolishing, or brush deburring systems. Major applications span critical sectors including automotive manufacturing (engine components, transmission parts), aerospace and defense (turbine blades, structural elements), medical device production (implants, surgical tools), and general precision engineering. The primary benefits derived from adopting these integrated solutions include significant reductions in cycle time, improved dimensional accuracy, consistent surface finish quality, and substantial labor cost savings compared to manual finishing methods. Key driving factors propelling market expansion include the global shift towards automated manufacturing processes (Industry 4.0), stringent quality control standards mandated across industries like medical and aerospace, and the continuous demand for lightweight, high-performance components requiring flawless edges and surfaces.

Cutting Deburring Machine Market Executive Summary

The global Cutting Deburring Machine Market is experiencing robust growth fueled by accelerated digitalization in manufacturing and the increasing adoption of multi-tasking machinery. Current business trends indicate a strong preference among major manufacturers for highly flexible, modular cutting and deburring systems capable of handling diverse materials, including advanced composites, high-strength steels, and titanium alloys. Furthermore, there is a distinct competitive shift towards providers offering comprehensive automation integration, predictive maintenance capabilities utilizing Industrial Internet of Things (IIoT), and seamless integration into existing production lines. Regional trends highlight Asia Pacific (APAC) as the fastest-growing market, primarily driven by massive investments in automotive and electronics manufacturing capacity in China, India, and Southeast Asian nations, alongside government initiatives promoting industrial modernization. Europe and North America maintain significant market shares, characterized by demand for high-end, highly accurate machines necessary for aerospace and precision medical engineering. Segment trends show that automated CNC integrated systems are dominating the technology landscape due to their superior throughput and consistency, while the abrasive flow machining (AFM) segment is gaining traction for deburring geometrically complex internal passages in critical components, addressing niche requirements for high-performance applications.

AI Impact Analysis on Cutting Deburring Machine Market

User queries regarding the impact of Artificial Intelligence (AI) on the Cutting Deburring Machine Market primarily revolve around optimizing machining parameters, enhancing quality inspection, and predicting tool wear. Users frequently ask how AI can improve the consistency of deburring complex internal geometries, which are traditionally challenging to inspect and standardize. Concerns focus on the cost and complexity of integrating AI models into legacy CNC infrastructure and the need for standardized data sets to train effective deburring models, given the variability of burr formation. Expectations center on AI's ability to transition from reactive parameter adjustments to proactive process optimization, drastically reducing scrap rates, extending tool life, and achieving 'lights-out' manufacturing capabilities. Specifically, AI and machine learning algorithms are anticipated to analyze sensor data (vibration, acoustic emission, power consumption) in real-time to adjust cutting speeds, feed rates, and deburring parameters dynamically, optimizing material removal while preserving base geometry tolerance. This predictive capability moves beyond simple automation, enabling machines to learn from subtle variations in material batches or tool condition, ensuring consistent output quality across millions of cycles, thereby fundamentally reshaping operational efficiency in high-volume, high-precision machining environments.

- AI-driven Predictive Maintenance: Utilizing sensor data to forecast failure points in deburring tools (brushes, abrasives, electrodes), minimizing unplanned downtime.

- Real-time Process Optimization: Machine learning algorithms dynamically adjust cutting and deburring parameters based on real-time feedback regarding burr size and location, ensuring optimal material removal.

- Automated Quality Inspection: Implementing computer vision and deep learning models for high-speed, non-contact inspection of deburred surfaces, significantly surpassing human capability in detecting micro-burrs or surface imperfections.

- Enhanced Robotics and Handling: AI improves the dexterity and path planning of robotic arms used for automated loading, unloading, and part presentation for complex deburring processes.

- Simulation and Digital Twins: Creating AI-enhanced digital models of the cutting and deburring process to simulate different scenarios and optimize tooling geometry before physical implementation, reducing setup time and costs.

DRO & Impact Forces Of Cutting Deburring Machine Market

The market growth is primarily driven by the escalating demand for flawless component quality in regulated industries, coupled with global manufacturing trends favoring automation and high-speed production lines. However, the high initial capital expenditure associated with advanced multi-axis CNC and integrated deburring systems poses a significant restraint, particularly for small and medium-sized enterprises (SMEs). Opportunities abound in developing specialized deburring technologies for next-generation materials like ceramics and fiber-reinforced polymers, which traditional methods struggle to process efficiently. The development of subscription-based or leasing models for high-cost machinery also presents a viable avenue for market penetration into emerging economies. The primary impact forces shaping this market include technological advancements in non-contact deburring methods (e.g., laser, thermal) offering greater precision and reduced mechanical stress, intense competition requiring continuous innovation in cycle time reduction, and the geopolitical influence on supply chains necessitating localized manufacturing capabilities, driving demand for efficient domestic machinery.

A major driver is the rigorous regulatory environment in sectors like aerospace (e.g., FAA, EASA) and medical devices (e.g., FDA), which mandates zero tolerance for burrs or sharp edges that could lead to structural failure or bio-incompatibility. The necessity to achieve sub-micron precision in high-volume applications, such as fuel injection components and orthopedic implants, necessitates automated, repeatable deburring solutions. Furthermore, the global automotive industry's transition towards electric vehicles (EVs) is creating new demands for processing complex internal cooling passages and high-tolerance gearing, requiring sophisticated abrasive flow machining (AFM) and electrochemical deburring (ECD) systems. This shift away from traditional internal combustion engine (ICE) machining presents a powerful long-term growth driver, compelling manufacturers to upgrade their current equipment base to handle the unique material and geometric requirements of EV components.

Restraints are compounded by the technical complexity involved in programming and maintaining highly integrated cutting and deburring lines. Specialized expertise is required for optimizing tool paths and managing wear in abrasive media, leading to challenges in finding and retaining skilled labor. Moreover, fluctuations in raw material costs, particularly specialized steels and tungsten carbide used in tooling, can impact the profitability of machine manufacturers and the overall cost of ownership for end-users. The continuous cycle of technological obsolescence, where newer, faster, and more efficient machines are introduced frequently, also pressures manufacturers regarding investment timing and depreciating existing assets quickly. Consequently, the market is characterized by a high barrier to entry for new technological solutions requiring validation across critical industrial standards.

Segmentation Analysis

The Cutting Deburring Machine Market is analyzed across various dimensions including technology type, level of automation, end-user industry, and regional geography. Technology segmentation encompasses the diverse methods employed for burr removal, ranging from conventional mechanical techniques to advanced non-conventional methods necessary for complex part geometries. Automation level categorizes machines based on their integration capabilities, from standalone manual units to fully automated, robot-integrated production cells. The end-user analysis provides critical insights into which sectors are driving demand for specific machine characteristics, such as precision versus volume throughput. Understanding these segments is crucial for manufacturers tailoring their product portfolios to meet specific industrial requirements for material handling, precision tolerances, and regulatory compliance, thereby optimizing market strategies and resource allocation for future development.

- By Technology:

- Abrasive Flow Machining (AFM)

- Thermal Energy Method (TEM)

- Electrochemical Deburring (ECD)

- Ultrasonic Deburring

- Mechanical Brushing/Honing (Integrated CNC)

- Waterjet Deburring

- By Automation Level:

- Fully Automated Integrated Systems

- Semi-Automated Machines

- Manual/Standalone Units

- By End-User Industry:

- Automotive (Engine, Transmission, EV Components)

- Aerospace and Defense

- Medical Devices and Implants

- Precision Electronics

- General Machinery and Tooling

- Hydraulics and Pneumatics

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Cutting Deburring Machine Market

The value chain for the Cutting Deburring Machine Market begins with upstream activities involving the sourcing of high-quality components, including sophisticated CNC controllers, high-precision mechanical structures (castings, linear guides), advanced servo motors, and specialized tooling materials (e.g., diamond or CBN abrasives). Key upstream suppliers include major automation companies (Siemens, Fanuc, Mitsubishi) and specialized tooling manufacturers. Efficient inventory management and strategic procurement of these complex systems are crucial for maintaining competitive pricing and timely delivery. Manufacturing focuses on assembly, rigorous calibration, and the integration of customized software for specific deburring routines. The subsequent downstream activities focus heavily on distribution, installation, and, critically, comprehensive after-sales service, including training, application support, and rapid spare parts supply. Direct distribution channels are often preferred for highly complex, customized, and high-value machines, allowing direct technical consultation and solution selling. Indirect channels, utilizing specialized distributors and agents, are common for standard, lower-cost machines or for expanding reach into geographically remote markets, focusing primarily on volume and localized support expertise.

The complexity of modern cutting and deburring machinery necessitates a robust service component within the value chain. OEMs often provide highly specialized application engineering services, helping clients determine the optimal deburring methodology and machine configuration for their unique part geometries and material types. This direct engagement ensures that the machine solution is perfectly tailored to the client's manufacturing workflow, maximizing efficiency and return on investment. Furthermore, the sustainability aspect is increasingly impacting the upstream stage, with manufacturers prioritizing suppliers who adhere to environmentally responsible manufacturing processes and offer components with extended lifecycles. The downstream aspect is also evolving with the advent of remote diagnostics and preventative maintenance contracts, which leverage IIoT to ensure maximum machine uptime, shifting the focus from transactional sales to long-term service partnerships and subscription-based service agreements.

Distribution channels are heavily influenced by the regional technological maturity and the specific segment being addressed. In highly mature markets like Germany or Japan, direct sales teams manage relationships with Tier 1 automotive and aerospace suppliers, often involving long negotiation cycles and complex integration requirements. Conversely, emerging markets rely significantly on channel partners who possess local regulatory knowledge, import/export expertise, and strong local technical teams capable of initial setup and troubleshooting. The success of the downstream operation hinges on the ability of the sales network to articulate the precise technical advantages of integrated cutting and deburring—specifically, the cost reduction achieved by eliminating bottlenecks associated with off-line, manual finishing processes—positioning the machinery as a strategic investment rather than merely a capital expense.

Cutting Deburring Machine Market Potential Customers

The primary customers for cutting deburring machines are manufacturers operating in high-precision, high-volume production environments where consistent surface quality and dimensional integrity are non-negotiable. The largest segment of end-users originates from the global automotive component manufacturing sector, including suppliers of powertrain parts, brake systems, chassis components, and specialized EV battery enclosures. Aerospace manufacturers constitute another critical customer base, requiring specialized non-contact deburring solutions for complex alloy components (e.g., nickel superalloys, titanium) used in jet engines and airframe structures, often utilizing AFM or TEM due to the extreme quality standards required. Medical device manufacturers, particularly those involved in producing orthopedic implants, surgical instruments, and fluid control systems, rely heavily on electrochemical and ultrasonic deburring to ensure bio-compatibility and sterile surfaces. Other significant buyers include manufacturers in the hydraulics, pneumatics, and general precision engineering industries who produce valves, fittings, and tooling that require smooth, burr-free internal passages for optimal flow dynamics and operational reliability. These customers prioritize machine throughput, repeatability, and the ability to integrate seamlessly with existing or future automated production lines.

A key factor driving purchase decisions among these potential customers is the Total Cost of Ownership (TCO) calculation, which includes initial capital cost, operational expenses (energy, consumables), and crucially, the cost savings derived from reduced scrap rates and eliminated manual labor. Precision engineering firms, often characterized by high-mix, low-volume production, seek flexible, quickly programmable machines that can switch between different part geometries with minimal setup time. Conversely, Tier 1 automotive suppliers, focusing on continuous, high-volume production, prioritize sheer speed, robustness, and maximum automation integration, frequently adopting large-scale, dedicated automation cells. Furthermore, as the trend toward miniaturization continues across electronics and micro-mechanics, a growing customer base is emerging for micro-deburring machines that employ laser or highly precise abrasive technologies to handle components measured in microns, catering to specialized segments like semiconductor manufacturing equipment and micro-fluidics.

The purchasing cycle for these specialized machines is typically long and involves complex technical validation, often requiring extensive application testing and demonstration phases carried out by the OEM. Technical buyers, including manufacturing engineers and quality control specialists, are the primary decision-makers, evaluating machines based on technical specifications such as achievable Ra values (surface roughness), cycle time per part, machine footprint, and compliance with specific industry quality standards (e.g., AS9100 for aerospace). Service and support agreements are often weighted heavily in the final decision, as the continuous operation of these high-value assets is critical to maintaining production schedules. Consequently, OEMs that can demonstrate proven reliability, extensive global service networks, and rapid technical responsiveness gain a significant competitive edge when targeting these high-stakes customer segments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 725 Million |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sugino Machine Limited, ATL-ASL Group, Kennametal Inc., Boschert GmbH & Co. KG, Extrude Hone Corporation (Kennametal), DVS Group, Saporiti SRL, Loeser GmbH, Abtex Corporation, The Ransohoff Company, SMT Technology, Finzer Corp., OTEC Präzisionsfinish GmbH, Acme Manufacturing Company, Bel Air Finishing Supply Corp., Bula Technologie SA, Flow International Corporation, Wöhler Brush Tech GmbH, Kadia Production, Advanced Deburring & Finishing |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cutting Deburring Machine Market Key Technology Landscape

The Cutting Deburring Machine Market is characterized by a technologically diverse landscape, where the choice of machine is highly dependent on the material, geometry, and required surface finish tolerance. Conventional mechanical methods, such as integrated CNC brush deburring and honing, remain foundational for large-volume, external surface finishing, offering high throughput and relatively low operational costs. However, the innovation focus has sharply shifted towards non-conventional methods to address complex internal features and difficult-to-machine materials. Electrochemical Deburring (ECD) utilizes electrical energy and electrolyte solutions to remove burrs without mechanical contact or heat stress, making it ideal for delicate and high-precision components like fuel injector nozzles and hydraulic valves. Another critical technology is Thermal Energy Method (TEM), or thermal deburring, which uses a controlled thermal pulse to combust burrs, proving highly effective for simultaneously deburring multiple external and internal faces on components like pump rotors and transmission gears.

Abrasive Flow Machining (AFM) represents a high-growth technological area, essential for components with intricate internal geometries, such as manifolds, turbocharger impellers, and medical implants. AFM forces a viscoelastic abrasive media through the component's internal passages, precisely honing and deburring areas inaccessible to mechanical tools. Advancements in AFM focus on optimizing the viscosity and composition of the media to achieve specific Ra values on increasingly sensitive materials. Furthermore, the integration of advanced sensors and control systems (IIoT) across all technology types is standardizing machine operation. This connectivity allows for continuous monitoring of process parameters, facilitating automated tool wear compensation and predictive maintenance, thereby reducing the variability inherent in traditional deburring processes and ensuring repeatable results critical for high-reliability components.

The emergence of additive manufacturing (AM) has also introduced a new technological requirement: specialized post-processing solutions to remove support structures and achieve desired surface finishes on AM parts. This has spurred development in laser-based cutting and deburring technologies, as well as specialized chemical and electropolishing techniques optimized for the porous or intricate surfaces characteristic of 3D-printed metal components. Manufacturers are continuously investing in developing modular machine designs that can accommodate multiple deburring processes (e.g., integrating ultrasonic cleaning with mechanical brushing) within a single cell, minimizing part handling and further streamlining the overall manufacturing workflow. This multi-process capability addresses the trend toward consolidation and efficiency in manufacturing operations globally.

Regional Highlights

- North America (USA and Canada): North America represents a mature, high-value market driven primarily by the stringent requirements of the aerospace, defense, and high-end medical device industries. The demand is concentrated on highly automated, integrated cutting and deburring systems capable of processing specialized, high-performance alloys such as titanium and nickel superalloys. Investment in Industry 4.0 initiatives and the reshoring of critical manufacturing capacity, especially in the US, are driving sustained demand for advanced machinery. Key factors include a strong emphasis on reducing labor dependency and achieving world-class precision standards mandated by regulatory bodies like the FDA and FAA. The region showcases high adoption rates of advanced technologies like AFM and TEM due to their necessity in handling complex component geometries found in engine components and surgical tools.

- Europe (Germany, Italy, UK): Europe maintains a leadership position in precision engineering, particularly in Germany and Italy, which are global hubs for high-end automotive, machinery, and tooling manufacturing. The region's market is characterized by a strong demand for sophisticated CNC-integrated systems and highly efficient, energy-saving deburring solutions. German manufacturers, known for their focus on quality and longevity, drive innovations in machine precision and long-term reliability. The transition towards electric mobility is significantly boosting demand for specialized gear and cooling component deburring solutions. Furthermore, European manufacturers are leading the charge in developing sustainable deburring processes, including reduced chemical usage in ECD and optimized abrasive recycling in AFM, aligning with EU environmental directives.

- Asia Pacific (APAC) (China, Japan, South Korea, India): APAC is the largest and fastest-growing market globally, fueled by massive industrialization, rapid urbanization, and significant foreign direct investment into the manufacturing sector, especially in China and India. China remains the dominant consumer, driven by its expansive automotive production and electronics supply chain requirements, prioritizing machines that offer high throughput at competitive costs. Japan and South Korea, however, lead in the adoption of cutting-edge automation and precision technologies, catering to their advanced electronics, robotics, and semiconductor equipment manufacturing sectors. The increasing labor costs in these countries are accelerating the shift from manual deburring to fully automated integrated systems, making automation efficiency a primary purchasing criterion across the region.

- Latin America (Brazil, Mexico): This region demonstrates moderate growth, primarily tied to the automotive assembly and component manufacturing sectors, particularly in Mexico (due to proximity to the US supply chain) and Brazil. The demand often focuses on cost-effective, durable, and reliable semi-automated or standard CNC cutting and deburring solutions. Market expansion is dependent on stable economic conditions and continued foreign investment in local manufacturing plants. Local firms are gradually upgrading their equipment to meet international quality standards for export, driving slow but steady adoption of integrated deburring technologies.

- Middle East & Africa (MEA): The MEA market is currently small but shows potential, driven by infrastructure projects, defense spending, and emerging manufacturing bases in Gulf Cooperation Council (GCC) countries. Demand is highly selective, focusing on equipment for oil & gas component manufacturing (requiring specialized deburring for internal passages) and nascent aerospace MRO (Maintenance, Repair, and Overhaul) facilities. The market is highly reliant on imported machinery, and growth is tied to government diversification efforts aimed at building non-hydrocarbon industrial capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cutting Deburring Machine Market.- Sugino Machine Limited

- ATL-ASL Group

- Kennametal Inc. (Extrude Hone Corporation)

- Boschert GmbH & Co. KG

- DVS Group

- Saporiti SRL

- Loeser GmbH

- Abtex Corporation

- The Ransohoff Company

- SMT Technology

- Finzer Corp.

- OTEC Präzisionsfinish GmbH

- Acme Manufacturing Company

- Bel Air Finishing Supply Corp.

- Bula Technologie SA

- Flow International Corporation

- Wöhler Brush Tech GmbH

- Kadia Production

- Advanced Deburring & Finishing

Frequently Asked Questions

Analyze common user questions about the Cutting Deburring Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Thermal Energy Method (TEM) and Electrochemical Deburring (ECD)?

TEM uses a controlled explosion of gas to combust burrs simultaneously on all surfaces, interior and exterior, providing rapid processing for large batches but limited by material volatility. ECD uses electrolysis to dissolve burrs in specific areas without heat or mechanical stress, offering high precision for complex internal geometries and delicate parts, essential in aerospace and medical applications.

How does the shift to Electric Vehicles (EVs) impact demand for cutting deburring machines?

The EV shift increases demand for high-precision deburring methods, particularly Abrasive Flow Machining (AFM) and electrochemical processes. These technologies are crucial for processing complex cooling channels, motor housings, and intricate gear systems required in EV powertrains, which demand flawless internal finishes for optimal thermal management and efficiency.

What are the key advantages of fully automated cutting and deburring integration?

Fully automated integration significantly reduces part handling time, minimizes human error, ensures consistently high quality and repeatability across large production runs, and allows for 'lights-out' manufacturing. Automation also enables real-time data collection for process optimization and predictive maintenance, lowering the overall Total Cost of Ownership (TCO) in high-volume production settings.

Which end-user industry drives the highest demand for Abrasive Flow Machining (AFM)?

The Aerospace and Defense industry drives the highest demand for AFM due to its unique ability to deburr and polish difficult-to-access internal passages, such as those found in turbine blades, hydraulic manifolds, and fuel systems, ensuring critical flow dynamics and component integrity in demanding operational environments.

What role does Industry 4.0 connectivity play in modern deburring equipment?

Industry 4.0 connectivity, enabled by IIoT sensors and cloud processing, allows modern deburring machines to self-diagnose, communicate real-time performance metrics, and dynamically adjust parameters using AI/ML algorithms. This connectivity maximizes machine uptime, optimizes consumable usage, and facilitates seamless integration into factory-wide Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES).

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager