Dairy Separator Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441441 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Dairy Separator Market Size

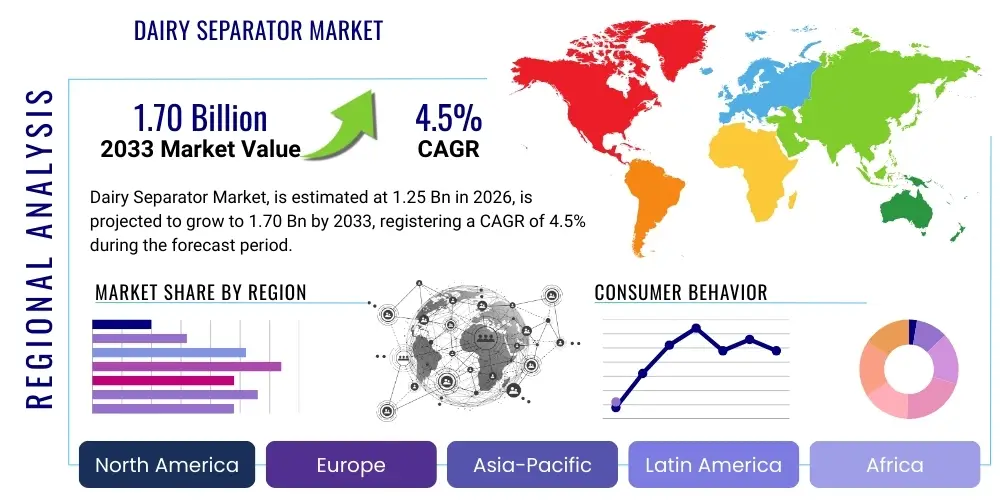

The Dairy Separator Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.70 Billion by the end of the forecast period in 2033. This consistent growth trajectory is primarily underpinned by the increasing global demand for processed and standardized dairy products, requiring precise and efficient separation technologies to meet stringent consumer and regulatory quality parameters. The standardization of milk fat content, coupled with the need for high throughput processing capabilities in emerging economies, solidifies the market expansion.

Dairy Separator Market introduction

The Dairy Separator Market encompasses specialized centrifugal equipment essential for separating raw milk into its constituent components, primarily skim milk and cream, based on density differences. These separators utilize high-speed rotation to generate massive centrifugal forces, ensuring efficient and rapid extraction of milk fat while also clarifying the liquid by removing somatic cells and solid impurities. This precision is vital for dairy processors globally who aim to standardize products such as fluid milk, butter, cheese, and yogurt, ensuring consistent quality and adherence to specific fat percentages dictated by regulatory bodies or brand specifications.

Modern dairy separators are critical tools in large-scale industrial dairy operations, offering unparalleled throughput capacity and operational reliability. Key applications span across the processing of various dairy streams, including cream separation, milk standardization, whey processing, and butter oil clarification. The inherent benefits of utilizing advanced separation technology include significantly increased yield rates, improved product quality and shelf life, and reduced operational downtime compared to traditional gravity-based separation methods. Furthermore, the integration of automation features, such as continuous monitoring and automatic sludge discharge, contributes significantly to operational efficiency and labor cost reduction, making these machines indispensable assets in the modern dairy processing landscape.

Driving factors propelling market growth include the burgeoning middle-class population globally, particularly in the Asia Pacific region, which is increasing the consumption of packaged and high-value dairy derivatives. Strict international food safety standards necessitate equipment capable of rigorous cleaning-in-place (CIP) protocols, driving demand for technologically advanced, hygienic stainless steel separators. Moreover, continuous innovation in optimizing bowl design to reduce energy consumption and maximize skimming efficiency ensures that dairies constantly seek upgrades and replacements for older, less efficient machinery, thereby sustaining market momentum across all major geographical regions.

Dairy Separator Market Executive Summary

The global Dairy Separator Market is experiencing robust expansion, fundamentally driven by shifts towards large-scale industrial dairy farming and processing, emphasizing high throughput and superior separation precision. Business trends indicate a strong focus on automation and integration of sensors, allowing processors to adjust operational parameters in real-time based on the incoming raw milk characteristics, thus maximizing efficiency and minimizing product loss. Leading manufacturers are increasingly developing modular systems that allow for scalability and rapid maintenance, addressing the dairy industry's crucial requirement for minimizing production downtime.

Regionally, the market dynamics show significant divergence. The Asia Pacific region is rapidly emerging as the primary growth engine, fueled by massive increases in local milk production, rising per capita consumption, and substantial government investments aimed at modernizing dairy infrastructure in countries like India and China. In contrast, mature markets such as North America and Europe emphasize technological replacement cycles, focusing intensely on separators that offer superior energy efficiency, reduced maintenance footprint, and compliance with the most stringent environmental and hygiene regulations. European trends also lean towards separators specialized for high-value organic and specialty dairy products, requiring extremely gentle handling and precise processing.

Segment trends highlight the dominance of the disc stack separator type due to its versatility and high G-force capabilities, essential for achieving ultra-low fat content in skim milk (high skimming efficiency). Furthermore, the application segment shows strong growth in whey processing and protein fractionation, driven by the surging popularity of protein-enriched nutritional and functional food products. Capacity segmentation reveals a higher demand growth rate for very large-capacity separators (over 40,000 liters per hour) required by multinational dairy giants, although the market also sees steady demand for medium-capacity units tailored for regional and cooperative dairies focused on localized production.

AI Impact Analysis on Dairy Separator Market

User inquiries regarding AI in the Dairy Separator Market consistently revolve around optimizing complex processes, ensuring proactive maintenance, and managing the inherent variability of raw milk quality. Users seek to understand how AI can transition separator operations from reactive monitoring to predictive modeling. Key themes include the implementation of machine learning algorithms to forecast component wear and scheduling maintenance precisely before failure (Predictive Maintenance 4.0), and utilizing AI to dynamically adjust centrifugal speed, flow rate, and back pressure in response to real-time sensor data regarding milk temperature, viscosity, and fat globule size. This optimization aims to maintain peak skimming efficiency regardless of input fluctuations, a critical concern for high-volume processors aiming for standardized outcomes.

- AI-driven Predictive Maintenance: Utilizing ML models trained on vibration and temperature data to anticipate mechanical failures, dramatically reducing unplanned downtime and minimizing maintenance costs by scheduling interventions precisely.

- Dynamic Process Optimization: Employing AI algorithms to automatically adjust separator parameters (speed, flow) in real-time based on incoming milk composition analysis, ensuring consistent fat standardization and maximizing yield under variable conditions.

- Automated Quality Control: Integrating vision systems and AI analysis for immediate detection of irregularities in separated products (e.g., flocculation, carry-over), triggering automated adjustments or alerts.

- Optimized CIP Cycles: Using machine learning to optimize Cleaning-in-Place (CIP) routines, adjusting chemical concentration, temperature, and duration based on historical usage and microbial load assessment, leading to reduced water, energy, and chemical consumption.

- Energy Footprint Reduction: Implementing AI to analyze energy consumption patterns during different operational phases, identifying efficiencies in motor use and centrifugation profiles to lower the overall operating cost of high-capacity units.

DRO & Impact Forces Of Dairy Separator Market

The Dairy Separator Market is propelled by powerful drivers centered on evolving consumer preferences and rigorous processing requirements, offset by significant capital constraints and regulatory hurdles. The primary driver is the escalating global consumption of processed dairy products such as standardized milk, specialized whey proteins, and fermented goods, which all necessitate initial, efficient separation. Restraints predominantly stem from the substantial initial capital investment required for purchasing high-capacity centrifugal separators, which can be prohibitive for small and medium-sized dairy operations, particularly in developing economies. Furthermore, the reliance on high-quality stainless steel and precision engineering components contributes to high manufacturing costs, affecting final prices and replacement rates.

Opportunities for market expansion are strongly concentrated in the development of specialized, smaller-scale separators tailored for niche applications, such as separating high-value components (e.g., lactoferrin, specific protein fractions) or catering to artisanal dairy producers requiring gentle, low-shear separation processes. Integrating advanced Internet of Things (IoT) sensors and remote diagnostics capabilities offers manufacturers an opportunity to provide value-added services, including remote monitoring and preventive service contracts, creating sustainable post-sales revenue streams. The rising global focus on sustainability also presents an opportunity for manufacturers to innovate in areas like water recycling within CIP systems and developing highly energy-efficient motors for centrifugal operation.

Impact forces in this market are high, driven by technological obsolescence rates and stringent governmental regulations. Technological impact is high because the difference in skimming efficiency (the ability to achieve extremely low residual fat content in skim milk) between older and newer models can dramatically affect product yield and profitability, driving rapid replacement cycles. Regulatory forces, particularly those relating to hygienic design (e.g., FDA, EHEDG standards), compel manufacturers to continuously upgrade materials and design to ensure zero bacterial risk, influencing procurement decisions and favoring suppliers capable of demonstrating the highest levels of sanitation compliance and validation documentation. The increasing volatility in raw milk prices also acts as a latent impact force, pushing processors to invest only in equipment that guarantees maximum yield recovery to protect thin profit margins.

Segmentation Analysis

The Dairy Separator Market is comprehensively segmented based on machine characteristics, capacity, and application scope, reflecting the diverse needs of the global dairy processing industry. Analyzing these segments provides critical insights into market penetration and growth opportunities across different processing scales and final product categories. The key differentiators often involve the centrifugal mechanism design, such as disc stack versus nozzle technology, and the operational throughput measured in liters per hour, which directly correlates with the size and scale of the end-user facility. Furthermore, the specialized use of the separator, whether for standard milk processing, high-fat cream production, or challenging applications like casein fines removal, defines specific demand patterns within the market.

- By Type

- Disc Stack Separators: Predominantly used for standardization, skimming, and clarification due to high efficiency and flexibility.

- Nozzle Separators: Primarily utilized for applications requiring high concentration of solids, such as in whey protein processing and yeast separation.

- Self-Cleaning Separators: Featuring automated sludge discharge, dominating the large-scale industrial segment due to reduced operational intervention.

- Manual/Semi-Automatic Separators: Typically used by small dairies or for batch processing.

- By Capacity

- Small Capacity (Up to 5,000 LPH): Suitable for artisan dairies and pilot plants.

- Medium Capacity (5,001 - 20,000 LPH): Common in regional cooperative dairies.

- Large Capacity (Above 20,000 LPH): Essential for multinational dairy giants and high-volume processing facilities.

- By Application

- Milk Processing and Standardization: The largest segment, covering fluid milk, UHT milk, and pasteurized milk production.

- Cream Separation and Concentration: Focused on butter and cream cheese manufacturing.

- Whey Processing: Critical for separating whey cream and clarifying whey prior to protein fractionation (WPC/WPI).

- Butter Oil Clarification: Used to refine and purify anhydrous milk fat.

- Casein Production: Separation of casein micelles from skim milk.

Value Chain Analysis For Dairy Separator Market

The value chain for the Dairy Separator Market begins upstream with the procurement of highly specialized raw materials and components, which significantly dictates the final quality and longevity of the machinery. Key upstream inputs include certified food-grade stainless steel (304 and 316L) to meet stringent hygienic standards, high-precision motors and drives, and sophisticated control systems (PLCs, sensors). The manufacturing process itself involves complex precision engineering, requiring specialized machining capabilities for balancing the high-speed bowls and ensuring dimensional accuracy, which is critical for operational stability and safety at high centrifugal forces. Manufacturers must maintain exceptionally high quality control standards, often requiring in-house testing facilities for pressure integrity and separation efficiency validation.

Midstream activities involve the core manufacturing, assembly, and rigorous testing of the separator units. Leading original equipment manufacturers (OEMs) often design proprietary bowl geometries and sealing systems to maximize skimming efficiency and ease of maintenance. The downstream segment focuses on distribution, installation, commissioning, and, most critically, ongoing maintenance and parts supply. Due to the high-value and technical nature of dairy separators, distribution channels predominantly rely on specialized direct sales teams for large processing plant installations, offering integrated engineering consulting services to ensure seamless integration into existing processing lines.

However, for spare parts, consumable components (like seals and gaskets), and smaller capacity units, indirect distribution via established local agents, technical service providers, and specialized food processing equipment distributors is common. Post-sales service is a major value contributor, as separators require scheduled maintenance, balancing, and occasional overhauls. Companies that provide robust, geographically dispersed service networks and rapid spare parts delivery maintain a significant competitive advantage. The focus across the entire value chain is shifting towards implementing traceability systems and digitalization to streamline supply chain transparency and expedite service response times, minimizing operational downtime for end-users.

Dairy Separator Market Potential Customers

The primary consumers of dairy separator equipment are large-scale industrial dairy processing corporations and multinational food and beverage conglomerates with extensive global production footprints. These entities require high-capacity, fully automated, and continuously operating separators (often exceeding 40,000 LPH) to handle massive volumes of milk, ensuring standardization for products destined for national and international markets. Their procurement decisions are heavily influenced by total cost of ownership (TCO), efficiency gains (yield maximization), energy consumption profiles, and adherence to global food safety certifications.

A second major customer segment includes cooperative dairies and regional processing plants, often governmental or producer-owned, focusing on supplying specific geographic areas. These customers typically invest in medium to large capacity separators (5,000 LPH to 30,000 LPH) that balance operational flexibility with reliable performance. For them, ease of use, local maintenance support, and moderate capital outlay are critical factors. They utilize separators primarily for standardization, producing pasteurized milk, yogurt bases, and regional cheese varieties, placing high importance on machine durability and ease of CIP protocols.

Finally, specialized manufacturers, including those producing infant formula, highly purified whey protein isolates (WPI), butter oil, and unique artisanal cheeses, constitute a growing niche segment. These customers often demand specialized, gentle separation technology (low-shear designs) or nozzle separators for high-solids applications. Their purchasing criteria prioritize process precision, capability for fractionation, and documentation regarding hygienic design integrity, regardless of the machine's absolute capacity. The proliferation of whey valorization projects globally further reinforces demand from this high-value processing sector.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.70 Billion |

| Growth Rate | 4.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Alfa Laval, GEA Group, Krones AG, Tetra Pak International SA, SPX FLOW, Seibu Giken Co., Ltd., Scherjon Equipment, Centrimax Separation, Pierre Guerin, JBT Corporation, H.T.S. High Tech Separation, Shanghai Jiesheng Centrifuge, Kiremko B.V., Milky Lab, Flottweg SE, Separator Spares International, IDMC Limited, A&B Process Systems. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dairy Separator Market Key Technology Landscape

The current technology landscape of the Dairy Separator Market is defined by the relentless pursuit of operational efficiency, ultra-high hygiene standards, and minimized product loss. One of the most significant technological advancements is the evolution of the centrifugal bowl design, specifically aimed at increasing the G-force applied to the milk while simultaneously improving the hydrodynamics to ensure gentle product handling. This allows for significantly enhanced skimming efficiency—often achieving residual fat content below 0.01% in skim milk—while operating at higher flow rates. Furthermore, the mandatory implementation of automated Cleaning-in-Place (CIP) systems, often integrated with automated partial and full discharge mechanisms, has minimized manual intervention and drastically reduced the risk of cross-contamination, aligning with global food safety protocols.

A second critical technological trend involves the integration of advanced sensor technology and sophisticated control units. Modern separators are equipped with sensors to monitor crucial operational parameters such as vibration levels, temperature, flow rate, and back pressure in real-time. These data points feed into Programmable Logic Controllers (PLCs) and HMI (Human Machine Interface) systems, allowing operators to monitor performance remotely and adjust settings for optimal standardization. This data capture capability is foundational for implementing future-ready concepts like AI-driven predictive maintenance and dynamic process control, enabling the separators to adapt instantaneously to variations in raw milk quality and temperature.

Finally, the focus on sustainable processing drives technological development in motor efficiency and energy recovery systems. High-capacity separators are energy-intensive, making the deployment of high-efficiency motors (IE3/IE4 standard) and systems capable of recovering braking energy essential for reducing the total operational footprint. Manufacturers are also innovating in sealing technology, utilizing mechanical seals that require less cooling water and offer increased durability. The convergence of hygienic design principles (EHEDG compliance), advanced monitoring systems, and energy optimization defines the competitive edge in the current market, moving dairy separation toward a fully autonomous, traceable, and highly efficient operation.

Regional Highlights

The regional dynamics of the Dairy Separator Market are highly segmented, reflecting disparate stages of dairy industry maturity, regulatory environments, and consumption patterns across the globe. North America and Europe, representing mature markets, exhibit strong demand primarily driven by replacement cycles and the adoption of high-automation, high-efficiency separators compliant with extremely stringent environmental and quality control standards. These regions prioritize technology upgrades that minimize utility consumption (water and energy) and maximize traceability through digital integration. Manufacturers focus on providing highly specialized equipment for niche products like organic milk and advanced protein derivatives.

Asia Pacific (APAC) stands out as the highest-growth market, characterized by massive investments in new processing capacity driven by population growth and changing dietary habits favoring westernized dairy products. Countries such as India, China, and Southeast Asian nations are rapidly modernizing their dairy infrastructure, transitioning from local, manual processing towards large, centralized industrial plants. This rapid expansion translates directly into high procurement volumes for medium and large-capacity disc stack separators. Government initiatives supporting dairy cooperatives and increasing domestic milk production are key accelerators in this region.

Latin America and the Middle East & Africa (MEA) represent emerging markets with moderate, but steadily increasing, demand. In Latin America, the market is influenced by exports, particularly from countries like Brazil and Argentina, necessitating equipment that meets international quality standards. In MEA, market growth is often linked to the establishment of large-scale dairy projects aimed at achieving food security and reducing import dependency, particularly for staple products like powdered milk and UHT products. The purchasing decisions in these regions are often sensitive to cost and reliant on suppliers offering robust training and technical support alongside the machinery.

- North America: Focus on high automation, energy efficiency, and low-maintenance solutions; demand centered around technological replacement and specialized applications (e.g., medical whey).

- Europe: Driven by strict EHEDG hygiene regulations and high demand for separators optimized for organic, specialty, and high-quality dairy components; emphasis on sustainability and traceability.

- Asia Pacific (APAC): Leading growth region; robust demand for new, large-capacity installations due to massive infrastructure expansion and rising per capita consumption of packaged dairy goods.

- Latin America (LATAM): Stable demand tied to regional processing expansion and meeting export standards; cost-efficiency and durability are key purchasing factors.

- Middle East & Africa (MEA): Growth fueled by national food security initiatives and investment in large-scale domestic dairy processing capabilities, often requiring robust equipment suitable for diverse operational conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dairy Separator Market.- Alfa Laval

- GEA Group

- Krones AG

- Tetra Pak International SA

- SPX FLOW

- Flottweg SE

- Seibu Giken Co., Ltd.

- Centrimax Separation

- JBT Corporation

- Pierre Guerin

- H.T.S. High Tech Separation

- Scherjon Equipment

- Shanghai Jiesheng Centrifuge

- Kiremko B.V.

- Milky Lab

- IDMC Limited

- A&B Process Systems

- Separator Spares International

Frequently Asked Questions

Analyze common user questions about the Dairy Separator market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving investment in new dairy separation technology?

The increasing need for milk standardization to meet precise fat content specifications and the continuous pressure to maximize product yield (skimming efficiency) from raw milk processing are the primary drivers for investing in new, high-efficiency centrifugal separators.

How do disc stack separators differ fundamentally from nozzle separators in dairy applications?

Disc stack separators are primarily used for clarification and separation into two phases (cream/skim milk) and feature automated discharge for solids removal, making them ideal for standardization. Nozzle separators are designed for continuous discharge of concentrated solids and are thus preferred for high-volume applications like continuous whey protein recovery or yeast harvesting.

What role does automation play in optimizing dairy separator operations and reducing costs?

Automation, particularly through integrated PLCs and self-cleaning (CIP) systems, reduces labor costs and ensures precise process control. Advanced automation using sensors and potentially AI enables dynamic adjustment of speed and flow, maximizing yield and minimizing energy and water consumption across varied raw material conditions.

Which geographical region is expected to demonstrate the highest growth rate for the Dairy Separator Market?

The Asia Pacific (APAC) region is projected to experience the highest growth rate, fueled by rapid urbanization, significant government investment in dairy infrastructure modernization, and surging consumer demand for processed and packaged dairy products.

What are the key maintenance challenges associated with industrial dairy separators?

Key challenges include managing the wear and tear of high-speed mechanical components like seals and bearings, ensuring critical bowl balance to prevent destructive vibration, and adhering to strict maintenance schedules required to preserve the hygienic integrity of the processing environment.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager