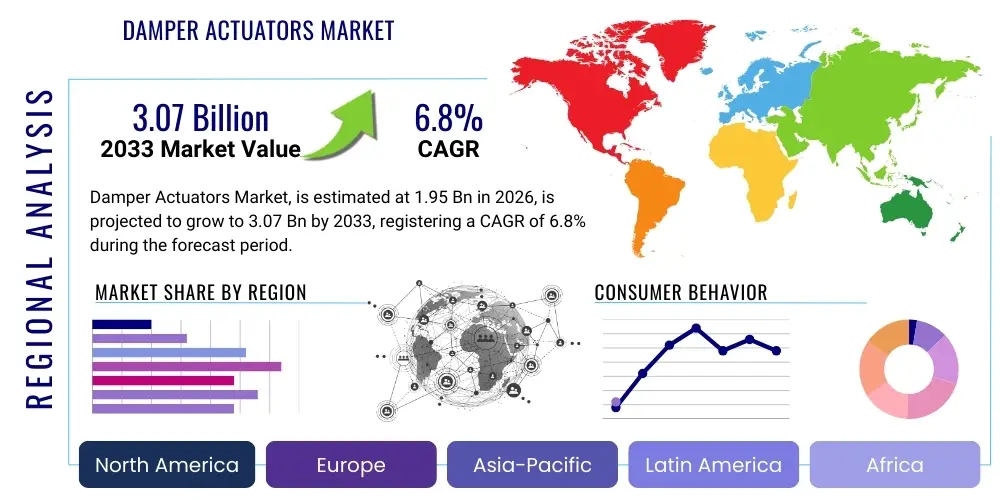

Damper Actuators Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443382 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Damper Actuators Market Size

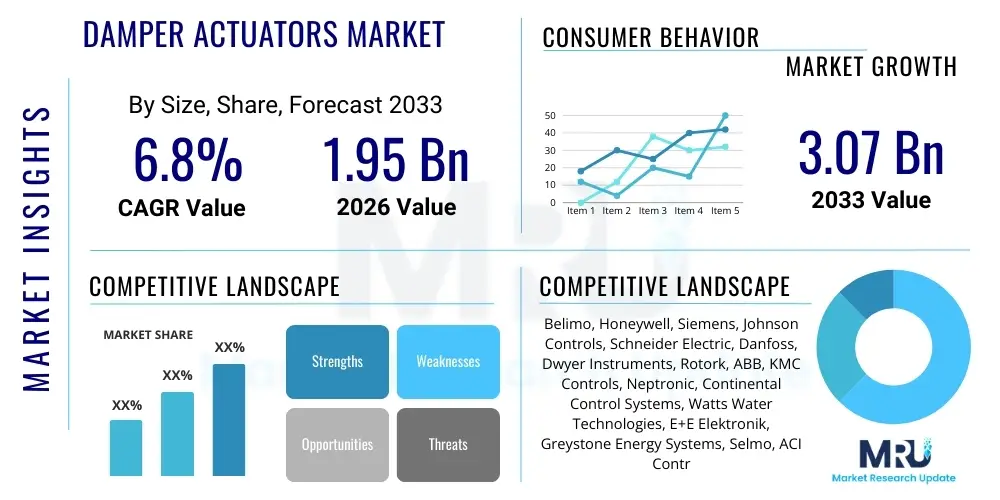

The Damper Actuators Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.95 Billion in 2026 and is projected to reach USD 3.07 Billion by the end of the forecast period in 2033.

Damper Actuators Market introduction

The Damper Actuators Market encompasses essential electromechanical or pneumatic devices designed to precisely control the opening and closing or modulation of dampers within air handling systems. These components are critical infrastructural elements primarily utilized in Heating, Ventilation, and Air Conditioning (HVAC) systems across various sectors, including commercial, institutional, and industrial facilities. Their core function involves receiving control signals from a Building Management System (BMS) or thermostat and translating that signal into mechanical movement to accurately position the damper, thereby regulating airflow, zone pressurization, and temperature distribution. This sophisticated control is paramount for achieving modern energy efficiency benchmarks and maintaining high standards of indoor air quality (IAQ), especially in sensitive environments like data centers, pharmaceutical manufacturing plants, and healthcare facilities where stable environmental parameters are non-negotiable.

The primary applications of these actuators extend beyond general climate control to include specialized safety functions, particularly in fire and smoke management systems, where highly reliable spring-return actuators ensure that ventilation paths are sealed or opened appropriately during emergency conditions. The significant benefits derived from implementing advanced damper actuators include reduced energy consumption achieved through efficient zoning and variable air volume (VAV) control, enhanced occupant comfort through superior thermal regulation, and compliance with increasingly stringent governmental and industrial safety regulations. As buildings become smarter and more integrated, the demand for networked, high-precision actuators that communicate seamlessly via digital protocols is surging. The key driving factors accelerating market expansion include the global push for sustainable building practices, the proliferation of smart building technology, and the continuous need for infrastructure modernization.

Product diversity within this market segment is extensive, ranging from small, low-torque rotary actuators used in terminal units to large, high-torque linear actuators employed in industrial air pollution control systems. Modern actuator design emphasizes longevity, low noise operation, and power efficiency, often incorporating features such as electronic failure detection and self-calibration capabilities. The market dynamics are highly competitive, driven by technological innovation focused on improving communication interoperability and simplifying the installation and commissioning process for mechanical contractors and system integrators. The foundational role of these devices in managing complex climate parameters positions the Damper Actuators Market as a crucial, steadily expanding segment within the broader building automation industry.

Damper Actuators Market Executive Summary

The global market for Damper Actuators is undergoing significant transformation, primarily characterized by a pivotal shift toward digitally enabled and IoT-integrated products that facilitate comprehensive energy management and advanced diagnostics within commercial and industrial facilities. Current business trends indicate a strong move away from traditional analog and pneumatic systems toward superior, network-compatible electronic actuators utilizing protocols like BACnet and Modbus, reflecting a broader industry commitment to the smart building ecosystem. Leading manufacturers are focusing strategic investments on R&D to enhance torque efficiency, reduce physical size, and extend product lifecycles through the adoption of advanced motor technologies, such as highly durable brushless DC motors. Competitive advantage is increasingly determined by the ability to offer comprehensive installation support and solutions that simplify integration into complex, multi-vendor Building Automation Systems (BAS), thereby accelerating project timelines and reducing commissioning costs for end-users.

Regional trends highlight the Asia Pacific (APAC) region as the epicenter of future market growth, propelled by unprecedented levels of commercial real estate development and substantial government spending on modern infrastructure projects, particularly in rapidly urbanizing economies like India and China. While the mature markets of North America and Europe maintain a high revenue contribution due to established regulatory mandates emphasizing energy efficiency and safety retrofitting, APAC is experiencing the highest year-over-year adoption rates for new actuator installations. This regional acceleration is compounded by a growing middle class that demands higher standards of indoor comfort and air quality, stimulating demand for precision-controlled HVAC systems. The regulatory frameworks in the West continue to enforce high standards, particularly for spring-return fire and smoke actuators, sustaining a robust replacement and upgrade cycle in those territories.

Segmentation analysis reveals that the HVAC application segment remains the foundational revenue driver, though the fastest growth is observed in the modulating actuator category, which supports the variable flow requirements of VAV systems crucial for optimal energy performance. The torque segment analysis indicates a sustained demand across all ranges, but technological advancements are allowing smaller, more power-dense units to handle tasks previously reserved for larger, high-torque devices. End-user trends show that commercial and institutional buildings, including healthcare and educational facilities, are the primary consumers, driven by non-negotiable requirements for operational reliability and stringent compliance with environmental control standards. The industrial sector, while smaller in volume, demands highly specialized, rugged actuators capable of withstanding extreme environmental conditions, representing a high-value niche segment within the overall market structure.

AI Impact Analysis on Damper Actuators Market

User queries regarding AI's influence on the Damper Actuators market overwhelmingly focus on the transition from reactive maintenance paradigms to proactive, predictive control mechanisms. Common inquiries center on how machine learning (ML) algorithms can utilize the operational data generated by networked actuators to forecast mechanical wear, thus preventing catastrophic system failures and the associated financial loss. Users are intensely interested in quantifying the energy savings achieved when AI dynamically adjusts damper positions based on predictive models incorporating factors like anticipated occupancy changes, external temperature fluctuations, and real-time localized pollution data. Key concerns remain about the data security framework required to protect proprietary building performance data and the necessary computational infrastructure needed to run real-time AI control loops within a BAS environment, highlighting a demand for integrated, secure, edge-computing solutions paired directly with actuator systems.

The operational integration of artificial intelligence with damper actuators is poised to revolutionize HVAC performance by moving beyond simplistic, rule-based control logic. AI platforms analyze complex patterns and correlations across thousands of data points—from actuator motor current draws to damper travel time and ambient air quality measurements—to establish a comprehensive baseline performance profile. When real-time data deviates marginally from this optimal baseline, AI can trigger sophisticated fault detection and diagnostics (FDD) alerts, identifying potential issues such as sticking dampers, failing motors, or calibration drift long before the issue causes a noticeable drop in comfort or a system breakdown. This highly granular level of insight drastically improves system resilience, ensuring continuous compliance with critical environmental specifications, especially in sensitive laboratory or manufacturing settings.

Furthermore, AI-driven optimization allows for the creation of truly autonomous building environments where actuators adjust dynamically without constant human oversight. For instance, ML models can learn building thermal dynamics over seasonal cycles, optimizing the starting and stopping times of AHUs and precisely modulating external air intake dampers to minimize heating or cooling load requirements, thereby maximizing efficiency. This sophisticated coordination between AI and smart actuators reduces overall energy consumption by ensuring that energy is expended only when and where it is absolutely necessary, aligning perfectly with global sustainability targets. The capability for self-learning and continuous optimization transforms the actuator from a simple mechanical device into an intelligent endpoint of the building automation network.

- AI enables sophisticated predictive maintenance by analyzing motor performance and operational cycle data, drastically reducing unexpected actuator failures.

- Machine learning algorithms optimize damper positioning based on forecasting external weather, occupancy levels, and internal thermal loads, achieving peak energy efficiency.

- Autonomous control systems utilize AI to dynamically adjust air volume and quality settings in real time, enhancing IAQ compliance and occupant comfort.

- Integration requires robust cybersecurity protocols to protect networked actuators and sensitive building operation data from external threats.

- AI-driven FDD capabilities significantly streamline maintenance by identifying minor anomalies before they escalate into major faults.

DRO & Impact Forces Of Damper Actuators Market

The sustained growth of the Damper Actuators Market is fundamentally propelled by powerful drivers centered on energy conservation and mandatory regulatory compliance. The global increase in construction of LEED-certified or equivalent green buildings necessitates the installation of high-precision, modulating damper actuators that are essential for minimizing energy waste by accurately controlling air distribution in VAV and zone control systems. Compounding this is the acceleration of smart city initiatives worldwide, which demand networked, digital components capable of integrating into centralized energy management platforms, providing real-time data necessary for facility optimization. Additionally, the replacement cycle in developed economies is a significant driver, as thousands of existing commercial buildings are upgrading archaic, maintenance-intensive pneumatic actuators to modern, reliable electronic digital systems to enhance operational efficiency and reduce long-term labor costs associated with calibration and repair.

Despite strong market drivers, several restraints pose challenges to widespread adoption. Chief among these is the notably higher initial capital cost associated with advanced electronic, network-enabled actuators compared to basic mechanical or older pneumatic alternatives. This financial barrier often delays or prevents implementation in small-to-mid-sized facilities or budget-constrained public sector projects. Furthermore, the specialized nature of modern digital actuators requires highly trained personnel for proper installation, commissioning, and system integration; a lack of qualified technicians in certain regional markets can complicate deployment and hinder market penetration. Complexity also arises from interoperability issues between different vendors' communication protocols, often requiring specialized gateways or custom integration solutions which increase project overhead and deployment risk.

The market is rich with opportunities, most prominently through the profound integration potential offered by the Internet of Things (IoT) and artificial intelligence. Developing actuators as intelligent endpoints that offer edge computing capabilities and transmit rich data streams opens doors for new service models centered around predictive maintenance and operational optimization as a service (OaaS). Secondly, there is substantial untapped potential for diversification beyond traditional HVAC applications; actuators are increasingly demanded in specialized industrial environments, such including high-purity air control in semiconductor manufacturing, toxic gas abatement in chemical processing, and precise flue gas management in power generation facilities. These non-HVAC industrial applications require customized, high-reliability products, offering manufacturers attractive high-margin niches for specialized product development.

The market is significantly shaped by several crucial impact forces. The Technological Advancement force continually pushes innovation, leading to actuators with higher torque density, faster response times, and greatly reduced power draw through the use of advanced motor and gear train design. The Regulatory Push force is highly influential, as continuous tightening of fire and safety codes necessitates the mandatory installation of robust, tested, and certified spring-return actuators in all public buildings, creating a constant baseline demand. Finally, the growing global focus on public health and Indoor Air Quality (IAQ), especially following global health crises, mandates precise ventilation and differential pressure control, cementing the damper actuator’s role as a critical component in public health infrastructure and ensuring its sustained relevance and market expansion.

Segmentation Analysis

The Damper Actuators Market is segmented based on several technical and application-specific parameters to accurately reflect the varied demands across the building automation and industrial sectors. This segmentation facilitates a deeper understanding of where technological investment and market growth are concentrated, whether in the volume-driven commercial HVAC sector or the high-reliability industrial niche. The primary product differentiation lies between rotary and linear actuation mechanisms, each catering to specific damper types and operational requirements—rotary actuators for common butterfly or blade dampers, and linear actuators typically employed for globe valves or large-scale multi-blade dampers requiring powerful thrust.

The Application segmentation underscores the dominance of the HVAC sector, which drives the majority of unit volumes for climate control, while the specialized Fire and Smoke Safety segment drives demand for higher-cost, high-reliability spring-return models. Furthermore, the segmentation by Communication Protocol is becoming increasingly relevant, distinguishing between older analog control signals (e.g., 0-10V or 4-20mA) and modern digital networking capabilities (BACnet, Modbus). This distinction is vital for future-proofing installations and integrating actuators into complex, data-rich Building Automation Systems, directly correlating the communication standard with the level of data fidelity and system responsiveness achievable.

Segmentation by Torque (measured in Newton meters, Nm) is critical as it dictates the actuator's physical capability to move and hold the damper position, especially against high air pressure differentials or in the case of heavy industrial dampers. Commercial VAV systems often require lower torque (less than 10 Nm), whereas large air handling units or heavy industrial blast dampers may demand torque exceeding 25 Nm. The End-Use segmentation confirms that Commercial Buildings, encompassing offices, healthcare facilities, and retail complexes, represent the largest consumer base, due to the sheer volume of controlled air zones required in such large facilities, emphasizing the market's dependence on sustainable urban development and commercial real estate investment cycles.

- By Product Type: Rotary Damper Actuators, Linear Damper Actuators.

- By Application: Heating Ventilation and Air Conditioning (HVAC), Industrial Process Control, Fire and Smoke Safety Systems.

- By Torque: Less than 10 Nm, 10 Nm to 25 Nm, More than 25 Nm.

- By End-Use: Commercial Buildings (Offices, Retail, Healthcare), Residential Buildings (Single Family, Multi-Family), Industrial Facilities (Manufacturing, Power Generation).

- By Communication Protocol: Analog (0-10V, 4-20mA), Digital (BACnet, Modbus, LonWorks, KNX).

Value Chain Analysis For Damper Actuators Market

The value chain for the Damper Actuators Market commences with the highly specialized upstream procurement of materials and electronic components. This phase involves sourcing precision-machined metals (aluminum, brass, high-grade plastics) for robust actuator housing and high-tolerance gearing mechanisms, alongside crucial electronic components such as microcontrollers, memory chips, communication interfaces, and efficient motors, notably BLDC types. Managing the complexities of the global semiconductor supply chain is paramount for manufacturers, as the intelligence and connectivity features of modern actuators are highly dependent on reliable access to microprocessors and specialized sensor technology. Efficiency in this upstream segment is gained through strategic long-term agreements with component suppliers and rigorous quality control to ensure component durability, which directly translates to the actuator's long operational lifespan.

Mid-stream activities focus on precision manufacturing, assembly, calibration, and quality assurance. Leading actuator manufacturers invest heavily in automated assembly lines and advanced testing facilities to ensure gear train accuracy, torque consistency, and flawless communication functionality. A critical step involves integrating the actuator with firmware and software that supports digital communication protocols (e.g., BACnet stack), which is often proprietary and serves as a key differentiator in the market. Manufacturers must also comply with numerous international standards and certifications (UL, CE, etc.), particularly for spring-return fire and smoke actuators, adding regulatory complexity to the manufacturing process. Value addition here is achieved through scalable production, rigorous testing, and continuous optimization of the manufacturing process to reduce per-unit cost.

The downstream segment is primarily defined by intricate distribution channels and specialized installation services. Distribution flows through both direct and indirect paths. Direct sales usually target large HVAC Original Equipment Manufacturers (OEMs) who integrate actuators into their air handling units and VAV boxes, and specialized industrial clients requiring custom solutions. Indirect channels, which dominate the retrofit and general commercial markets, rely on a network of electrical wholesalers, specialized HVAC distributors, and, most critically, system integrators. System integrators play an essential role, serving as the technical interface between the product and the final Building Automation System, responsible for programming, commissioning, and ensuring interoperability. Effective channel management, including providing excellent technical training and localized support to integrators, is key to market success, given that the installation quality significantly impacts the actuator’s perceived performance and reliability.

Damper Actuators Market Potential Customers

Potential customers for Damper Actuators span a wide spectrum of the infrastructure landscape, with the largest volume consumers residing in the commercial and institutional construction sectors. These include major Mechanical, Electrical, and Plumbing (MEP) contractors who execute new construction projects, requiring large quantities of actuators for air handling unit installations and duct system zoning. A second crucial customer group comprises Facility Management (FM) organizations and building owners (e.g., REITs, corporate real estate departments) who initiate and fund retrofit projects aimed at improving energy efficiency, reducing operational costs, and modernizing aging HVAC systems. For these commercial end-users, the purchasing decision is heavily influenced by the actuator's Total Cost of Ownership (TCO), focusing on reliability, warranty coverage, and compatibility with proprietary or open-source BAS platforms, prioritizing long-term value over initial cost savings.

Another significant, distinct customer segment involves Original Equipment Manufacturers (OEMs) of various air distribution products. This includes manufacturers of Variable Air Volume (VAV) terminals, fan coil units, and specialized laboratory ventilation hoods. OEMs represent high-volume, repetitive customers who seek standardized, robust actuators at competitive pricing, often requiring actuators that meet precise dimensional and communication specifications for integration into their standardized product lines. Their requirement is less about bespoke solutions and more about consistent quality, high inventory availability, and ease of mass integration, often leading to deep supply partnership arrangements with major actuator vendors to ensure stable production flows.

Finally, the industrial sector constitutes a high-value niche market of customers including power generation utilities, petrochemical plants, and large-scale manufacturing facilities. These customers require actuators capable of handling extremely harsh operating conditions—high temperatures, corrosive environments, or potentially explosive atmospheres—demanding specialized, heavy-duty linear or rotary actuators with specific industrial certifications (e.g., NEMA ratings, explosion-proof classifications). Procurement in this sector is driven by strict safety and regulatory compliance, where reliability is the foremost purchasing criterion, significantly superseding cost considerations. This segment often involves direct consultation with manufacturers for customized product design and specialized service support throughout the actuator’s lifespan.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.95 Billion |

| Market Forecast in 2033 | USD 3.07 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Belimo, Honeywell, Siemens, Johnson Controls, Schneider Electric, Danfoss, Dwyer Instruments, Rotork, ABB, KMC Controls, Neptronic, Continental Control Systems, Watts Water Technologies, E+E Elektronik, Greystone Energy Systems, Selmo, ACI Controls, Thermokon Sensortechnik, Beckhoff Automation, Eldon |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Damper Actuators Market Key Technology Landscape

The technological landscape of the Damper Actuators Market is defined by continuous evolution towards higher intelligence, greater connectivity, and superior energy performance. A foundational shift is the pervasive adoption of sophisticated electronic components, transforming actuators into intelligent network nodes rather than simple mechanical positioning devices. Key innovations center on Brushless DC (BLDC) motor technology, which delivers substantially higher energy efficiency, reduced audible noise, and significantly extended operational life compared to older AC synchronous motors, directly addressing end-user demands for sustainability and reliability. Accompanying this is the trend toward extreme miniaturization, enabling manufacturers to achieve high torque ratings within compact footprints, crucial for installation flexibility within confined HVAC infrastructure.

Connectivity and digital communication are paramount technological drivers. The transition from basic analog control signals (like 0-10V) to robust digital bus communication protocols, primarily BACnet MS/TP and BACnet IP, is nearly complete in new commercial constructions. This digital foundation enables actuators to transmit a wealth of diagnostic and status information—such as running hours, power consumption, and error codes—back to the central Building Management System (BMS), facilitating advanced predictive maintenance and condition monitoring. Furthermore, advanced features like Near Field Communication (NFC) and integrated Bluetooth are increasingly utilized to simplify the commissioning process, allowing technicians to program and troubleshoot actuators quickly and wirelessly using mobile devices, drastically cutting down on installation time and labor costs.

In addition to enhanced connectivity, sensor fusion is rapidly changing the actuator's functionality. Modern high-end actuators often incorporate integrated position feedback mechanisms, ensuring precise modulation accuracy crucial for VAV systems. The frontier of technological advancement involves integrating local environmental sensors directly into the actuator housing or immediate vicinity. This allows the actuator to make highly localized control decisions based on duct-level temperature, humidity, or CO2 measurements, supplementing global control inputs from room sensors. This distributed intelligence enables faster reaction times to environmental changes and finer optimization of air flow, crucial for maintaining optimal indoor air quality (IAQ) and achieving the maximum possible energy savings in modern, highly sealed building envelopes. Technological competition is heavily focused on secure data transmission and interoperability between various generations of protocols.

Regional Highlights

- North America: This region represents a mature and highly regulated market, dominated by the United States and Canada, where demand is strongly driven by rigorous energy codes (ASHRAE, California Title 24) and the widespread adoption of comprehensive Building Automation Systems (BAS). The emphasis here is on premium products, advanced digital communication capabilities (BACnet IP), and a massive ongoing retrofitting cycle to replace legacy pneumatic systems with high-efficiency electronic actuators. The commercial and healthcare sectors are particularly strong drivers, necessitating fail-safe and high-reliability actuators for critical applications.

- Europe: Characterized by stringent environmental policies, such as the Energy Performance of Buildings Directive (EPBD), Europe maintains a high demand for energy-efficient, modulating actuators. Germany, the UK, and France are key markets focusing on both new smart building construction and the renovation of aging commercial infrastructure. The market prioritizes quality, certified products (CE, VDE), and strong adherence to safety standards, resulting in high uptake of specialized fire and smoke safety actuators.

- Asia Pacific (APAC): The APAC region exhibits the fastest growth trajectory globally, fueled by rapid urbanization and large-scale public and private investments in infrastructure, particularly in China, India, and Southeast Asia. While cost competition is intense, the sheer volume of new commercial, educational, and hospitality construction projects ensures robust demand. There is a noticeable trend towards adopting digital control systems, though analog remains prevalent in cost-sensitive segments. Growing awareness of IAQ and energy management is quickly accelerating the adoption of mid-to-high-range intelligent actuators.

- Middle East and Africa (MEA): Growth in the MEA region, particularly the Gulf Cooperation Council (GCC) states, is highly correlated with mega-project development in the commercial and hospitality sectors, driven by extreme climatic conditions that require powerful, reliable HVAC systems. This necessitates high-torque actuators and resilient components capable of handling constant high operational loads. Africa remains an emerging market, with growth concentrated in commercial hubs and resource extraction industries.

- Latin America: This region is characterized by steady, moderate growth, driven by gradual modernization of commercial infrastructure and increasing foreign investment. Key markets like Brazil and Mexico are slowly increasing the adoption of advanced building automation technologies, moving towards electronic actuators to realize long-term operational savings, though the market is often influenced by economic volatility and reliance on imported technology.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Damper Actuators Market.- Belimo

- Honeywell

- Siemens

- Johnson Controls

- Schneider Electric

- Danfoss

- Dwyer Instruments

- Rotork

- ABB

- KMC Controls

- Neptronic

- Continental Control Systems

- Watts Water Technologies

- E+E Elektronik

- Greystone Energy Systems

- Selmo

- ACI Controls

- Thermokon Sensortechnik

- Beckhoff Automation

- Eldon

Frequently Asked Questions

Analyze common user questions about the Damper Actuators market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a damper actuator in an HVAC system?

The primary function of a damper actuator is to mechanically move and position a damper blade—either continuously (modulating) or fully open/closed—to regulate the flow of conditioned or unconditioned air within ductwork, crucial for maintaining zone temperature, pressure equalization, and ensuring overall system energy efficiency.

What is the difference between spring-return and non-spring-return actuators?

Spring-return actuators incorporate an internal spring that drives the damper to a default fail-safe position (typically open or closed) upon loss of power, making them mandatory for critical fire and smoke safety applications. Non-spring-return actuators rely solely on electrical power for positioning and are typically used in non-safety-critical environmental control applications.

Which communication protocols are dominating the smart damper actuator market?

Digital communication protocols, particularly BACnet (Building Automation and Control Networks) and Modbus, are dominating the market. These protocols allow for two-way communication, enabling actuators to transmit detailed diagnostic data and receive precise, complex control signals from Building Management Systems (BMS).

How is the integration of IoT impacting the operational lifespan of damper actuators?

IoT integration allows damper actuators to participate in predictive maintenance routines. By continuously monitoring performance metrics like torque applied, runtime hours, and deviation from optimal position, potential mechanical failures can be flagged by AI systems, allowing for proactive servicing and significantly extending the effective operational lifespan of the components.

What torque range is most commonly used in commercial HVAC VAV applications?

In standard commercial Variable Air Volume (VAV) box and smaller zone control applications, damper actuators typically utilize a low-to-medium torque range, generally falling into the Less than 10 Nm or 10 Nm to 25 Nm category, offering the necessary responsiveness and precision for modulation control in small to mid-sized air ducts.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- HVAC Damper Actuators Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Damper Actuators Market Size Report By Type (Pneumatic type, Electric type, Others), By Application (Residential, Commercial, Public Utilities, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Electric Damper Actuators Market Statistics 2025 Analysis By Application (Commercial Building, Industrial Facilities, Public Utilities, Others), By Type (Spring Return Damper Actuators, Non-Spring Return Damper Actuators), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Pneumatic Damper Actuators Market Statistics 2025 Analysis By Application (Commercial Building, Industrial Facilities, Public Utilities, Others), By Type (Spring Return Damper Actuators, Non-Spring Return Damper Actuators), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- HVAC Damper Actuators Market Statistics 2025 Analysis By Application (Commercial Building, Industrial Facilities, Public Utilities), By Type (Spring Return Damper Actuators, Non-Spring Return Damper Actuators), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager