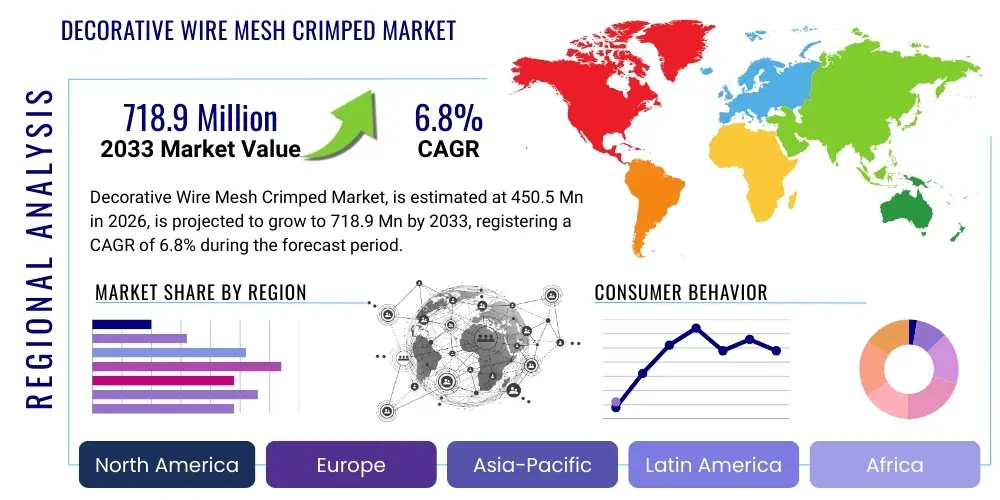

Decorative Wire Mesh Crimped Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442977 | Date : Feb, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Decorative Wire Mesh Crimped Market Size

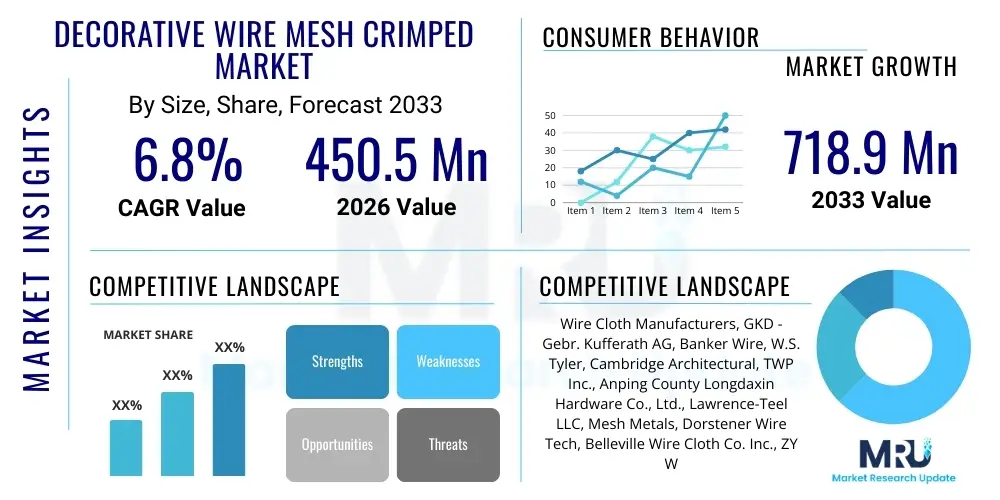

The Decorative Wire Mesh Crimped Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 718.9 Million by the end of the forecast period in 2033. This consistent growth trajectory is fundamentally supported by the global renaissance in high-end architectural design and the increasing requirement for aesthetically pleasing, yet durable, building materials that offer both visual appeal and functional benefits such as light filtration and ventilation.

The valuation reflects robust demand stemming from the commercial and high-end residential construction sectors, particularly for facade systems, interior partitioning, and acoustic ceilings. Investment in urban infrastructure revitalization projects, especially in developed economies seeking sustainable and long-lasting material solutions, further underpins the market expansion. Furthermore, the rising popularity of industrial-chic and modern minimalist design aesthetics directly translates to increased specification of crimped wire mesh products by architects and interior designers globally.

Decorative Wire Mesh Crimped Market introduction

The Decorative Wire Mesh Crimped Market encompasses the manufacturing, distribution, and installation of woven metal fabrics where the wires (warp and weft) are crimped or pre-bent prior to the weaving process. This crimping technique ensures rigid structure, durability, precise aperture sizing, and creates distinctive aesthetic textures that are highly valued in architectural and design applications. These meshes are typically fabricated from corrosion-resistant materials such as stainless steel (304, 316 grades), copper, brass, and aluminum alloys, offering long life cycles and minimal maintenance requirements. They serve a dual purpose: providing necessary functionality like security, safety, and shading, while significantly enhancing the visual complexity and sophistication of interior and exterior spaces. Key applications range from architectural facades and cladding to interior dividers, elevator cabin screens, balustrades, sunscreens, and retail displays, driving consistent demand across global construction, design, and manufacturing industries.

The fundamental benefits driving the adoption of decorative crimped mesh include unparalleled design flexibility, superior ventilation properties, effective light diffusion without compromising visibility, and inherent resistance to harsh environmental conditions. Driving factors for market growth include the escalating global focus on sustainable building practices requiring durable, recyclable materials, increasing disposable income in emerging economies fueling premium residential and commercial construction, and technological advancements in weaving machinery enabling the production of highly customized and complex crimp patterns. Architects are increasingly utilizing these materials to achieve unique visual effects, leveraging the interplay of light and shadow on the metallic surfaces, further solidifying the material’s position as a premium decorative element in modern architecture.

Decorative Wire Mesh Crimped Market Executive Summary

The Decorative Wire Mesh Crimped Market exhibits significant momentum characterized by expanding application diversity and increasing material sophistication. Business trends indicate a shift towards customization and integrated solutions, where manufacturers are offering complete design-to-installation services, addressing specific project requirements related to large-format architectural screens and complex interior systems. Innovation in surface treatments, including PVD coatings and specialized anodization, is allowing for a broader color palette and enhanced material longevity, catering to high-end luxury segments. Strategic partnerships between mesh manufacturers and leading architectural firms are becoming pivotal, ensuring product development aligns with future aesthetic and functional demands of the construction industry, thus securing a competitive edge in mature markets.

Regional trends highlight North America and Europe as established centers of high-value consumption, driven by stringent building codes favoring durable materials and a strong legacy of contemporary architectural design. However, the Asia Pacific (APAC) region is forecasted to display the highest growth rate, fueled by rapid urbanization, massive infrastructure projects in countries like China and India, and the rising adoption of international design standards in commercial real estate development. Segment trends show that stainless steel remains the material of choice due to its robustness and corrosion resistance, while the Interior Design application segment, particularly for acoustic dampening and space separation, is demonstrating accelerated uptake, outpacing purely exterior facade applications in terms of volume growth.

AI Impact Analysis on Decorative Wire Mesh Crimped Market

User inquiries regarding AI's impact on the Decorative Wire Mesh Crimped Market primarily revolve around three core themes: optimizing manufacturing efficiency, facilitating complex design parametrization, and enhancing predictive maintenance of large-scale mesh installations (such as dynamic facades). Users frequently question how AI can manage the complexity of bespoke crimp specifications, reduce material waste in cutting and shaping processes, and integrate mesh design with Building Information Modeling (BIM) systems. There is a palpable expectation that AI and machine learning will lead to hyper-customization at mass production scales, effectively democratizing access to highly complex, specialized mesh patterns that were previously prohibitively expensive or time-consuming to produce, thereby accelerating innovation in material application and architectural expression.

The influence of artificial intelligence is transforming the operational landscape of crimped mesh manufacturing from raw material inventory management through to quality assurance. AI-driven vision systems are increasingly deployed to detect minute flaws in woven patterns and consistency of crimp depth, ensuring products meet stringent aesthetic and structural specifications before leaving the factory floor. Furthermore, predictive algorithms are being utilized to optimize machine settings based on material properties (e.g., wire gauge, alloy composition) and desired output geometry, drastically reducing setup time and minimizing machine downtime. This integration of smart manufacturing principles allows producers to handle a greater variety of customized orders efficiently, addressing the market's growing demand for unique, project-specific solutions and leading to improved profitability margins for specialized producers.

Beyond manufacturing, AI significantly contributes to the design phase. Generative design tools powered by AI allow architects to input functional constraints—such as required daylighting levels, acoustic performance, and wind load resistance—and rapidly generate optimal mesh patterns and installation geometries that satisfy all parameters simultaneously. This algorithmic approach dramatically shortens the design cycle for complex architectural elements like responsive facades or unique interior partitions. Furthermore, in large infrastructure projects, AI analytics are being applied to sensor data collected from mesh installations to predict potential material fatigue or structural issues, facilitating proactive maintenance schedules and extending the service life of high-value architectural installations, offering superior long-term value to end-users and asset managers.

- AI-Optimized Production: Machine learning models enhance weaving loom precision and speed, minimizing material waste.

- Generative Design Integration: AI tools create complex, bespoke crimp patterns based on performance criteria (e.g., shading, acoustic).

- Predictive Quality Control: Automated visual inspection systems utilizing AI detect weave inconsistencies and defects with high accuracy.

- Supply Chain Efficiency: AI algorithms optimize raw material sourcing and inventory management for specialty metals.

- BIM Integration: Seamless incorporation of complex mesh geometry and performance data into digital construction workflows.

DRO & Impact Forces Of Decorative Wire Mesh Crimped Market

The Decorative Wire Mesh Crimped Market is propelled by robust Drivers (D) such as the increasing global emphasis on aesthetic architecture and sustainable building materials, which favor the long lifespan and recyclability of metal mesh products. Restraints (R) primarily include the high initial cost of specialized metal alloys and complex manufacturing equipment, which can deter smaller construction projects, alongside volatility in raw material prices (e.g., stainless steel, copper). Opportunities (O) emerge from technological advancements in coatings and surface treatments, enabling new applications in corrosive environments, and expansion into high-growth markets like the Middle East and Southeast Asia. The resultant Impact Forces are significantly positive, driven by the architectural design community's growing acceptance of these materials as essential elements for modern, high-performance building envelopes, offsetting cost concerns with superior longevity and design flexibility.

Key drivers include regulatory mandates promoting green building standards, especially in Europe and North America, which prioritize materials with high recycled content and low maintenance requirements, attributes intrinsic to metal mesh. Furthermore, the rising trend in urban revitalization and retrofitting existing structures mandates lightweight, adaptable cladding solutions that crimped mesh provides effectively. However, the market faces constraints related to the specialized nature of installation, often requiring highly skilled labor, which contributes to overall project complexity and cost. The perception of crimped mesh as a premium product also limits its penetration in value-focused construction segments, posing a continuous challenge that manufacturers attempt to mitigate through material substitutions and optimization of manufacturing processes.

The greatest growth opportunities lie in the integration of crimped mesh with smart building technologies, such as responsive facades that adjust permeability based on solar exposure. There is also a significant potential for market expansion in non-traditional construction applications, including specialized automotive interior design and high-security infrastructure where aesthetics are also critical. The overall impact forces suggest sustained growth, driven by innovation in product functionality (e.g., acoustic absorption properties) and design versatility, making crimped mesh an indispensable material for architects looking to achieve unique visual identities and meet contemporary performance requirements.

Segmentation Analysis

The Decorative Wire Mesh Crimped Market is meticulously segmented across key dimensions including Material Type, Application, End-User, and Crimp Pattern, each providing distinct value propositions tailored to specific industry needs. Understanding these segmentation layers is crucial for stakeholders to identify niche opportunities and formulate effective market penetration strategies. The segmentation highlights the dominance of stainless steel due to its balance of cost, durability, and aesthetic versatility, while specialized alloys like copper and brass command higher prices in luxury and bespoke projects requiring specific color and patina characteristics. Application segmentation clearly delineates the high-volume demand from Architectural Facades versus the rapidly expanding demand from Interior Design elements such as space dividers and custom furnishings.

Further analysis of the Crimp Pattern segment reveals a trend towards complexity, moving beyond simple intermediate and plain crimp structures to intricate patterns like lock crimp and flat top, which offer enhanced structural rigidity and unique light refraction properties. End-User analysis confirms the Commercial sector (including corporate offices, retail complexes, and hospitality) as the primary consumer, driven by the need for high-impact, durable public-facing aesthetics. Residential consumption, while smaller in volume, accounts for high-value custom installations. This multi-layered segmentation underscores the market's maturity and its ability to cater to a broad spectrum of project scales and budgetary requirements, ranging from standardized mesh panels for general construction to highly customized, artistic installations.

- Material Type:

- Stainless Steel (304, 316, 316L)

- Copper and Brass

- Aluminum Alloys

- Other Exotic Alloys (e.g., Bronze, Titanium)

- Application:

- Architectural Facades and Cladding

- Interior Partitioning and Space Dividers

- Balustrades and Railings

- Acoustic Ceilings and Sound Dampening

- Sun Screening and Shading Systems

- Display and Retail Shelving

- Elevator Cabin Screens

- Crimp Pattern:

- Plain Weave

- Intermediate Crimped

- Lock Crimped

- Flat Top Crimped

- Custom/Specialty Crimped

- End-User:

- Commercial (Offices, Retail, Hospitality)

- Residential (High-End Custom Homes)

- Public Infrastructure (Museums, Airports, Transit Stations)

- Industrial and Manufacturing Facilities

Value Chain Analysis For Decorative Wire Mesh Crimped Market

The value chain for the Decorative Wire Mesh Crimped Market begins with upstream activities centered on the procurement and processing of specialty metals, primarily high-grade stainless steel wire rods and copper/brass ingots. This stage is characterized by intense price sensitivity dictated by global commodity markets and requires specialized metallurgical expertise to draw and anneal wires to the exact gauge and tensile strength required for precision weaving. Key upstream challenges include maintaining consistent quality and managing supply chain resilience against geopolitical instability impacting metal supply. Success at this stage relies heavily on establishing long-term contracts with reputable metal suppliers who can guarantee material purity and consistency, directly impacting the aesthetic finish and structural integrity of the final crimped mesh product. Manufacturers often employ hedging strategies to mitigate commodity price volatility, ensuring stable production costs and reliable pricing for downstream partners.

The manufacturing and processing stage, representing the core of the value chain, involves specialized machinery for wire crimping and automated weaving. Direct channels focus on large, customized architectural projects where the mesh manufacturer works closely with the architect and façade contractor from the design phase through to installation, offering highly personalized service and technical consultation. Indirect distribution involves leveraging established networks of building material distributors, specialized metal fabricators, and interior design suppliers, particularly for standardized mesh panels used in smaller commercial and residential projects. Downstream activities involve professional installation and fabrication, often requiring collaboration with specialized metalworkers to cut, frame, and secure the heavy-duty mesh panels according to complex architectural specifications, emphasizing precision and adherence to strict safety standards, especially for exterior cladding applications.

Distribution channels are bifurcated between project-specific direct sales and standardized indirect sales. Direct channels are essential for maintaining quality control and technical assistance on complex, high-value installations, ensuring that custom patterns and structural requirements are met accurately. Indirect channels, through specialized metal distributors and interior furnishing suppliers, facilitate broader market reach for standard product lines, targeting smaller architectural firms and local fabrication shops. The efficiency of the downstream network, particularly the skill level of certified installers, directly impacts the reputation and subsequent adoption rate of these decorative materials in the competitive building and construction sector.

Decorative Wire Mesh Crimped Market Potential Customers

Potential customers for Decorative Wire Mesh Crimped products are primarily found within the commercial construction and high-end architectural design ecosystem, representing a diverse group of professional buyers focused on achieving specific aesthetic and functional objectives. Architectural firms and specialized facade engineers constitute the primary influencers and specifiers, selecting the appropriate material and crimp pattern during the early design phase of major projects such as corporate headquarters, luxury hotels, cultural centers, and large-scale retail complexes. These buyers prioritize product characteristics like durability, unique visual textures, compliance with fire safety and wind load standards, and the manufacturer’s capability for customized, large-format production. The increasing demand for signature architectural elements makes this demographic critical, requiring manufacturers to maintain extensive product libraries and provide in-depth technical specification support.

The second major group includes General Contractors and Construction Management firms, who act as the direct purchasers and installation coordinators. Their primary concerns revolve around lead times, budget adherence, ease of installation, and structural reliability. Manufacturers must ensure their products are delivered precisely to specification and on schedule, offering installation guidelines and logistical support for complex site conditions. A growing segment of customers includes interior design firms specializing in high-end residential and hospitality fit-outs, where crimped mesh is used for sophisticated interior applications such as feature walls, custom furniture screens, and bespoke lighting fixtures. These buyers value aesthetic range, material finish quality, and the ability to integrate mesh seamlessly with other luxury interior components, driving demand for polished and specialty-coated metal meshes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 718.9 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Wire Cloth Manufacturers, GKD - Gebr. Kufferath AG, Banker Wire, W.S. Tyler, Cambridge Architectural, TWP Inc., Anping County Longdaxin Hardware Co., Ltd., Lawrence-Teel LLC, Mesh Metals, Dorstener Wire Tech, Belleville Wire Cloth Co. Inc., ZY Wire Mesh Products, Dongfu Wire Mesh, Marco Specialty Steel, Metal Mesh, Mcnichols Co., IKG, P&F Manufacturing, MetalDek Group, and Accurate Perforating. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Decorative Wire Mesh Crimped Market Key Technology Landscape

The technological landscape of the Decorative Wire Mesh Crimped Market is defined by the integration of advanced manufacturing techniques designed to enhance precision, material performance, and aesthetic versatility. Key technological advancements center on automated high-speed weaving looms equipped with computer numerical control (CNC) systems. These systems allow for highly precise control over the crimping depth, pitch, and pattern repeatability, which is essential for producing large panels that must align perfectly across vast architectural facades. Innovations in wire drawing technology enable the production of specialized, highly durable wires with precise diameters and customized surface finishes, significantly influencing the visual effect and longevity of the final mesh product. Furthermore, the adoption of specialized welding and tensioning technologies is crucial for manufacturing framed mesh panels used in architectural applications, ensuring they maintain optimal flatness and structural integrity under dynamic environmental loads.

Surface treatment technology represents another critical area of innovation. Manufacturers are increasingly utilizing advanced coating techniques, such as Physical Vapor Deposition (PVD), electroplating, and specialized powder coating, to apply decorative and protective finishes to the mesh. PVD coatings, in particular, offer superior durability, resistance to UV radiation and corrosion, and allow for a wider spectrum of metallic and non-metallic colors, meeting the complex aesthetic demands of modern architects. The development of self-cleaning or photocatalytic coatings is also gaining traction, particularly for exterior mesh cladding in heavily polluted urban environments, minimizing maintenance costs and enhancing the sustainability profile of the installation.

Furthermore, digital technologies, especially 3D modeling and parametric design software, are profoundly influencing how crimped mesh is specified and fabricated. This technology allows for the precise simulation of light transmission, shading coefficients, and wind resistance properties before physical production, enabling architects to integrate the mesh design into complex building performance models. The ability to simulate the material's interaction with natural light—a crucial aesthetic consideration—through advanced rendering technology minimizes design errors and streamlines the production of highly customized geometries, further cementing the role of technology in achieving both functional and artistic objectives within the market.

Regional Highlights

The market dynamics of Decorative Wire Mesh Crimped materials are deeply interconnected with regional construction spending, architectural traditions, and adherence to sustainability mandates. North America, driven by the United States and Canada, holds a significant market share, characterized by a high demand for premium, stainless steel meshes in commercial high-rise construction and institutional projects. The region is highly focused on performance specifications, including anti-corrosion properties and fire resistance, driving innovation toward higher-grade materials (316L stainless steel) and complex installation systems. The prominence of leading architectural firms and a strong emphasis on design-build approaches contribute to the continuous high specification rates for customized, large-format decorative mesh panels, often integrating them into sophisticated, dynamic facade systems that respond to climate conditions and energy efficiency goals.

Europe represents a mature and highly innovative market, especially in Germany, the UK, and Scandinavian countries, driven by stringent European Union (EU) directives promoting circular economy principles and energy-efficient building design. The aesthetic preference in Europe leans towards sophisticated, minimalist designs, favoring materials like copper and bronze meshes for their natural patina and warm tones, particularly in historical restoration and high-end residential developments. European manufacturers often lead the way in sustainable production practices and the integration of mesh technology into BIPV (Building-Integrated Photovoltaics) systems, utilizing the mesh structure to simultaneously generate energy and provide shading. The strong regulatory environment necessitates detailed documentation of material sourcing and lifecycle assessment, pushing the market toward verifiable sustainability claims and certified products.

Asia Pacific (APAC) is projected to be the fastest-growing region, primarily fueled by massive infrastructure expansion, rapid urbanization, and a burgeoning luxury real estate sector in countries such as China, India, and Southeast Asian nations. While the market initially focused on cost-effectiveness, the increasing influx of international architecture and design standards is elevating the demand for high-quality, aesthetic crimped mesh, especially in major commercial hubs like Shanghai, Singapore, and Dubai (often included in APAC/MEA analyses). Investment in large public projects, including airport terminals and high-speed rail stations, provides substantial opportunities for large-volume mesh orders. The Middle East and Africa (MEA) region, particularly the Gulf Cooperation Council (GCC) countries, shows high growth potential driven by mega-projects that require visually striking, heat-resistant materials capable of performing reliably in extreme desert climates, thereby increasing demand for specialized aluminum and treated stainless steel meshes used for expansive solar shading and decorative screens.

- North America: Strong emphasis on high-performance materials (316L SS) and customized facade systems in commercial architecture.

- Europe: Focus on sustainability, circular economy compliance, high-end design, and BIPV integration in mature markets.

- Asia Pacific (APAC): Highest growth region driven by rapid urbanization, infrastructure development, and growing adoption of international aesthetic standards.

- Latin America: Emerging market with growing demand in commercial centers, influenced by economic stability and increasing foreign investment in construction.

- Middle East and Africa (MEA): High demand for specialized, durable meshes designed for extreme heat and UV exposure in mega-projects (e.g., hospitality and retail sectors).

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Decorative Wire Mesh Crimped Market.- GKD - Gebr. Kufferath AG

- Banker Wire

- Cambridge Architectural

- W.S. Tyler

- Wire Cloth Manufacturers, Inc.

- Mesh Metals

- Dorstener Wire Tech

- TWP Inc.

- McNichols Co.

- Belleville Wire Cloth Co. Inc.

- Marco Specialty Steel

- Accurate Perforating

- Metal Mesh

- P&F Manufacturing

- IKG

- Lawrence-Teel LLC

- Zhengzhou Baina Wire Mesh Co., Ltd.

- Anping County Longdaxin Hardware Co., Ltd.

- Dongfu Wire Mesh

- MetalDek Group

Frequently Asked Questions

Analyze common user questions about the Decorative Wire Mesh Crimped market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary material driving growth in the Decorative Wire Mesh Crimped Market?

Stainless steel, specifically grades 304 and 316, is the primary material driving market growth due to its superior corrosion resistance, high tensile strength, longevity, and aesthetic versatility, making it ideal for both exterior architectural facades and interior design elements.

How does the crimping process enhance the functionality of architectural mesh?

Crimping involves pre-bending the wire before weaving, which significantly enhances the structural rigidity, maintains precise and consistent aperture sizes, and creates distinctive textures, allowing the mesh to withstand high wind loads and maintain flatness when used in large facade installations.

Which application segment is expected to show the highest expansion rate?

The Interior Partitioning and Space Dividers segment is expected to show the highest expansion rate, driven by commercial office redesign trends favoring open-plan offices that require aesthetically pleasing, semi-transparent, and acoustically favorable materials for flexible space separation.

What are the key sustainability benefits associated with crimped wire mesh materials?

The key sustainability benefits include high recyclability (especially stainless steel), minimal maintenance requirements over a long lifecycle (often exceeding 50 years), and functional contributions to green buildings by reducing solar heat gain and improving natural ventilation.

How does raw material price volatility affect the market profitability?

Volatility in raw metal prices, particularly nickel and chromium used in stainless steel, directly impacts manufacturer profitability and pricing stability. Leading companies mitigate this risk through long-term supply contracts and effective commodity hedging strategies to ensure competitive pricing for large projects.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager