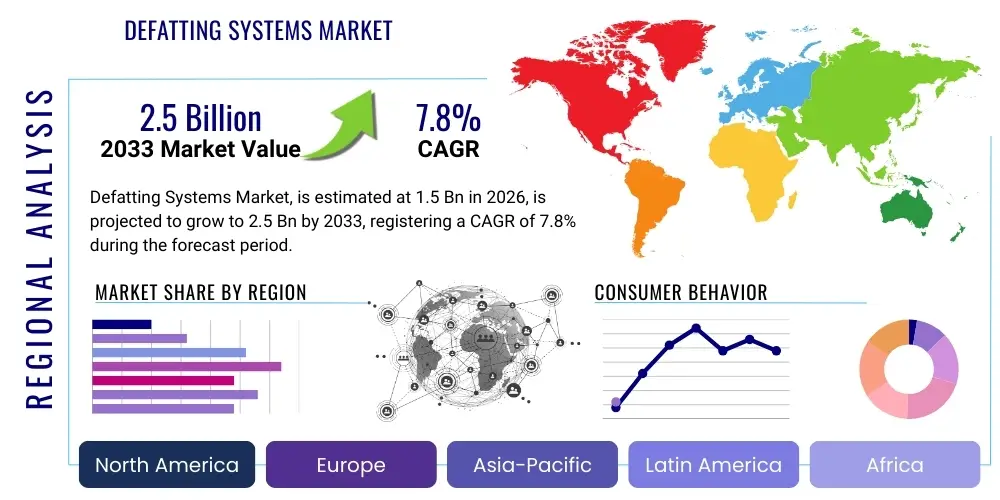

Defatting Systems Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442585 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Defatting Systems Market Size

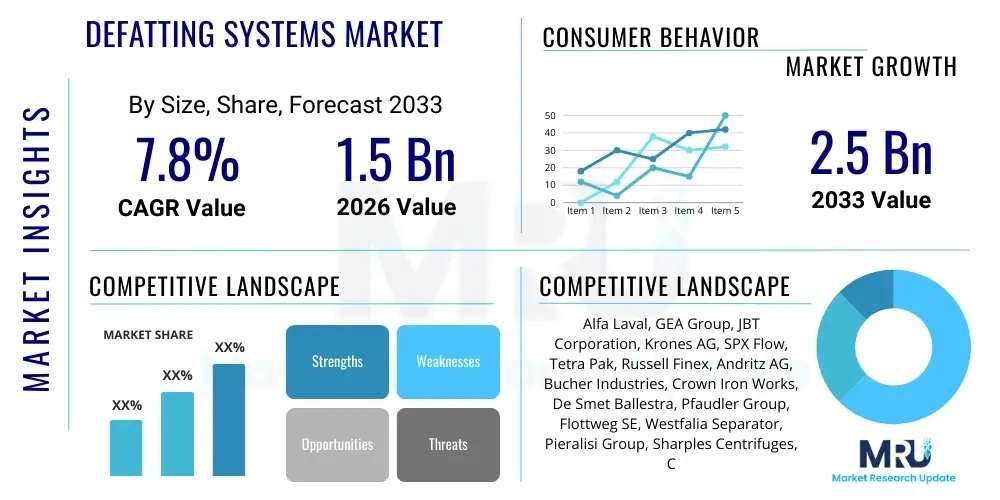

The Defatting Systems Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.5 Billion by the end of the forecast period in 2033.

Defatting Systems Market introduction

The Defatting Systems Market encompasses specialized industrial machinery and processing units designed to separate lipids (fats and oils) from solid or semi-solid materials, such as protein meals, rendering by-products, nuts, seeds, and various food ingredients. These systems are crucial in achieving desired material specifications, enhancing product shelf life, improving nutritional profiles, and preparing intermediate products for further processing in high-value industries. The core objective of defatting technology is to maximize the extraction efficiency of valuable oils while simultaneously lowering the residual fat content in the remaining solids, which often serve as high-protein animal feed or specialized food additives. Technological innovation in this domain focuses heavily on minimizing solvent use, improving energy efficiency, and ensuring the final product maintains high purity and functional integrity.

Major applications for defatting systems span across the global food and beverage industry, particularly in soy and palm oil processing, dairy substitutes, and specialized protein extraction. Beyond food, these systems are vital in the nutraceutical sector for extracting high-ppurity fatty acids and botanical oils, in cosmetics for natural ingredient preparation, and in the burgeoning biofuel industry where efficient lipid separation from algae or plant matter is paramount. The increasing global consumer demand for lower-fat food options and high-quality, plant-based proteins is fundamentally driving the adoption of sophisticated defatting solutions, pushing manufacturers toward more reliable and scalable continuous processing equipment. The systems range from traditional mechanical pressing (expellers) to advanced solvent extraction (hexane or ethanol based) and highly efficient, environmentally friendlier supercritical fluid extraction (SFE) methods.

The primary benefits derived from modern defatting systems include superior product yield, reduced operational costs through improved energy recovery, and compliance with stringent food safety and environmental regulations concerning residual solvents and waste disposal. Key driving factors accelerating market expansion include rapid urbanization leading to increased consumption of processed foods, the rising global focus on sustainable protein sources (such as insect protein and specialized defatted plant meals), and ongoing technological advancements, particularly in automated control and monitoring systems that optimize extraction parameters in real-time. Moreover, the expanding application scope within the pharmaceutical sector for lipid removal in drug encapsulation processes further solidifies the market’s growth trajectory, positioning defatting systems as indispensable assets in modern industrial biotechnology.

Defatting Systems Market Executive Summary

The Defatting Systems Market is poised for substantial expansion, underpinned by shifting global dietary preferences favoring lean protein sources and the escalating need for efficient resource utilization within the food and chemical processing industries. Business trends highlight a strong movement toward continuous processing systems, which offer superior throughput, reduced labor requirements, and enhanced product consistency compared to traditional batch systems. Furthermore, market players are increasingly investing in proprietary solvent recovery technologies and adopting sustainable extraction mediums, such as green solvents and CO2, to meet strict regulatory standards regarding air quality and environmental protection. Strategic partnerships focusing on integrating defatting equipment with downstream refining and finishing processes are becoming common, offering end-to-end solutions that maximize overall plant operational efficiency and minimize capital expenditure for end-users seeking turnkey installations.

Regional trends indicate that the Asia Pacific (APAC) region will dominate the market growth, primarily driven by the massive scale of soybean and oilseed processing operations in countries like China and India, coupled with rapid industrialization across Southeast Asia, necessitating high-capacity defatting infrastructure. North America and Europe, while mature markets, emphasize technological superiority, focusing investment on supercritical fluid extraction (SFE) systems for high-value applications such as nutraceuticals and pharmaceuticals, where precise control over extraction purity and absence of residual chemicals is paramount. The increasing regulatory pressure in these developed economies compels businesses to phase out older, less efficient solvent-based systems, fueling the demand for new, environmentally compliant machinery that meets stringent worker safety and environmental emission standards.

Segment trends reveal that the Solvent Extraction segment currently holds the largest market share due to its proven efficacy and cost-effectiveness in large-scale bulk processing, particularly for vegetable oils. However, the SFE technology segment is anticipated to register the highest CAGR, driven by its non-toxic, non-flammable nature and its suitability for extracting heat-sensitive, high-value components used in cosmetic and pharmaceutical formulations. In terms of application, the Food & Beverage sector remains the principal consumer, led by the surging demand for defatted protein powders and low-fat food ingredients globally. System type segmentation shows that continuous systems are rapidly gaining preference over batch systems across all major applications, owing to their ability to handle large volumes of raw material with greater operational predictability and lower per-unit processing cost, optimizing supply chain logistics.

AI Impact Analysis on Defatting Systems Market

User questions regarding AI's influence on the Defatting Systems Market often revolve around predictive maintenance, real-time yield optimization, and autonomous process control. Key concerns include how AI algorithms can improve the dynamic tuning of complex variables—such as pressure, temperature, solvent flow rate, and residence time—to maximize lipid separation efficiency while minimizing energy consumption and waste generation. Users are keen to understand if AI integration can drastically reduce downtime by forecasting equipment failure based on vibrational data and operational metrics (predictive maintenance). Furthermore, there is significant interest in using machine learning models to analyze raw material variations (e.g., moisture content, particle size) and automatically adjust system parameters, thus ensuring consistent, high-quality output regardless of feedstock variability, a critical factor in large-scale, high-throughput industrial operations. Users anticipate that AI will transition defatting processes from reactive monitoring to proactive, self-optimizing operations, leading to substantial cost savings and environmental benefits.

- AI-Powered Predictive Maintenance: Utilizing machine learning algorithms to analyze sensor data (vibration, temperature, pressure) and forecast potential equipment failures, significantly reducing unplanned downtime and maintenance costs.

- Real-Time Process Optimization: Deployment of neural networks to dynamically adjust extraction parameters (flow rate, temperature, solvent ratios) based on immediate feedback loops, maximizing extraction yield and minimizing energy consumption.

- Automated Quality Control: Employing computer vision and spectral analysis coupled with AI to assess the purity and residual fat content of both extracted oil and defatted meal instantaneously, ensuring strict adherence to quality specifications.

- Feedstock Variability Management: Machine learning models analyze incoming raw material composition (e.g., moisture, protein content) and automatically recalibrate the defatting system, ensuring consistent process performance despite fluctuations in material input.

- Energy Efficiency Optimization: AI algorithms identify and implement optimal operational schedules and load balancing strategies for pumps, heaters, and centrifuges, reducing the overall energy footprint of the defatting plant.

DRO & Impact Forces Of Defatting Systems Market

The Defatting Systems Market is significantly influenced by a confluence of accelerating drivers (D), formidable restraints (R), and compelling opportunities (O), collectively shaping the market's trajectory and defining the competitive landscape. A primary driver is the pervasive global health consciousness, which has spurred immense demand for low-fat processed foods and high-quality, functional protein ingredients derived from defatted meals (e.g., soy protein isolates). This consumer shift mandates that food processors invest in advanced equipment capable of producing specialized ingredients with minimal residual fat. Simultaneously, the burgeoning global population requires sustainable and efficient protein sources, further catalyzing the adoption of high-capacity industrial defatting systems for oilseeds and novel protein sources like microalgae and insects. Furthermore, the stringent enforcement of food safety and quality standards globally compels manufacturers to upgrade outdated machinery to modern, closed-loop systems that minimize contamination risks and ensure traceability.

Conversely, the market faces significant restraints, chief among them being the extremely high capital investment required for establishing or upgrading modern industrial defatting plants, especially those utilizing advanced technologies like Supercritical Fluid Extraction (SFE). This high barrier to entry restricts small and medium-sized enterprises (SMEs) from rapid adoption. Another critical restraint is the complex regulatory environment surrounding the use of chemical solvents, particularly hexane, in food processing applications across various jurisdictions, forcing costly re-engineering of established production lines. Operational complexity and the necessity for highly skilled technical personnel to maintain and optimize sophisticated defatting machinery also pose a logistical and financial challenge for companies operating in regions with limited technical expertise, impacting operational expenditure and efficiency.

Opportunities for growth are abundant, particularly in the rapid commercialization of continuous extraction technologies and the development of sustainable, non-toxic alternatives to traditional organic solvents, such as water-based processes or green solvents like ethanol. The rising demand for specialized ingredients in niche markets—such as high-purity omega-3 fatty acids from marine sources or specialized lipids for pharmaceuticals—creates a lucrative avenue for vendors specializing in precision defatting equipment (e.g., SFE). Furthermore, integrating the defatting stage with upstream preparation (e.g., flaking, conditioning) and downstream refining (e.g., bleaching, deodorization) into fully automated, integrated processing lines presents significant growth opportunities for offering complete turnkey solutions to large agribusiness conglomerates. The continuous pursuit of zero-waste processing also drives opportunities in utilizing residual by-products more effectively, enhancing the overall economic viability of the entire defatting operation.

Segmentation Analysis

The Defatting Systems Market is meticulously segmented based on technology utilized, the application sector, and the operational system type, allowing for precise market analysis tailored to diverse industrial requirements. Technology segmentation distinguishes systems based on the mechanism of fat separation, ranging from mechanical force to chemical solubility differences. The application landscape reflects the broad end-use of the defatted materials, spanning critical industries such as large-scale food manufacturing, high-purity cosmetic ingredient production, and specialized pharmaceutical preparations. System type differentiation focuses on the mode of operation, specifically distinguishing between scalable, highly efficient continuous processing lines and smaller, more flexible batch operations, influencing purchasing decisions based on desired throughput and product variability.

- By Technology

- Solvent Extraction (e.g., Hexane, Ethanol)

- Supercritical Fluid Extraction (SFE)

- Mechanical Pressing (Expellers)

- Aqueous Extraction

- By Application

- Food and Beverage (Oilseed Processing, Protein Meal)

- Nutraceuticals (Omega-3 Extraction, Botanical Lipids)

- Cosmetics and Personal Care

- Pharmaceuticals

- Biofuels and Industrial

- By System Type

- Batch Defatting Systems

- Continuous Defatting Systems

Value Chain Analysis For Defatting Systems Market

The value chain for the Defatting Systems Market commences with upstream analysis, involving the raw material suppliers (steel, specialized alloys, components, and electronics) crucial for manufacturing robust and corrosion-resistant industrial machinery. Key upstream activities include research and development focused on creating highly efficient separation mechanisms, developing automated control systems, and incorporating energy recovery technologies. Manufacturers must establish strong relationships with specialized component suppliers, particularly those providing high-pressure pumps, advanced filtration systems, and precision heat exchangers, as the quality and reliability of these components directly impact the final system’s performance and longevity. Cost management in the upstream segment focuses on bulk purchasing of raw materials and optimizing fabrication processes through advanced robotics and modular design, minimizing production lead times.

The core of the value chain involves the system manufacturing and integration stage, where major original equipment manufacturers (OEMs) design, assemble, and test the complex defatting machinery. This stage includes meticulous engineering to ensure regulatory compliance, particularly regarding pressure vessel standards and explosion proofing necessary for solvent-based systems. Distribution channels are bifurcated into direct sales—where large, global OEMs handle complex custom projects directly with major agribusiness and industrial clients—and indirect distribution, utilizing specialized regional distributors or engineering procurement and construction (EPC) firms who manage smaller sales, installation, and localized technical support. The choice of channel depends heavily on the project scale, geographical location, and the complexity of the required technological integration, ensuring specialized technical knowledge is available near the end-user.

Downstream analysis focuses on the end-users: large-scale food processors, chemical manufacturers, and pharmaceutical companies who utilize the defatting systems. This phase includes installation, commissioning, training, and crucially, long-term service and maintenance contracts. Post-sales service is a vital differentiator, often encompassing predictive maintenance powered by IoT sensors, spare parts provision, and continuous process optimization consulting to help clients maximize yield and minimize operational expenditure. The value chain concludes with the final product consumers (food, pharmaceuticals, etc.), whose evolving preferences for lower fat content and high-purity ingredients drive demand back up the chain, influencing R&D priorities for equipment manufacturers toward cleaner, more efficient extraction methods like SFE, thus closing the continuous loop of innovation and implementation within the defatting technology sector.

Defatting Systems Market Potential Customers

The primary potential customers for Defatting Systems are extensive, spanning multiple large-scale industrial sectors where the separation of lipids from solid materials is a critical process step. The largest customer segment resides within the Food and Beverage industry, specifically large oilseed crushers and processors of soy, palm, sunflower, and rapeseed. These entities utilize high-capacity, continuous solvent extraction systems to maximize crude oil yield while simultaneously producing high-protein defatted meal crucial for the animal feed and increasingly, the human protein supplement markets. Given the scale of operation, these customers prioritize throughput, energy efficiency, and low maintenance costs. The transition towards plant-based diets further solidifies this segment's importance, as new protein sources require novel and efficient defatting techniques to isolate high-purity proteins suitable for texture and functional food applications.

Another rapidly expanding customer base includes the Nutraceutical and Pharmaceutical industries, which require precision defatting technology for the extraction of high-value compounds. These customers utilize technologies like Supercritical Fluid Extraction (SFE) due to its ability to perform solvent-free, gentle extraction necessary to preserve sensitive bioactive components, such as specific omega fatty acids from marine or algal sources, or botanical extracts. Their purchasing criteria heavily emphasize product purity, absence of residual solvents, and compliance with Good Manufacturing Practice (GMP) standards, often justifying the higher capital cost associated with SFE technology due to the premium price of their final products. Smaller, specialized firms in the cosmetics sector also fall into this category, seeking systems for extracting natural, clean-label oils and butters.

Finally, industrial sectors, including the emerging Biofuel and Waste Management industries, represent growing potential customers. Biofuel producers require efficient defatting of microalgae biomass or dedicated energy crops to harvest lipids for conversion into biodiesel or sustainable aviation fuels. Furthermore, rendering plants and waste processors utilize defatting systems to recover animal fats and technical oils from slaughterhouse by-products or food waste, creating value-added inputs for chemical or feed applications. These customers are driven by regulatory mandates for waste reduction, the necessity for cost-effective resource recovery, and the desire to monetize previously discarded materials, requiring robust, reliable systems capable of handling high moisture and variability in feedstock composition.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.5 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Alfa Laval, GEA Group, JBT Corporation, Krones AG, SPX Flow, Tetra Pak, Russell Finex, Andritz AG, Bucher Industries, Crown Iron Works, De Smet Ballestra, Pfaudler Group, Flottweg SE, Westfalia Separator, Pieralisi Group, Sharples Centrifuges, Cimbria, CPM Roskamp, Wenger Manufacturing, Hosokawa Micron. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Defatting Systems Market Key Technology Landscape

The Defatting Systems market is characterized by a sophisticated technological landscape where innovation is driven primarily by the need for higher yield, cleaner extraction methods, and improved energy efficiency. Traditional technologies, such as mechanical pressing (expellers), remain relevant for pre-pressing high-oil-content seeds and smaller operations due to their robust nature and lower initial investment, but they are limited by their residual oil content in the defatted cake. Solvent extraction, predominantly utilizing hexane, represents the high-throughput, industrial standard for bulk oilseed processing, offering high yields and scalability. However, regulatory pressures and safety concerns associated with flammable solvents are pushing R&D towards enhanced solvent recovery systems and the exploration of alternative, safer solvents like ethanol or proprietary non-flammable mixtures, requiring significant re-tooling and process optimization in existing plants.

The forefront of technological advancement is dominated by Supercritical Fluid Extraction (SFE), primarily using carbon dioxide (CO2). SFE is highly valued for its ability to extract sensitive components without the use of toxic solvents and at lower temperatures, preserving the integrity of heat-labile substances. This technology is crucial in high-value segments like pharmaceuticals and nutraceuticals where product purity is non-negotiable. Ongoing research focuses on optimizing SFE conditions (pressure and temperature profiles) to enhance selectivity and reduce operational costs, which traditionally have been high due to the energy required for compression and recycling CO2. Furthermore, advancements in specialized membranes and chromatographic separation techniques are being integrated with SFE to achieve ultra-high purity fractionation of lipids immediately post-extraction, streamlining the downstream refining process significantly.

A burgeoning area of technology is Aqueous Extraction, particularly relevant for novel protein sources like pulses and microalgae. These water-based methods eliminate the use of organic solvents entirely, appealing heavily to the clean-label and organic food markets. While historically challenged by lower yield and complex emulsion breaking, modern aqueous defatting techniques leverage pH shifts, enzyme treatments, and advanced centrifugation and membrane separation technologies to achieve competitive yields. Manufacturers are also focusing on integrating IoT and AI into system controls across all technologies. This integration allows for predictive maintenance, real-time optimization of variable process parameters (flow rates, solvent ratios, pressure dynamics), and enhanced remote monitoring capabilities, ultimately improving overall system reliability and operational responsiveness to fluctuating raw material quality and changing output requirements.

Regional Highlights

The global Defatting Systems Market exhibits distinct consumption patterns and growth dynamics across major geographical regions, influenced by localized agricultural output, regulatory environments, and industrial development stages. Asia Pacific (APAC) stands out as the primary engine for market growth, driven by its massive oilseed production capacity, particularly in China, India, and Indonesia. This region requires high-capacity, robust solvent extraction systems to process vast volumes of soybeans and palm kernels. Rapid urbanization and the resultant surge in demand for processed foods and animal feed further necessitate continuous investment in large-scale, automated defatting infrastructure across APAC. Government initiatives supporting domestic edible oil production and protein independence also fuel the purchase of modern, efficient machinery to replace older equipment.

North America and Europe represent mature markets characterized by stringent regulatory environments regarding solvent use and a strong emphasis on high-value, niche applications. In these regions, the demand is concentrated on advanced technologies such as Supercritical Fluid Extraction (SFE) for nutraceuticals (e.g., concentrated omega-3s) and specialized food ingredients, where premium pricing justifies the investment in higher-cost, solvent-free systems. European countries, particularly Germany and the Netherlands, are leaders in developing and manufacturing these sophisticated systems, focusing heavily on sustainability, energy efficiency, and low-emission operation. Market expansion here is driven less by capacity increase and more by technological upgrade and replacement cycles mandated by evolving environmental regulations.

Latin America (LATAM) is a significant and growing market, largely due to its substantial agricultural base in soybean and sunflower processing, particularly in Brazil and Argentina. Demand in LATAM often mirrors APAC in the need for high-volume solvent extraction plants, but the market also displays a growing interest in technology transfer and locally optimized manufacturing solutions. The Middle East and Africa (MEA), while currently smaller in market size, show potential for future growth driven by food security initiatives and investments in local oilseed cultivation and processing capabilities. This region seeks reliable, mid-range capacity systems and often relies on imports of integrated processing lines to minimize reliance on volatile global supply chains for essential food commodities.

- North America: Focus on technological substitution (replacing older solvent systems with SFE), high demand in nutraceuticals, strict environmental compliance driving machinery upgrades.

- Europe: Strong manufacturing base for advanced defatting technology, market driven by sustainability mandates, robust demand for specialized food ingredients and premium cosmetic extracts.

- Asia Pacific (APAC): Dominates market volume due to massive oilseed processing (Soybean, Palm), high demand for continuous, high-throughput solvent extraction systems, rapid investment in new processing infrastructure.

- Latin America (LATAM): Significant growth driven by major agricultural exports (Soy, Sunflower), increasing need for domestic processing capabilities, focus on capacity expansion and efficiency improvements.

- Middle East and Africa (MEA): Emerging market potential linked to national food security strategies, initial investments in localized processing plants, preference for cost-effective and robust imported solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Defatting Systems Market.- Alfa Laval

- GEA Group

- JBT Corporation

- Krones AG

- SPX Flow

- Tetra Pak

- Russell Finex

- Andritz AG

- Bucher Industries

- Crown Iron Works

- De Smet Ballestra

- Pfaudler Group

- Flottweg SE

- Westfalia Separator

- Pieralisi Group

- Sharples Centrifuges

- Cimbria

- CPM Roskamp

- Wenger Manufacturing

- Hosokawa Micron

Frequently Asked Questions

Analyze common user questions about the Defatting Systems market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the growth of the Defatting Systems Market?

The central driver is the escalating global consumer demand for low-fat food products and high-purity, defatted protein ingredients, particularly plant-based proteins, which necessitates efficient industrial extraction and separation technologies.

How does Supercritical Fluid Extraction (SFE) differ from traditional solvent extraction in defatting?

SFE utilizes pressurized carbon dioxide (CO2) as a non-toxic solvent replacement, enabling extraction without chemical residues, making it ideal for high-value, heat-sensitive products like nutraceuticals and pharmaceuticals, unlike traditional solvent methods which often use hexane.

Which geographical region holds the largest market share for Defatting Systems?

The Asia Pacific (APAC) region currently holds the largest market share, driven by its expansive oilseed crushing capacity (soybean and palm oil) and robust growth in processed food manufacturing across countries like China and India.

What are the main restraints impacting the Defatting Systems Market?

Key restraints include the extremely high initial capital investment required for establishing modern industrial plants and the complex, continuously tightening regulatory constraints concerning the use and management of organic chemical solvents in food processing.

How is AI technology being applied to optimize defatting system operations?

AI is applied through machine learning algorithms for predictive maintenance, real-time adjustments of extraction parameters to maximize yield, and automated quality control, ensuring consistent and energy-efficient system performance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager