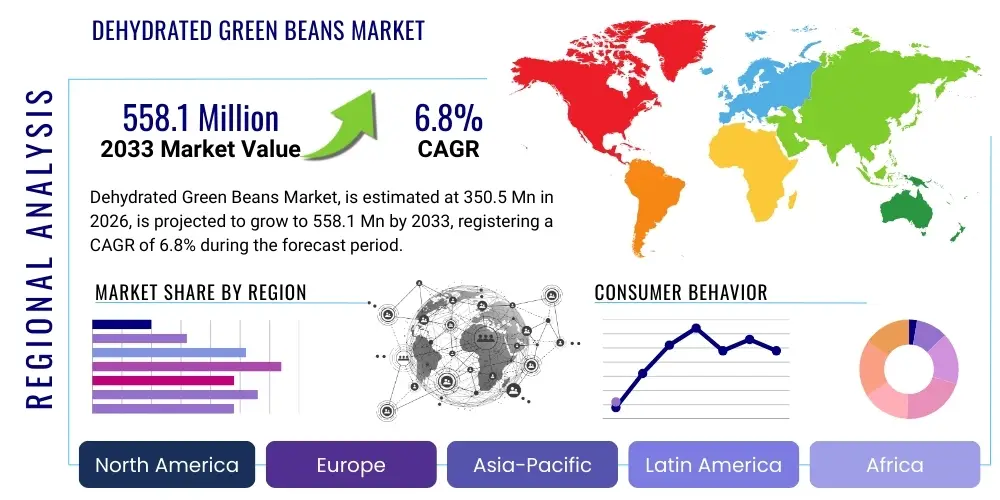

Dehydrated Green Beans Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442848 | Date : Feb, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Dehydrated Green Beans Market Size

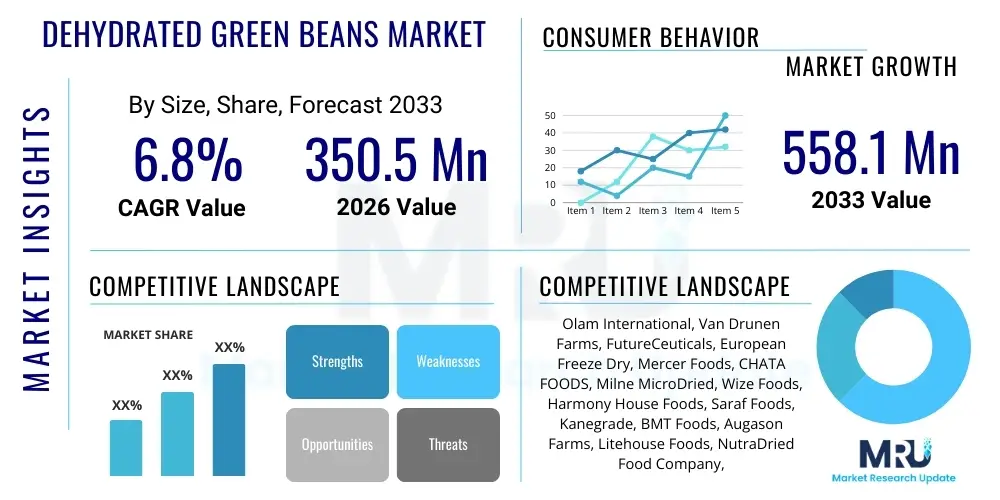

The Dehydrated Green Beans Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 350.5 Million in 2026 and is projected to reach USD 558.1 Million by the end of the forecast period in 2033. This robust growth trajectory is primarily driven by the increasing consumer demand for convenient, shelf-stable, and nutrient-dense food options globally. The enhanced shelf life and reduced weight characteristics of dehydrated green beans make them highly attractive for both industrial food manufacturers and end-users seeking practicality without compromising nutritional value, especially in emergency preparedness kits and specialized outdoor/military rations.

Dehydrated Green Beans Market introduction

The Dehydrated Green Beans Market encompasses the production, distribution, and sale of snap beans (Phaseolus vulgaris) that have undergone moisture removal through processes such as freeze-drying, air-drying, or vacuum drying, resulting in a significantly extended shelf life and reduced volume. These products retain most of their essential nutrients and flavor profile, making them a popular ingredient in various food applications. The primary product is utilized across multiple sectors, ranging from large-scale food manufacturing to direct consumer consumption, capitalizing on global trends toward convenience and waste reduction.

Major applications of dehydrated green beans include integration into instant soup mixes, ready-to-eat meals (RTE), backpacking and camping food supplies, military rations (MREs), and as a standalone retail product for household cooking. Key benefits driving market penetration are their exceptional shelf stability, ease of storage, lightweight nature, and reduced transportation costs compared to fresh or frozen alternatives. This convenience factor aligns well with modern consumer lifestyles characterized by limited cooking time and a preference for minimally processed ingredients that can be quickly rehydrated.

Driving factors propelling this market expansion include the exponential growth of the global processed food industry, especially the surge in demand for clean-label, plant-based ingredients. Furthermore, increasing urbanization and the associated demand for convenient, non-perishable food items, coupled with rising awareness regarding food waste reduction facilitated by long-shelf-life ingredients, are crucial drivers. Regulatory support for food safety and the continuous innovation in dehydration technologies, particularly freeze-drying which preserves texture and nutrients optimally, further contribute to the market's positive outlook.

Dehydrated Green Beans Market Executive Summary

The global Dehydrated Green Beans Market is witnessing substantial expansion, underpinned by evolving consumer preferences for functional foods and convenient meal solutions. Business trends indicate a strong move toward sustainable sourcing and advanced drying technologies, with key players investing heavily in freeze-drying capabilities to maximize product quality and nutritional retention. Strategic partnerships between raw material suppliers (green bean growers) and large food processors are becoming common, aimed at ensuring a steady supply chain and maintaining consistent product standards across international markets. Furthermore, the market is characterized by increasing specialization, targeting niche applications such as high-altitude nutrition and emergency relief provisions.

Regionally, the market is highly dynamic. Asia Pacific (APAC) is emerging as the fastest-growing region, driven by rapid industrialization, increasing disposable incomes, and the massive scale of its food processing sector, especially in China and India where demand for packaged soups and ready-to-use vegetable components is surging. North America and Europe maintain significant market shares, characterized by high consumer awareness regarding health and convenience, and stringent quality control standards that favor premium, often organic, dehydrated products. Latin America and the Middle East & Africa (MEA) offer substantial growth opportunities, spurred by government initiatives for food security and rising adoption of modern retailing formats.

Segment trends highlight the dominance of the freeze-drying segment in terms of value, owing to its superior ability to maintain organoleptic properties, despite higher production costs. By application, the Food Processing Industry, particularly for snack manufacturing and instant meals, accounts for the largest share, leveraging dehydrated green beans as cost-effective and functionally adaptable ingredients. The retail and household segment is simultaneously growing rapidly, fueled by the rising popularity of home meal kits and gourmet cooking where dehydrated ingredients offer year-round availability and preparation simplicity. This dual growth across industrial and retail applications ensures robust market stability and diverse revenue streams.

AI Impact Analysis on Dehydrated Green Beans Market

Common user questions regarding AI's impact on the Dehydrated Green Beans Market typically revolve around optimizing agricultural yields, enhancing quality control during processing, and streamlining complex supply chains. Users are keenly interested in how predictive analytics can forecast demand shifts, minimize spoilage, and fine-tune drying parameters for energy efficiency and consistent product texture. Concerns often focus on the initial capital investment required for AI implementation in traditionally low-margin processing environments and the need for skilled labor to manage advanced automation systems. Overall, the collective expectation is that AI will drive efficiency, reduce production variability, and enable more targeted customization of dehydrated products based on end-user specifications.

The application of Artificial Intelligence and Machine Learning (ML) is beginning to revolutionize the entire value chain of dehydrated green beans, from farming practices to final product logistics. In the agricultural phase, AI-powered systems are used for precision farming, monitoring soil health, predicting optimal harvest times to maximize bean quality, and identifying pest infestations early, leading to higher yields and better raw material quality for dehydration. This optimization minimizes agricultural waste, which is critical for cost-sensitive markets. During the processing stage, computer vision systems combined with ML algorithms are used for automated sorting and quality inspection, accurately removing defective beans or foreign materials at speeds unachievable by human labor, thereby ensuring consistent quality control before the drying process begins.

Further downstream, AI plays a pivotal role in optimizing the energy-intensive dehydration process. ML models analyze real-time data from drying chambers—including temperature, humidity, and air flow—to dynamically adjust parameters, minimizing energy consumption while ensuring rapid and uniform moisture removal. This not only reduces operational costs significantly but also enhances the uniformity and structural integrity of the final dehydrated product. Furthermore, AI-driven demand forecasting and supply chain management systems are improving inventory accuracy, predicting logistical bottlenecks, and optimizing distribution routes, ensuring that shelf-stable dehydrated green beans reach end markets efficiently and reliably, minimizing stockouts and excess inventory across the global supply network.

- AI optimizes green bean farming through precision irrigation and yield forecasting.

- Machine Learning enhances processing quality control via automated visual inspection and sorting.

- Predictive analytics minimizes energy consumption during freeze-drying and air-drying processes.

- AI-driven supply chain management improves inventory handling and reduces global logistical costs.

- Natural Language Processing (NLP) aids in analyzing consumer feedback and customizing product formulation.

DRO & Impact Forces Of Dehydrated Green Beans Market

The Dehydrated Green Beans Market is shaped by a confluence of powerful dynamics, encapsulated by key Drivers, Restraints, and Opportunities. The primary driver is the pervasive demand for convenience foods that offer extended shelf life and reduced preparation time, catering to the fast-paced lives of urban populations globally. Simultaneously, heightened consumer awareness regarding health and nutrition promotes the uptake of dehydrated vegetables, which are often perceived as retaining more nutrients than heavily processed canned alternatives. Conversely, a significant restraint is the high capital expenditure required for advanced drying technologies, particularly freeze-drying, which limits market entry for smaller players and contributes to higher final product costs compared to fresh or frozen counterparts. This cost differential remains a key barrier to widespread adoption in price-sensitive markets.

Opportunities for growth are abundant, primarily centered around expanding applications in the emerging Ready-to-Eat (RTE) and functional food sectors, alongside penetration into developing economies with improving cold chain infrastructure. Innovation in packaging, such as introducing smaller, single-serving packs or eco-friendly materials, presents a substantial opportunity to attract environmentally conscious consumers and expand retail reach. Furthermore, the increasing use of dehydrated vegetables in emergency preparedness and disaster relief provisioning represents a consistent, high-volume market segment that offers stability regardless of consumer economic cycles. Manufacturers who can successfully blend cost-effective air drying with the quality benefits of vacuum or freeze drying will capture significant market advantage.

The impact forces driving the market are multifaceted, combining economic, technological, and socio-demographic factors. Economically, the volatile costs of fresh produce and energy directly influence operational expenses; technological advancements in drying efficiency mitigate energy impacts while improving product quality; and socio-demographic shifts, such as rising veganism and vegetarianism, broaden the target consumer base. The overall impact favors manufacturers who can achieve economies of scale and maintain superior quality standards. Competitive intensity is moderate but rising, focused primarily on securing high-quality raw material sourcing and differentiating products based on drying method (e.g., Freeze-Dried vs. Air-Dried).

Segmentation Analysis

The Dehydrated Green Beans Market is meticulously segmented based on the drying technology employed, the end-use application, and the specific distribution channel utilized, allowing manufacturers to tailor products to distinct consumer needs and industry requirements. Understanding these segmentations is critical for market players to develop targeted strategies, ensuring optimal resource allocation and maximizing market penetration. The choice of drying method fundamentally impacts product quality, cost structure, and target application, while application segmentation determines volume demand and required packaging formats. Distribution channels delineate the access points for the product, ranging from direct business-to-business (B2B) supply to retail consumer markets.

Segmentation by Type (Drying Technology) reveals a trade-off between preservation quality and operational cost. Freeze drying yields the highest quality product in terms of nutrient retention, color, and texture but carries the highest processing cost. Conversely, air drying is the most economical, leading to high-volume use in bulk food manufacturing, although it may compromise certain sensory attributes. Vacuum drying offers a middle ground, providing improved quality over traditional air drying at a lower energy expenditure than freeze drying. This technological diversity allows the market to serve a wide array of applications, from high-end gourmet meals to staple ingredients for humanitarian aid.

Application analysis shows that the industrial sector is the primary consumer, utilizing dehydrated green beans as components in packaged soups, instant noodles, and specialized spice blends. However, the retail segment, driven by pandemic-induced stocking behavior and the increasing adoption of long-term food storage by households, is expanding rapidly. The distinct needs of these segments—high volume and low cost for industrial use versus premium quality and smaller packaging for retail—require tailored production and marketing efforts, ensuring that segmentation drives product portfolio development rather than simply distribution strategy.

- By Type:

- Air Drying

- Freeze Drying

- Vacuum Drying

- By Application:

- Food Service (HoReCa)

- Retail/Household

- Food Processing Industry (Snacks, Soups, Ready Meals)

- By Distribution Channel:

- Online Retail

- Supermarkets/Hypermarkets

- Convenience Stores

- Direct Sales (B2B)

Value Chain Analysis For Dehydrated Green Beans Market

The value chain of the Dehydrated Green Beans Market begins with the upstream activities of raw material sourcing, involving specialized cultivation and harvesting of high-quality green beans suitable for industrial processing. This stage is critical as the quality of the final dehydrated product is directly dependent on the freshness and physical characteristics of the harvested green beans. Upstream stability relies heavily on agricultural technology and favorable climate conditions, making contracts with reliable, large-scale growers essential for processors. Following sourcing, the core transformation process involves washing, blanching (a critical step for enzyme deactivation and color retention), and the specialized dehydration process (freeze, air, or vacuum drying). Investment in efficient drying equipment represents the primary cost driver at this stage.

The midstream phase focuses on packaging, quality assurance, and initial storage. Due to the hygroscopic nature of dehydrated products, high-barrier packaging materials are mandatory to prevent rehydration and maintain shelf stability, often utilizing nitrogen flushing or vacuum sealing. Quality control checks are stringent, ensuring compliance with international food safety standards (e.g., HACCP, ISO 22000). The downstream analysis involves distribution, which is bifurcated into direct and indirect channels. Direct distribution (B2B) targets large food processing companies and military/governmental contracts, demanding high volume and specialized bulk packaging. Indirect distribution focuses on reaching the retail consumer through a network of wholesalers, distributors, and modern retail formats.

Distribution channels heavily influence pricing and market reach. Supermarkets and hypermarkets serve as the primary indirect channel for household consumption, demanding attractive packaging and consistent supply. Online retail is rapidly gaining prominence, offering convenience and direct-to-consumer delivery, which is especially beneficial for niche products like organic or specialty freeze-dried beans. Efficient logistics management, leveraging the lightweight nature of the product, is key to competitive advantage. The value chain concludes with end-users—ranging from individual consumers preparing meals to large industrial kitchens and institutional buyers—whose feedback drives innovation in flavor profiles, rehydration time, and packaging sizes, completing the market feedback loop.

Dehydrated Green Beans Market Potential Customers

The potential customer base for the Dehydrated Green Beans Market is diverse, encompassing both industrial purchasers requiring bulk ingredients and individual consumers seeking convenience and long shelf life. The largest segment of potential customers is the global Food Processing Industry. This includes manufacturers specializing in instant soups, packaged side dishes, specialized dry mixes, and functional snacks. These industrial buyers value dehydrated green beans for their stable pricing, consistent quality, ease of storage, and ability to be integrated seamlessly into complex formulated food products, significantly reducing their internal preparation and inventory management costs associated with fresh produce. Consistency in moisture content and rehydration capacity is paramount for these high-volume clients.

Another major customer group is the Food Service sector, particularly catering companies, restaurants (HoReCa), and institutional kitchens. While traditional food service often relies on fresh or frozen vegetables, dehydrated options are increasingly utilized in remote locations, military bases, disaster relief efforts, and by outdoor catering services where refrigeration or weight reduction is a necessity. Customers in this sphere prioritize rapid rehydration and flavor consistency to maintain quality across large batches. Furthermore, governments and non-profit organizations represent significant, stable customers for emergency food aid and strategic national stockpiles, purchasing large quantities packaged for long-term storage, often spanning decades.

Finally, the Retail/Household consumer represents a rapidly expanding customer segment, driven by interest in camping/backpacking rations, long-term pantry storage, and convenience cooking. These customers often purchase smaller, attractively packaged containers via supermarkets or online channels. They are typically discerning about product quality, favoring freeze-dried variants for superior texture and color. Specific niches within this group include preppers, health-conscious buyers seeking nutrient-dense additions to their diet, and consumers participating in subscription boxes focusing on meal kits that utilize shelf-stable ingredients.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350.5 Million |

| Market Forecast in 2033 | USD 558.1 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Olam International, Van Drunen Farms, FutureCeuticals, European Freeze Dry, Mercer Foods, CHATA FOODS, Milne MicroDried, Wize Foods, Harmony House Foods, Saraf Foods, Kanegrade, BMT Foods, Augason Farms, Litehouse Foods, NutraDried Food Company, Green Bulk Foods, Mother Earth Products, Freeze-Dry Foods GmbH, Valley Green Beans Inc., Sun-Maid Growers of California |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dehydrated Green Beans Market Key Technology Landscape

The technological landscape of the Dehydrated Green Beans Market is characterized by continuous refinement aimed at improving energy efficiency, reducing processing time, and maximizing the retention of nutritional and organoleptic properties. The primary technologies employed are conventional Air Drying (AD), advanced Freeze Drying (FD), and Vacuum Microwave Drying (VMD). Air drying, while cost-effective, relies on hot air circulation, which can cause significant shrinkage, color degradation, and potential nutrient loss due to prolonged exposure to heat. Recent innovations in AD focus on incorporating infrared or solar power to reduce operational energy costs and shorten drying cycles, thereby minimizing heat exposure effects and improving product quality marginally.

Freeze Drying (Lyophilization) remains the gold standard for high-quality dehydrated green beans. This process involves freezing the beans and then subjecting them to a high vacuum, allowing the ice to sublime directly into vapor, bypassing the liquid phase. This method preserves the cellular structure, resulting in a product that retains its original shape, color, flavor, and nearly all nutritional value, and rehydrates exceptionally well. Technological advancements in FD focus on optimizing cycle times and developing continuous processing units rather than traditional batch systems, aiming to lower the high fixed and variable costs associated with deep freezing and maintaining high vacuum levels, thus making premium freeze-dried products more economically viable for bulk purchase.

Vacuum Microwave Drying (VMD) and Refractance Window Drying (RWD) represent promising intermediate technologies gaining traction. VMD combines microwave energy for volumetric heating with reduced atmospheric pressure to rapidly evaporate water at lower temperatures, offering substantial reductions in drying time and energy use compared to conventional AD, while yielding a superior product that bridges the quality gap between AD and FD. RWD uses infrared radiation through water to heat the product, offering high heat transfer rates at atmospheric pressure, making it highly energy efficient. The successful integration of these hybrid and novel drying technologies into commercial operations is crucial for maintaining competitive edge, especially as consumer demand for high-quality, minimally processed ingredients continues to escalate globally.

Regional Highlights

- North America: North America holds a substantial share of the global Dehydrated Green Beans Market, characterized by high consumer awareness regarding health and the strong presence of convenience food culture. The market here is mature and dominated by freeze-dried products, driven by demanding quality standards in the food service and military sectors. The robust prepper and outdoor recreation communities contribute significantly to the retail segment's stability, ensuring continuous demand for long-shelf-life vegetable provisions. Technological adoption is high, with processors continuously investing in automation and sustainable practices to meet stringent regulatory requirements and consumer expectations for clean labeling and minimal environmental impact. The United States, in particular, showcases high consumption of dehydrated components in packaged soups and meal kits, reflecting the fast-paced lifestyle.

- Europe: The European market is defined by stringent food safety regulations and a strong consumer focus on organic and Non-GMO verification. Demand for dehydrated green beans is robust within the food processing sector, especially in Germany, France, and the UK, where they are utilized in savory snacks, instant meals, and gourmet dry mixes. The trend toward reducing food waste has significantly boosted the appeal of shelf-stable vegetables. Eastern Europe is emerging as a growing production hub, leveraging competitive operational costs, although Western Europe remains the key consumer market. European processors often face pressure to minimize energy consumption, driving innovation in efficient air-drying and vacuum drying techniques.

- Asia Pacific (APAC): APAC is poised for the fastest growth globally, fueled by rapid urbanization, substantial growth in disposable incomes, and the modernization of the retail infrastructure. China and India are the primary growth engines, characterized by massive populations and a quickly expanding processed food industry that requires bulk, reliable vegetable inputs for instant noodles, dehydrated sauces, and local seasoning mixes. The demand here is highly sensitive to pricing, making air-dried and conventionally dehydrated products the dominant type by volume. However, as middle-class populations grow, demand for premium, freeze-dried options used in high-end packaged foods is accelerating. Investment in local processing capabilities across Southeast Asia is expanding market accessibility and reducing reliance on imports.

- Latin America (LATAM): The LATAM market, while smaller, presents significant untapped potential. Growth is stimulated by increasing foreign investment in the food processing sector and the gradual improvement in regional logistics and cold chain management. Dehydrated green beans are primarily used in industrial applications, serving as low-cost, reliable ingredients. Countries like Brazil and Mexico, with large domestic food manufacturing bases, are key demand centers. Challenges in this region include economic volatility and fragmented distribution networks, making direct B2B sales more critical than widespread retail penetration. The focus remains on cost-effective dehydration methods to cater to the predominantly price-conscious consumer base.

- Middle East and Africa (MEA): The MEA market is exhibiting steady growth, particularly in the Middle East due to high import reliance for packaged foods and significant institutional demand arising from large expatriate communities and regional tourism. Dehydrated products are vital for long-term storage and use in regions with limited agricultural output or challenging climates. In Africa, the market is primarily driven by humanitarian aid programs and governmental food security initiatives, requiring large volumes of air-dried, fortified products. Opportunities lie in establishing local processing facilities to capitalize on favorable climates for green bean cultivation and serving the growing demand for convenient, non-perishable food items in urban centers.

- Detailed Analysis - North American Market Dynamics: The North American landscape is characterized by high levels of technological sophistication, with leading manufacturers leveraging advanced sorting technologies and continuous freeze-drying systems to ensure unparalleled product quality and rapid scalability. Consumer preferences are highly attuned to health attributes, driving demand for organic certifications, non-GMO verified status, and transparent labeling regarding sourcing and processing methods. Retail channels, especially specialized health food stores and major grocery chains, heavily promote freeze-dried green beans for inclusion in emergency kits and everyday cooking. Regulatory adherence, particularly to FDA standards, mandates rigorous quality control, favoring established companies with documented robust processing protocols. The strong emphasis on reducing overall supply chain waste also bolsters the adoption of long-life dehydrated vegetables over alternatives with shorter expiration windows.

- Detailed Analysis - Asia Pacific Market Expansion: The expansion in APAC is structurally supported by major infrastructure development in countries like Vietnam, Thailand, and Indonesia, which facilitate faster distribution of packaged goods. The cultural shift towards Westernized eating habits and the increased consumption of convenience foods, such as instant noodles, instant soups, and ready meals popular in urban settings, directly fuels the demand for dehydrated vegetables as primary components. Local processors are increasingly moving away from basic sun drying towards commercial air drying and, in high-value export markets like Japan and South Korea, investing in vacuum drying to meet specific texture and flavor requirements. Government policies aimed at reducing post-harvest losses in agricultural production further incentivize the dehydration sector as a viable preservation method.

- Detailed Analysis - European Market Trends and Sustainability: Sustainability is a paramount factor influencing the European dehydrated market. Buyers, both industrial and retail, increasingly demand products processed using energy-efficient methods and packaged in recyclable or biodegradable materials. This focus is pushing processors towards optimizing air and vacuum drying units to reduce the environmental footprint per kilogram of output. Furthermore, Europe serves as a crucial hub for the trade of dehydrated ingredients globally, with ports like Rotterdam and Antwerp facilitating extensive import and re-export activities. The market highly values suppliers capable of providing certifications related to ethical sourcing and low carbon footprint processing, making supply chain transparency a significant competitive differentiator within the European Union.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dehydrated Green Beans Market.- Olam International

- Van Drunen Farms

- FutureCeuticals

- European Freeze Dry

- Mercer Foods

- CHATA FOODS

- Milne MicroDried

- Wize Foods

- Harmony House Foods

- Saraf Foods

- Kanegrade

- BMT Foods

- Augason Farms

- Litehouse Foods

- NutraDried Food Company

- Green Bulk Foods

- Mother Earth Products

- Freeze-Dry Foods GmbH

- Valley Green Beans Inc.

- Sun-Maid Growers of California

Frequently Asked Questions

Analyze common user questions about the Dehydrated Green Beans market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary differences between freeze-dried and air-dried green beans?

Freeze-dried green beans maintain superior nutritional content, original structure, color, and flavor profile, rehydrating quickly and fully, but are significantly more expensive. Air-dried green beans are cost-effective for bulk industrial use but may exhibit shrinkage and slight flavor degradation due to heat exposure during processing.

Which application segment drives the highest demand in the Dehydrated Green Beans Market?

The Food Processing Industry segment currently drives the highest volume demand, utilizing dehydrated green beans as a stable, bulk ingredient in instant soups, packaged snacks, and ready-to-eat meals due to their extended shelf life and reduced inventory complexity.

How is the market addressing the high energy costs associated with freeze-drying technology?

The market is addressing high energy costs through continuous technological innovation, including optimizing vacuum and sublimation cycles, developing hybrid drying methods (e.g., VMD), and increasing the use of renewable energy sources in processing facilities to improve operational efficiency and lower the unit cost of production.

Which geographical region is expected to show the fastest growth rate for dehydrated green beans?

Asia Pacific (APAC), particularly driven by the rapid expansion of the food processing industry in countries like China and India and increasing consumer adoption of packaged convenience foods, is projected to register the highest Compound Annual Growth Rate (CAGR) during the forecast period.

What impact does the trend toward clean labeling have on the dehydration market?

The clean labeling trend strongly favors dehydrated green beans, as the dehydration process is minimally invasive and requires few, if any, additives or preservatives, allowing manufacturers to market them as natural, single-ingredient components, appealing directly to health-conscious consumers.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager