Dental Hand Instruments Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441984 | Date : Feb, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Dental Hand Instruments Market Size

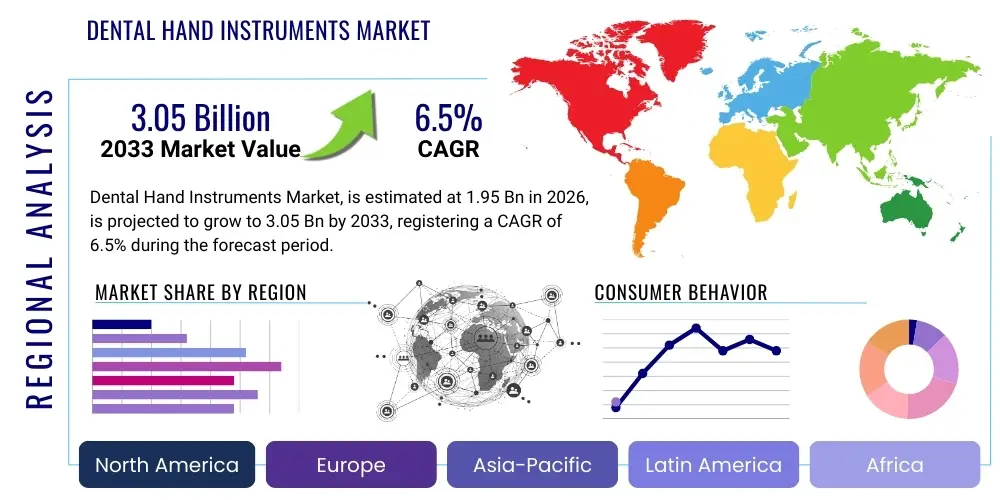

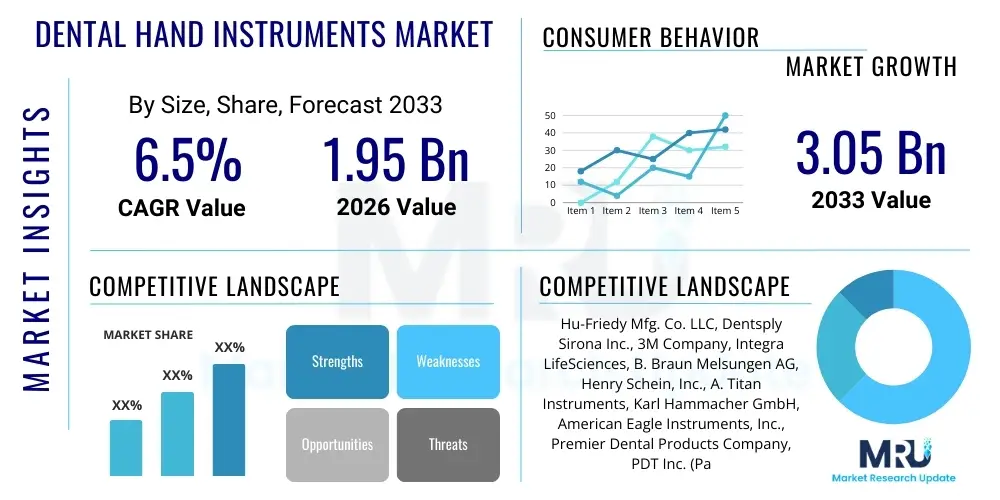

The Dental Hand Instruments Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at $1.95 Billion in 2026 and is projected to reach $3.05 Billion by the end of the forecast period in 2033.

Dental Hand Instruments Market introduction

The Dental Hand Instruments Market encompasses a diverse range of precision tools essential for diagnostic, restorative, endodontic, surgical, and prophylactic procedures within dentistry. These instruments are fundamental to the daily operations of dental professionals, providing the necessary dexterity and accuracy required for complex treatments. Key product categories include diagnostic instruments such as explorers and mirrors, restorative instruments like amalgam carriers and condensers, and specialized tools for extraction and periodontics. The demand for these instruments is intrinsically linked to the global prevalence of oral health issues, including dental caries and periodontal disease, which necessitate frequent clinical intervention. Advancements in material science, focusing on durability, ergonomics, and enhanced sterilization capabilities, continue to drive product innovation, ensuring instruments meet rigorous standards for patient safety and clinical efficacy.

Major applications of dental hand instruments span the entire spectrum of dental care, from routine check-ups utilizing mirrors and probes to complex surgical interventions requiring scalpels, bone chisels, and specialized elevators. The primary benefit derived from high-quality hand instruments is the assurance of precise clinical outcomes, minimizing patient discomfort and reducing the risk of procedural errors. Modern instruments are increasingly designed with ergonomic handles to mitigate strain on the practitioner, a crucial factor considering the repetitive nature of dental work. Furthermore, the longevity and resistance to corrosion provided by materials such as surgical-grade stainless steel and tungsten carbide contribute significantly to the total value proposition for dental practices.

Driving factors propelling market expansion include the rapidly aging global population, which typically requires more extensive restorative and prosthetic dental services, and the rising awareness concerning preventive dental care. Increases in discretionary spending on healthcare, particularly in emerging economies, alongside government initiatives promoting oral health standards, further contribute to robust market growth. The proliferation of dental clinics and the establishment of large Dental Support Organizations (DSOs) that standardize equipment purchasing across multiple locations are creating consistent demand streams for high-volume instrument sets. The transition towards minimally invasive procedures also necessitates newer, smaller, and more specialized instrument designs, forcing manufacturers to continuously adapt their product portfolios.

Dental Hand Instruments Market Executive Summary

The Dental Hand Instruments Market is experiencing a strategic shift driven by heightened demand for single-use instruments and the integration of advanced material technologies to enhance longevity and sterilization effectiveness. Business trends indicate a strong move toward ergonomic designs and lightweight construction, reflecting professional requirements for reducing occupational hazards and improving procedural efficiency. Key manufacturers are focusing on automating parts of the production process to ensure consistency and are heavily investing in research and development to introduce specialized instruments tailored for procedures like implantology and laser dentistry. The market remains highly competitive, characterized by intense pricing pressure, necessitating manufacturers to differentiate through superior quality assurance and comprehensive after-sales support, particularly for high-cost specialized tools.

Regionally, the market exhibits dynamic growth, with North America and Europe retaining the largest market shares due to established healthcare infrastructure, high healthcare spending, and favorable reimbursement policies for dental treatments. However, the Asia Pacific (APAC) region is projected to register the highest Compound Annual Growth Rate (CAGR) over the forecast period. This surge is attributed to improving economic conditions, increased accessibility to dental care in populous nations like China and India, the expansion of dental tourism, and aggressive government investments in healthcare infrastructure modernization. Latin America and the Middle East and Africa (MEA) present emerging opportunities, primarily fueled by the increasing establishment of private dental clinics and growing dental insurance coverage.

Segment trends reveal that diagnostic instruments, essential for initial examinations, maintain significant volume dominance, while restorative instruments are witnessing value growth due to complex aesthetic dentistry procedures. Within product materials, instruments utilizing tungsten carbide tips or inserts are gaining popularity due to their exceptional durability and edge retention compared to traditional stainless steel, despite a higher initial cost. Furthermore, the end-user segment is increasingly dominated by independent dental clinics and small to medium-sized practices, which prioritize instrument kits and standardized sterile processing protocols, driving the demand for specialized instrument management systems alongside the tools themselves.

AI Impact Analysis on Dental Hand Instruments Market

User queries regarding AI’s impact on the Dental Hand Instruments Market commonly center on whether AI-powered diagnostics will render certain manual diagnostic tools obsolete, how AI will influence the manufacturing and design precision of instruments, and the potential for robotic assistance to decrease reliance on highly specialized manual instruments. The consensus among market stakeholders is that AI will primarily serve as an enhancing technology rather than a direct replacement for manual dexterity. AI algorithms are rapidly improving the interpretation of dental radiographs and patient scans, leading to more accurate diagnosis and precise treatment planning, which in turn necessitates specific, high-precision instruments for execution. This shift places a premium on instruments designed for minimally invasive, AI-guided procedures. Furthermore, AI is revolutionizing manufacturing processes, optimizing material usage, and performing rigorous quality control checks on the instruments themselves, ensuring higher consistency and reliability in the final product.

- AI-enhanced diagnostic software improves treatment planning precision, increasing demand for corresponding specialized restorative and surgical instruments.

- Integration of AI in manufacturing allows for superior quality control and geometric optimization of instrument tips and working ends, ensuring better ergonomic and functional profiles.

- Robotic assistance systems, often leveraging AI for navigation and procedural guidance, require compatible, high-tolerance manual instruments for seamless integration and hybrid procedures.

- Predictive maintenance analytics, driven by AI, can track instrument usage and sterilization cycles, optimizing replacement schedules and potentially increasing the lifetime utility of high-value handpieces.

- AI aids in customized instrument design (via CAD/CAM), allowing manufacturers to rapidly prototype and produce instruments tailored for highly specific, patient-unique anatomical requirements.

DRO & Impact Forces Of Dental Hand Instruments Market

The Dental Hand Instruments Market is subject to a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively define the market's growth trajectory and competitive landscape. The primary driver is the escalating prevalence of chronic oral diseases globally, necessitating consistent restorative and surgical interventions. This is compounded by increasing dental expenditures in developed nations and the expansion of healthcare access in developing regions. Furthermore, technological advancements in material science, leading to the development of instruments with improved tactile feedback, anti-corrosive properties, and enhanced sterilization compatibility, act as significant market boosters. The transition from traditional, less ergonomic designs to contemporary, user-friendly instrument profiles is a crucial driving force, directly influencing purchasing decisions among dental professionals focused on long-term career health and procedural efficiency.

However, the market faces several formidable restraints. The high initial capital investment required for acquiring specialized, high-quality instruments, particularly in smaller clinics or emerging markets, poses a significant barrier. Moreover, stringent regulatory requirements regarding medical device classification, sterilization protocols, and material biocompatibility lead to lengthy and costly approval processes for new products. A major ongoing restraint is the risk of instrument damage during repeated sterilization cycles and the necessity of frequent replacement, contributing to high operational costs for dental practices. The proliferation of low-cost, inferior quality instruments from unregulated sources also creates pricing pressure and risks compromising patient safety and professional reputation, challenging established market players.

Opportunities for growth are abundant, primarily through the untapped potential of emerging markets where the penetration rate of advanced dental care is still low but rapidly increasing. The rising trend of Dental Support Organizations (DSOs) offers opportunities for large volume contracts and standardization of instrument sets. Innovation in 3D printing and Additive Manufacturing processes promises cost-effective production of customized instruments with complex geometries, opening new avenues for product differentiation. Furthermore, the focus on sustainable dentistry and the development of reusable instruments with exceptional lifespan present strategic growth paths. The market is also heavily influenced by impact forces derived from Porter's Five Forces analysis. Buyer bargaining power is high due to the standardized nature of many instruments and the presence of numerous suppliers. Supplier bargaining power is moderate, influenced by the specialized nature of raw materials like tungsten carbide. The threat of substitutes is low, as manual instruments are essential, though technology like advanced laser surgery could marginally replace certain surgical instruments. Competitive rivalry is intense, driven by global and regional manufacturers vying for dominance through quality, brand reputation, and price wars.

The dynamic regulatory environment across various geographies necessitates adaptive manufacturing and distribution strategies. For instance, the transition in the European Union to the Medical Device Regulation (MDR) has required significant operational and quality system overhauls for companies selling dental instruments. This regulatory complexity, while a restraint, simultaneously serves as an opportunity for market leaders who can quickly achieve and maintain compliance, thereby establishing a trust advantage over smaller competitors. Addressing the environmental concerns related to disposable instruments through developing biodegradable or more efficiently recyclable options is also becoming a key strategic imperative, transforming potential market risks into sustainable competitive advantages. The continuous professional development of dentists in new techniques, such as implant placement and advanced periodontology, creates a direct demand pull for specialized instrument categories.

Segmentation Analysis

The Dental Hand Instruments Market is rigorously segmented based on product type, material, end-user, and specific application areas, allowing manufacturers and distributors to tailor their strategies to specific clinical needs. Product segmentation is crucial, differentiating between instruments used for diagnostic purposes (e.g., mirrors, probes, tweezers) which are high-volume consumables, and those used for complex restorative or surgical work (e.g., elevators, bone files) which represent higher value purchases. The materials segment reflects ongoing efforts to balance cost and performance, with stainless steel dominating basic instruments and advanced materials like tungsten carbide reserved for critical cutting or working surfaces requiring enhanced longevity and sharpness. Understanding these segment dynamics is vital for market forecasting and competitive positioning, particularly as technological improvements continue to blur the lines between traditional and advanced instrument functionalities.

End-user segmentation clearly defines the primary purchasing channels, with General Dental Practitioners (GDPs) and specialized clinics (orthodontics, periodontics, endodontics) forming the largest consumer base. Hospitals, particularly those with attached dental surgery departments, represent a stable segment requiring specialized surgical instruments and adhering to strict procurement protocols. The growing presence of Dental Support Organizations (DSOs) as aggregated buyers is transforming the distribution landscape, favoring manufacturers capable of offering bulk discounts and standardized global supply chains. Furthermore, applications-based segmentation, such as Restorative Dentistry, Oral Surgery, and Orthodontics, highlights specific procedural growth areas that drive demand for specialized kits and instrument sets designed for maximum procedural efficiency and standardization.

The intersection of these segments drives specialized product development. For instance, the rise in aesthetic dentistry fuels demand for sophisticated composite placement instruments (restorative segment, advanced material), while the global increase in implant procedures boosts the market for dedicated surgical implant kits (surgical segment, specialized end-user). Manufacturers must align their R&D initiatives with these intersecting needs, ensuring that new instruments not only meet clinical requirements but also address ergonomic concerns and comply with global sterilization and infection control guidelines, which are critical procurement criteria across all end-user categories and geographical regions.

- By Product Type:

- Diagnostic Instruments (Mirrors, Probes, Explorers, Tweezer)

- Restorative Instruments (Amalgam Carriers, Carvers, Burnishers, Condensers, Composite Instruments)

- Surgical Instruments (Elevators, Forceps, Scalpels, Bone Chisels, Retractors)

- Periodontal Instruments (Scalers, Curettes, Files, Hoes)

- Endodontic Instruments (Spreaders, Pluggers, Files, Reamers)

- By Material:

- Stainless Steel

- Tungsten Carbide

- Plastics and Polymers (for disposable options)

- Titanium Alloys

- By Application:

- General Dentistry

- Oral Surgery

- Orthodontics

- Periodontics

- Endodontics

- By End-User:

- Dental Clinics (Independent and Chain)

- Hospitals

- Dental Academic and Research Institutes

Value Chain Analysis For Dental Hand Instruments Market

The value chain for the Dental Hand Instruments Market begins with upstream activities focused on sourcing specialized raw materials. This stage involves procuring high-grade surgical stainless steel (e.g., 420 or 440 grade), tungsten carbide inserts, titanium, and advanced polymer composites. Material quality is paramount, as it directly impacts the instrument’s durability, resistance to corrosion, and sterilization tolerance. Key upstream challenges include maintaining consistent supply chain transparency and mitigating volatility in metal prices. Manufacturers often forge long-term relationships with specialized metal foundries and precision component suppliers to ensure materials meet stringent biocompatibility and mechanical property standards required for medical devices. High-precision machinery and advanced casting or milling techniques are employed during this stage to create the initial blanks and complex handle components before assembly.

The midstream section of the value chain is dominated by manufacturing and assembly. This involves highly specialized processes such as precision forging, computer-numerical control (CNC) machining, laser etching, heat treatment for hardening (particularly for working ends), and meticulous grinding and polishing to achieve optimal tactile surfaces and working angles. Quality control is a critical bottleneck, involving rigorous checks for geometric accuracy, surface finish, and sterility assurance. The implementation of ergonomic design principles is a major focus here, often utilizing CAD/CAM systems to optimize handle shapes and weight distribution. Direct and indirect distribution channels then move the finished products downstream towards the end-users. Direct channels involve manufacturers selling directly to large hospitals or Dental Support Organizations (DSOs) through dedicated sales forces, which allows for better profit margins and direct feedback loops.

Indirect distribution is managed through a complex network of authorized regional distributors, wholesalers, and specialized medical device dealers who provide logistical support, inventory management, and localized marketing efforts to individual dental clinics and smaller practices. These intermediaries often provide value-added services such as instrument repair, refurbishment, and sterilization compliance consulting, critical elements that influence purchase decisions. The final stage involves marketing, sales, and post-sales support, including education on proper instrument maintenance and sterilization protocols. Effective distribution relies heavily on reliable warehousing and inventory systems that can handle the large volume and variety of instruments required by a global market, emphasizing speed and efficiency in order fulfillment to minimize clinical downtime for customers.

Dental Hand Instruments Market Potential Customers

The primary consumers and end-users of dental hand instruments are professional entities engaged in providing oral healthcare services, ranging from small private practices to large governmental institutions. The largest customer segment comprises independent dental clinics and specialized practices, including those focused on endodontics, periodontics, and oral surgery. These clinics represent a consistent and fragmented demand base, prioritizing instrument quality, ergonomic features, and the availability of comprehensive instrument kits for specific procedures. Their purchasing decisions are often influenced by local distributor relationships, professional recommendations, and the perceived long-term value and durability of the instruments, given the necessity of repeated sterilization cycles.

A rapidly expanding segment of potential customers includes Dental Support Organizations (DSOs) and large chain dental practices. DSOs act as centralized procurement entities, leveraging their scale to negotiate favorable pricing and standardization agreements with instrument manufacturers. This customer type places a high value on consistent quality, reliable global supply chain logistics, and instrument management systems that facilitate efficient inventory tracking and sterilization across multiple affiliated locations. Manufacturers targeting DSOs must demonstrate the ability to handle high-volume orders while maintaining strict quality control and regulatory compliance across diverse geographic regions where the DSO operates.

Furthermore, major hospitals, medical university dental departments, and academic research institutions constitute another vital customer segment. These entities typically require specialized surgical instruments for complex maxillofacial surgeries and demanding educational instruments for clinical training programs. Their procurement processes are often characterized by rigorous tendering, long sales cycles, and strict adherence to institutional purchasing guidelines and budget allocations. Research institutions also drive demand for niche, high-precision instruments used in experimental or developmental dentistry. Successfully serving this segment requires robust technical documentation, clinical validation data, and strong professional relationships with key opinion leaders within these academic and institutional environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.95 Billion |

| Market Forecast in 2033 | $3.05 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hu-Friedy Mfg. Co. LLC, Dentsply Sirona Inc., 3M Company, Integra LifeSciences, B. Braun Melsungen AG, Henry Schein, Inc., A. Titan Instruments, Karl Hammacher GmbH, American Eagle Instruments, Inc., Premier Dental Products Company, PDT Inc. (Paradise Dental Technologies), Asa Dental S.p.A., Nordent Manufacturing, Inc., Coltene Holding AG, Medline Industries, Inc., Miltex (Integra LifeSciences), Helmut Zepf Medizintechnik GmbH, Septodont, J.S. Dental Mfg., Otto Leibinger GmbH. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dental Hand Instruments Market Key Technology Landscape

The technological landscape of the Dental Hand Instruments Market is undergoing continuous innovation driven by material science, manufacturing precision, and enhanced ergonomic considerations. A primary area of focus is the development of superior materials, such as specialized surgical stainless steel alloys and high-grade tungsten carbide inserts, which offer exceptional edge retention and resistance to degradation from acidic environments and high-temperature sterilization. Manufacturers are employing advanced surface treatments, including specialized coatings (e.g., titanium nitride or diamond-like carbon coatings), to reduce friction, improve non-stick properties for composite handling, and enhance overall lifespan. Furthermore, the push for lighter yet stronger instruments is promoting the use of titanium alloys in certain applications, reducing practitioner fatigue and improving tactile sensitivity necessary for intricate procedures.

In manufacturing, the adoption of sophisticated processes like 5-axis CNC machining, micro-welding, and additive manufacturing (3D printing) is setting new standards for instrument precision and customization. CNC technology ensures incredibly tight tolerances for working ends, leading to more predictable clinical outcomes. 3D printing is specifically being explored for prototyping and producing complex handle geometries that are highly ergonomic and customized to specific user preferences or functional requirements. This technological leap allows for faster iteration in R&D and potentially more cost-effective production of highly specialized or limited-run instrument kits, particularly those required for advanced implantology or guided surgery techniques.

Another crucial technological element is the integration of instrument management and tracing systems. Laser etching and specialized markings (like RFID tags or data matrix codes) are being incorporated onto instruments to facilitate automated tracking through sterilization cycles, aiding in infection control compliance and inventory management. This technology minimizes human error in tracking instrument usage and maximizes the utilization period, ensuring that instruments are only replaced when their functional life is genuinely exhausted. This technological convergence—combining advanced material science with digital tracking capabilities and precision manufacturing—is pivotal in maintaining the high standards of safety and efficiency demanded by modern dental practice globally.

Regional Highlights

The global dental hand instruments market exhibits distinct regional dynamics shaped by healthcare expenditure, regulatory environments, and demographic trends. North America, specifically the United States, commands a significant market share due to its well-established dental insurance market, high awareness of preventive oral healthcare, and the rapid adoption of advanced dental technologies and specialized procedures like cosmetic dentistry and implantology. The region features numerous large DSOs and a high concentration of specialized dental practitioners, driving consistent demand for premium, high-quality instruments and sterile management systems. Furthermore, strong local manufacturing bases contribute to market stability and quick adoption of new product innovations, often setting global trends.

Europe represents the second-largest market, characterized by mature healthcare systems and stringent regulatory frameworks (such as the EU MDR) that prioritize quality and patient safety. Western European nations, including Germany, the UK, and France, are major consumers, fueled by aging populations and state-supported healthcare systems that mandate high standards of dental care. The European market shows a strong preference for durable, reusable instruments, leading manufacturers to focus heavily on enhanced sterilization compatibility and long-term warranties. However, economic disparity across Eastern and Western Europe impacts pricing and procurement strategies, with Eastern Europe exhibiting faster growth potential due to infrastructure modernization.

The Asia Pacific (APAC) region is forecasted to be the fastest-growing market globally. This exponential growth is driven by massive untapped potential in populous nations like India and China, where expanding middle classes are increasing discretionary spending on healthcare. Government initiatives aimed at improving dental infrastructure, coupled with the rise of dental tourism, are accelerating the establishment of modern dental clinics requiring high volumes of standard and specialized hand instruments. While price sensitivity remains a key factor, the growing emphasis on infection control standards is increasingly pushing practitioners away from low-quality substitutes towards certified, reliable instrument brands. Latin America and the Middle East and Africa (MEA) are emerging markets, where urbanization and improvements in basic healthcare access drive steady, if localized, market expansion.

- North America: Dominant market share due to advanced healthcare infrastructure, high per capita dental expenditure, and strong presence of Dental Support Organizations (DSOs) standardizing instrument procurement.

- Europe: Large, mature market prioritizing high-quality, durable instruments compliant with stringent regulations (MDR); significant demand generated by aging demographics and robust public healthcare systems.

- Asia Pacific (APAC): Fastest-growing region driven by infrastructure investment, increasing access to dental care in emerging economies, rising dental tourism, and growing adoption of modern treatment methodologies.

- Latin America: Steady growth fueled by increasing private dental practice investments and growing awareness of basic oral hygiene, though hindered by economic volatility in certain countries.

- Middle East and Africa (MEA): Emerging growth sector centered around wealthy Gulf Cooperation Council (GCC) countries investing heavily in medical infrastructure and specialized dental services, driving demand for premium surgical kits.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dental Hand Instruments Market.- Hu-Friedy Mfg. Co. LLC

- Dentsply Sirona Inc.

- 3M Company

- Integra LifeSciences

- B. Braun Melsungen AG

- Henry Schein, Inc.

- A. Titan Instruments

- Karl Hammacher GmbH

- American Eagle Instruments, Inc.

- Premier Dental Products Company

- PDT Inc. (Paradise Dental Technologies)

- Asa Dental S.p.A.

- Nordent Manufacturing, Inc.

- Coltene Holding AG

- Medline Industries, Inc.

- Miltex (Integra LifeSciences)

- Helmut Zepf Medizintechnik GmbH

- Septodont

- J.S. Dental Mfg.

- Otto Leibinger GmbH

Frequently Asked Questions

Analyze common user questions about the Dental Hand Instruments market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected growth rate (CAGR) for the Dental Hand Instruments Market?

The Dental Hand Instruments Market is projected to exhibit a steady Compound Annual Growth Rate (CAGR) of 6.5% between the forecast years of 2026 and 2033, driven by increasing global oral disease prevalence and technological advancements in instrument design.

Which material segment is currently dominating the market?

Surgical-grade Stainless Steel remains the dominant material segment in terms of volume due to its cost-effectiveness and broad utility, although Tungsten Carbide is rapidly gaining market value share, especially in specialized cutting and restorative instruments, owing to superior durability and edge retention.

How is technological innovation affecting the design of dental hand instruments?

Technology is driving innovation through enhanced ergonomics, integrating lightweight titanium alloys, and utilizing high-precision manufacturing techniques like CNC machining to improve tactile feedback and procedural efficiency. Digital tracking via laser etching and RFID is also becoming standard for improved inventory management and sterilization compliance.

Which geographical region is expected to show the highest market growth?

The Asia Pacific (APAC) region is anticipated to demonstrate the highest market growth rate (CAGR) during the forecast period. This acceleration is linked to significant investment in dental infrastructure, increasing middle-class disposable income, and the expansion of accessible dental care services across major economies like China and India.

What are the primary restraints challenging the expansion of the Dental Hand Instruments Market?

Key restraints include the high initial procurement cost of advanced, specialized instruments, the administrative burden of complying with stringent global regulatory standards, and the operational challenge posed by the need for frequent replacement due to wear and tear from repeated high-temperature sterilization cycles.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager