Dibutyltin Oxide Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440852 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Dibutyltin Oxide Market Size

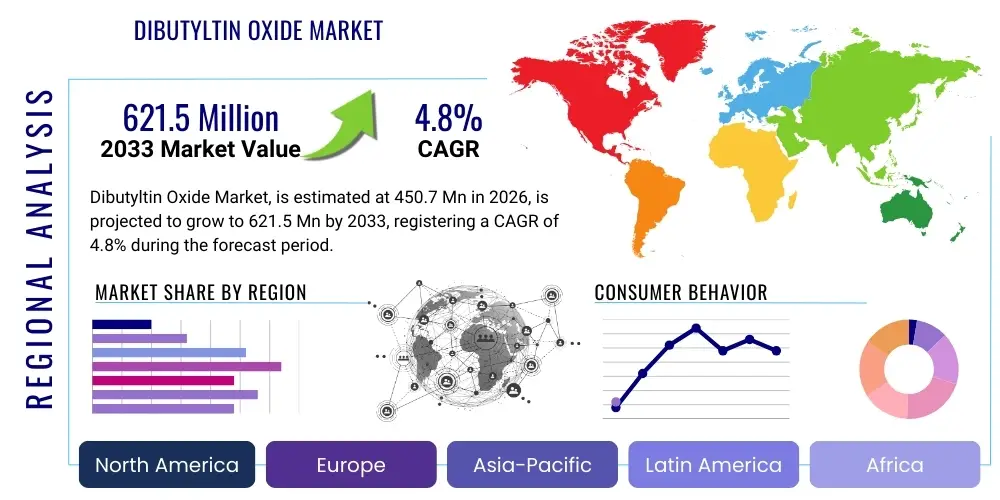

The Dibutyltin Oxide Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 450.7 Million in 2026 and is projected to reach USD 621.5 Million by the end of the forecast period in 2033. This growth is underpinned by its versatile applications across various industrial sectors, most notably in the production of PVC stabilizers, where it imparts crucial heat stability and processing advantages. The increasing demand from the plastics, automotive, and construction industries, particularly in emerging economies, is a primary driver fueling this consistent expansion. Furthermore, the compound's role as a catalyst in various organic synthesis reactions and in the formulation of specialized coatings and glass materials contributes significantly to its market trajectory.

Dibutyltin Oxide Market introduction

Dibutyltin Oxide (DBTO), a highly versatile organotin compound, holds a critical position within numerous industrial applications due to its unique chemical properties. As a white, amorphous, and insoluble powder, its primary function lies in stabilizing PVC against heat degradation, a process vital for extending the lifespan and enhancing the performance of plastic products. Beyond its role as a PVC stabilizer, DBTO acts as an effective catalyst in the production of polyurethane foams, silicones, and various esters, facilitating crucial chemical reactions with high efficiency and selectivity. Its multifaceted utility extends to applications in specialized glass coatings, where it improves durability and optical properties, and in certain types of marine antifouling paints, although environmental regulations are increasingly impacting this particular segment.

The product's description encapsulates its significance as a bifunctional compound, capable of stabilizing polymers and catalyzing complex chemical syntheses. Its thermal stability and insolubility in common organic solvents make it an ideal choice for high-temperature applications and situations requiring robust chemical inertness. Major applications include the manufacturing of PVC pipes, window profiles, cables, films, and various automotive components, where heat resistance and longevity are paramount. In the catalysts sector, it is indispensable for esterification, transesterification, and condensation reactions, playing a pivotal role in the production of polyesters, polyurethanes, and silicones that are fundamental to modern material science.

The benefits derived from using Dibutyltin Oxide are extensive, encompassing enhanced product longevity, improved processing efficiency for polymers, and the facilitation of complex chemical reactions at industrial scale. These advantages are significant driving factors for the market. The growing demand for PVC products in construction, automotive, and packaging industries, especially in rapidly urbanizing regions, directly correlates with the increased consumption of DBTO. Additionally, the continuous innovation in polymer science and the development of new synthetic pathways requiring efficient catalysts further bolster the market's expansion. However, regulatory scrutiny regarding organotin compounds due to environmental and health concerns acts as a significant restraint, compelling manufacturers to invest in cleaner production technologies and explore alternative solutions.

Dibutyltin Oxide Market Executive Summary

The Dibutyltin Oxide market is characterized by dynamic business trends, marked by a growing emphasis on product innovation, sustainable manufacturing practices, and strategic collaborations aimed at navigating stringent regulatory landscapes. Key industry players are increasingly investing in research and development to formulate novel DBTO variants with reduced environmental impact and enhanced performance characteristics, particularly in applications requiring higher purity and stability. Consolidation activities, including mergers and acquisitions, are also observed as companies seek to expand their market share, optimize supply chains, and gain access to specialized technologies or customer bases. Furthermore, there is a clear trend towards optimizing production processes to improve efficiency and reduce waste, driven by both economic incentives and corporate social responsibility initiatives.

Regionally, the market exhibits diverse growth patterns. The Asia Pacific (APAC) region currently dominates the Dibutyltin Oxide market, primarily fueled by robust industrial growth in countries like China, India, and Southeast Asian nations. Rapid urbanization, significant investments in infrastructure development, and the burgeoning automotive and electronics manufacturing sectors in APAC are driving substantial demand for PVC stabilizers and catalysts. In contrast, mature markets in North America and Europe are experiencing more moderate growth, largely influenced by stringent environmental regulations and a shift towards sustainable, non-tin alternatives, prompting innovation in greener product formulations. Latin America and the Middle East & Africa (MEA) represent emerging markets with considerable potential, driven by developing industrial bases and increasing demand for infrastructure materials, though they currently contribute a smaller share to the global market.

Segment-wise, the PVC stabilizers application segment continues to be the largest consumer of Dibutyltin Oxide, reflecting the widespread use of PVC in construction, automotive, and consumer goods. This segment's growth is inherently linked to the expansion of the plastics industry. The catalyst segment, encompassing applications in polyurethane, silicone, and ester synthesis, is also witnessing steady growth, propelled by the expanding chemical manufacturing sector and the demand for high-performance materials. Emerging trends within these segments include the development of specialized grades of DBTO tailored for specific polymer types or reaction conditions, aiming to optimize performance and efficiency. The ongoing search for tin-free alternatives, while a restraint, also pushes innovation within the DBTO market, as manufacturers strive to develop safer and more environmentally friendly organotin compounds to maintain market relevance.

AI Impact Analysis on Dibutyltin Oxide Market

Users frequently inquire about how artificial intelligence (AI) can revolutionize the Dibutyltin Oxide market, focusing on optimizing production processes, enhancing supply chain transparency, and accelerating R&D for safer alternatives. Common themes revolve around the potential for AI to predict market demand more accurately, manage inventory efficiently, and improve quality control in manufacturing. There's significant interest in AI's role in synthesizing new organotin compounds or identifying non-tin alternatives with similar performance profiles, thereby addressing existing regulatory concerns. Concerns often touch upon the initial investment costs, the need for specialized data infrastructure, and the ethical implications of AI-driven decision-making in chemical production, particularly regarding worker safety and environmental monitoring. Overall, the expectation is that AI will drive efficiency, innovation, and sustainability, while also presenting challenges related to implementation and data management within this specialized chemical sector.

- AI-driven predictive analytics can significantly optimize Dibutyltin Oxide production schedules by forecasting demand more accurately, leading to reduced waste and improved resource allocation in manufacturing plants.

- Integration of AI in supply chain management systems enables real-time tracking of raw materials and finished products, enhancing transparency, reducing logistical bottlenecks, and ensuring timely delivery of DBTO to end-users globally.

- AI algorithms can accelerate the discovery and development of novel Dibutyltin Oxide formulations or entirely new, sustainable chemical stabilizers and catalysts by rapidly analyzing complex chemical structures and predicting their properties and efficacy.

- Machine learning models can enhance quality control processes during DBTO synthesis, identifying impurities or deviations in real-time, thereby ensuring consistent product quality and reducing batch failures, leading to higher manufacturing yields.

- AI-powered process optimization tools can fine-tune reaction parameters for DBTO production, minimizing energy consumption and maximizing catalytic efficiency, contributing to more environmentally friendly and cost-effective manufacturing operations.

- Advanced data analytics through AI can identify emerging market trends and regulatory shifts related to organotin compounds, allowing manufacturers to proactively adapt their product portfolios and business strategies to remain competitive and compliant.

DRO & Impact Forces Of Dibutyltin Oxide Market

The Dibutyltin Oxide (DBTO) market is primarily driven by the sustained and growing demand from its major end-use industries, particularly the PVC stabilization sector. The inherent advantages of DBTO in imparting superior heat stability, weatherability, and processability to PVC products ensure its continued relevance in a market that constantly seeks durable and high-performance plastic solutions. Furthermore, its crucial role as a catalyst in the production of polyurethanes, silicones, and various esterification processes contributes significantly to its market expansion, supporting the manufacturing of a diverse range of materials from automotive components to construction sealants. Growth in emerging economies, marked by robust infrastructure development and rising industrialization, further amplifies the demand for DBTO-containing products, serving as a powerful impetus for market growth. The ongoing search for performance-enhancing additives in the plastics and chemical industries also acts as a continuous driver for innovation and application expansion.

However, the market faces significant restraints, primarily stemming from increasing regulatory scrutiny and environmental concerns associated with organotin compounds. The perceived toxicity and bioaccumulation potential of some organotins have led to stringent regulations and outright bans in certain applications and regions, particularly in marine antifouling paints and some consumer products. This regulatory pressure compels manufacturers to invest heavily in R&D for less toxic alternatives or to develop cleaner production methods, which can increase operational costs and shift market preferences. Additionally, volatility in raw material prices, particularly for tin metal and butyl alcohol derivatives, can impact production costs and overall market stability. Competition from alternative stabilizers, such as calcium-zinc (Ca-Zn) stabilizers and liquid mixed metal stabilizers, especially in regions with strict environmental policies, also poses a significant challenge, limiting market share and growth potential for DBTO.

Despite these challenges, opportunities abound for the Dibutyltin Oxide market, driven by the exploration of new application areas and the development of advanced formulations. Innovations in polymer science and material engineering are opening doors for DBTO in niche applications requiring high-performance catalysts or stabilizers with specific properties, such as in advanced composites or specialized coatings. The focus on sustainable production methods, including the development of low-VOC (Volatile Organic Compound) DBTO formulations and greener synthesis routes, presents an opportunity for manufacturers to differentiate their products and comply with evolving environmental standards. Furthermore, strategic market penetration in developing regions, where industrial growth and less restrictive regulations may allow for greater adoption, offers significant growth prospects. The continuous need for high-quality, durable materials across various sectors ensures a persistent underlying demand for efficient stabilizers and catalysts like DBTO, prompting ongoing research into its optimized and responsible use.

Segmentation Analysis

The Dibutyltin Oxide market is comprehensively segmented to provide a granular understanding of its diverse applications, end-user industries, and geographical distribution. This detailed segmentation allows for a precise analysis of market dynamics, identifying key growth drivers and restraints within each category. The primary segmentation includes analysis by application, discerning between its various uses like PVC stabilization and catalysis, and by end-use industry, categorizing the sectors that significantly consume DBTO. Further divisions based on grade and physical form offer additional insights into product specifications and market preferences, while regional analysis maps out the geographical spread of demand and supply. This structured breakdown is critical for stakeholders to understand market opportunities, competitive landscapes, and strategic positioning across the global value chain.

- By Application:

- PVC Stabilizers: Used to prevent degradation of polyvinyl chloride due to heat and UV light, extending product lifespan.

- Catalysts: Employed in the synthesis of polyurethane, silicones, and various esters, accelerating chemical reactions.

- Coatings: Integrated into specialized coatings for improved durability, adhesion, and anti-corrosive properties.

- Glass: Utilized in surface treatments for glass, enhancing scratch resistance and optical clarity.

- Others: Includes applications in agricultural chemicals, wood preservatives, and specific research compounds.

- By End-Use Industry:

- Plastics & Polymers: Dominant segment, driven by PVC manufacturing for various products.

- Chemical Manufacturing: Significant consumer for catalysis in organic synthesis and polymer production.

- Automotive: Used in PVC components, coatings, and sealants for vehicles.

- Construction: Essential for PVC pipes, window profiles, flooring, and other building materials.

- Electronics: Utilized in specialized polymers and coatings for electronic devices.

- Marine: Historically used in antifouling paints, now under stringent regulatory scrutiny.

- Others: Includes applications in agriculture, textiles, and research laboratories.

- By Grade:

- Technical Grade: Standard purity for most industrial applications where high precision is not critical.

- High Purity Grade: Refined for sensitive applications such as pharmaceuticals intermediates or specialized catalysts, requiring minimal impurities.

- By Form:

- Powder: The most common form, suitable for bulk handling and incorporation into solid matrices.

- Liquid/Paste: Specialized formulations offering ease of dispersion and specific handling advantages for certain processes.

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Dibutyltin Oxide Market

The value chain for the Dibutyltin Oxide market begins with upstream activities, primarily involving the sourcing and refining of raw materials. The key raw material is tin metal, which is extracted and processed to produce inorganic tin compounds. Butyl alcohol is another crucial precursor, typically derived from petrochemical sources. These basic chemicals undergo several intermediate synthesis steps to form tributyltin chloride or similar organotin intermediates, which are then further processed to yield Dibutyltin Oxide. Key players in this upstream segment include mining companies, tin refiners, and bulk chemical manufacturers specializing in petrochemical derivatives and inorganic tin compounds. The quality and stable supply of these upstream components are critical to the cost-effectiveness and consistency of DBTO production.

Moving downstream, the Dibutyltin Oxide product reaches various end-user industries through well-established distribution channels. Manufacturers of DBTO directly supply to large-scale industrial consumers such as PVC compounders, plastics processors, and major chemical companies that utilize DBTO as a catalyst in their synthesis operations. These end-users integrate DBTO into their manufacturing processes to produce a wide array of final products, including PVC pipes, window profiles, electrical cables, automotive components, polyurethane foams, and silicone sealants. The performance requirements and regulatory compliance of these downstream industries heavily influence the demand for specific grades and forms of DBTO, driving innovation and customization within the market.

The distribution channel for Dibutyltin Oxide involves a combination of direct and indirect sales. Direct sales are common for large volume orders and strategic customers, allowing for closer collaboration, technical support, and customized solutions. This approach is favored by major DBTO manufacturers for their key accounts, ensuring strong client relationships and streamlined logistics. Indirect channels, on the other hand, involve a network of distributors, agents, and specialty chemical suppliers who cater to smaller volume buyers, regional markets, and diverse end-user segments. These intermediaries play a vital role in market penetration, inventory management, and providing localized support, expanding the reach of DBTO manufacturers. The efficiency of these distribution networks is crucial for timely delivery, competitive pricing, and overall market accessibility.

Dibutyltin Oxide Market Potential Customers

The Dibutyltin Oxide market serves a diverse range of potential customers across various industrial sectors, primarily those involved in materials manufacturing and chemical synthesis. A significant portion of the demand originates from PVC manufacturers and compounders who utilize DBTO as a crucial heat stabilizer to extend the lifespan and enhance the processing characteristics of polyvinyl chloride products. These customers are fundamental to the market, producing everything from construction materials like pipes and window frames to automotive interiors and medical devices, all requiring the superior thermal stability imparted by DBTO. The consistent growth in global infrastructure development and automotive production directly translates into sustained demand from these plastic industry players, making them a cornerstone of the customer base.

Another major segment of potential customers includes chemical manufacturing companies, particularly those involved in the production of polyurethanes, silicones, and various esters. In these applications, Dibutyltin Oxide functions as a highly effective catalyst, facilitating complex chemical reactions that are essential for creating high-performance polymers and specialty chemicals. Manufacturers of coatings, sealants, and adhesives also represent key buyers, as DBTO can improve the curing process, adhesion properties, and durability of their products. This segment is driven by innovation in material science and the continuous development of new chemical formulations that leverage DBTO's catalytic capabilities to achieve desired material properties and processing efficiencies, thereby broadening the market's reach beyond traditional plastic stabilization.

Beyond these core industries, Dibutyltin Oxide finds potential customers in niche applications such as specialized glass manufacturing, where it's used to enhance surface properties, and in certain agricultural chemical formulations. While these segments represent smaller volumes compared to plastics and catalysis, they contribute to the overall diversification of the market. The common characteristic among all these potential customers is the need for a highly effective and reliable chemical additive that can deliver specific performance benefits, whether it's enhanced thermal stability, efficient catalysis, or improved material characteristics. Manufacturers of DBTO focus on offering customized grades and technical support to meet the unique requirements of these varied end-user segments, solidifying their position as critical suppliers in the industrial chemical landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.7 Million |

| Market Forecast in 2033 | USD 621.5 Million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ADEKA CORPORATION, Albemarle Corporation, BASF SE, ChemPartners, Dow Chemical Company, Fushun Special Chemicals Co., Ltd., Galata Chemicals, G&S Organotin International, Kyodo Chemical Co., Ltd., Langfang Kaiyuan Chemical Co., Ltd., Nitto Kasei Co., Ltd., PMC Biogenix, Reagens Deutschland GmbH, Showa Denko K.K., Songwon Industrial Co., Ltd., TIB Chemicals AG, Unisys Chemical Co., Ltd., Valtris Specialty Chemicals, Wuxi Jinchang Chemical Co., Ltd., Zhejiang Sunny Chemical Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dibutyltin Oxide Market Key Technology Landscape

The Dibutyltin Oxide market is underpinned by a sophisticated technology landscape, primarily revolving around advanced chemical synthesis routes and purification techniques designed to ensure product purity, efficiency, and environmental compliance. Traditional manufacturing processes for DBTO often involve the Grignard reaction or direct synthesis methods, where tin metal reacts with butyl halides to form organotin intermediates, which are then hydrolyzed and oxidized to yield Dibutyltin Oxide. Continuous advancements in reaction engineering, including the development of more efficient catalysts for the synthesis steps and optimized reactor designs, are crucial for reducing production costs and enhancing overall yield. Furthermore, process intensification techniques are being explored to streamline the manufacturing process, making it more energy-efficient and reducing the generation of by-products, aligning with modern green chemistry principles.

Beyond synthesis, the technology landscape encompasses critical purification and formulation technologies that significantly impact the end-product's performance and application versatility. Advanced filtration systems, crystallization techniques, and drying methods are employed to achieve various grades of DBTO, from technical to high-purity, catering to diverse industry requirements. For instance, high-purity grades are essential for sensitive applications like pharmaceutical intermediates or specialized catalysts where even trace impurities can affect performance. In terms of formulation, technologies for producing specific physical forms, such as micronized powders for improved dispersion or liquid/paste forms for easier integration into liquid matrices, are vital for meeting specific customer needs and expanding application possibilities. These formulation innovations also address handling properties, ensuring safety and ease of use in industrial settings.

The evolving regulatory environment and a growing emphasis on sustainability are also driving technological innovation in the DBTO market. This includes the development of cleaner production technologies aimed at minimizing waste generation, reducing solvent usage, and mitigating the environmental footprint of organotin manufacturing. Research into alternative, more sustainable precursors and less hazardous synthesis routes is ongoing, even as manufacturers work to optimize current processes. Moreover, advanced analytical methods, such as Gas Chromatography-Mass Spectrometry (GC-MS), High-Performance Liquid Chromatography (HPLC), and Inductively Coupled Plasma-Mass Spectrometry (ICP-MS), are routinely employed for rigorous quality control, ensuring that DBTO products meet stringent specifications for composition, purity, and environmental safety. These analytical capabilities are essential for demonstrating regulatory compliance and maintaining customer trust in a highly scrutinized chemical sector.

Regional Highlights

- North America: This region presents a mature market for Dibutyltin Oxide, characterized by stable demand from established plastics and chemical industries. Stringent environmental regulations, particularly from agencies like the EPA, drive manufacturers to focus on high-purity grades and sustainable production practices, and also encourage research into non-tin alternatives, impacting overall growth. The automotive sector, a significant consumer of PVC and various catalysts, remains a key demand driver, alongside steady growth in specialized chemical manufacturing.

- Europe: The European market for Dibutyltin Oxide is heavily influenced by strict REACH regulations and a strong emphasis on environmental protection and worker safety. While demand from the construction and automotive sectors is consistent, there's a pronounced shift towards more sustainable and low-toxicity stabilizers and catalysts. This region is a hub for innovation in green chemistry, pushing for cleaner production technologies and the development of organotin compounds with reduced environmental impact, influencing global standards.

- Asia Pacific (APAC): APAC stands as the largest and fastest-growing market for Dibutyltin Oxide, primarily driven by rapid industrialization, massive infrastructure development, and burgeoning manufacturing sectors in countries like China, India, and Southeast Asia. The construction, automotive, and electronics industries are experiencing exponential growth, leading to substantial demand for PVC stabilizers and various catalysts. While environmental regulations are tightening, the sheer scale of industrial output ensures this region's dominance in DBTO consumption.

- Latin America: This region is an emerging market for Dibutyltin Oxide, exhibiting moderate growth driven by developing industrial bases, increasing foreign investment in manufacturing, and growing construction activities. Countries like Brazil and Mexico are leading the demand, particularly for PVC-based construction materials and automotive components. The market here is characterized by increasing adoption of industrial chemicals as local manufacturing capabilities expand, gradually contributing more to the global market share.

- Middle East & Africa (MEA): The MEA region represents another developing market for Dibutyltin Oxide, with growth primarily linked to ongoing infrastructure projects, particularly in the Gulf Cooperation Council (GCC) countries, and expanding petrochemical industries. While currently a smaller market, investments in industrial diversification and the need for durable materials in challenging climatic conditions are creating a steady demand for PVC stabilizers and catalysts. Market expansion is gradual but promising, supported by regional economic development.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dibutyltin Oxide Market.- ADEKA CORPORATION

- Albemarle Corporation

- BASF SE

- ChemPartners

- Dow Chemical Company

- Fushun Special Chemicals Co., Ltd.

- Galata Chemicals

- G&S Organotin International

- Kyodo Chemical Co., Ltd.

- Langfang Kaiyuan Chemical Co., Ltd.

- Nitto Kasei Co., Ltd.

- PMC Biogenix

- Reagens Deutschland GmbH

- Showa Denko K.K.

- Songwon Industrial Co., Ltd.

- TIB Chemicals AG

- Unisys Chemical Co., Ltd.

- Valtris Specialty Chemicals

- Wuxi Jinchang Chemical Co., Ltd.

- Zhejiang Sunny Chemical Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Dibutyltin Oxide market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Dibutyltin Oxide (DBTO) and its primary uses in the market?

Dibutyltin Oxide (DBTO) is a versatile organotin compound, predominantly used as a heat stabilizer for Polyvinyl Chloride (PVC), which enhances the durability and processing efficiency of plastic products. It also serves as a crucial catalyst in various chemical syntheses, including the production of polyurethanes, silicones, and esters. Its chemical properties, such as thermal stability and insolubility, make it indispensable across diverse industrial applications, including construction, automotive, and chemical manufacturing.

How do environmental regulations impact the Dibutyltin Oxide market?

Environmental regulations, particularly those concerning organotin compounds due to their perceived toxicity and bioaccumulation, significantly impact the Dibutyltin Oxide market. Stricter rules in regions like Europe (REACH) and North America have led to bans in certain applications and pushed manufacturers to invest in research and development for more sustainable alternatives or cleaner production methods. This regulatory pressure fosters innovation but also creates challenges for market growth and product acceptance, especially as industries seek greener chemical solutions.

Which regions are driving the growth of the Dibutyltin Oxide market?

The Asia Pacific (APAC) region is the primary driver of growth in the Dibutyltin Oxide market, fueled by rapid industrialization, extensive infrastructure development, and a booming manufacturing sector in countries like China, India, and Southeast Asia. The robust demand from construction, automotive, and plastics industries in these economies significantly outweighs the more mature and regulated markets of North America and Europe, positioning APAC as the largest and fastest-growing regional market for DBTO.

What are the main alternatives to Dibutyltin Oxide as a PVC stabilizer?

The main alternatives to Dibutyltin Oxide as a PVC stabilizer include calcium-zinc (Ca-Zn) stabilizers, liquid mixed metal stabilizers, and organic-based stabilizers. Ca-Zn stabilizers are gaining significant traction due to their lower toxicity and better environmental profile, making them preferred in regions with strict regulations, particularly for sensitive applications. Liquid mixed metal stabilizers offer good thermal stability and processing characteristics, while organic-based stabilizers represent a growing segment focused on highly sustainable and non-metallic options, although they may have different performance characteristics.

How is technological innovation influencing the Dibutyltin Oxide market?

Technological innovation is profoundly influencing the Dibutyltin Oxide market by focusing on optimizing synthesis routes for higher purity and yield, developing greener manufacturing processes with reduced environmental footprints, and creating advanced formulations tailored for specific applications. Innovations include improved purification techniques to meet high-purity grade demands, and the development of low-VOC variants. Additionally, research into AI-driven process optimization and the discovery of novel, safer organotin compounds or alternatives continues to shape the market's future trajectory, enhancing both efficiency and sustainability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager