Dicyclopentenyloxyethyl-Acrylate Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441660 | Date : Feb, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Dicyclopentenyloxyethyl-Acrylate Market Size

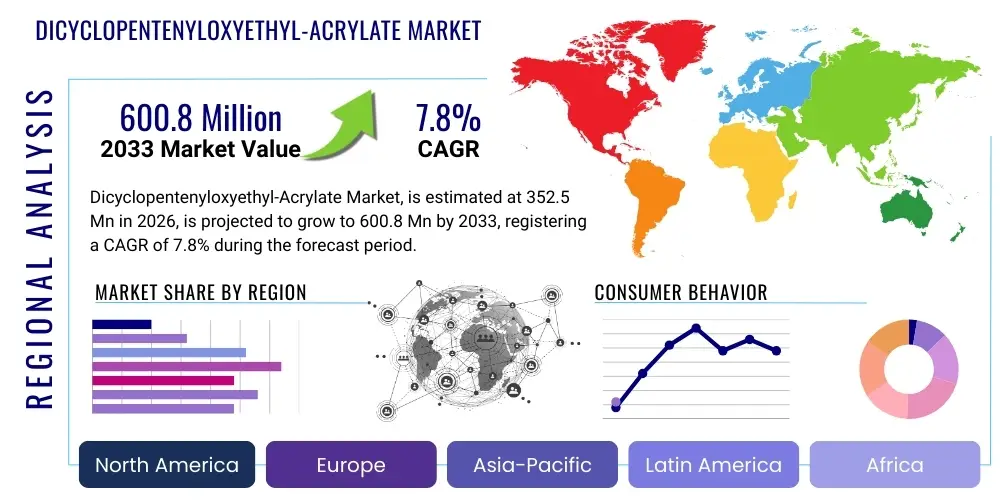

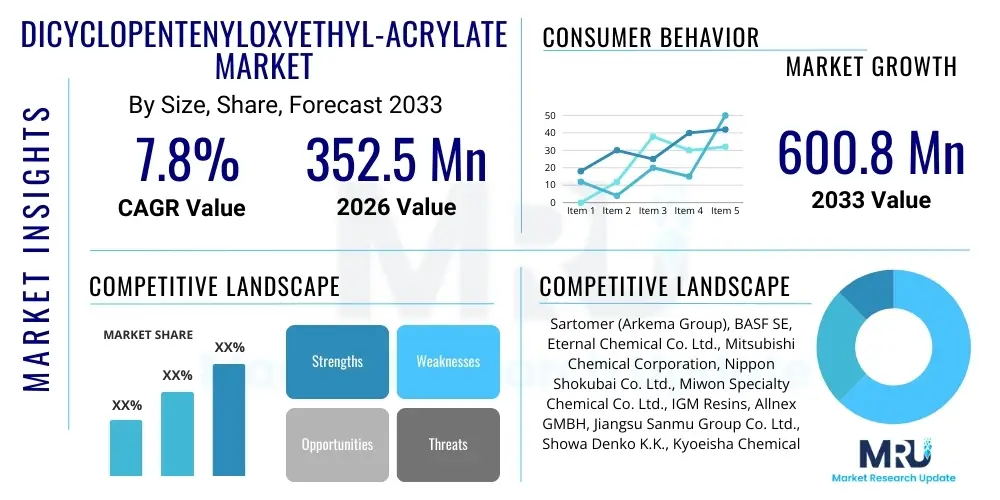

The Dicyclopentenyloxyethyl-Acrylate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 352.5 Million in 2026 and is projected to reach USD 600.8 Million by the end of the forecast period in 2033.

Dicyclopentenyloxyethyl-Acrylate Market introduction

Dicyclopentenyloxyethyl-Acrylate (DPOA) is a specialty monofunctional monomer renowned for its unique molecular structure derived from dicyclopentadiene (DCPD). This structure imparts exceptional properties, making it highly valuable in the formulation of high-performance materials, particularly in UV/EB (Ultraviolet/Electron Beam) curing applications. DPOA is characterized by its low viscosity, which significantly aids in formulation processing, along with high reactivity, excellent hardness, and strong adhesion capabilities. Its ability to introduce hydrophobic properties and enhance chemical resistance makes it a critical component where durability and fast processing speeds are paramount.

The primary applications of DPOA are concentrated in the coatings, inks, and adhesives sectors, serving as a reactive diluent or a core building block monomer. In coatings, it improves surface hardness, scratch resistance, and weatherability, essential for automotive finishes, protective wood coatings, and floor lacquers. For printing inks, particularly high-speed UV lithographic inks, DPOA ensures rapid cure rates and excellent pigment wetting, contributing to sharp, durable print quality. Its low volatility compared to traditional solvents aligns with increasing environmental regulations mandating lower VOC (Volatile Organic Compounds) content, positioning DPOA as a preferred green chemistry solution.

The market growth for Dicyclopentenyloxyethyl-Acrylate is intrinsically linked to the expansion of industries requiring high-speed, high-quality finishing processes. Key driving factors include the rapid adoption of UV LED curing technology across Asia Pacific manufacturing hubs, the growing demand for durable protective coatings in infrastructure and automotive sectors, and the specialized need for low-shrinkage, high-resolution resins in advanced 3D printing and additive manufacturing applications. The combination of superior performance metrics, such as enhanced flexibility and resistance to common industrial solvents, ensures its continued relevance and market penetration across specialized chemical markets.

Dicyclopentenyloxyethyl-Acrylate Market Executive Summary

The Dicyclopentenyloxyethyl-Acrylate market is experiencing robust growth driven by accelerating demand for high-performance UV-curable formulations across global manufacturing sectors. Business trends indicate a strong shift toward sustainable and low-VOC materials, favoring specialty acrylate monomers like DPOA, which offer exceptional reactivity without relying on traditional, volatile solvents. Strategic investments are focusing on increasing production capacity and optimizing purification processes to maintain competitive pricing amid fluctuating raw material costs (DCPD and acrylic acid derivatives). Furthermore, merger and acquisition activities among key specialty chemical manufacturers are aimed at consolidating market share and expanding technical expertise in niche applications, such as microelectronics encapsulation and biomedical coatings, signaling a maturing, yet dynamic, competitive landscape.

Regionally, Asia Pacific (APAC) stands as the dominant market, contributing the largest share of consumption due to the high concentration of electronics manufacturing, automotive production, and packaging industries, all rapid adopters of UV curing technology. China, South Korea, and Japan are pivotal consumption centers, driving demand for high-quality protective coatings for consumer electronics and displays. North America and Europe, while having lower production capacities, show significant demand for premium, highly regulated DPOA grades used in medical devices and specialized aerospace coatings, reflecting stringent regulatory environments and a focus on high-value applications. Emerging economies in Latin America and the Middle East are also beginning to integrate UV curing systems into construction and industrial coating operations, offering new market frontiers for future growth.

Segment trends highlight the dominance of the Coatings application segment, particularly industrial and wood coatings, where DPOA's characteristics significantly enhance product lifespan and aesthetic appeal. However, the fastest growth is anticipated in the Additive Manufacturing (3D Printing) segment. DPOA-based resins provide the necessary low viscosity for precise printing and high cross-linking density post-cure, resulting in parts with superior mechanical strength and thermal stability, crucial for engineering-grade components. The end-use segment analysis indicates that Electronics and Automotive industries are the primary revenue drivers, continually seeking performance enhancements in protective layers, insulation materials, and durable exterior finishes, thereby solidifying the market’s trajectory toward high-end technical applications rather than commodity usage.

AI Impact Analysis on Dicyclopentenyloxyethyl-Acrylate Market

Users frequently inquire about how Artificial Intelligence (AI) and Machine Learning (ML) can mitigate operational complexities inherent in specialty chemical synthesis, particularly for monomers like Dicyclopentenyloxyethyl-Acrylate, which require tight control over purity and consistency. Common themes revolve around optimizing reaction conditions (temperature, pressure, catalyst loading) to maximize yield and minimize energy consumption, forecasting raw material price volatility, and accelerating new product development cycles. Users are keen to understand if AI-driven material informatics can predict the performance characteristics of new DPOA formulations before expensive physical testing, specifically regarding UV cure speed, adhesion strength, and environmental stability. Furthermore, questions address the role of AI in predictive maintenance for complex polymerization reactors and enhancing quality control systems through real-time sensor data analysis, ensuring batch-to-batch consistency which is critical for demanding end-use industries like microelectronics.

- AI-driven optimization of synthesis pathways to enhance DPOA yield and purity.

- Machine Learning models utilized for predictive maintenance of complex UV curing equipment and chemical reactors, reducing downtime.

- Implementation of AI in formulation informatics to predict coating performance (e.g., scratch resistance, cure depth) based on DPOA concentration and co-monomer selection, accelerating R&D.

- Advanced forecasting algorithms used to model and hedge against volatility in Dicyclopentadiene (DCPD) and acrylic acid feedstock pricing.

- Enhanced quality control systems leveraging computer vision and ML for real-time defect detection in cured films and coatings using DPOA.

- Development of AI tools for rapid screening of sustainable, bio-based alternatives for Dicyclopentenyloxyethyl-Acrylate and related specialty monomers, driving green chemistry initiatives.

- AI integration into supply chain management for optimized inventory tracking and logistics planning for specialized, hazardous chemical transport.

DRO & Impact Forces Of Dicyclopentenyloxyethyl-Acrylate Market

The market for Dicyclopentenyloxyethyl-Acrylate is significantly influenced by a strong interplay of drivers, restraints, and opportunities. The primary driver is the accelerating global adoption of energy-efficient UV/EB curing technologies across industrial applications, replacing traditional solvent-based systems. This shift is highly beneficial for DPOA due to its excellent performance profile in UV LED systems, which require monomers with high photon absorption efficiency and rapid polymerization kinetics. Coupled with tightening global regulations aimed at reducing VOC emissions, DPOA's inherently low-volatile nature makes it an environmentally compliant and technically superior choice, further bolstering its market appeal and increasing its substitution rate against conventional monomers and oligomers.

However, the market faces notable restraints, chiefly related to the volatility and secure sourcing of key raw materials, primarily Dicyclopentadiene (DCPD). DCPD is a co-product of naphtha cracking, meaning its supply and price are directly tied to the highly cyclical petrochemical industry and global crude oil markets, leading to unpredictable operational costs for DPOA manufacturers. Furthermore, the specialized nature and complex synthesis process of DPOA result in higher production costs compared to commodity acrylates, making it price-sensitive in applications where cost reduction is prioritized over extreme performance. Managing stringent health and safety regulations surrounding the handling and transport of reactive specialty monomers also poses a consistent logistical and compliance challenge across key manufacturing regions, requiring significant investment in specialized infrastructure and training.

Opportunities for market expansion are abundant, particularly through technological diversification and geographical penetration. The rapidly evolving additive manufacturing sector, especially stereolithography (SLA) and Digital Light Processing (DLP), offers a high-growth avenue where DPOA’s low volume shrinkage and high resolution are indispensable for engineering-grade resins. Moreover, research into functionalizing DPOA derivatives for enhanced flame retardancy or antimicrobial properties opens doors into high-value niche markets such as aerospace interiors and medical device coatings. The focus on developing bio-based or recycled DPOA precursors, driven by corporate sustainability goals, presents a strategic opportunity for manufacturers to secure long-term raw material supply stability and differentiate their product offering in a crowded specialty chemical space, ultimately strengthening market resilience and capturing environmentally conscious consumer demand.

Segmentation Analysis

The Dicyclopentenyloxyethyl-Acrylate market segmentation provides a granular view of consumption patterns, driven primarily by application area and the end-use industry utilizing the specialized chemical properties of the monomer. Understanding these segments is crucial for strategic market positioning, as performance requirements vary significantly; for instance, UV coatings for automotive exteriors demand high chemical and weather resistance, while 3D printing resins prioritize precise viscosity and low volumetric shrinkage. This market is predominantly segmented by its primary use functions—reactive diluents, resin components—and the final products, which include various coatings, inks, adhesives, and niche materials, reflecting its versatility as a cross-linking agent and viscosity modifier in advanced polymer systems. The analysis reveals distinct growth rates across these segments, with additive manufacturing experiencing the fastest acceleration.

The core segment is typically bifurcated by application (e.g., Coatings, Adhesives, Inks) and by end-use industry (e.g., Automotive, Electronics, Construction). Within the Coatings segment, DPOA is categorized by the substrate it protects (wood, plastic, metal), showing heavy penetration in industrial maintenance and protective coatings where its superior mechanical properties are utilized to extend the service life of assets. Geographically, segmentation highlights the dominance of Asia Pacific in bulk consumption for electronics and packaging, contrasting with the high-value, low-volume consumption in North America and Europe, centered around aerospace and medical applications. This detailed segmentation allows manufacturers to tailor their product offerings, focusing on grades that meet specific regulatory and performance thresholds required by leading end-users in each vertical.

Further analysis of segmentation also addresses the purity and grade of DPOA offered. Specialty chemical companies often supply technical grades for general industrial use and ultra-high-purity grades required for microelectronics or optical fiber coatings, where even trace impurities can compromise performance. The trend toward customized monomer blends, incorporating DPOA to achieve specific characteristics such as increased flexibility without compromising hardness, dictates that future segmentation might increasingly focus on functional attributes rather than generic product categories. This bespoke approach to formulation highlights the market's trajectory towards highly specialized and application-specific chemical solutions, necessitating advanced technical support and deeper collaboration between monomer producers and final product formulators.

- By Application:

- UV/EB Curable Coatings

- Printing Inks (Flexo, Screen, Lithographic)

- Adhesives (Pressure Sensitive, Structural)

- 3D Printing Resins (SLA/DLP)

- Optical Fiber Coatings

- Electronic Encapsulants

- By End-Use Industry:

- Automotive & Transportation

- Electronics & Semiconductors

- Industrial Wood & Furniture

- Packaging & Graphic Arts

- Construction & Infrastructure

- Medical & Healthcare Devices

- By Grade:

- Technical Grade

- High Purity Grade (Electronics/Optics)

Value Chain Analysis For Dicyclopentenyloxyethyl-Acrylate Market

The value chain for Dicyclopentenyloxyethyl-Acrylate is highly integrated, beginning with the complex petrochemical sourcing of raw materials. Upstream analysis focuses on the supply of Dicyclopentadiene (DCPD) and Acrylic Acid, which are derived from crude oil refining processes, primarily naphtha cracking. The stability of this upstream segment is critical, as DCPD procurement requires specialized storage and handling due to its reactive nature and susceptibility to dimerization. Key upstream players include major petrochemical companies and chemical intermediates suppliers who exert significant influence over production costs. DPOA manufacturers then synthesize the specialized monomer through esterification and subsequent purification steps, which require high capital expenditure and sophisticated process control to ensure the high purity required for performance applications.

The midstream stage involves the formulation and distribution of DPOA. Monomer producers often sell directly to large-scale formulators or compounders who integrate DPOA into proprietary blends, such as UV oligomers, specialized coatings, or ready-to-use 3D printing resins. Distribution channels are highly specialized, relying on chemical distributors capable of handling and shipping reactive monomers under strict temperature and safety protocols. Direct distribution is common for high-volume contracts with major global coating manufacturers, ensuring product integrity and technical support, whereas indirect distribution through regional distributors serves smaller custom formulators and niche market players who require smaller batch sizes and localized technical expertise. Efficiency in the midstream hinges on minimizing logistics costs and ensuring rapid, safe delivery.

Downstream analysis centers on the vast array of end-use industries. Major consumers include automotive original equipment manufacturers (OEMs) using UV-curable clear coats, electronics assemblers needing protective dielectric layers, and packaging companies employing high-speed UV inks for flexible films and labels. The final consumption is driven by the performance characteristics DPOA imparts, such as superior weatherability, chemical resistance, and rapid cure speed, which translates directly into manufacturing efficiency and product quality for the end-user. The success of DPOA in the downstream relies heavily on collaborative innovation between monomer suppliers and end-product users to fine-tune formulations for emerging technologies, such as advanced additive manufacturing techniques that require highly specific material properties, completing a sophisticated value chain where purity and technical service are competitive differentiators.

Dicyclopentenyloxyethyl-Acrylate Market Potential Customers

The primary potential customers and end-users of Dicyclopentenyloxyethyl-Acrylate are sophisticated industrial entities that utilize advanced chemical processes, particularly those involving UV/EB curing technology, seeking materials that offer enhanced physical properties and operational efficiency. This demographic includes large multinational coating manufacturers, specialized printing ink producers, and high-tech companies engaged in electronics assembly and 3D printing. These buyers prioritize product consistency, high monomer purity, and a reliable supply chain, as DPOA's quality directly impacts the final product performance, such as scratch resistance, adhesion, and cure speed. Their purchasing decisions are highly influenced by total cost of ownership, regulatory compliance, and the ability of the monomer to contribute to low-VOC or solvent-free formulations.

Specific customer groups include Automotive Tier 1 suppliers who require durable, high-gloss finishes and protective underbody coatings that resist harsh environments and chemicals, leveraging DPOA’s resistance properties. The Electronics sector, particularly manufacturers of display panels, circuit boards, and optical components, represents another key customer base, utilizing DPOA for encapsulants and protective varnishes where low dielectric constant and long-term thermal stability are critical requirements. Furthermore, companies specializing in digital light processing (DLP) and stereolithography (SLA) 3D printing are rapidly expanding their material portfolio to include engineering-grade resins, becoming high-growth potential customers, provided the DPOA derivatives meet strict parameters for shrinkage control and post-cure mechanical performance.

Another significant group of potential customers encompasses industrial manufacturers focused on wood coatings (furniture, flooring) and metal coatings (pipes, appliances). In these areas, the rapid cure time enabled by DPOA allows for high-throughput manufacturing lines, which translates into substantial operational savings. The decision-makers in these customer organizations—typically formulation chemists, procurement managers, and R&D directors—are constantly evaluating new monomers that offer a superior balance of performance and environmental compliance. Securing long-term relationships with these diverse, technical buyers necessitates providing comprehensive technical documentation, strong application support, and ensuring that DPOA products consistently meet or exceed international regulatory standards for safety and environmental stewardship.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 352.5 Million |

| Market Forecast in 2033 | USD 600.8 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sartomer (Arkema Group), BASF SE, Eternal Chemical Co. Ltd., Mitsubishi Chemical Corporation, Nippon Shokubai Co. Ltd., Miwon Specialty Chemical Co. Ltd., IGM Resins, Allnex GMBH, Jiangsu Sanmu Group Co. Ltd., Showa Denko K.K., Kyoeisha Chemical Co. Ltd., Bimax Chemical Co. Ltd., Wanhua Chemical Group Co. Ltd., Dymax Corporation, Lamberti S.p.A., Double Bond Chemical Ind. Co., Evonik Industries AG, Nagase ChemteX Corporation, Rahn AG, and Hitachi Chemical Co. Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dicyclopentenyloxyethyl-Acrylate Market Key Technology Landscape

The technology landscape surrounding the Dicyclopentenyloxyethyl-Acrylate market is characterized by innovations in synthesis methodologies, purification techniques, and the complementary curing technologies that facilitate its end-use application. In synthesis, manufacturers are increasingly adopting continuous flow chemistry rather than traditional batch processes. Continuous flow reactors offer superior temperature and pressure control, which is essential for maximizing yield and reducing the formation of unwanted side products, ensuring the high purity levels required for optical and electronic applications. This shift enhances scalability, reduces operational footprints, and significantly improves safety during the handling of reactive intermediates. Furthermore, advanced distillation and chromatography techniques are being employed post-synthesis to strip out trace impurities, critical for maintaining long-term stability in formulated products.

A crucial technological driver influencing DPOA consumption is the proliferation of high-intensity UV LED curing systems. Unlike traditional mercury vapor lamps, UV LEDs offer narrow-band radiation (e.g., 365 nm, 395 nm), which necessitates monomers and photoinitiators optimized for specific wavelengths. DPOA formulations are increasingly being engineered to maximize photo reactivity under these energy-efficient LED sources, promoting faster through-cure and surface hardness development. This technological synergy allows end-users, especially in packaging and printing, to achieve higher production speeds with significantly reduced energy consumption and heat generation, broadening the applicability of UV curing to heat-sensitive substrates like thin plastics and flexible packaging films, which previously could not withstand the higher temperatures of conventional curing methods.

The technology landscape also encompasses the development of specialized polymer modification and formulation platforms. Research efforts are focused on creating co-monomers or functionalized derivatives of DPOA, such as those featuring siloxane or fluorinated groups, to further enhance surface properties like hydrophobicity, oleophobicity, and low surface energy. This innovation allows DPOA to address highly demanding niche markets, including anti-fingerprint coatings for consumer electronics screens and self-cleaning industrial surfaces. Lastly, the implementation of Industry 4.0 principles, including sensor integration and data analytics in blending and coating application machinery, provides real-time feedback loops, allowing formulators to fine-tune DPOA concentration for optimal performance and consistency, solidifying the market’s reliance on advanced manufacturing and material science principles for sustained growth and superior product quality control.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing regional market for Dicyclopentenyloxyethyl-Acrylate, primarily driven by massive industrial capacity and rapid technological adoption in economies such as China, South Korea, Japan, and India. This region is the global hub for electronics manufacturing, automotive production, and consumer goods packaging, all of which are heavy users of UV/EB curable protective coatings and high-performance inks. The relaxed regulatory environment compared to Western markets, coupled with intense competitive pressures leading to the rapid adoption of cost-effective, high-speed UV processing technologies, fuels continuous high-volume consumption of DPOA. Furthermore, local manufacturing expertise and robust supply chains for raw materials contribute significantly to APAC's market dominance, with manufacturers investing heavily in expanding local production capabilities to meet the soaring demand for specialized acrylates used in high-density printed circuit boards (PCBs) and optical fiber coatings.

- North America: The North American market is characterized by high-value, quality-driven applications and stringent environmental regulations (particularly EPA and state-level VOC limits). Consumption is focused primarily on high-performance industrial coatings, aerospace finishes, and medical device assembly, where DPOA's purity and mechanical stability are highly valued. While volume consumption is lower than APAC, the average selling price (ASP) for DPOA in this region tends to be higher due to the premium nature of the end-products and the strict compliance costs associated with manufacturing and distribution. The region shows strong growth in the 3D printing resins segment, as numerous tech startups and industrial innovators integrate advanced UV-curable materials into prototyping and short-run production applications, emphasizing material science innovation over mass production capacity.

- Europe: Europe is a mature market defined by strict chemical regulations, most notably REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), which significantly impacts the chemical selection process. European consumers of DPOA are predominantly found in the high-end automotive, industrial wood coatings, and graphic arts industries. The European focus on sustainability and eco-friendliness drives strong demand for low-VOC and solvent-free solutions, positioning DPOA favorably against conventional alternatives. Germany, France, and the Benelux countries are major consumers, emphasizing quality, long-term durability, and compliance with high safety standards. Innovation here focuses on developing bio-based or partially bio-derived specialty monomers that can offer similar performance profiles to DPOA while addressing sustainability mandates and consumer preference for green chemistry solutions, often requiring complex R&D cycles.

- Latin America (LATAM): The LATAM market, while smaller, is exhibiting steady growth, particularly in Brazil and Mexico, driven by foreign investment in automotive assembly plants and expanding infrastructure projects. The demand for DPOA is concentrated in industrial protective coatings and certain packaging applications, reflecting the region's developing manufacturing base. Market growth is often tethered to macroeconomic stability and industrialization trends, with consumption sensitive to import duties and local currency volatility. As UV curing technology becomes more accessible and economically viable, adoption is gradually increasing, replacing older, solvent-heavy coating practices in the region’s growing industrial clusters, but reliance on imported specialized monomers remains high.

- Middle East & Africa (MEA): The MEA region is characterized by fragmented demand, primarily focused on construction and oil & gas protective coatings, particularly in the Gulf Cooperation Council (GCC) countries. The use of DPOA is specific to industrial maintenance applications requiring extreme durability and resistance to harsh climatic conditions (high temperatures, sand, and chemical exposure). While the market size is currently modest, strategic governmental investments in diversification (away from oil) and infrastructure development are expected to drive future demand for high-performance chemical specialties. Local manufacturing is limited, making the region heavily reliant on imports from Europe and Asia, requiring suppliers to manage complex international logistics to meet the specialized, high-specification demands of key industrial projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dicyclopentenyloxyethyl-Acrylate Market.- Sartomer (Arkema Group)

- BASF SE

- Eternal Chemical Co. Ltd.

- Mitsubishi Chemical Corporation

- Nippon Shokubai Co. Ltd.

- Miwon Specialty Chemical Co. Ltd.

- IGM Resins

- Allnex GMBH

- Jiangsu Sanmu Group Co. Ltd.

- Showa Denko K.K.

- Kyoeisha Chemical Co. Ltd.

- Bimax Chemical Co. Ltd.

- Wanhua Chemical Group Co. Ltd.

- Dymax Corporation

- Lamberti S.p.A.

- Double Bond Chemical Ind. Co.

- Evonik Industries AG

- Nagase ChemteX Corporation

- Rahn AG

- Hitachi Chemical Co. Ltd.

Frequently Asked Questions

Analyze common user questions about the Dicyclopentenyloxyethyl-Acrylate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications of Dicyclopentenyloxyethyl-Acrylate (DPOA)?

DPOA is primarily used as a specialty monofunctional monomer and reactive diluent in high-performance UV/EB curable formulations, notably in industrial coatings (wood, metal, plastic), advanced printing inks, specialty adhesives, and engineering-grade resins for 3D printing due to its rapid cure speed, low viscosity, and excellent mechanical properties.

Why is Dicyclopentenyloxyethyl-Acrylate preferred over standard acrylates in UV LED curing?

DPOA is favored in modern UV LED systems because its molecular structure allows for high photo-reactivity and fast polymerization kinetics under narrow-band LED wavelengths. This characteristic enables quicker curing cycles and contributes to superior surface hardness and chemical resistance in the final film, maximizing the efficiency of energy-saving LED technology.

What are the key drivers of market growth for DPOA?

The primary drivers include the stringent global transition toward low-VOC (Volatile Organic Compounds) and solvent-free coating technologies, the accelerating adoption of high-speed UV/EB curing processes across the manufacturing sector, and the increasing demand for high-resolution, dimensionally stable resins for professional additive manufacturing (3D printing).

Which region dominates the Dicyclopentenyloxyethyl-Acrylate market consumption?

The Asia Pacific (APAC) region currently holds the largest share of DPOA consumption. This dominance is attributed to the high concentration of major electronics manufacturing, automotive production, and packaging industries in countries like China, Japan, and South Korea, which are major consumers of UV-curable protective materials.

What challenges exist in the supply chain for DPOA manufacturers?

The main challenge is the inherent price volatility and supply risk associated with DPOA’s primary raw material, Dicyclopentadiene (DCPD). DCPD is a petrochemical co-product, meaning its availability and cost are heavily dependent on the highly cyclical global crude oil and naphtha cracking markets, requiring robust supply chain risk management.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager