Diffraction Gratings Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440815 | Date : Feb, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Diffraction Gratings Market Size

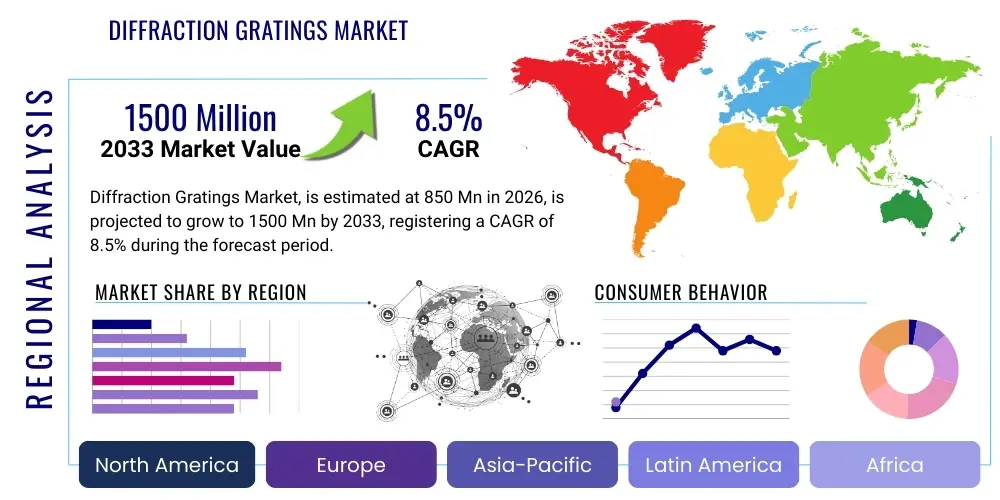

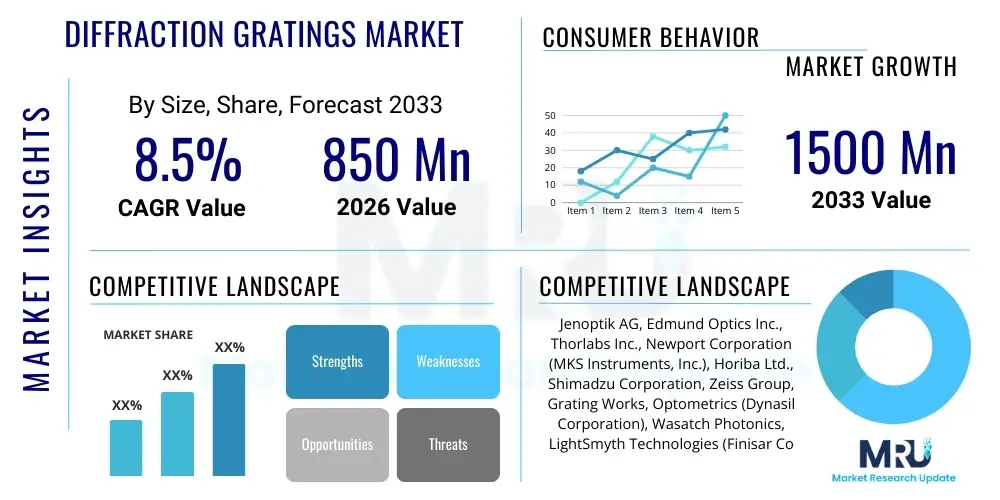

The Diffraction Gratings Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1500 Million by the end of the forecast period in 2033.

Diffraction Gratings Market introduction

Diffraction gratings are sophisticated optical components characterized by a precisely engineered periodic structure, specifically designed to effectively diffract incident light and meticulously disperse it into its constituent wavelengths. This fundamental principle of light manipulation renders them absolutely indispensable across an extraordinarily wide spectrum of scientific, industrial, and commercial applications, particularly in scenarios where the precise control, spectral analysis, and selective manipulation of light are of paramount importance for achieving high-fidelity results. These gratings function by splitting an incoming light beam into several distinct output beams, each traveling in a slightly different direction and corresponding to a specific wavelength within the incident light spectrum, thereby enabling exceptionally detailed spectral analysis and sophisticated light manipulation crucial for various advanced optical systems. The global market for diffraction gratings is currently experiencing robust and sustained growth, primarily driven by continuous technological advancements in the dynamic fields of photonics and advanced materials science, coupled with an ever-increasing global demand for high-performance optical solutions across a multitude of high-tech sectors, ranging from telecommunications to medical diagnostics and fundamental scientific research.

The primary product categories within this highly specialized market encompass ruled gratings, which are meticulously manufactured by mechanically engraving an array of parallel, equally spaced grooves onto a reflective or transmissive substrate using a diamond-tipped tool, offering robust, cost-effective, and historically established solutions for many industrial and scientific applications. Complementing these are holographic gratings, which are intricately created using advanced interferometric patterns generated by coherent laser beams, recording a high-fidelity periodic structure onto a photosensitive material, typically resulting in superior imaging quality, higher groove densities, significantly reduced stray light, and greater precision compared to their traditional ruled counterparts. Further distinctions also exist in their functional characteristics and design, such as reflection gratings, which are specifically designed to reflect and disperse light, and transmission gratings, which allow light to pass through while simultaneously dispersing it. These diverse types of gratings collectively offer unparalleled spectral resolution, exceptional dispersion capabilities, and often render them fundamentally superior to conventional prisms in a myriad of applications where a very high degree of spectral purity, precise wavelength selection, minimal aberration, and robust performance across broad spectral ranges are critical requirements.

The major applications for diffraction gratings span an impressive and growing range of industries and scientific disciplines, starting from essential analytical instrumentation such as high-resolution spectrometers and versatile monochromators, where they are absolutely vital for accurate chemical analysis, detailed material characterization, and environmental monitoring in diverse industries including pharmaceuticals, chemicals, and environmental science. They are also integral components in advanced laser systems, supporting sophisticated scientific research (e.g., in atomic and molecular physics), demanding industrial processing (such as precision laser cutting, welding, and micromachining), and critical medical procedures (e.g., ophthalmology). Furthermore, diffraction gratings play a pivotal role in modern optical communication networks for efficient wavelength division multiplexing (WDM) and dense wavelength division multiplexing (DWDM), enabling the transmission of vast amounts of data over fiber optic cables with high reliability and speed. Their utility extends to cutting-edge medical diagnostics (e.g., optical coherence tomography and flow cytometry), advanced astronomical instruments for observing and analyzing distant celestial bodies, sophisticated metrology systems for ultra-precise measurements in manufacturing, and even in robust security features embedded in banknotes, identification cards, and important documents to effectively prevent counterfeiting. The sustained innovation in their design and manufacturing processes, combined with their inherent and profound benefits in optical performance and versatility, collectively underpins the consistent growth and strategic importance of the global diffraction gratings market.

Diffraction Gratings Market Executive Summary

The global diffraction gratings market is currently experiencing robust and sustained growth, primarily fueled by the pervasive expansion of the photonics industry and increasing global investments in intensive research and development activities across various scientific and technological domains. Key business trends influencing market dynamics include the ongoing miniaturization of optical components, which enables the integration of gratings into compact and portable devices; the widespread adoption of advanced manufacturing techniques such as electron-beam lithography and reactive ion etching, leading to higher precision and efficiency; and the continuous development of highly specialized gratings tailored for emerging applications like quantum computing, advanced biosensors, and next-generation telecommunications. Leading companies in this sector are strategically focusing their efforts on improving grating efficiency, extending the operational spectral range, and enhancing the ruggedness and environmental stability of their products to meet the increasingly stringent performance requirements in demanding operational environments, thereby maintaining competitive advantage and fostering market expansion. Strategic collaborations, joint ventures, and targeted mergers and acquisitions are also shaping the competitive landscape, primarily aimed at expanding comprehensive product portfolios, acquiring crucial technological expertise, and enhancing regional market penetration.

Regionally, the market exhibits highly dynamic growth patterns and diverse maturity levels, with North America and Europe currently leading in innovation, advanced application development, and overall market share due to their strong foundational R&D infrastructure, significant government funding for scientific research, and high adoption rates of advanced optical technologies in defense, aerospace, and academic research sectors. The Asia Pacific (APAC) region is rapidly emerging as a critically significant and fast-growing market, driven by its burgeoning electronics manufacturing sector, the rapid expansion of its telecommunications industry, and substantial increases in government investments in scientific research and ambitious space exploration programs, particularly in technologically advanced nations such as China, Japan, South Korea, and India. Latin America and the Middle East & Africa (MEA) regions are also demonstrating considerable market potential, albeit at a relatively slower growth pace, primarily driven by expanding healthcare infrastructure, increasing industrial automation, and diversification efforts away from traditional resource-based economies towards technology and research-intensive sectors.

Segment-wise, the market continues to witness substantial and persistent demand from the spectroscopy segment, which remains a foundational and cornerstone application for diffraction gratings across diverse fields including analytical chemistry, environmental science, and materials research, owing to their unparalleled ability to provide high-resolution spectral data. The holographic gratings segment is specifically anticipated to witness considerable growth and adoption due to their inherent superior imaging quality, significantly reduced scattered light, and higher diffraction efficiency compared to traditional ruled gratings, making them ideal for high-precision and demanding applications where signal-to-noise ratio is critical. Furthermore, the increasing integration of sophisticated gratings into advanced optical communication systems for efficient wavelength management and the burgeoning utilization in complex medical diagnostics and precise industrial metrology are identified as key drivers propelling overall market expansion. The diffraction gratings market is strategically poised for continued expansion, synergistically propelled by relentless technological advancements, continuous product innovation, and the diversification of application areas into new and emerging high-tech domains globally.

AI Impact Analysis on Diffraction Gratings Market

Artificial Intelligence (AI) is poised to fundamentally revolutionize the diffraction gratings market by optimizing various critical stages, ranging from the initial conceptual design and precise manufacturing processes to the advanced application and data interpretation phases. AI algorithms, particularly those based on machine learning and deep learning, can significantly enhance the design phase of gratings, allowing for rapid and iterative simulation and rigorous optimization of increasingly complex grating structures to achieve highly specific and desired optical properties, such as superior efficiency, precise dispersion characteristics, and broad operational bandwidths, far more efficiently and comprehensively than conventional iterative or heuristic design methods. This advanced capability enables the accelerated creation of novel and highly specialized grating designs meticulously tailored for specific, high-performance applications, thereby drastically reducing development cycles, minimizing costly material waste, and improving overall design accuracy. Furthermore, sophisticated AI-driven quality control systems, leveraging computer vision and anomaly detection, can continuously monitor intricate manufacturing processes in real-time, detecting subtle defects, microscopic imperfections, and process variations with unprecedented accuracy and speed, consequently improving overall production yield and ensuring consistent product quality across large batches.

Beyond the direct realm of manufacturing and design, AI will profoundly impact the application and operational effectiveness of diffraction gratings, particularly in the domain of advanced analytical instrumentation. In spectroscopy, for instance, powerful machine learning models are capable of analyzing vast and complex datasets generated by grating-based spectrometers to rapidly identify intricate patterns, accurately classify unknown substances, and even predict material properties with an unprecedented level of speed, sensitivity, and accuracy. This significantly accelerates research and development endeavors in critical fields such as material science, chemistry, life sciences, environmental monitoring, and pharmaceutical discovery by extracting deeper insights from spectral data. AI-powered algorithms can also intelligently compensate for inherent instrument imperfections, subtle environmental factors (e.g., temperature or pressure variations), or sample-specific effects, leading to the acquisition of more precise, reliable, and robust measurements, thereby enhancing the overall trustworthiness and utility of grating-based analytical systems.

The strategic integration of AI also fundamentally opens entirely new avenues for the development of smart, adaptive optical systems that possess the capability to dynamically adjust grating parameters or autonomously interpret complex spectral signatures with minimal human intervention. This transformative potential could lead to the emergence of self-optimizing optical sensors for continuous monitoring, advanced remote sensing platforms with enhanced capabilities, and more intelligent and automated medical diagnostic tools that can provide instantaneous and accurate results. As the sheer volume, velocity, and complexity of data generated by advanced optical systems continue to grow exponentially, AI is rapidly becoming an indispensable and critical tool for effectively extracting actionable insights, driving continuous innovation, and strategically expanding the utility and applicability of diffraction gratings across an even wider array of advanced technological and scientific applications, from quantum optics to sophisticated environmental analysis.

- Enhanced grating design optimization through advanced machine learning algorithms, leading to superior optical performance and rapid prototyping.

- Real-time quality control and highly accurate defect detection in manufacturing processes using AI-driven computer vision and anomaly recognition systems.

- Accelerated data analysis, precise pattern recognition, and predictive modeling in spectroscopy applications, significantly boosting research efficiency.

- Development of self-calibrating, adaptive, and intelligent optical systems capable of dynamic performance adjustments.

- Improved precision, accuracy, and reliability of measurements by AI-driven compensation for instrument imperfections and environmental factors.

- Enabling novel applications in AI-driven material characterization, quantum optics, advanced medical imaging, and smart sensing technologies.

- Reduction in development cycles and manufacturing costs through optimized resource utilization and predictive maintenance facilitated by AI.

DRO & Impact Forces Of Diffraction Gratings Market

The diffraction gratings market is profoundly propelled by several significant drivers that underscore its critical role in modern technology and scientific advancement. A primary driver is the escalating global demand for high-resolution analytical instruments across diverse sectors, including scientific research, industrial quality control, environmental monitoring, and pharmaceutical analysis, where gratings are indispensable for precise spectral analysis. Furthermore, the pervasive expansion and continuous upgrading of optical communication networks, particularly the growth of 5G infrastructure and data centers, necessitate efficient wavelength management through grating-based technologies like WDM and DWDM. Technological advancements, encompassing miniaturization techniques and improved fabrication processes such as advanced lithography and replication, are continuously expanding the application spectrum of gratings into new, compact, and portable devices. Additionally, increasing investments in research and development activities in photonics, quantum technologies, and advanced materials science globally further fuel the demand for high-performance and customized diffraction gratings, enhancing their market presence and utility.

Despite these robust drivers, the market faces several inherent restraints that can temper its growth trajectory and adoption rates. One significant restraint is the relatively high manufacturing costs associated with the production of high-precision and customized diffraction gratings, which stems from the need for specialized equipment, cleanroom environments, and highly skilled labor. The inherent technical complexity involved in fabricating advanced grating structures with precise groove profiles, high groove densities, and exceptional optical efficiency also poses a challenge, often requiring extensive R&D and specialized expertise that limits the number of market participants. Moreover, the availability of alternative light dispersion technologies, such as prisms or thin-film filters, albeit often offering less spectral resolution or efficiency, can present a competitive challenge in price-sensitive applications or those with less stringent performance requirements, potentially diverting some market share. Furthermore, the long lead times required for custom grating production can occasionally delay project timelines, impacting market responsiveness and flexibility.

However, substantial opportunities exist within the diffraction gratings market, particularly in rapidly emerging and high-growth fields that demand extreme precision and custom optical solutions. These include nascent areas like quantum technology (e.g., quantum computing and quantum communication), advanced medical diagnostics (e.g., point-of-care testing and ultra-sensitive biosensors), and ambitious space exploration missions requiring robust and high-performance optical payloads. The ongoing trend towards developing integrated photonics and micro-optics presents fertile avenues for the innovation of novel grating designs, such as waveguide gratings and grating couplers, which enable compact and highly efficient on-chip optical systems. Furthermore, the increasing global focus on environmental monitoring, industrial automation, and smart agriculture necessitates more sophisticated and reliable sensing technologies, creating a burgeoning demand for specialized diffraction gratings in new sensing platforms. Strategic collaborations between leading manufacturers, academic research institutions, and end-user industries can significantly unlock these opportunities by fostering joint innovation, accelerating product development, and effectively addressing complex technical challenges.

Segmentation Analysis

The diffraction gratings market is meticulously segmented across various crucial parameters, including specific type, base material composition, primary application area, and distinct end-user industries, providing a highly granular and comprehensive view of the intricate market dynamics and effectively catering to the immensely diverse industrial, scientific, and commercial needs. This highly detailed and multi-faceted segmentation is absolutely crucial as it enables manufacturers to precisely tailor their diverse product offerings, accurately identify lucrative niche markets, and effectively address the highly specific technological and performance requirements of different sectors, thereby maximizing market penetration and customer satisfaction. Understanding these granular segments is fundamental for strategic planning, targeted product development, informed market entry decisions, and effective competitive positioning, empowering companies to strategically leverage their core strengths and specialized expertise in particular areas of optical technology. Each segment reflects unique demand patterns, technological preferences, and growth trajectories, collectively shaping the complex and evolving overall market landscape for diffraction gratings.

The segmentation by type typically differentiates between ruled gratings, which are historically significant and manufactured using mechanical inscription techniques; holographic gratings, which are optically recorded using laser interference patterns and offer superior performance; alongside more specialized and high-performance types such as echelle gratings, known for high dispersion and broad spectral coverage, and volume phase gratings (VPGs), which provide high diffraction efficiency and spectral selectivity, particularly for laser applications. Material segmentation rigorously considers the specific substrate used for grating fabrication, encompassing commonly used materials such as high-purity optical glass, fused silica (known for its excellent UV transparency and thermal stability), various robust polymers, semiconductor materials like silicon (for integrated photonics), and certain reflective metals, each offering distinct optical, mechanical, and thermal properties tailored for specific operating environments and performance criteria. Application-based segmentation critically highlights the primary uses of gratings, including their indispensable roles in high-resolution spectroscopy, advanced laser systems (e.g., ultrafast lasers), complex optical communications infrastructure, precise metrology and measurement systems, critical medical diagnostics and biomedical imaging, demanding astronomy and space research, sophisticated security and anti-counterfeiting measures, advanced industrial processing, and a wide array of fundamental scientific research endeavors.

Finally, the end-user segmentation meticulously categorizes the market by the specific industries, institutions, and organizations that extensively utilize diffraction gratings, thereby providing invaluable insights into the primary demand drivers stemming from sectors such as academic and government research institutions, the rapidly expanding telecommunications industry, the critical healthcare and life sciences sector, diverse industrial applications (including advanced manufacturing and stringent quality control), the defense and aerospace sector (for remote sensing and surveillance), and the highly specialized semiconductor industry (for lithography and inspection). This multi-faceted and comprehensive segmentation emphatically underscores the inherent versatility, technological sophistication, and indispensable nature of diffraction gratings across an exceptionally broad spectrum of advanced technologies and scientific disciplines. As various industries continue to evolve rapidly and novel applications dynamically emerge, the relative importance and market demand for specific grating types, materials, and their seamless integration into complex optical systems will continue to shift, necessitating continuous market monitoring and adaptive strategies from market players to capitalize on emerging growth opportunities.

- By Type

- Ruled Gratings: Mechanically inscribed, robust, cost-effective for general applications.

- Holographic Gratings: Optically recorded, superior imaging, low stray light, high precision.

- Echelle Gratings: Coarsely grooved, high dispersion, broad spectral range, often used in echelle spectrometers.

- Volume Phase Gratings (VPGs): High diffraction efficiency, spectral selectivity, used in high-power lasers and OCT.

- Others: Includes specialized grisms (grating-prism combination) and transmission gratings for specific optical setups.

- By Material

- Glass: Common substrate, good optical clarity, cost-effective.

- Fused Silica: Excellent UV transmission, high thermal stability, low coefficient of thermal expansion.

- Polymers: Lightweight, flexible, suitable for replication, emerging for disposable applications.

- Silicon: Used in integrated photonics and MEMS-based gratings.

- Metals: Highly reflective, robust, often used as coatings or direct substrates.

- Ceramics: High temperature resistance, chemical inertness, specialized applications.

- By Application

- Spectroscopy: Essential for chemical analysis, material characterization, environmental monitoring, and astronomical studies.

- Lasers: Used in laser cavities, pulse compression, beam shaping, and spectral tuning for various laser types.

- Optical Communications (WDM, DWDM): Key components for multiplexing and demultiplexing wavelengths in fiber optic networks.

- Metrology: Precision measurement systems, interferometry, optical encoders, and surface inspection.

- Medical Diagnostics & Biomedical Imaging: Optical coherence tomography (OCT), flow cytometry, medical spectroscopy, and lab-on-a-chip devices.

- Astronomy & Space Research: Spectrographs on telescopes, satellite-based remote sensing, planetary exploration.

- Security & Anti-Counterfeiting: Embedded in banknotes, identity documents, and brand protection elements.

- Industrial Processing: Laser material processing, quality control in manufacturing lines, process analytical technology (PAT).

- Scientific Research: Fundamental physics, chemistry, biology, and materials science experiments requiring light manipulation.

- By End-User

- Research & Academia: Universities, government labs, and private research institutions conducting fundamental and applied science.

- Telecommunications: Manufacturers of optical network components, service providers deploying fiber optics.

- Healthcare & Life Sciences: Medical device manufacturers, diagnostic labs, pharmaceutical companies, and biotech firms.

- Industrial (Manufacturing, Quality Control): Automotive, electronics, aerospace, and general manufacturing industries for inspection and process control.

- Defense & Aerospace: Military applications, surveillance, remote sensing, laser guidance systems, and space-borne instruments.

- Semiconductor Industry: Lithography, defect inspection, and metrology in microchip manufacturing.

Value Chain Analysis For Diffraction Gratings Market

The comprehensive value chain for the diffraction gratings market encompasses a meticulously structured series of interconnected stages, initiating with the upstream sourcing of highly specialized raw materials and culminating in the precise delivery and diverse application of the finished optical product to a wide array of discerning end-users. Upstream activities are predominantly focused on the procurement of high-quality optical substrates, which serve as the foundational base for grating fabrication; these include highly pure specialized glass, ultra-transparent fused silica, and various engineering polymer resins, all meticulously selected for their specific optical and mechanical properties. Additionally, specialized coating materials, such as thin-film metals and dielectrics, are procured to enhance grating performance, particularly in terms of reflectivity and efficiency. These raw material suppliers represent a critical first link in the chain, as the ultimate performance, spectral range, and environmental stability of the final diffraction grating are heavily reliant on the intrinsic purity, optical homogeneity, and mechanical integrity of the chosen substrate and coating materials. Precision engineering firms also play a vital supportive role by supplying the sophisticated machinery, specialized tooling, and advanced equipment necessary for the intricate fabrication processes.

Midstream activities are primarily dominated by the diffraction grating manufacturers themselves, who employ an array of highly sophisticated and proprietary techniques to create the periodic structures on the substrate with extreme precision. These advanced manufacturing methods include mechanical ruling, which utilizes diamond-tipped tools for physical groove engraving; sophisticated holographic exposure, where interference patterns from coherent laser beams are recorded onto photosensitive materials; and cutting-edge advanced lithography techniques, such as electron-beam (E-beam) lithography and deep UV photolithography, which allow for the creation of incredibly fine and complex grating patterns with unparalleled resolution and repeatability. This crucial stage involves substantial capital investment in state-of-the-art R&D facilities, specialized cleanroom environments, and highly precise fabrication equipment to achieve the required groove density, profile accuracy, and optical efficiency. Following fabrication, the gratings undergo rigorous and comprehensive quality control and characterization processes, utilizing advanced metrology tools to ensure they meticulously meet precise specifications for wavelength range, dispersion properties, diffraction efficiency, and minimal wavefront distortion. The careful packaging and robust protection of these delicate optical components are also critical subsequent steps before their organized distribution to prevent damage during transit.

Downstream activities involve the crucial distribution channels, which can be broadly categorized as either direct or indirect, depending on the scale and nature of the customer. Direct channels typically involve manufacturers selling their diffraction gratings directly to large-scale scientific institutions, prominent government research laboratories, or major Original Equipment Manufacturers (OEMs) who seamlessly integrate these gratings into their larger, complex optical systems, such as advanced spectrometer manufacturers, high-power laser system integrators, or telecommunications equipment providers. Indirect channels, conversely, generally involve a well-established network of specialized distributors, value-added resellers, and technical sales representatives who cater to a broader range of smaller academic laboratories, universities, emerging startups, or specific industrial clients, often providing essential technical support, integration services, and localized inventory. The diverse group of end-users, comprising research scientists, medical professionals, telecommunication engineers, defense contractors, and industrial quality control specialists, represents the final and most crucial link in this elaborate value chain, utilizing the gratings for their highly specific and demanding applications, thereby completing the market's value delivery process and driving continuous innovation.

Diffraction Gratings Market Potential Customers

The potential customer base for diffraction gratings is remarkably broad and diverse, encompassing a wide array of scientific, industrial, and commercial entities that consistently require precise control, intricate analysis, and advanced manipulation of light across various spectral ranges. These discerning end-users are primarily driven by the fundamental need for exceptionally high spectral resolution, highly efficient light dispersion capabilities, minimal optical aberration, and robust, reliable optical components within their respective and often mission-critical applications. Key buyers include an extensive network of research institutions and universities globally, particularly those actively involved in cutting-edge fields such as physics, chemistry, materials science, environmental science, and astronomy, where diffraction gratings are considered fundamental and indispensable components in their sophisticated spectroscopic, interferometric, and imaging setups, crucial for both fundamental scientific inquiry and advanced applied studies that push the boundaries of knowledge.

Beyond the realm of academic and basic research, the telecommunications industry stands as an immensely significant and rapidly growing customer segment, extensively utilizing diffraction gratings in advanced wavelength division multiplexing (WDM) and dense wavelength division multiplexing (DWDM) systems for high-bandwidth optical fiber communication, which is absolutely critical for enabling the ultra-fast and reliable transmission of vast amounts of data over global networks. The healthcare and life sciences sectors are increasingly adopting sophisticated diffraction gratings for advanced medical diagnostics, high-resolution biomedical imaging (such as optical coherence tomography and confocal microscopy), and crucial pharmaceutical research, where precise spectral analysis and optical filtering are pivotal for drug discovery, disease detection, cell analysis, and personalized medicine. Industrial sectors, including advanced manufacturing, petrochemicals, and stringent quality control, extensively employ gratings in sophisticated metrology systems, process analytical technology (PAT) for real-time process monitoring, and surface inspection systems to ensure uncompromising product quality, optimize production processes, and meet rigorous industry standards.

Furthermore, defense and aerospace organizations represent a substantial and strategically important customer base, integrating high-performance diffraction gratings into critical surveillance systems, advanced remote sensing platforms, sophistica

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1500 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Jenoptik AG, Edmund Optics Inc., Thorlabs Inc., Newport Corporation (MKS Instruments, Inc.), Horiba Ltd., Shimadzu Corporation, Zeiss Group, Grating Works, Optometrics (Dynasil Corporation), Wasatch Photonics, LightSmyth Technologies (Finisar Corporation), Kaiser Optical Systems, Toptica Photonics AG, Headwall Photonics Inc., Holographix LLC, Plymouth Grating Lab, Ibsen Photonics A/S, Spectrogon AB, Photop Technologies, RGLabs. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Diffraction Gratings Market Key Technology Landscape

The diffraction gratings market is profoundly characterized by a highly sophisticated and continuously evolving technological landscape, meticulously driven by relentless innovation in advanced fabrication methods, precise material science, and cutting-edge optical engineering to consistently meet the ever-increasing demands for unparalleled precision, superior efficiency, and extreme versatility across a multitude of high-tech applications. Key traditional manufacturing technologies include mechanical ruling, which utilizes ultra-sharp diamond-tipped tools to meticulously engrave an array of parallel and equally spaced grooves onto reflective surfaces, a technique renowned for its robustness and cost-effectiveness in large-scale production. Complementing this is holographic recording, which employs intricate interference patterns from highly coherent laser beams to create high-resolution, aberration-free gratings on photosensitive polymer- or photoresist-coated substrates, offering superior optical performance and reduced stray light. Advancements in these foundational methods have rigorously focused on improving groove accuracy and uniformity, increasing groove density, and precisely optimizing blaze angles for significantly enhanced diffraction efficiency at specific, targeted wavelengths, thereby pushing the boundaries of traditional grating performance.

More recently, advanced lithographic techniques have become increasingly prominent and indispensable, particularly state-of-the-art electron-beam (E-beam) lithography and deep UV photolithography, which allow for the creation of exceptionally fine, complex, and arbitrary grating patterns with unparalleled precision, sub-nanometer resolution, and remarkable repeatability. E-beam lithography is absolutely critical for producing gratings with sub-micron features, highly customized groove profiles, and extremely high aspect ratios, which are essential for cutting-edge applications in integrated photonics, advanced semiconductor devices, and high-performance, compact spectroscopic systems. Following the lithographic patterning, sophisticated ion-etching techniques, such as reactive ion etching (RIE) or inductively coupled plasma (ICP) etching, are often meticulously employed to precisely transfer these delicate patterns into durable and optically robust substrate materials, ensuring long-term stability, high environmental robustness, and consistent optical performance even in harsh operating conditions, thereby making them suitable for demanding industrial and aerospace applications.

Emerging and innovative technologies also prominently include the rapid development and widespread adoption of Volume Phase Gratings (VPGs), which utilize holographic recording within photosensitive polymers or specialized glass media to create gratings with exceptionally high diffraction efficiency, superior spectral selectivity, and minimal absorption, making them particularly useful in high-power laser applications (e.g., pulse compression in ultrafast lasers), advanced optical coherence tomography, and astronomical spectrographs. The strategic integration of diffraction gratings with advanced MEMS (Micro-Electro-Mechanical Systems) technology represents another significant and transformative trend, enabling the creation of compact, dynamically tunable, and highly integrated spectroscopic systems and optical switches, which are ideal for portable analytical devices and miniaturized optical communication modules. Furthermore, ongoing intensive research into novel materials, such as metamaterials and plasmonic structures, combined with advanced replication techniques and sophisticated nanofabrication methods, continues to aggressively push the boundaries of performance, enabling the cost-effective production of highly customized gratings with bespoke specifications for an even wider range of niche, high-volume, and next-generation applications.

Regional Highlights

- North America: This region maintains a dominant position in the diffraction gratings market, primarily driven by substantial investments in advanced research and development activities, the robust presence of leading key players in the photonics, defense, and aerospace industries, and the high adoption rate of sophisticated analytical instruments across scientific research, healthcare, and semiconductor sectors. The United States, in particular, is a global innovation hub for laser technology, quantum computing, and ambitious space exploration programs, fostering continuous demand.

- Europe: Europe represents a highly mature and technologically advanced market with strong and consistent growth, significantly driven by continuous advancements in industrial metrology, innovative medical technology, and intensive academic research across leading scientific institutions. Countries such as Germany, France, and the United Kingdom are at the forefront of advanced optical manufacturing, precision instrumentation, and fundamental physics research, fostering a consistent and high demand for high-performance diffraction gratings in various specialized applications.

- Asia Pacific (APAC): The APAC region is projected to be the fastest-growing market globally for diffraction gratings, primarily fueled by rapid industrialization, increasing government funding for scientific and technological research, and the burgeoning expansion of the telecommunications, electronics manufacturing, and automotive sectors in key economies. Countries like China, Japan, South Korea, and India are rapidly becoming global hubs for advanced optical component manufacturing, R&D, and adoption, driven by their vast consumer markets and technological prowess.

- Latin America: This region is exhibiting steady and gradual market growth, primarily driven by increasing investments in healthcare infrastructure, the expansion of the mining and oil & gas industries, and growing academic research. Brazil and Mexico are emerging as key markets within Latin America, with a rising demand for analytical instruments in environmental monitoring, industrial quality control, and agricultural research, indicating diversification of their economies.

- Middle East and Africa (MEA): The MEA market for diffraction gratings is gradually expanding, propelled by strategic diversification efforts in oil-dependent economies towards developing scientific research capabilities, improving healthcare infrastructure, and enhancing telecommunications networks. Investments in educational institutions, burgeoning industrial development, and growing defense expenditures are collectively creating new opportunities for the application and adoption of diffraction gratings in the region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Diffraction Gratings Market.- Jenoptik AG

- Edmund Optics Inc.

- Thorlabs Inc.

- Newport Corporation (MKS Instruments, Inc.)

- Horiba Ltd.

- Shimadzu Corporation

- Zeiss Group

- Grating Works

- Optometrics (Dynasil Corporation)

- Wasatch Photonics

- LightSmyth Technologies (Finisar Corporation)

- Kaiser Optical Systems

- Toptica Photonics AG

- Headwall Photonics Inc.

- Holographix LLC

- Plymouth Grating Lab

- Ibsen Photonics A/S

- Spectrogon AB

- Photop Technologies

- RGLabs

Frequently Asked Questions

What are diffraction gratings and how do they fundamentally work?

Diffraction gratings are advanced optical components featuring a precisely engineered periodic structure, such as an array of fine, parallel grooves or lines. Their fundamental operation involves diffracting incident light, which means they cause light waves to bend and spread as they pass through or reflect off the grating's structure. This interaction disperses the light into its constituent wavelengths, effectively separating a complex light beam into its spectral components. The angle of diffraction for each wavelength is distinct, allowing for precise spectral analysis.

What are the primary and most significant applications of diffraction gratings across industries?

The primary applications of diffraction gratings are extensive and critical across numerous high-tech industries. They are indispensable in spectroscopy for detailed chemical analysis, material characterization, and environmental monitoring. They play a vital role in advanced laser systems for scientific research and industrial processing. Furthermore, they are crucial in optical communication networks for wavelength division multiplexing (WDM), in medical diagnostics (e.g., OCT), in astronomy for observing celestial bodies, in precise metrology systems, and embedded in security features for anti-counterfeiting purposes.

How is Artificial Intelligence (AI) impacting the manufacturing and application of diffraction gratings?

AI is profoundly impacting the diffraction gratings market by revolutionizing both their manufacturing and application. In manufacturing, AI optimizes grating design through rapid simulations, enhancing efficiency and reducing development cycles. It also drives real-time quality control and defect detection, improving production yield. In applications, AI accelerates data analysis and pattern recognition in grating-based instruments, such as spectrometers, leading to more accurate and faster results in fields like material science and medical diagnostics, and enabling self-optimizing optical systems.

What are the main types of diffraction gratings currently available in the market?

The main types of diffraction gratings available in the market include ruled gratings, which are mechanically inscribed with grooves and known for robustness; holographic gratings, created using laser interference patterns, offering superior imaging quality and reduced stray light; echelle gratings, characterized by high dispersion and broad spectral coverage for demanding spectroscopic applications; and volume phase gratings (VPGs), renowned for their high diffraction efficiency and spectral selectivity, particularly valuable in high-power laser systems and optical coherence tomography.

Which geographical regions are demonstrating leadership and significant growth in the diffraction gratings market?

North America and Europe currently exhibit leadership in innovation and market adoption, supported by robust R&D infrastructure and high utilization in defense, scientific research, and healthcare. The Asia Pacific region is rapidly emerging as the fastest-growing market, driven by its burgeoning electronics manufacturing, telecommunications expansion, and increasing government investments in scientific research in countries like China, Japan, and South Korea, which are expanding their technological capabilities and adoption rates.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager