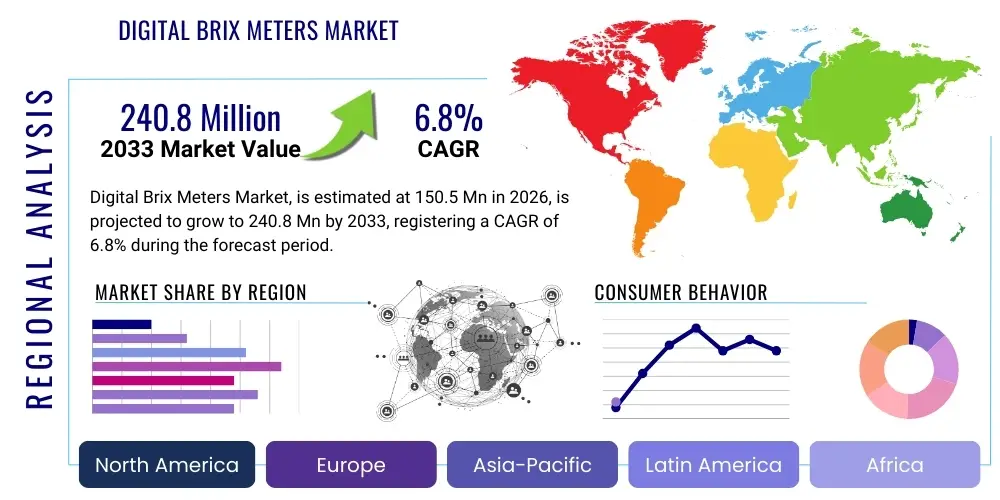

Digital Brix Meters Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441297 | Date : Feb, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Digital Brix Meters Market Size

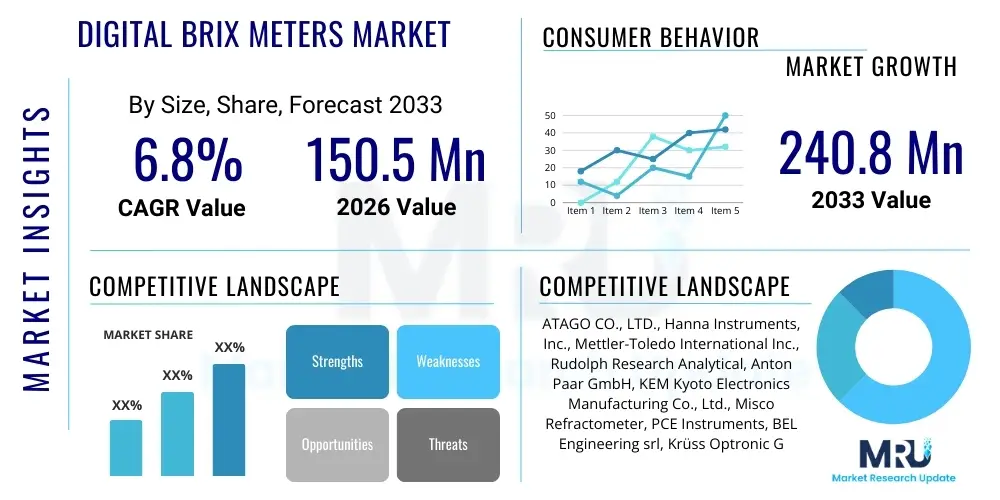

The Digital Brix Meters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 150.5 Million in 2026 and is projected to reach USD 240.8 Million by the end of the forecast period in 2033.

Digital Brix Meters Market introduction

The Digital Brix Meters Market encompasses sophisticated analytical instrumentation designed to measure the concentration of dissolved solids, primarily sucrose, in liquid solutions. The unit of measurement, Brix (symbol °Bx), indicates the percentage of sucrose by weight in the solution. These digital devices operate on the principle of refractometry, where the refractive index of a liquid solution changes proportionally to the concentration of dissolved solids. Unlike traditional optical or handheld analog refractometers, digital meters offer enhanced accuracy, automatic temperature compensation (ATC), and digital data output, significantly streamlining quality control and research processes across various industries. This technological shift addresses the critical industry need for rapid, repeatable, and traceable measurements.

Key applications of digital Brix meters span the entire production chain in sectors focused on food, beverages, and pharmaceuticals. In the food and beverage industry, they are indispensable for controlling sugar content in fruit juices, soft drinks, wines, syrups, and confectionery products, ensuring both product quality consistency and adherence to labeling requirements. For the agricultural sector, these meters are utilized in the field to determine the optimal harvest time for fruits and vegetables based on sugar maturity. Furthermore, in pharmaceutical manufacturing, they are used to monitor the concentration of active ingredients or excipients in liquid formulations, where precision and compliance with stringent regulatory standards are paramount.

The core benefits driving market adoption include high measurement speed, minimal sample volume requirements, robust data management capabilities (including LIMS integration), and reduced potential for human error inherent in analog readings. Major driving factors include the global shift towards stricter food safety and quality regulations, the increasing demand for automation in manufacturing and processing facilities (Industry 4.0), and the necessity for accurate, temperature-stable results crucial for modern scientific research and high-volume production lines. The integration of advanced features such as calibration tracking, wireless connectivity, and ruggedized designs for field use further solidifies the position of digital Brix meters as essential laboratory and quality control tools.

Digital Brix Meters Market Executive Summary

The Digital Brix Meters Market is currently undergoing significant transformation driven by technological advancements focusing on miniaturization and enhanced data connectivity. Business trends indicate a robust competition centered around accuracy specifications, measurement speed, and device portability. Handheld models are experiencing accelerated demand, particularly in field applications and smaller quality assurance laboratories due to their ease of use and affordability, while high-precision benchtop units continue to dominate R&D and pharmaceutical sectors where extreme accuracy and compliance (e.g., CFR 21 Part 11) are mandatory. Strategic mergers, acquisitions, and partnerships aimed at expanding product portfolios and geographical reach are commonplace among key players seeking to consolidate market share in specialized application segments.

Regionally, the Asia Pacific (APAC) market is projected to exhibit the highest growth rate throughout the forecast period, fueled by rapid expansion in the food and beverage manufacturing sector, especially in developing economies like China and India, coupled with increasing governmental scrutiny on food quality standards. North America and Europe, while mature markets, maintain dominance in terms of value, primarily due to high investment in advanced laboratory automation and pharmaceutical R&D activities. Regional growth strategies often involve establishing localized distribution channels and technical support teams to cater to the unique regulatory environments and specific industrial needs across diverse geographies.

Segment trends highlight the growing preference for advanced digital features, such as integrated databases for storing thousands of measurements, automatic calibration routines, and integrated Peltier cooling/heating systems for superior temperature control precision. In terms of application, the Food & Beverage segment remains the cornerstone, but the Pharmaceutical and Chemical segments are increasingly demanding highly accurate digital Brix meters capable of measuring beyond simple sugar solutions to analyze complex mixtures, solvents, and chemicals. This increasing complexity necessitates instruments capable of dual-purpose functionality, often incorporating specific density or concentration algorithms alongside standard Brix scales, pushing manufacturers to innovate optics and processing power.

AI Impact Analysis on Digital Brix Meters Market

User inquiries regarding AI's influence on the Digital Brix Meters Market frequently revolve around automation capabilities, predictive quality control, integration into larger laboratory information systems (LIMS), and the interpretation of high-volume data streams generated in modern facilities. Common questions include: Can AI algorithms predict quality deviations before they occur? How will machine learning enhance calibration accuracy over time? And, how can AI streamline regulatory compliance documentation? The overwhelming expectation is that AI will move these devices beyond simple measurement tools into intelligent quality management nodes. Based on this analysis, the key thematic concern is the integration of predictive analytical capabilities into instruments that traditionally provide only static measurement data. Users anticipate AI will leverage historical environmental, calibration, and product data to provide real-time adjustments and forecast future quality risks, thereby transforming instantaneous readings into actionable strategic insights for production optimization.

The current impact of Artificial Intelligence (AI) and Machine Learning (ML) on digital Brix meters is primarily focused on post-measurement data handling and optimization of operational efficiency, rather than the core measurement principle itself. AI algorithms are being deployed to analyze vast datasets of Brix readings, temperature profiles, and batch information to detect subtle trends, identify potential calibration drift before it becomes critical, and ensure optimal consistency in high-throughput manufacturing environments. Furthermore, integrating ML models enables instruments to adapt and learn specific product matrices, reducing the need for manual fine-tuning and calibration adjustments for every new sample type. This enhancement significantly reduces operational downtime and boosts the reliability of the measurement process, making the quality control workflow smarter and less reliant on operator expertise.

- Enhanced Predictive Quality Control: AI models analyze historical Brix trends against production variables (e.g., raw material source, processing time) to predict potential quality non-conformance in real-time.

- Automated Calibration Management: Machine learning algorithms track instrument performance drift and automatically schedule or recommend calibration checks, minimizing measurement uncertainty.

- Optimized Data Interpretation: AI assists in rapid identification and classification of outlier measurements, differentiating between genuine sample abnormalities and external factors like temperature fluctuation or sample contamination.

- Seamless LIMS/ERP Integration: AI-powered middleware facilitates structured data transfer and semantic interpretation, allowing Brix readings to be instantly contextualized within enterprise resource planning and laboratory management systems.

- Diagnostic and Maintenance Forecasting: Using sensor data, AI predicts component failure (e.g., light source or temperature control unit), enabling proactive maintenance and maximizing instrument uptime.

DRO & Impact Forces Of Digital Brix Meters Market

The Digital Brix Meters Market is strongly influenced by a complex interplay of drivers necessitating higher precision, restraints limiting adoption in certain segments, and opportunities for technological expansion, all governed by critical impact forces reshaping the competitive landscape. A primary driver is the accelerating consumer demand for standardized quality and nutritional transparency in food and beverages, compelling manufacturers globally to adopt highly accurate digital measurement tools to meet regulatory requirements and consumer expectations regarding sugar content and product consistency. Simultaneously, the market faces restraints, notably the relatively high initial capital investment required for high-end benchtop digital meters compared to traditional analog refractometers, creating a barrier to entry for smaller enterprises or facilities in emerging markets with tighter budget constraints. The opportunity landscape is vast, particularly concerning the integration of these devices into the Internet of Things (IoT) ecosystem, enabling remote monitoring and central data aggregation, crucial for decentralized manufacturing operations and large-scale agricultural monitoring.

Key drivers include the global push for automation in quality assurance laboratories, where digital meters eliminate the subjectivity and labor associated with manual readings, thereby increasing throughput and reducing labor costs. This automation driver is intrinsically linked to the demand for compliance with international standards such as ISO and regulatory frameworks like the FDA’s requirements, which necessitate tamper-proof, time-stamped, and easily auditable measurement records, functionalities inherent in modern digital devices. The rapid growth of specialty food and craft beverage industries also contributes significantly, as these segments require hyper-accurate control over ingredient ratios to maintain brand consistency and quality differentiation. Technological advancements in optics and sensor technology, leading to smaller, more robust, and faster instruments, further fuel replacement cycles and new market adoption.

Conversely, the impact forces of technological advancement and competitive rivalry are continuously shaping market dynamics. While technology offers opportunities, it also creates challenges, such as the increasing complexity of calibration and maintenance requiring specialized training, especially for advanced models equipped with density measurement capabilities. Competitive forces are driving down the price of entry-level digital models, commoditizing the basic handheld segment, and forcing established market leaders to focus their innovation efforts on high-margin, specialized instrumentation for regulated industries like pharmaceuticals and high-volume industrial processing. Furthermore, global supply chain disruptions, particularly affecting specialized optical components and microprocessors, pose periodic impact risks on manufacturing output and lead times, influencing overall market stability and price volatility across various product tiers.

Segmentation Analysis

The Digital Brix Meters Market is primarily segmented based on the instrument type, the specific application industry, and the end-user environment where the device is deployed. This three-dimensional segmentation provides a clear framework for understanding market needs, pricing strategies, and regional consumption patterns. Instrument segmentation is critical as it defines the trade-off between portability and precision—handheld devices prioritize speed and field use, whereas benchtop models offer maximum laboratory-grade accuracy and temperature control. Application segmentation highlights the dominance of the Food & Beverage sector but also indicates the high-value specialized needs arising from the Pharmaceutical and Chemical industries, which demand compliance-focused features and often measurement ranges beyond standard sugar solutions. The market structure, therefore, is highly differentiated, allowing manufacturers to target specific industrial requirements with tailored instruments.

Detailed analysis of the market segments reveals distinct purchasing drivers. Within the Food & Beverage segment, the main drivers are volume testing, rapid throughput, and robustness to handle diverse production environments. Conversely, the Pharmaceutical sector emphasizes regulatory compliance (e.g., audit trails, security features, compliance with USP standards), unparalleled measurement precision, and the ability to integrate seamlessly with validated laboratory environments. Geographically, demand for handheld meters is often higher in agricultural regions and smaller quality control stations, whereas benchtop units are concentrated in major metropolitan R&D hubs and large-scale manufacturing quality assurance departments. These variations in requirements dictate the necessary features, such as the sophistication of Automatic Temperature Compensation (ATC), the level of ruggedization, and the depth of data logging capabilities offered by the instrument.

- By Type:

- Handheld Digital Brix Meters (Portable, Battery-operated, Field Use)

- Benchtop Digital Brix Meters (High-precision, Laboratory Use, Advanced ATC)

- By Application:

- Food & Beverage Industry (Juice, Dairy, Wine, Brewing, Confectionery)

- Pharmaceutical & Biotechnology

- Agriculture (Crop Maturity Testing, Soil Analysis)

- Chemical Industry (Solvent and Concentration Monitoring)

- Research & Laboratory (Academic and Industrial R&D)

- By End-User:

- Quality Control Laboratories (QC)

- Manufacturing and Processing Facilities

- Research and Development (R&D)

- Field Testing and Inspection

Value Chain Analysis For Digital Brix Meters Market

The value chain for Digital Brix Meters begins with highly specialized upstream suppliers providing critical raw materials and components, including precision optical elements, high-resolution CCD/CMOS sensors, highly stable light sources (LEDs), and advanced microprocessor units required for data processing and temperature compensation (ATC). Upstream analysis is critical because the performance and cost of the final instrument are heavily dependent on the quality and miniaturization of these components. Manufacturers often engage in long-term relationships with specialized optical fabrication firms to ensure the highest quality prism and sensor assemblies, which are the heart of the digital refractometer. Supply chain stability, particularly for microcontrollers and specialized temperature control units (Peltier elements), is a consistent challenge affecting lead times and inventory management for downstream activities.

The core manufacturing stage involves complex assembly, software integration, stringent quality assurance testing, and comprehensive factory calibration against certified reference materials. This stage adds significant value through proprietary algorithms for temperature compensation and software designed for compliance (e.g., 21 CFR Part 11). Distribution channels are bifurcated into direct sales models for large pharmaceutical and academic institutions, where specialized technical consultation is required, and indirect channels relying on regional distributors and specialized scientific equipment dealers. Indirect channels are crucial for penetrating geographically dispersed markets, particularly in Asia Pacific and Latin America, where local presence and fast service are competitive differentiators. The effectiveness of the indirect channel is determined by the distributor’s technical expertise and ability to provide local calibration and maintenance support.

Downstream activities center around installation, training, routine maintenance, and required recalibration services, which are vital for maintaining measurement accuracy over the instrument's lifecycle. Post-sales support represents a substantial portion of the total value proposition, especially for benchtop models used in validated environments. Direct sales models often incorporate comprehensive service contracts, providing recurring revenue for manufacturers. The relationship between the manufacturer, the distributor, and the end-user is critical in ensuring the continuous accuracy and reliability of the meters, particularly in industries where measurement uncertainty can lead to significant financial or regulatory penalties. Continuous product updates, firmware upgrades, and software patches for compliance features further extend the value delivered downstream.

Digital Brix Meters Market Potential Customers

The primary consumers and end-users of Digital Brix Meters are diverse, spanning major industrial sectors focused on quality control, process monitoring, and research activities requiring precise liquid concentration measurements. The largest segment remains the Food and Beverage industry, encompassing massive multi-national beverage corporations, large-scale juice and dairy processing plants, sugar refineries, breweries, and wineries. These customers use digital meters extensively for incoming raw material inspection (e.g., checking sugar levels in fruit concentrates), in-process monitoring (e.g., fermentation control), and final product quality assurance, often deploying hundreds of units across multiple global sites, thereby driving demand for networked, high-throughput instruments.

A second critical customer base is the Pharmaceutical and Biotechnology sector. Here, digital Brix meters are essential for quality control of liquid drug formulations, intravenous solutions, ophthalmic preparations, and monitoring concentration in bioprocesses. These customers prioritize instruments offering the highest levels of accuracy, robust data integrity features, compliance with regulatory standards such as FDA's 21 CFR Part 11, and seamless integration with validated Laboratory Information Management Systems (LIMS). Procurement decisions in this sector are driven less by price and more by validation documentation, traceability, and instrument reliability to maintain regulatory compliance and batch release integrity.

Other significant potential customers include large-scale agricultural operations and food research institutions, which use portable digital meters for field testing of crop maturity (determining harvest index), and academic or industrial research laboratories focused on material science, chemical engineering, and formulation development. The increasing global focus on non-sugar sweeteners and complex formulations (e.g., sports drinks, specialized nutritional supplements) is expanding the customer base to include niche formulation houses that require meters with extended measurement capabilities beyond standard Brix scales, sometimes incorporating scales for specific gravity or concentration by mass.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 150.5 Million |

| Market Forecast in 2033 | USD 240.8 Million |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ATAGO CO., LTD., Hanna Instruments, Inc., Mettler-Toledo International Inc., Rudolph Research Analytical, Anton Paar GmbH, KEM Kyoto Electronics Manufacturing Co., Ltd., Misco Refractometer, PCE Instruments, BEL Engineering srl, Krüss Optronic GmbH, Reichert Inc., Xylem Inc. (YSI), DKSH Holding AG, Schmidt + Haensch GmbH & Co., A.KRÜSS Optronic GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Digital Brix Meters Market Key Technology Landscape

The core technology driving the Digital Brix Meters Market is sophisticated digital refractometry, which utilizes Snell's Law to measure the angle of refraction as light passes through a liquid sample and a prism. Modern instruments incorporate advanced components to ensure precision and stability, crucial among them being the light source, typically a high-intensity LED with a specific wavelength, and the sensor array, usually a high-resolution CCD or CMOS sensor. These sensors capture the critical angle light boundary, translating the optical phenomenon into a digital signal that is processed by embedded microprocessors. Technological improvements are constantly focused on enhancing the resolution of these sensors and improving the signal-to-noise ratio, allowing for accurate measurements with increasingly smaller sample volumes, a requirement critical in R&D and pharmaceutical applications where samples are often scarce or expensive.

A crucial technological differentiator in high-end digital Brix meters is Automatic Temperature Compensation (ATC) and active temperature control. Since the refractive index is highly sensitive to temperature fluctuations, advanced benchtop models employ integrated Peltier elements capable of rapidly heating or cooling the sample stage to a precise, user-defined temperature (e.g., 20°C). This stability eliminates thermal measurement drift and is essential for achieving high accuracy and repeatability mandated by international standards. Handheld devices utilize passive ATC algorithms, leveraging internal temperature sensors and software correction factors, making them highly effective for rapid field measurements under varying environmental conditions. The move towards more powerful microprocessors allows for faster temperature stabilization and more complex, customized calibration curves tailored to specific industrial samples, enhancing measurement versatility.

Further innovation is centered on connectivity and data management, reflecting the trend towards laboratory digitalization (LIMS integration). Modern digital meters feature various outputs, including USB, Ethernet, and increasingly, wireless connectivity (Wi-Fi or Bluetooth), enabling seamless, automated transfer of measurement data directly to central servers or LIMS without manual intervention. This connectivity supports compliance requirements by providing audit trails, time stamps, and secure data storage, reducing the risk of data manipulation. Advanced models often include onboard memory for hundreds of measurements and secure user access controls. Future technological trajectory involves utilizing AI for enhanced self-diagnosis, predicting maintenance needs, and optimizing the measurement process based on real-time environmental data, further solidifying the device’s role as an intelligent node in the digitized laboratory ecosystem.

Regional Highlights

The global demand for Digital Brix Meters demonstrates distinct geographical patterns driven by varying industrial maturity, regulatory landscapes, and agricultural practices. North America, particularly the United States and Canada, represents a high-value market characterized by stringent food quality and pharmaceutical manufacturing regulations. The market here is dominated by demand for high-precision benchtop models featuring advanced connectivity and compliance features (e.g., 21 CFR Part 11 support). High adoption rates are sustained by robust R&D spending and a technologically sophisticated manufacturing sector focused on efficiency and regulatory adherence, leading to steady investment in instrument replacement and upgrades.

Europe stands as another major revenue generator, driven primarily by the strong presence of the European Union’s extensive food safety directives and the concentration of leading pharmaceutical and chemical companies. Countries like Germany, France, and Switzerland are leaders in adopting automated laboratory equipment, favoring instruments that integrate seamlessly into complex quality control workflows. The brewing and wine industries across Europe are significant consumers, requiring highly accurate digital meters for fermentation monitoring and quality consistency. While growth rates are moderate compared to emerging markets, the emphasis remains heavily on precision, longevity, and adherence to established EU standards and certifications.

Asia Pacific (APAC) is forecast to be the fastest-growing region, presenting the largest opportunity for market expansion. This explosive growth is fueled by massive demographic expansion, corresponding growth in the regional food processing and beverage industry, and rising governmental efforts in countries like China, India, and Southeast Asia to enforce higher food quality standards. The demand in APAC is diverse, ranging from low-cost, durable handheld meters for large-scale agricultural testing and small processing units to sophisticated benchtop models for rapidly expanding pharmaceutical and R&D facilities. Manufacturers are heavily investing in establishing local sales, distribution, and service networks to capitalize on the region’s diverse, high-volume needs and localized procurement preferences.

Latin America (LATAM) and the Middle East & Africa (MEA) represent burgeoning markets driven by growing investments in agricultural modernization, especially in sugar and fruit production, and the development of local beverage manufacturing capabilities. While these regions may face infrastructure challenges, the core demand for accurate digital measurement tools to ensure export quality standards and improve local processing efficiency is accelerating adoption, particularly in segments related to quality inspection and primary production monitoring. Handheld digital meters offer practical, cost-effective solutions for field use in these regions, making portability and ruggedness key purchasing criteria.

- North America: Focus on high-compliance instruments for Pharma/R&D; strong replacement market; emphasis on connectivity and data integrity.

- Europe: High adoption in Food Safety and Chemical sectors; driven by EU regulatory standards; high demand for integrated laboratory automation solutions.

- Asia Pacific (APAC): Highest growth rate; demand driven by expansion of Food & Beverage manufacturing; diverse requirement for both high-end and cost-effective handheld meters.

- Latin America (LATAM): Growth driven by agricultural output (sugar, fruits) and local beverage production; increasing need for reliable field testing solutions.

- Middle East & Africa (MEA): Emerging market driven by food safety initiatives and local industrialization; focus on durable, simple-to-use digital quality control equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Digital Brix Meters Market.- ATAGO CO., LTD.

- Hanna Instruments, Inc.

- Mettler-Toledo International Inc.

- Rudolph Research Analytical

- Anton Paar GmbH

- KEM Kyoto Electronics Manufacturing Co., Ltd.

- Misco Refractometer

- PCE Instruments

- BEL Engineering srl

- Krüss Optronic GmbH

- Reichert Inc.

- Xylem Inc. (YSI)

- DKSH Holding AG

- Schmidt + Haensch GmbH & Co.

- A.KRÜSS Optronic GmbH

Frequently Asked Questions

Analyze common user questions about the Digital Brix Meters market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the key difference between analog and digital Brix meters, and why is the digital market growing?

Digital Brix meters offer superior accuracy, eliminate subjective reading errors, and incorporate Automatic Temperature Compensation (ATC), which is critical for reliable data. The market growth is fueled by the need for regulatory compliance, automated data logging, and seamless integration into modern Laboratory Information Management Systems (LIMS), functionalities unavailable in basic analog refractometers.

Which industrial application segment holds the largest share in the Digital Brix Meters Market?

The Food and Beverage (F&B) industry segment consistently holds the largest market share. Digital Brix meters are indispensable in F&B for quality control, ensuring product consistency, monitoring sugar content in juices, wines, and syrups, and meeting stringent labeling regulations globally.

How does Automatic Temperature Compensation (ATC) affect the reliability of Brix measurements?

ATC is vital because the refractive index of a solution is highly sensitive to temperature changes. Digital meters with ATC or integrated Peltier control automatically correct the measured value to a standard reference temperature (typically 20°C), ensuring that results are accurate, comparable, and reliable regardless of environmental thermal fluctuations, thereby maximizing data integrity.

What role does the Asia Pacific (APAC) region play in the future growth of the Digital Brix Meters Market?

APAC is projected to be the fastest-growing market due to rapid industrialization, significant expansion of the regional food processing and beverage sectors, and increasing regulatory pressure from governments demanding higher food quality standards. This expansion drives substantial demand for both portable field units and high-throughput laboratory instrumentation.

Are digital Brix meters compatible with Industry 4.0 and IoT frameworks?

Yes, modern digital Brix meters are increasingly designed with features like Ethernet and Wi-Fi connectivity, allowing them to interface directly with IoT and Industry 4.0 frameworks. This enables real-time remote monitoring, centralized data aggregation, automated quality reporting, and integration with Enterprise Resource Planning (ERP) systems for enhanced operational efficiency and predictive maintenance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager