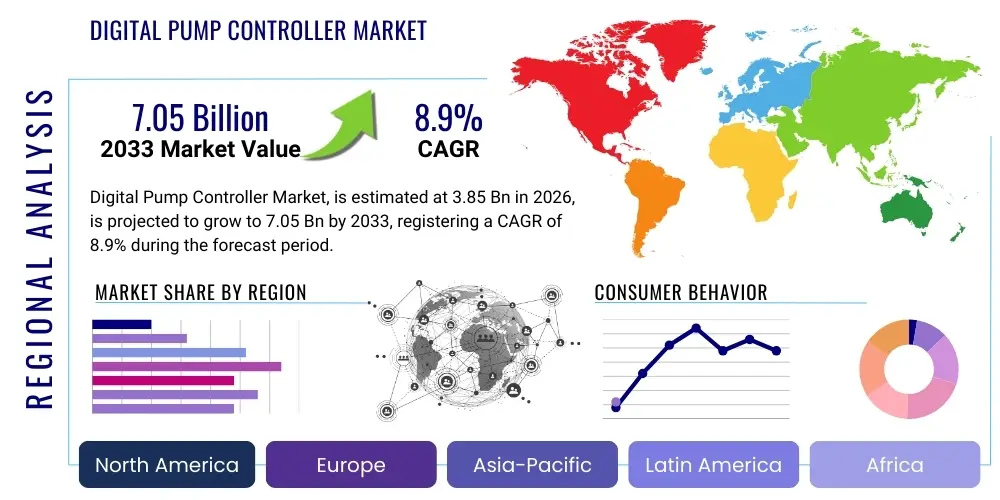

Digital Pump Controller Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440826 | Date : Feb, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Digital Pump Controller Market Size

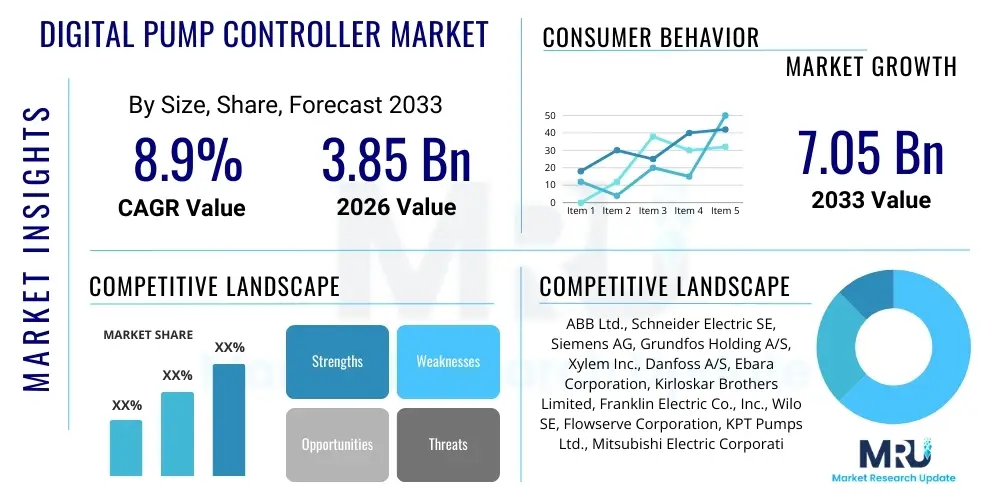

The Digital Pump Controller Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.9% between 2026 and 2033. The market is estimated at USD 3.85 Billion in 2026 and is projected to reach USD 7.05 Billion by the end of the forecast period in 2033.

Digital Pump Controller Market introduction

The Digital Pump Controller Market encompasses sophisticated electronic devices designed to manage, monitor, and protect pumps across a multitude of applications. These controllers offer precise control over pump operations, optimizing performance, extending equipment lifespan, and significantly reducing energy consumption. They integrate advanced functionalities such as variable speed control, remote monitoring, fault detection, and predictive maintenance capabilities, moving beyond traditional electromechanical starters to provide intelligent pump management solutions.

Major applications for digital pump controllers span diverse sectors including water and wastewater treatment, oil and gas, agriculture, HVAC systems, and various industrial manufacturing processes. In water utilities, they ensure efficient water distribution and waste processing, while in agriculture, they optimize irrigation schedules based on real-time data. The primary benefits include enhanced operational efficiency, reduced maintenance costs, improved system reliability, and compliance with stringent environmental regulations regarding energy use. Key driving factors for market expansion include the global push for energy efficiency, rapid industrialization and urbanization, the increasing adoption of automation technologies, and the rising demand for intelligent infrastructure solutions that support sustainable resource management.

Digital Pump Controller Market Executive Summary

The Digital Pump Controller Market is experiencing robust growth, driven by a confluence of business trends emphasizing operational optimization, energy conservation, and remote management capabilities. Industries globally are increasingly investing in smart infrastructure, fueling demand for advanced pump control systems that offer data analytics and predictive insights. This shift is particularly evident in the manufacturing and utilities sectors, where minimizing downtime and maximizing efficiency are critical to profitability. Furthermore, the integration of digital pump controllers with broader IoT and Industrial Internet of Things (IIoT) ecosystems is creating new revenue streams for manufacturers and service providers, transforming traditional pump operations into interconnected, intelligent systems.

Regionally, the market exhibits dynamic trends with Asia Pacific emerging as a significant growth engine due to rapid industrialization, extensive infrastructure development, and growing adoption of smart city initiatives, particularly in countries like China and India. North America and Europe, characterized by mature industrial bases and stringent energy efficiency mandates, continue to lead in technological adoption and innovation, focusing on retrofitting existing systems with advanced digital solutions. Emerging economies in Latin America, the Middle East, and Africa are also contributing to market expansion as investments in water infrastructure, oil and gas exploration, and industrial facilities increase. Across market segments, variable speed digital pump controllers are gaining prominence due to their superior energy-saving attributes and flexibility in managing varying flow demands, while sophisticated software platforms for monitoring and control are seeing increased penetration across all end-user categories, from industrial to agricultural applications.

AI Impact Analysis on Digital Pump Controller Market

User inquiries concerning AI's influence on the Digital Pump Controller Market frequently revolve around the potential for enhanced predictive maintenance, optimization of energy consumption, and autonomous operation. Users are keen to understand how AI can move beyond simple automation to truly intelligent management, anticipating equipment failures before they occur and dynamically adjusting pump parameters for peak efficiency in real-time. There's significant interest in AI's role in processing vast amounts of operational data from sensors and integrating this with weather patterns or demand forecasts to create highly adaptive and resilient pumping systems. Concerns often touch upon data security, the complexity of implementation, and the need for skilled personnel to manage these advanced AI-driven solutions, alongside expectations for substantial reductions in operational costs and environmental footprint.

- AI enables advanced predictive maintenance by analyzing sensor data for anomalies and degradation patterns, forecasting potential equipment failures, and scheduling maintenance proactively to minimize downtime and extend pump lifespan.

- Real-time optimization of pump performance is achieved through AI algorithms that learn optimal operating parameters based on fluctuating demand, energy prices, and environmental conditions, leading to significant energy savings and reduced operational expenses.

- AI facilitates autonomous operation by allowing controllers to make intelligent decisions without constant human intervention, such as adjusting flow rates, switching pumps, or responding to fault conditions, enhancing system reliability and responsiveness.

- Enhanced data analytics and actionable insights are provided by AI, transforming raw operational data into valuable intelligence for better decision-making, trend identification, and performance benchmarking across entire pump networks.

- AI integration supports smart grid initiatives and demand-side management by coordinating pump operations with energy availability and pricing, helping to stabilize grids and reduce peak load consumption.

- Improved fault detection and diagnostics become possible as AI systems can quickly identify the root cause of issues, reducing troubleshooting time and enabling faster recovery from system disturbances.

- Adaptive control systems benefit from AI, allowing digital pump controllers to continuously learn and adapt to changing system dynamics, wear and tear, and environmental factors, ensuring sustained optimal performance over time.

- AI contributes to resource optimization, particularly in water management and irrigation, by predicting water needs more accurately based on soil moisture, weather forecasts, and crop type, leading to more efficient water usage.

DRO & Impact Forces Of Digital Pump Controller Market

The Digital Pump Controller Market is significantly influenced by a dynamic interplay of drivers, restraints, opportunities, and broader impact forces that shape its growth trajectory. Key drivers include the escalating global demand for energy-efficient industrial and utility solutions, propelled by increasing operational costs and stringent environmental regulations aimed at reducing carbon footprints. The rapid pace of industrialization and urbanization in emerging economies necessitates robust and intelligent water and wastewater management systems, further bolstering the adoption of advanced pump controllers. Additionally, the widespread integration of automation and IoT technologies across various sectors is creating a favorable environment for digital pump controller solutions that offer remote monitoring, data analytics, and predictive capabilities, thereby enhancing operational control and system reliability.

Conversely, several restraints impede faster market expansion. The relatively high initial investment costs associated with upgrading to digital pump controller systems, especially for smaller enterprises or those with legacy infrastructure, pose a significant barrier. Technical complexity in the integration of these advanced systems with existing infrastructure, along with a shortage of skilled personnel capable of deploying and maintaining them, can deter adoption. Furthermore, growing concerns regarding cybersecurity vulnerabilities in interconnected industrial control systems represent a critical restraint, as breaches could lead to significant operational disruptions and data loss. Opportunities for market growth are abundant, particularly in the expanding water and wastewater treatment infrastructure projects globally, the increasing adoption of smart city initiatives, and the vast potential for retrofitting older, less efficient pump systems with modern digital controls. The continuous advancements in AI and machine learning offer significant opportunities for developing highly intelligent and autonomous pump management solutions, moving towards truly predictive and self-optimizing systems. Moreover, the increasing focus on sustainable practices and resource management provides a strong impetus for solutions that conserve energy and water. The market is also heavily impacted by technological innovations, especially in sensor technology, communication protocols, and data processing capabilities, which continuously enhance the performance and feature set of digital pump controllers. Regulatory mandates for energy efficiency and emission reductions, along with global economic fluctuations and supply chain resilience, also exert significant influence on market dynamics.

Segmentation Analysis

The Digital Pump Controller Market is comprehensively segmented to provide granular insights into its diverse components, technologies, applications, and end-user adoption patterns. This segmentation allows for a detailed understanding of market dynamics within specific niches, identifying high-growth areas and informing strategic decision-making for market players. The market can be broadly categorized by product type, underlying component technology, specific application areas where pumps are utilized, and the ultimate end-user industries.

- By Type:

- Fixed Speed Digital Pump Controllers: These controllers manage pumps operating at a constant speed, typically used in applications with stable flow requirements, offering basic protection and monitoring.

- Variable Speed Digital Pump Controllers: Employing technologies like Variable Frequency Drives (VFDs) or soft starters, these controllers adjust pump speed to match demand, significantly reducing energy consumption and wear.

- VFD-Based Controllers: Offer precise speed control, energy efficiency, and advanced motor protection.

- Soft Starter Controllers: Gradually ramp up motor speed, reducing mechanical stress and current surges during startup.

- By Component:

- Hardware: The physical elements enabling control and monitoring.

- Sensors: Pressure sensors, flow sensors, level sensors, and temperature sensors provide real-time operational data for precise control and protection.

- PLCs (Programmable Logic Controllers): Industrial computers that automate electromechanical processes, serving as the brain of the pump control system.

- Variable Frequency Drives (VFDs): Electronic devices that adjust the frequency and voltage supplied to electric motors, controlling their speed and torque.

- Motor Protection Relays: Devices designed to protect motors from overcurrent, undervoltage, phase loss, and other electrical faults.

- Human Machine Interfaces (HMIs): User-friendly interfaces for operators to monitor, control, and interact with the pump system.

- Communication Modules: Facilitate data exchange between the controller, sensors, and central control systems using protocols like Modbus, Ethernet/IP, or cellular.

- Software: The logical instructions and platforms that enable intelligent pump management.

- SCADA Systems (Supervisory Control and Data Acquisition): Centralized systems for monitoring and controlling entire industrial processes, including multiple pump stations.

- Cloud-based Monitoring Platforms: Allow remote access, data storage, analysis, and management of pump systems from anywhere with an internet connection.

- Predictive Analytics Software: Utilizes algorithms to analyze historical and real-time data to forecast maintenance needs and potential failures.

- Energy Management Software: Tracks and optimizes energy consumption of pump systems, identifying areas for efficiency improvements.

- By Application:

- Water and Wastewater Management: Critical for pumping stations, treatment plants, irrigation, and dewatering.

- Pumping Stations: Manage raw water intake, treated water distribution, and sewage collection.

- Treatment Plants: Control chemical dosing, filtration, and sludge handling pumps.

- Irrigation Systems: Optimize water delivery for agricultural fields based on demand.

- Dewatering Systems: Remove excess water from construction sites or mines.

- Oil and Gas: Used in various stages of exploration, production, and refining.

- Upstream Operations: Control pumps for drilling fluids, well injection, and crude oil extraction.

- Midstream Operations: Manage pumps in pipelines for crude oil and gas transportation.

- Downstream Operations: Control pumps in refineries for processing and product transfer.

- Chemical and Pharmaceutical: Ensure precise fluid transfer and process control in sensitive environments.

- Process Control: Maintain precise flow and pressure for chemical reactions.

- Fluid Transfer: Handle corrosive or sensitive liquids with accuracy.

- HVAC Systems: Regulate pumps for heating, ventilation, and air conditioning.

- Chillers and Boilers: Control circulation pumps for temperature regulation.

- Cooling Towers: Manage pumps for water circulation and heat dissipation.

- Agriculture: Optimize water usage and nutrient delivery.

- Irrigation Pumping: Automated control of pumps for field irrigation.

- Fertigation Systems: Precise control of fertilizer and nutrient injection into irrigation water.

- Building Automation: Enhance efficiency and safety in commercial and residential buildings.

- Booster Systems: Maintain consistent water pressure in multi-story buildings.

- Fire Fighting Systems: Ensure reliable operation of fire pumps during emergencies.

- Manufacturing and Industrial: Broad applications across various manufacturing processes.

- Material Handling: Control pumps for fluid transfer in industrial processes.

- Process Cooling: Manage pumps for cooling systems in machinery and production lines.

- Pressure Boosting: Maintain consistent pressure for various industrial applications.

- By End-User:

- Industrial: Factories, plants, mining operations, and large-scale processing facilities.

- Commercial: Commercial buildings, hotels, hospitals, shopping malls, and institutional facilities.

- Residential: Smart homes, multi-dwelling units, and individual residential properties.

- Agricultural: Farms, greenhouses, and aquaculture operations requiring irrigation and water management.

Value Chain Analysis For Digital Pump Controller Market

The value chain for the Digital Pump Controller Market involves a series of interconnected activities that collectively bring the product from raw materials to the end-user, emphasizing efficiency and technological integration at each stage. It commences with upstream activities focusing on the sourcing and manufacturing of critical components, followed by the core manufacturing and assembly of the controllers themselves. Downstream activities then concentrate on the distribution, installation, and ongoing support for these sophisticated systems, ultimately serving diverse end-user applications.

Upstream analysis reveals key players such as semiconductor manufacturers providing microcontrollers and integrated circuits, sensor manufacturers supplying pressure, flow, and level sensors, and electrical component suppliers for relays, contactors, and enclosures. These specialized component providers are crucial for the technological capability and reliability of the final product. Midstream, digital pump controller manufacturers integrate these components, develop proprietary software, and assemble the final units, often customizing solutions for specific industry requirements. Downstream activities involve system integrators who design and implement complete pump control solutions, distributors who handle sales and logistics to a broad customer base, and service providers offering installation, commissioning, maintenance, and technical support. Distribution channels are varied, including direct sales from manufacturers to large industrial clients, through a network of specialized distributors and resellers, and indirectly via original equipment manufacturers (OEMs) who integrate these controllers into their larger systems, ensuring broad market reach and tailored service delivery for different customer segments.

Digital Pump Controller Market Potential Customers

The potential customer base for digital pump controllers is remarkably broad and diverse, spanning nearly every sector that relies on fluid management and requires optimized, reliable, and energy-efficient pumping operations. End-users and buyers range from large-scale industrial complexes and municipal utilities to individual commercial establishments and even residential property owners. Industries such as water and wastewater treatment plants represent a cornerstone of demand, constantly seeking to improve efficiency, reduce operational costs, and comply with environmental regulations through advanced pump control systems.

Beyond utilities, the oil and gas sector, including upstream, midstream, and downstream operations, heavily invests in these controllers to manage complex fluid transfer and process control with enhanced safety and precision. Manufacturing and processing industries, from food and beverage to pharmaceuticals and chemicals, are critical customers, utilizing digital pump controllers for precise ingredient handling, process cooling, and waste management. Furthermore, the burgeoning smart building and HVAC sectors are increasingly adopting these solutions to optimize heating, ventilation, and air conditioning systems, while the agricultural sector leverages them for efficient irrigation and fertigation. Essentially, any entity that uses pumps and seeks to improve performance, save energy, monitor operations remotely, or prevent costly downtime is a potential customer for digital pump controller technology.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.85 Billion |

| Market Forecast in 2033 | USD 7.05 Billion |

| Growth Rate | 8.9% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., Schneider Electric SE, Siemens AG, Grundfos Holding A/S, Xylem Inc., Danfoss A/S, Ebara Corporation, Kirloskar Brothers Limited, Franklin Electric Co., Inc., Wilo SE, Flowserve Corporation, KPT Pumps Ltd., Mitsubishi Electric Corporation, Rockwell Automation, Inc., Telemecanique Sensors, Emerson Electric Co., Honeywell International Inc., SPP Pumps Limited, DAB PUMPS S.p.A., Pentair plc |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Digital Pump Controller Market Key Technology Landscape

The Digital Pump Controller Market is characterized by a rapidly evolving technological landscape, driven by the relentless pursuit of greater efficiency, intelligence, and connectivity in pump management. Central to this evolution is the widespread adoption of IoT (Internet of Things) and IIoT (Industrial Internet of Things) technologies, which enable seamless communication between pumps, controllers, sensors, and central monitoring systems. This connectivity facilitates real-time data acquisition and remote control, allowing operators to monitor performance, diagnose issues, and adjust parameters from any location, thereby significantly improving operational responsiveness and reducing the need for on-site inspections.

Advanced sensor technology forms the bedrock of these systems, providing precise measurements of critical parameters such as pressure, flow, level, and temperature, which are essential for accurate control and protective functions. Cloud computing platforms play a pivotal role in handling and processing the vast amounts of data generated by these connected devices, offering scalable storage, sophisticated analytics, and accessibility for various stakeholders. Furthermore, the integration of Artificial Intelligence (AI) and Machine Learning (ML) algorithms is transforming digital pump controllers from mere control units into intelligent, predictive systems capable of anticipating maintenance needs, optimizing energy consumption based on learned patterns, and even adapting to changing environmental conditions. Communication protocols such as Modbus, PROFINET, and Ethernet/IP ensure interoperability within complex industrial automation ecosystems, while intuitive Human-Machine Interfaces (HMIs) and SCADA (Supervisory Control and Data Acquisition) systems provide comprehensive visualization and control over entire pump networks, ensuring a high degree of operational insight and management capability.

Regional Highlights

- North America: This region is a leading adopter of advanced digital pump controller technologies, driven by a strong focus on industrial automation, water infrastructure modernization, and stringent energy efficiency regulations. The presence of major technology providers and a mature industrial base contributes to significant market value.

- Europe: Europe demonstrates robust growth, largely due to strict environmental policies, initiatives for smart water management, and sustained investments in renewable energy and industrial efficiency. Countries like Germany and the UK are at the forefront of implementing sophisticated pump control solutions.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, fueled by rapid industrialization, urbanization, and large-scale infrastructure projects, especially in water and wastewater treatment in countries such as China, India, and Southeast Asian nations. Increasing awareness of energy conservation and the push for smart cities further accelerate market expansion.

- Latin America: This region is experiencing steady growth, driven by increasing investments in industrial development, mining activities, and agricultural modernization. The need for efficient water management in both urban and rural areas also contributes to market demand.

- Middle East and Africa (MEA): The MEA region is witnessing considerable growth, primarily due to significant investments in oil and gas infrastructure, ongoing construction projects, and efforts to address water scarcity through advanced water management systems. Economic diversification initiatives also play a role in technology adoption.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Digital Pump Controller Market.- ABB Ltd.

- Schneider Electric SE

- Siemens AG

- Grundfos Holding A/S

- Xylem Inc.

- Danfoss A/S

- Ebara Corporation

- Kirloskar Brothers Limited

- Franklin Electric Co., Inc.

- Wilo SE

- Flowserve Corporation

- KPT Pumps Ltd.

- Mitsubishi Electric Corporation

- Rockwell Automation, Inc.

- Telemecanique Sensors

- Emerson Electric Co.

- Honeywell International Inc.

- SPP Pumps Limited

- DAB PUMPS S.p.A.

- Pentair plc

Frequently Asked Questions

Analyze common user questions about the Digital Pump Controller market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a digital pump controller and how does it differ from traditional systems?

A digital pump controller is an advanced electronic device that precisely monitors, controls, and protects a pump's operation using digital logic and sensor feedback. Unlike traditional electromechanical starters, which primarily offer basic on/off control and overload protection, digital controllers provide sophisticated features such as variable speed control, remote monitoring, data logging, and intelligent fault diagnostics, significantly enhancing efficiency, reliability, and lifespan of pumping systems. They integrate advanced algorithms to optimize performance based on real-time conditions.

What are the primary benefits of implementing digital pump controllers?

Implementing digital pump controllers offers numerous benefits, including substantial energy savings through optimized pump speed and flow control, extended pump and motor lifespan due to reduced wear and tear, and improved system reliability through advanced protection features. They also provide real-time performance monitoring and data analytics, enabling predictive maintenance, reducing costly downtime, and enhancing overall operational efficiency. Remote access and control capabilities further streamline management, offering greater flexibility and responsiveness to changing demands.

Which industries are the major adopters of digital pump controller technology?

Major adopters of digital pump controller technology span a wide array of industries. The water and wastewater management sector heavily relies on these controllers for efficient water distribution, sewage treatment, and irrigation systems. The oil and gas industry utilizes them across upstream, midstream, and downstream operations for precise fluid transfer and process control. Other significant end-users include the HVAC sector for building climate control, chemical and pharmaceutical industries for accurate fluid handling, agricultural businesses for optimized irrigation, and various general industrial and manufacturing facilities requiring robust fluid management solutions.

How does AI impact the functionality and future of digital pump controllers?

AI significantly enhances digital pump controller functionality by enabling advanced predictive maintenance through pattern recognition in operational data, forecasting potential failures, and scheduling proactive interventions. It optimizes energy consumption by dynamically adjusting pump parameters based on real-time and historical data, leading to greater efficiency. In the future, AI will facilitate more autonomous pump operations, smarter fault diagnostics, and seamless integration into broader smart infrastructure and IoT ecosystems, transforming pump management into a highly intelligent, self-optimizing system.

What are the key considerations when choosing a digital pump controller?

Key considerations when selecting a digital pump controller include the specific application requirements, such as pump type, flow capacity, and pressure demands, to ensure compatibility and optimal performance. Energy efficiency features, such as variable speed drive (VFD) capabilities, are crucial for long-term cost savings. Robust protection features for the pump and motor, remote monitoring and control capabilities, ease of integration with existing systems (e.g., SCADA, BMS), and cybersecurity measures are also vital. Finally, the total cost of ownership, including installation, maintenance, and potential energy savings, should be evaluated.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager