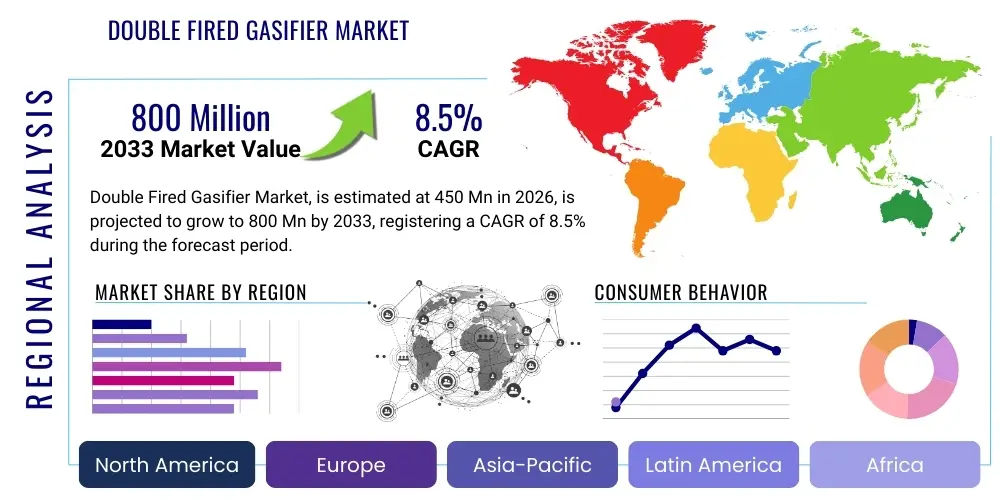

Double Fired Gasifier Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443388 | Date : Feb, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Double Fired Gasifier Market Size

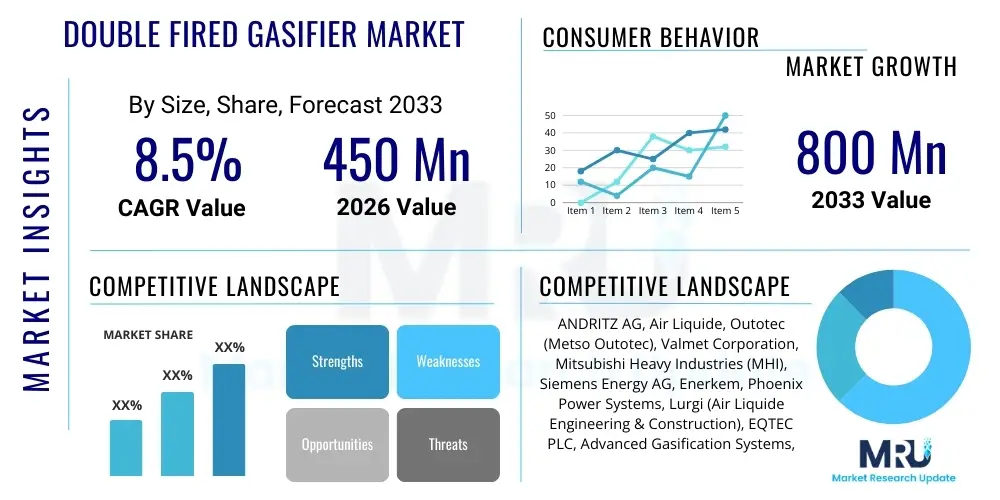

The Double Fired Gasifier Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 800 Million by the end of the forecast period in 2033.

Double Fired Gasifier Market introduction

The Double Fired Gasifier Market encompasses systems designed for highly efficient biomass and waste-to-energy conversion, employing dual combustion zones to maximize syngas quality and minimize tar content. This advanced thermochemical technology separates the pyrolysis and gasification processes, optimizing control over reaction temperatures and oxygen levels. The resulting syngas, rich in hydrogen and carbon monoxide, is exceptionally clean, making it suitable for direct use in sensitive applications such as internal combustion engines, gas turbines, and fuel cells for combined heat and power (CHP) generation. Major applications span power generation, industrial heating, chemical production (e.g., synthetic fuels, methanol), and decentralized energy solutions in rural areas. The inherent benefits of double-fired gasification include fuel flexibility, high thermal efficiency (often exceeding 80%), reduced greenhouse gas emissions compared to traditional combustion, and significant waste volume reduction. Key driving factors propelling market expansion include stringent global mandates for renewable energy integration, escalating volatility in fossil fuel prices, increasing focus on waste management solutions (especially agricultural and municipal solid waste), and substantial governmental incentives promoting biomass utilization and bioenergy infrastructure development across developed and developing economies.

Double Fired Gasifier Market Executive Summary

Current business trends in the Double Fired Gasifier Market are heavily influenced by the transition toward circular economy models, emphasizing efficient waste utilization and decentralized energy generation. Strategic collaborations between technology providers and engineering, procurement, and construction (EPC) firms are accelerating project deployment, particularly in Southeast Asia and Africa where biomass resources are abundant. Technological advancements focusing on modular and skid-mounted gasifier designs are lowering capital expenditure (CAPEX) barriers for small to medium-scale enterprises (SMEs) and industrial parks seeking self-sufficiency in power and heat. Regional trends show robust growth in the Asia Pacific (APAC) region, driven by rapid industrialization, large agricultural waste streams (rice husks, sugarcane bagasse), and urgent energy access needs in populous nations like India and China. Europe maintains market leadership in technology adoption, spurred by high carbon taxes and ambitious decarbonization targets, while North America focuses on converting forest residues and municipal waste into renewable natural gas (RNG) and biofuels. Segment trends indicate the dominance of the Industrial Heating segment due to high demand for high-temperature steam and process heat, followed closely by the Power Generation segment, where double-fired systems offer superior grid stability compared to intermittent renewables. The market is characterized by intense research and development (R&D) aimed at enhancing operational resilience, increasing tolerance to varied feedstock moisture content, and integrating advanced automation and sensor technology for real-time optimization of the gasification process, further solidifying the technology's appeal across diverse industrial landscapes.

AI Impact Analysis on Double Fired Gasifier Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Double Fired Gasifier Market primarily revolve around operational efficiency, predictive maintenance, and feedstock management. Users frequently question how AI algorithms can optimize the complex air and steam ratios within the dual chambers to maintain consistent syngas quality despite fluctuating biomass input characteristics. Key concerns address the reliability of AI-driven control systems in extreme operating environments and the potential for maximizing uptime through advanced anomaly detection and predictive failure analytics for critical components like reactors, cyclones, and cooling systems. Expectations center on AI's ability to create "digital twins" of gasifier plants for rigorous simulation and training, enabling operators to achieve higher overall equipment effectiveness (OEE), significantly reduce unscheduled downtime, and adapt seamlessly to various fuel mixes, thereby broadening the practical application range of double-fired gasification technology in challenging industrial settings.

- AI-driven Predictive Maintenance: Utilizing machine learning to analyze sensor data (temperature, pressure, vibration) and anticipate equipment failure, drastically reducing unscheduled downtime and optimizing maintenance scheduling.

- Optimized Process Control: Implementing neural networks to dynamically adjust steam-to-carbon ratios, oxygen injection rates, and reactor temperatures in real-time, ensuring optimal syngas composition and minimizing tar formation under varying loads.

- Enhanced Feedstock Management: Employing computer vision and AI algorithms to analyze and sort mixed biomass or waste feedstocks, predicting their energy content and moisture level to automatically adjust gasifier operating parameters for peak efficiency.

- Digital Twin Simulation: Creating virtual replicas of gasifier plants for scenario testing, operator training, and rigorous optimization of complex startups and shutdowns before implementation in the physical plant.

- Improved Emissions Monitoring and Compliance: AI systems continuously monitor flue gas composition, identifying deviations instantly and automatically adjusting process controls to ensure strict adherence to stringent environmental regulations regarding NOx, SOx, and particulate matter.

DRO & Impact Forces Of Double Fired Gasifier Market

The Double Fired Gasifier Market is primarily driven by the imperative need for sustainable and decentralized energy solutions, particularly in industries generating large quantities of combustible waste that require efficient conversion into valuable energy carriers, thus addressing waste disposal and energy security simultaneously. Governments worldwide are providing significant financial incentives, subsidies, and favorable policy frameworks, such as feed-in tariffs and renewable portfolio standards, which substantially reduce the payback period for capital-intensive gasification projects. However, the market faces significant restraints, notably the relatively high initial capital investment required for establishing dual-reactor gasification facilities and the technical complexity associated with reliably handling diverse, non-uniform biomass feedstocks, which demands sophisticated pre-treatment and specialized operational expertise. Opportunities abound in developing waste-to-hydrogen pathways, utilizing the clean syngas produced by double-fired systems as a precursor for highly purified hydrogen generation, aligning with global decarbonization efforts and the emerging hydrogen economy. Furthermore, the modularization trend offers substantial scope for deployment in remote or off-grid locations, addressing energy poverty and reducing reliance on centralized power infrastructure. The primary impact forces shaping the market trajectory include escalating environmental legislation pushing industries away from fossil fuels, technological breakthroughs in catalyst development for tar cracking, and the critical global focus on energy resilience and independence, especially in regions politically vulnerable to conventional fuel supply disruptions.

The market’s competitive landscape is fundamentally shaped by external and internal impact forces, particularly the volatility of global energy prices. When natural gas prices are high, the economic attractiveness of biomass gasification substantially increases, driving industrial adoption. Conversely, periods of low fossil fuel prices can slow investment momentum. Regulatory forces, such as the European Union’s renewed focus on sustainable biomass sourcing and stricter waste diversion mandates in North America, consistently compel heavy industrial users to seek robust waste-to-energy alternatives, favoring high-efficiency technologies like double-fired gasifiers. Internally, technological forces are paramount; ongoing research into high-pressure gasification and advanced heat recovery systems improves overall system efficiency and lowers the operational threshold for economically viable projects. The increasing availability of standardized, containerized gasification units significantly democratizes access to this technology, expanding the market reach beyond large utility companies to smaller independent power producers and municipal waste facilities.

The strategic deployment of double-fired gasifiers is highly sensitive to local resource economics, serving as a critical differentiator for market penetration. In agricultural economies, the reliable supply of specific crop residues, such as corn cobs or straw, acts as a powerful driver, guaranteeing fuel security. Conversely, inadequate infrastructure for biomass aggregation, storage, and transport acts as a significant restraint, particularly in sparsely populated regions. The shift toward carbon neutrality has positioned high-quality syngas as a flexible intermediate product, not only for heat and power but also for the creation of sustainable aviation fuels (SAFs) and bio-plastics, representing a lucrative long-term opportunity. Overall, the market's growth trajectory is anchored to its proven ability to deliver highly versatile, low-emission energy solutions that mitigate both energy dependence and environmental pollution concerns, placing it centrally within global sustainability agendas.

Segmentation Analysis

The Double Fired Gasifier Market is extensively segmented based on key structural components, operational characteristics, application verticals, and geographical boundaries. Understanding these segments is crucial for identifying areas of highest growth potential and tailoring technology deployment to specific end-user requirements. The market structure reflects the diversity of available biomass resources and the varied energy demands across different industrial and utility sectors. Segmentation by feedstock reveals a strong reliance on high-volume, readily available resources like wood biomass and agricultural residues, though there is increasing R&D focus on commercializing systems capable of efficiently processing challenging feedstocks such as municipal solid waste (MSW) and industrial sludge. Application segmentation clearly delineates the market’s primary value proposition: efficient, decentralized energy supply for both power grids and localized industrial processes requiring high-grade thermal energy, such as cement production and textile drying.

Further granularity in segmentation involves classifying gasifiers by capacity, ranging from small-scale units (below 5 MWth) suitable for distributed generation or farm operations, to large-scale industrial systems (above 30 MWth) integrated into existing power infrastructure or chemical complexes. This capacity segmentation reflects the varying investment appetites and scale requirements across the global energy landscape. For instance, developing nations often prioritize modular, small-scale units for rapid deployment and energy access improvement, whereas mature industrial economies invest in larger, highly automated systems to achieve economies of scale and meet stringent environmental performance targets. The inherent flexibility of double-fired technology allows it to capture market share across these diverse capacity spectrums by mitigating feedstock quality issues that plague simpler gasifier designs.

Geographically, market segmentation highlights the crucial role of local policy and resource availability. Regions with extensive forestry operations and timber industries, such as Scandinavia and parts of North America, lead in utilizing wood biomass. Conversely, regions dominated by sugar production, like Brazil and Southeast Asia, heavily rely on bagasse and other agricultural residues. This intricate structure underscores that market success is not solely dependent on technological superiority but also on the ability to customize solutions that align with regional biomass logistics, regulatory frameworks, and specific energy end-use requirements, ensuring a globally fragmented yet highly specialized market environment.

- By Feedstock Type:

- Wood Biomass (Chips, Pellets, Forestry Residues)

- Agricultural Residues (Bagasse, Rice Husks, Straw)

- Municipal Solid Waste (MSW)

- Industrial Waste and Sludge

- Energy Crops

- By Application:

- Power Generation (Electricity only)

- Combined Heat and Power (CHP)

- Industrial Heating and Process Heat (Steam Generation)

- Chemical Synthesis (Methanol, Fischer-Tropsch Fuels)

- Hydrogen Production

- By Capacity:

- Small Scale (Up to 5 MWth)

- Medium Scale (5 MWth to 30 MWth)

- Large Scale (Above 30 MWth)

- By End-Use Industry:

- Chemicals and Petrochemicals

- Pulp and Paper

- Cement and Ceramics

- Food and Beverages

- Utilities and Independent Power Producers (IPPs)

Value Chain Analysis For Double Fired Gasifier Market

The value chain for the Double Fired Gasifier Market begins with the upstream segment, dominated by feedstock sourcing and pre-treatment, which is critical given the technology's sensitivity to feedstock uniformity. This phase involves extensive logistics networks for collecting, drying, grinding, and pelletizing raw biomass or waste, ensuring optimal moisture content and particle size before introduction into the gasifier. Key upstream players include biomass aggregators, specialized machinery manufacturers (e.g., choppers, dryers), and certification bodies ensuring sustainable sourcing. The efficiency and cost-effectiveness of this upstream stage directly dictate the operating expenditure (OPEX) and ultimately the profitability of the entire gasification project. Technological innovation here focuses on low-cost drying techniques and robust screening systems to remove contaminants that could disrupt the gasification process.

The central manufacturing and deployment segment involves the core intellectual property and engineering expertise. This includes the design, fabrication, and integration of the specialized dual-reactor systems, heat exchangers, syngas clean-up units (e.g., hot gas filtration, catalytic tar crackers), and automation controls. Original Equipment Manufacturers (OEMs) and specialized engineering firms hold significant influence, competing on system efficiency, reliability, and modularity. Distribution channels are predominantly indirect, relying heavily on Engineering, Procurement, and Construction (EPC) contractors who manage the complex integration of the gasifier package within existing industrial facilities or new power plants. Direct sales often occur only for highly standardized, small-scale units or when dealing directly with large, established utility companies that possess in-house construction capabilities.

The downstream segment encompasses the utilization of the resulting energy carriers—syngas, heat, and electricity—and the management of byproducts. The distribution of electricity is handled by existing grid infrastructure (utilities/IPPs), while heat distribution is localized for industrial processes (e.g., providing high-pressure steam for manufacturing). Byproducts, particularly ash and char, often find secondary value as soil amendments or activated carbon, completing the circular economy loop. This downstream maximization of value, especially through co-generation (CHP) and the sale of bio-char, significantly enhances project economics. The overall profitability of the double-fired gasifier technology hinges on seamless integration across these stages, optimizing feedstock preparation upstream and maximizing energy and byproduct monetization downstream through efficient distribution channels.

Double Fired Gasifier Market Potential Customers

The primary potential customers for Double Fired Gasifier technology are large industrial users characterized by high, constant energy demand and significant availability of in-house organic waste streams, positioning them as ideal candidates for self-sufficient, decentralized energy generation. Chemical and petrochemical manufacturers represent a critical customer segment, utilizing clean syngas not only for heat and power but also as a direct chemical feedstock to produce high-value chemicals like methanol, ammonia, or hydrogen, thereby integrating energy production directly into their primary manufacturing processes. Similarly, the pulp and paper industry, which generates massive amounts of wood waste (black liquor, bark), finds double-fired gasification highly attractive for generating baseload power and steam, reducing both disposal costs and reliance on external energy sources, consequently stabilizing their operational costs against volatile fuel markets. These heavy industrial sectors prioritize reliability and syngas quality, making the double-fired approach superior due to its effective tar removal capabilities.

Beyond traditional manufacturing, municipal waste management authorities and independent power producers (IPPs) focused on waste-to-energy projects constitute a rapidly growing customer base. Municipalities seek proven, environmentally sound methods for diverting non-recyclable solid waste from landfills while simultaneously generating renewable electricity for urban centers. IPPs view these projects as long-term, stable revenue streams, secured by long-term power purchase agreements (PPAs) that incentivize sustainable resource management. The decentralized nature and fuel flexibility of double-fired systems allow them to be strategically placed near urban waste sources or regional industrial clusters, minimizing logistics costs associated with feedstock transportation, which is a major barrier for conventional power plants. Furthermore, large agricultural cooperatives and food processing companies, particularly those dealing with large volumes of byproducts like rice husks, coffee grounds, or fruit pits, are increasingly adopting this technology to generate heat for drying processes and internal electricity, transforming a liability (waste) into a valuable energy asset, driven by strong economic and environmental rationale.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 800 Million |

| Growth Rate | CAGR 8.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ANDRITZ AG, Air Liquide, Outotec (Metso Outotec), Valmet Corporation, Mitsubishi Heavy Industries (MHI), Siemens Energy AG, Enerkem, Phoenix Power Systems, Lurgi (Air Liquide Engineering & Construction), EQTEC PLC, Advanced Gasification Systems, Bioneer Oy, ThyssenKrupp AG, Synthesis Energy Systems, Choren Industries GmbH, Standardkessel Baumgarte, Waste Management Inc., Infinite Energy Inc., NextGen Power. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Double Fired Gasifier Market Key Technology Landscape

The core technology driving the Double Fired Gasifier Market relies on physically separating the primary biomass pyrolysis step from the subsequent char gasification step, typically achieved using two interconnected fluid bed reactors—a pyrolysis reactor and a combustion reactor. This separation allows for precise control over the gasification environment, notably eliminating oxygen from the pyrolysis zone, which results in a high-quality, nitrogen-free syngas that requires minimal downstream cleaning. Key technological innovations center around optimizing heat transfer between the two reactors, frequently employing circulating bed material (such as sand or specialized ceramics) to transfer thermal energy from the high-temperature combustion zone to the low-temperature pyrolysis zone. Continuous R&D efforts are focused on improving the design of these circulating systems to minimize energy losses and enhance operational longevity, a crucial factor given the abrasive nature of many biomass feedstocks.

A significant technological focus area involves advanced syngas cleaning and conditioning, essential for enabling the use of the product gas in sensitive downstream equipment like solid oxide fuel cells or high-efficiency gas turbines. While the double-fired method inherently produces less tar than single-stage gasifiers, residual tars and particulates must be meticulously removed. This involves integrating catalytic tar cracking systems, where specialized catalysts (often nickel-based or dolomite) break down complex hydrocarbon chains into simple gaseous components, and high-efficiency filtration systems, such as ceramic candle filters, operating at high temperatures to maintain thermal efficiency. The development of robust, cost-effective catalysts that resist poisoning from sulfur and alkali metals present in biomass ashes is a major competitive differentiator, directly influencing the reliability and maintenance costs of the overall system.

Furthermore, the integration of advanced process control systems (APCS) and sensor technology is paramount for maintaining optimal performance across varied operating conditions. Modern double-fired gasifiers incorporate sophisticated sensors to continuously monitor parameters such as bed temperature profiles, syngas composition, and differential pressures across the reactors. These data streams feed into proprietary control algorithms—often utilizing AI and machine learning techniques as previously noted—that adjust feedstock input rates, bed material circulation, and reactor temperatures in real-time. This level of automation ensures consistent syngas quality, minimizes the risk of system upsets, and allows the gasifier to efficiently handle fluctuations in biomass quality, transforming what was once a highly technical, operator-dependent process into a more robust and industrially scalable technology platform suitable for widespread deployment globally.

Regional Highlights

- Asia Pacific (APAC): Expected to be the fastest-growing region, driven by immense volumes of agricultural residues (rice husks, bagasse) and urgent demands for decentralized power solutions in developing economies (India, Indonesia). Government mandates to manage municipal solid waste and reduce reliance on coal strongly support market adoption, particularly in Southeast Asia where urbanization and industrial growth are surging.

- Europe: Leads the market in terms of advanced technology adoption and stringent environmental policy frameworks (e.g., EU Renewable Energy Directive). High biomass availability, particularly in Nordic countries, combined with high carbon pricing, makes double-fired gasifiers economically compelling for CHP generation and synthetic fuel production, focusing heavily on maximizing system efficiency and meeting strict air quality standards.

- North America (US and Canada): Characterized by significant investment in converting forestry residues and industrial wood waste into bioenergy and renewable natural gas (RNG). The region benefits from established biomass supply chains and supportive federal policies like tax credits for renewable energy production, with the focus shifting toward large-scale projects integrated with chemical processing facilities.

- Latin America: Driven primarily by the vast sugarcane industry (Brazil), which supplies abundant bagasse for bioenergy. Double-fired gasifiers are increasingly used by sugar mills and ethanol refineries to achieve energy self-sufficiency and sell surplus power back to the grid, stabilizing local energy supply and supporting rural economic development.

- Middle East and Africa (MEA): Represents an emerging market with significant long-term potential, particularly in regions facing water scarcity and energy access issues. Focus is on utilizing agricultural byproducts and managing rapidly growing urban waste streams. Pilot projects, often supported by international development banks, are exploring the use of these gasifiers for off-grid power generation in remote industrial or rural communities, leveraging modular designs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Double Fired Gasifier Market.- ANDRITZ AG

- Air Liquide

- Outotec (Metso Outotec)

- Valmet Corporation

- Mitsubishi Heavy Industries (MHI)

- Siemens Energy AG

- Enerkem

- Phoenix Power Systems

- Lurgi (Air Liquide Engineering & Construction)

- EQTEC PLC

- Advanced Gasification Systems

- Bioneer Oy

- ThyssenKrupp AG

- Synthesis Energy Systems

- Choren Industries GmbH

- Standardkessel Baumgarte

- Waste Management Inc.

- Infinite Energy Inc.

- NextGen Power

- Foster Wheeler (Amec Foster Wheeler)

- Dürr Group

Frequently Asked Questions

Analyze common user questions about the Double Fired Gasifier market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of a double fired gasifier over a single-stage gasifier?

The primary advantage is the separation of pyrolysis and gasification into two distinct zones, allowing for the generation of a high-quality, low-tar syngas that is nearly nitrogen-free. This clean syngas is essential for sensitive downstream applications like gas turbines, fuel cells, or chemical synthesis, significantly improving overall system efficiency and reducing maintenance on cleaning systems.

What types of feedstock are most suitable for double fired gasification systems?

Double fired systems exhibit high fuel flexibility but perform optimally with woody biomass, agricultural residues (such as straw and bagasse), and specific types of pre-treated municipal solid waste (MSW). The technology excels at processing fuels with higher moisture content and non-uniform particle sizes compared to fixed-bed gasifiers, though consistency in pre-treatment remains vital for maximizing efficiency.

How does government regulation impact the growth of the double fired gasifier market?

Government regulations are a major market driver. Policies such as stringent renewable energy portfolio standards (RPS), carbon emission taxes, and favorable feed-in tariffs (FITs) significantly enhance the economic viability of gasification projects by guaranteeing long-term revenue streams and penalizing reliance on high-carbon conventional fuels.

What are the typical end-use applications for the syngas produced by this technology?

The ultra-clean syngas produced by double fired gasifiers is highly versatile. Primary end-use applications include combined heat and power (CHP) generation for industrial sites, direct fuel for electricity generation using gas engines or turbines, and as a synthesis gas precursor for chemical production, specifically methanol, sustainable aviation fuels (SAF), and green hydrogen.

What is the main financial barrier to adopting double fired gasification technology?

The principal financial barrier is the high initial capital expenditure (CAPEX). Implementing a double-fired system requires investment in two specialized reactors, complex circulating bed material handling systems, and advanced syngas cleaning infrastructure, making the upfront cost higher than simpler combustion or single-stage gasification alternatives, although operational savings often lead to favorable long-term return on investment (ROI).

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager