Drum Typenobbing Line Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443020 | Date : Feb, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Drum Typenobbing Line Market Size

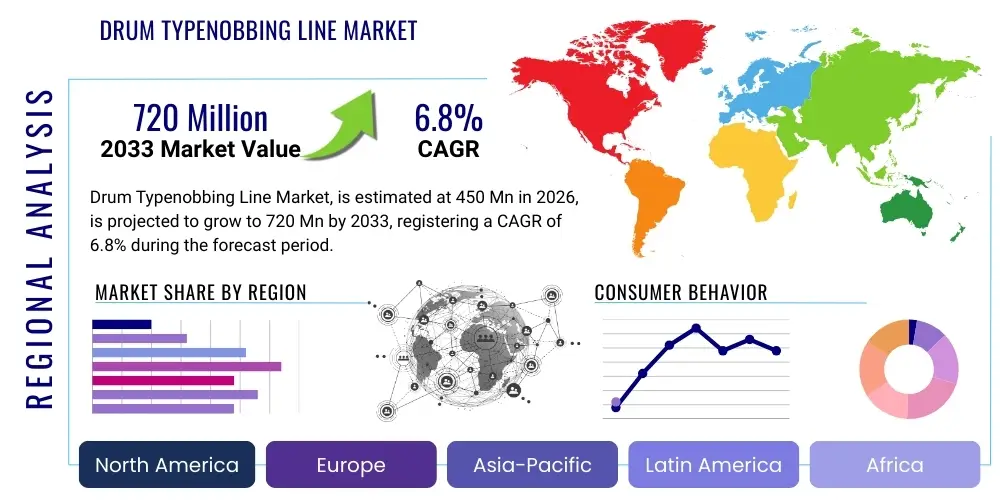

The Drum Typenobbing Line Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $450 Million in 2026 and is projected to reach $720 Million by the end of the forecast period in 2033.

Drum Typenobbing Line Market introduction

The Drum Typenobbing Line Market encompasses specialized industrial machinery designed for the automated manufacturing of industrial drums, barrels, and large containers. These sophisticated lines perform the critical process known as 'nobbing' or necking, which involves precision forming of the drum's opening (neck) to ensure optimal functionality, sealing integrity, and compatibility with various closure systems, such as screw caps or flanges. The primary function of this equipment is to ensure that manufactured drums meet stringent international standards for packaging, particularly those used for hazardous materials, chemicals, petroleum products, and high-volume industrial liquids.

Major applications of Drum Typenobbing Lines span various heavy industrial sectors, including chemical processing, oil and gas, food and beverage packaging (for bulk ingredients), and pharmaceutical raw material storage. The core benefits derived from implementing these advanced systems include significant improvements in production throughput, enhanced dimensional accuracy, and reduced material waste compared to traditional manual or semi-automated processes. Furthermore, modern nobbing lines integrate advanced features such as hydraulic or servo-electric actuation, precision CNC control, and automated material handling, ensuring consistency across high-volume batches.

Key driving factors fueling the market growth include the robust expansion of global manufacturing and logistics networks, particularly in emerging economies, which necessitates standardized, durable packaging solutions. Regulatory pressures demanding higher safety standards for the transportation of dangerous goods (e.g., UN certification requirements) further mandate the use of precise, automated manufacturing equipment like typenobbing lines. Additionally, the growing trend toward factory automation and Industry 4.0 integration pushes manufacturers to invest in highly efficient, data-driven machinery to maximize operational efficiency and maintain competitive pricing in the global market.

Drum Typenobbing Line Market Executive Summary

The Drum Typenobbing Line Market is currently characterized by strong demand for fully automated systems capable of high throughput and rapid changeover times, reflecting broader industry trends toward lean manufacturing and operational agility. Business trends indicate a shift in technological preference towards servo-driven systems over traditional hydraulic mechanisms due to superior energy efficiency, reduced noise, and enhanced precision control, which is crucial for achieving tight tolerances required by high-performance industrial containers. Furthermore, market competition is intensifying, driven by Asian manufacturers offering cost-effective, high-capacity machinery, compelling established Western vendors to innovate in areas such as modular design, integration capabilities, and advanced diagnostics.

Regionally, the Asia Pacific (APAC) stands out as the primary engine of market expansion, propelled by massive industrialization, infrastructure development, and increased domestic chemical and lubricant production in countries like China, India, and Southeast Asia. Europe and North America, while mature, maintain substantial market shares driven by strict quality assurance standards, high rates of automation adoption, and a strong emphasis on sustainability, leading to demand for lines capable of handling recyclable or multi-use drum materials efficiently. Geopolitical considerations, including supply chain vulnerabilities and escalating costs of raw materials (steel and aluminum), necessitate strategic geographical diversification among equipment suppliers.

Segment trends demonstrate increasing sophistication in customization, particularly lines designed for specialty drums, such as those made from complex alloys or composite materials, crucial for niche chemical applications. The automation segment, specifically fully automatic lines featuring integrated beading, seaming, and testing modules, continues to dominate new sales as end-users seek minimal human intervention to ensure consistency and compliance. The aftermarket service and tooling segment is also experiencing substantial growth, underpinned by the large installed base of machinery requiring regular maintenance, precision tooling replacement, and software updates to maximize operational lifespan and throughput efficiency.

AI Impact Analysis on Drum Typenobbing Line Market

User inquiries regarding the integration of Artificial Intelligence (AI) and Machine Learning (ML) in Drum Typenobbing Lines frequently revolve around achieving zero-defect manufacturing, predictive maintenance scheduling, and optimization of operational parameters for energy consumption and material utilization. Key concerns focus on the complexity of retrofitting existing machinery with AI capabilities and the necessary data infrastructure requirements. Users express high expectations that AI will transition drum manufacturing from reactive maintenance schedules to highly efficient, anticipatory operational models, significantly reducing costly downtime and improving overall equipment effectiveness (OEE). The primary themes highlight AI's role in real-time quality inspection (e.g., using visual AI systems to detect micro-cracks or imperfect neck formations) and in fine-tuning the pneumatic and hydraulic pressures dynamically based on material feedback, compensating for slight variations in sheet metal thickness or material temper, thereby optimizing the nobbing process for peak performance and consistency.

- AI-driven Predictive Maintenance: Utilizing sensor data (vibration, temperature, current draw) to forecast equipment failures, minimizing unexpected downtime and optimizing replacement schedules for tooling and critical components.

- Real-time Quality Control: Implementing machine vision and deep learning algorithms for instantaneous, non-contact inspection of the formed neck geometry, ensuring compliance with strict dimensional and structural tolerances.

- Process Parameter Optimization: ML algorithms dynamically adjust machine settings (speed, pressure, dwell time) based on historical material input and desired output quality, maximizing energy efficiency and throughput.

- Automated Fault Diagnosis: Rapid identification and categorization of operational issues, reducing reliance on specialized technicians for initial troubleshooting and accelerating recovery times.

- Supply Chain Integration: AI-enhanced forecasting tools linking drum demand directly to production scheduling and raw material ordering, improving inventory management and reducing carrying costs across the value chain.

DRO & Impact Forces Of Drum Typenobbing Line Market

The Drum Typenobbing Line Market is primarily driven by the escalating demand for industrial packaging, intrinsically linked to the growth of global logistics and manufacturing sectors, especially the chemical and petrochemical industries requiring robust, compliant containment solutions. The mandatory transition towards higher automation levels, pushed by rising labor costs and the need for precision manufacturing associated with UN standards for hazardous materials transport, acts as a significant market driver. Conversely, major restraints include the substantial initial capital expenditure required for purchasing and installing these specialized, heavy-duty production lines, which often poses a barrier to entry for smaller or developing manufacturers. Furthermore, the technical complexity of integrating high-speed, automated lines into existing factory footprints and the reliance on specialized, proprietary tooling for varied drum sizes also restrict market flexibility.

Opportunities in the market center around the development of multi-format nobbing lines that can rapidly switch between different drum specifications and materials (e.g., steel, stainless steel, composite drums), catering to the diverse needs of modern industrial clients. The expansion into emerging economies across Africa and Latin America, where industrial infrastructure is rapidly developing, presents a strong geographical opportunity for machinery sales and subsequent service contracts. Furthermore, the growing focus on environmental sustainability is opening doors for manufacturers specializing in lines optimized for lighter-gauge materials or for refurbished drum production, adhering to circular economy principles while maintaining safety integrity.

The interplay of these forces profoundly impacts market direction. The persistent regulatory push for safer packaging standards globally serves as a foundational driving force, compelling continuous investment in precision machinery. However, the cyclical nature of raw material pricing (steel coils) creates significant volatility, acting as an impactful restraint that dictates purchasing timing and overall profitability for both equipment vendors and end-users. Technological advancements in servo-mechanics and IoT integration are impact forces that redefine performance benchmarks, forcing manufacturers to accelerate R&D efforts to maintain competitiveness, leading to an overall positive evolution in machine sophistication and operational efficiency across the sector.

Segmentation Analysis

The Drum Typenobbing Line Market is structurally segmented based on crucial operational and technical characteristics, allowing for targeted analysis of diverse end-user needs and technological adoption rates. These segmentation axes provide granular insights into machine capability, production environment suitability, and investment justification. Primary segmentation is based on the level of automation, differentiating between high-CAPEX, high-throughput fully automatic lines and more flexible, lower-cost semi-automatic variants. Further segmentation considers the material compatibility (Steel Drums, Plastic Drums, Composite Drums) and the output capacity of the lines (Low, Medium, and High Volume), directly correlating with the scale of the customer's manufacturing operations. This layered approach enables market participants to effectively tailor their machinery offerings and strategic positioning in relation to evolving industrial packaging requirements globally.

- By Automation Level:

- Fully Automatic Typenobbing Lines

- Semi-Automatic Typenobbing Lines

- By Drum Material:

- Steel Drum Typenobbing Lines (including carbon steel and stainless steel)

- Plastic/HDPE Drum Typenobbing Lines

- Composite Drum Typenobbing Lines

- By Capacity (Drums per Hour):

- Low Capacity (<200 DPH)

- Medium Capacity (200 - 500 DPH)

- High Capacity (>500 DPH)

- By End-User Application:

- Chemical and Petrochemical Industry

- Food and Beverage (Bulk)

- Pharmaceutical and Healthcare (Raw Materials)

- Logistics and Transportation

- Waste Management and Recycling

Value Chain Analysis For Drum Typenobbing Line Market

The value chain for the Drum Typenobbing Line Market is complex, beginning with upstream raw material suppliers, primarily providers of specialized high-strength steel, aluminum alloys, and sophisticated electronic components (e.g., CNC controllers, servo motors, hydraulic pumps). Upstream analysis highlights the dependency of equipment manufacturers on global commodity markets; fluctuations in steel and aluminum prices directly impact the cost of production for the machinery itself, subsequently affecting end-user purchase prices. Key technological vendors providing proprietary software for control systems and specialized tooling materials also hold significant leverage in this upstream segment, influencing the innovation cycle and precision capabilities of the final production lines.

The midstream stage involves the core activity of specialized Drum Typenobbing Line equipment manufacturing. This segment is characterized by intense R&D investment focused on automation, energy efficiency, and compliance with increasingly strict international manufacturing standards. Equipment manufacturers manage complex assembly processes, integrating components from diverse geographical sources. Distribution channels are varied: large, established manufacturers often utilize direct sales models for major contracts involving customization and integration, while smaller, general machinery providers may rely on a network of regional industrial distributors and agents. Direct channels ensure technical expertise transfer, crucial for high-CAPEX equipment, whereas indirect channels offer wider geographical reach and localized after-sales support.

Downstream analysis focuses on installation, commissioning, after-sales service, and the relationship with end-users. The lifecycle cost of the machinery, including maintenance contracts and the supply of consumable tooling (dies and punches), represents a significant revenue stream. Potential customers, spanning petrochemical giants to regional industrial packaging firms, prioritize long-term reliability and quick access to spare parts. The efficiency of the downstream support network, including local technical training and rapid response times for complex machinery troubleshooting, is a crucial determinant of vendor selection and market competitiveness, directly influencing customer satisfaction and repeat business.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $450 Million |

| Market Forecast in 2033 | $720 Million |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SCHULER Group, FACCIN S.p.A., Dimeco Group, Suteau-Anver, Comac Engineering, LMT Tools, S&R Maschinenbau GmbH, Sacal S.r.l., Dongguan Chuangjia Machinery, Qingdao Sanfeng Machinery, Hangzhou Zhongtian Industrial Co., Ltd., Jorss Machinery, Samco Machinery, Dalian Huarui Heavy Industry Group Co., Ltd., Zani Group, Stamco, Formtek, Inc., Bekaert, SMS Group, and Hebei Longway Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Drum Typenobbing Line Market Potential Customers

The primary potential customers for Drum Typenobbing Lines are organizations engaged in the mass production or refurbishment of industrial containers, where high precision and compliance are paramount. This includes large-scale chemical manufacturing companies that require standardized, robust packaging for intermediate and final products, adhering strictly to global dangerous goods regulations (IMDG, ADR). Furthermore, integrated oil and gas companies, alongside major lubricant manufacturers, constitute a crucial customer base, relying on these lines for high-volume production of barrels and drums used in transportation and storage. The logistical sector, including third-party logistics (3PL) providers specializing in industrial commodity handling, also invests in these lines to ensure their reusable or owned packaging fleet meets necessary quality thresholds.

A growing segment of potential customers includes specialized drum refurbishing and reconditioning facilities. As sustainability and circular economy mandates gain traction, these facilities require compact, highly precise nobbing lines designed specifically to reshape and verify the integrity of used drums, extending their lifecycle safely. Finally, manufacturers of specialized bulk food ingredients (e.g., high-fructose corn syrup, industrial solvents) and bulk pharmaceutical raw materials represent niche but high-value customers, demanding stainless steel compatible lines capable of meeting stringent hygienic processing standards while ensuring absolute seal integrity for sensitive materials.

Drum Typenobbing Line Market Key Technology Landscape

The technological landscape of the Drum Typenobbing Line Market is rapidly evolving, driven by the shift from purely mechanical operations to sophisticated mechatronic systems integrated with digital control. Central to this evolution is the widespread adoption of Computer Numerical Control (CNC) and PLC systems, which manage the complex, multi-stage processes of drum manufacturing, ensuring repeatability and allowing for quick digital adjustments to handle varied drum specifications and material thicknesses. The transition from hydraulic actuation, which is often energy-intensive and less precise, to advanced servo-electric systems represents a major technological leap, offering superior velocity control, positioning accuracy, and significantly reduced operational noise, aligning with modern industrial safety standards and sustainability goals.

A critical technical focus is the development of modular and flexible tooling systems. Modern nobbing lines are increasingly designed with quick-change tooling cartridges and automated setup features, drastically reducing the changeover time required to switch between different drum sizes (e.g., 55-gallon vs. 30-gallon drums) or neck geometries. This modularity is essential for manufacturers running diversified production schedules. Furthermore, the incorporation of Internet of Things (IoT) sensors is standard practice, enabling comprehensive data collection on parameters such as forming force, temperature, vibration, and energy consumption. This data feed is vital for advanced diagnostics and allows for real-time adjustments to maintain optimal operational performance and prevent premature wear of expensive tooling.

Safety and integration technologies also define the cutting-edge landscape. Enhanced safety features include advanced light curtains, automatic safety stops, and comprehensive interlocks designed to meet stringent OSHA and European machinery directives. On the production flow side, Typenobbing lines are now often fully integrated into larger drum processing ecosystems, communicating seamlessly with upstream body welding machines and downstream seaming and painting robots. This integration relies on industrial Ethernet protocols and standardized communication architectures (like OPC UA), facilitating a complete, automated, and traceable production environment essential for high-value industrial packaging that requires detailed manufacturing provenance records.

Regional Highlights

- Asia Pacific (APAC): Dominates the market share due to unprecedented growth in industrial manufacturing, especially in China and India. The region serves as a global hub for chemical, pharmaceutical, and lubricant production, driving consistent demand for new, high-capacity automatic nobbing lines. Government initiatives supporting infrastructure and manufacturing modernization, coupled with competitive labor costs, solidify APAC’s position as both a major producer and consumer of these specialized machines.

- Europe: Characterized by high technological maturity and stringent regulatory environments (e.g., REACH and Seveso Directives), Europe demands sophisticated, high-precision equipment focusing on energy efficiency and environmental compliance. Key market drivers include the refurbishment sector and the requirement for stainless steel drums in the high-value specialty chemical and food/pharma industries, favoring vendors known for precision engineering and advanced automation features.

- North America: Holds a significant market position driven by the large-scale petrochemical industry and the robust logistics sector. The market here shows high penetration of established, heavy-duty machinery. Current investments are primarily focused on retrofitting existing lines with AI-enabled diagnostics and IoT capabilities, seeking operational efficiencies and alignment with Industry 4.0 standards, while also catering to the needs of the dynamic oil and gas supply chain.

- Latin America (LATAM): Represents an emerging growth opportunity, fueled by increasing industrialization in Brazil and Mexico. The market is currently price-sensitive, with demand concentrated in semi-automatic and medium-capacity lines. Future growth hinges on foreign direct investment in petrochemical processing and mining, which will necessitate compliant industrial packaging infrastructure.

- Middle East and Africa (MEA): Growth is primarily driven by massive investments in oil and gas infrastructure and chemical production hubs, particularly in the Gulf Cooperation Council (GCC) states. Demand centers on robust, customized lines capable of handling large production volumes and operating reliably in challenging environmental conditions (high heat, dust). Localizing manufacturing capacity is becoming a strategic focus.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Drum Typenobbing Line Market.- SCHULER Group

- FACCIN S.p.A.

- Dimeco Group

- Suteau-Anver

- Comac Engineering

- LMT Tools

- S&R Maschinenbau GmbH

- Sacal S.r.l.

- Dongguan Chuangjia Machinery

- Qingdao Sanfeng Machinery

- Hangzhou Zhongtian Industrial Co., Ltd.

- Jorss Machinery

- Samco Machinery

- Dalian Huarui Heavy Industry Group Co., Ltd.

- Zani Group

- Stamco

- Formtek, Inc.

- Bekaert

- SMS Group

- Hebei Longway Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Drum Typenobbing Line market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a Drum Typenobbing Line?

The Drum Typenobbing Line is specialized machinery used in the manufacturing of industrial drums and barrels to precisely form the drum's neck or opening (nobbing/necking). This process ensures the structural integrity, compatibility with closures (caps/flanges), and compliance with international standards required for safe containment of industrial goods, particularly hazardous materials.

Which technologies are driving efficiency in new Typenobbing Lines?

Efficiency improvements are primarily driven by the integration of servo-electric actuation, replacing older hydraulic systems for enhanced precision, speed, and energy conservation. Furthermore, advanced CNC controls and IoT integration for predictive maintenance and real-time quality monitoring are crucial for maximizing throughput and minimizing material waste in high-volume production environments.

How does the AI impact the operational lifespan of Typenobbing equipment?

AI significantly extends the operational lifespan of Drum Typenobbing Lines by implementing predictive maintenance schedules based on machine learning analysis of sensor data. This capability allows operators to replace tooling and critical components proactively before catastrophic failure occurs, optimizing resource allocation and dramatically reducing unanticipated downtime and wear.

What regulatory standards most influence the design of Drum Typenobbing machinery?

The design and operational precision of these machines are heavily influenced by UN standards for the transport of dangerous goods (e.g., UN 3H1/1A2 ratings) and regional regulatory frameworks like ISO standards and occupational safety regulations (e.g., OSHA and CE marking). These mandates necessitate highly accurate and repeatable neck forming to guarantee seal security.

Which geographic region offers the highest growth potential for this market?

The Asia Pacific (APAC) region, driven by continuous industrialization, robust infrastructure development, and substantial investments in the chemical and energy sectors in countries such as China, India, and Vietnam, presents the highest compounded annual growth rate potential for the adoption of new Drum Typenobbing Lines throughout the forecast period.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager