Dry Ice Pellet Blasting Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443412 | Date : Feb, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Dry Ice Pellet Blasting Machine Market Size

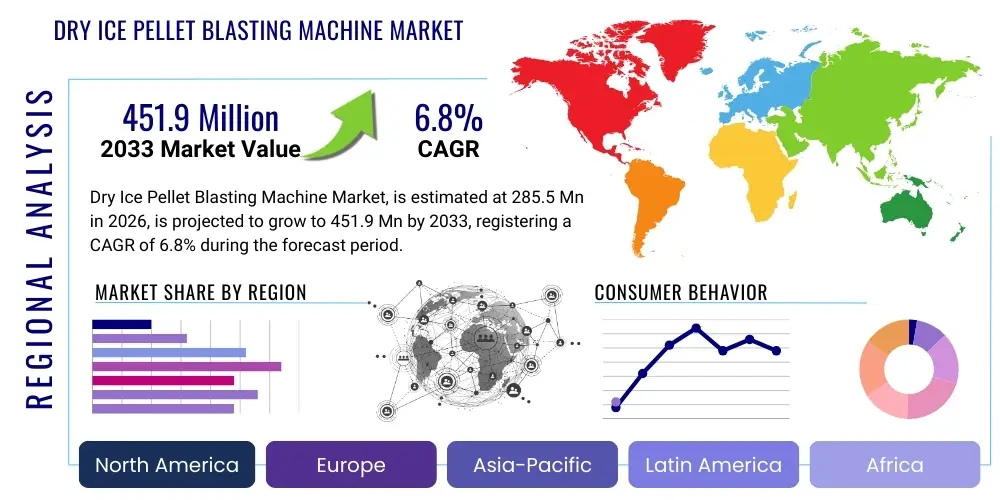

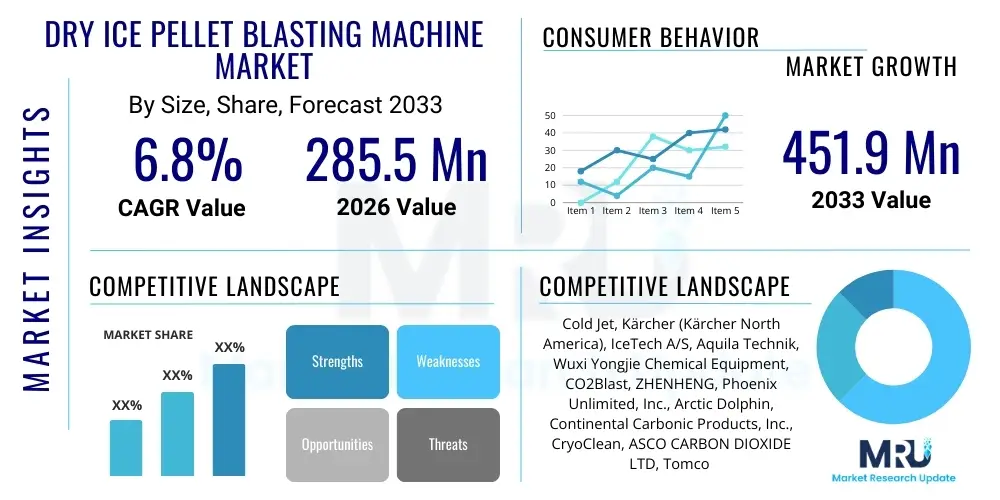

The Dry Ice Pellet Blasting Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 285.5 Million in 2026 and is projected to reach USD 451.9 Million by the end of the forecast period in 2033.

Dry Ice Pellet Blasting Machine Market introduction

The Dry Ice Pellet Blasting Machine Market encompasses equipment designed for non-abrasive cleaning, preparation, and decontamination processes across diverse industrial sectors. This technology utilizes pressurized air to accelerate solid carbon dioxide (CO2) pellets toward a surface, removing contaminants through a combination of kinetic energy, thermal shock, and the instantaneous sublimation of the dry ice upon impact. The immediate transition of the CO2 from solid to gas leaves no secondary waste stream, distinguishing it fundamentally from traditional methods like sandblasting or chemical cleaning, which typically require extensive post-process cleanup and disposal procedures. The growing emphasis on sustainable industrial practices and regulatory compliance regarding wastewater and hazardous waste disposal is a central pillar supporting the increased adoption of dry ice blasting systems globally.

Dry ice blasting systems offer substantial operational advantages, including minimized downtime due to the non-conductive nature of the cleaning medium, allowing for in-place cleaning of complex machinery and electrical components. Major applications span industries such as automotive manufacturing, where it is used for cleaning molds and robotics; food and beverage processing, where stringent hygiene standards are met without using water or chemicals; and aerospace, utilized for delicate surface preparation and component maintenance. The product portfolio ranges from high-pressure, robust industrial units suitable for heavy contamination removal to smaller, portable systems designed for intricate detail work and field service applications. The market structure is characterized by continuous innovation focused on improving pellet feeding consistency, optimizing air consumption efficiency, and enhancing portability and operator safety.

Key benefits driving market expansion include reduced environmental footprint, enhanced equipment lifespan by avoiding abrasive damage, and significant time savings compared to manual cleaning or disassembly required by conventional methods. The versatility of the technology allows it to remove residues like grease, oil, paint, rust, adhesives, and bio-contaminants effectively, addressing a broad spectrum of industrial cleaning challenges. Furthermore, the inherent sterility of dry ice makes it particularly valuable in sensitive environments such as pharmaceutical manufacturing and medical device production, where contamination control is paramount. This confluence of operational efficiency, environmental responsibility, and quality assurance continues to solidify the dry ice pellet blasting machine’s position as a critical industrial cleaning tool.

Dry Ice Pellet Blasting Machine Market Executive Summary

The Dry Ice Pellet Blasting Machine Market demonstrates robust growth driven by accelerating demand for efficient, non-destructive, and environmentally sustainable industrial cleaning solutions across major global economies. Key business trends include the shift toward fully automated blasting systems integrated into manufacturing assembly lines, particularly in the automotive and rubber tire sectors, aiming to minimize labor dependency and maximize consistency. Strategic partnerships focusing on vertical integration—from CO2 supply logistics to specialized equipment training—are defining competitive landscapes. Furthermore, the development of dual-hose systems and variable-pressure nozzles, allowing for finer control and application-specific tailoring, represents significant product innovation aimed at expanding the market's addressable cleaning challenges, including delicate surfaces and complex geometries.

Regional trends indicate that North America and Europe currently dominate the market, primarily due to stringent environmental regulations (mandating low-waste processes) and the high penetration of advanced manufacturing and aerospace maintenance facilities. However, the Asia Pacific (APAC) region is projected to exhibit the fastest growth rate throughout the forecast period. This rapid expansion in APAC is fueled by massive industrialization, the proliferation of globalized manufacturing hubs (especially in China, India, and Southeast Asia), and increasing awareness regarding the long-term cost benefits associated with preventative maintenance and non-abrasive cleaning methods. Latin America and the Middle East & Africa (MEA) are emerging markets, primarily adopting this technology in localized heavy industries such as oil and gas refineries and power generation plants, emphasizing operational efficiency gains.

Segmentation trends highlight the dominance of medium-pressure machines (75-200 PSI) by type, offering the best balance between cleaning power and surface safety across general industrial applications. By application, the molding industry (rubber, plastics, composites) remains a cornerstone, heavily reliant on dry ice blasting for residue removal without causing mold damage or requiring extensive cooling periods. The service segment, encompassing rental and contract cleaning services utilizing these machines, is also experiencing disproportionate growth. This growth is attributable to smaller enterprises testing the viability of the technology before committing to substantial capital expenditure on purchasing equipment, indicating a maturity in the service ecosystem surrounding dry ice blasting technology.

AI Impact Analysis on Dry Ice Pellet Blasting Machine Market

Common user questions regarding the influence of Artificial Intelligence (AI) on the Dry Ice Pellet Blasting Machine Market frequently center on automation possibilities, optimization of cleaning parameters, and integration with Industry 4.0 platforms. Users are keen to understand if AI can effectively replace the need for highly skilled human operators by automating the process trajectory, adjusting pellet feed rates, and compensating for surface irregularities in real-time. Specific concerns relate to the feasibility of predictive maintenance enabled by AI, where sensor data—tracking air pressure fluctuations, pellet consumption, nozzle wear, and vibration levels—could anticipate equipment failures before they occur. This analysis summarizes the key themes, concerns, and expectations users have, focusing on efficiency maximization and quality assurance through intelligent systems.

The primary expectation is that AI will move dry ice blasting from a reactive cleaning method to a proactive, highly controlled process. AI algorithms, leveraging machine vision and deep learning models, are anticipated to accurately identify contamination levels and material types, automatically adjusting blasting settings (pressure, flow rate, angle) to achieve optimal cleaning effectiveness with minimal dry ice consumption and zero substrate damage. This level of precision is crucial for highly sensitive applications, such as cleaning intricate circuitry or delicate historical artifacts, where manual adjustments carry inherent risk. Furthermore, AI integration is expected to enhance compliance reporting by logging detailed, time-stamped operational parameters and cleaning outcomes, meeting rigorous quality control standards demanded in regulated industries like aerospace and pharmaceuticals.

The realized impact of AI integration will manifest in several critical areas: substantially reducing operational waste by optimizing pellet usage, minimizing human error through robotic automation guided by intelligent pathfinding, and extending the lifespan of both the machine components and the cleaned assets. While the initial capital investment in AI-enabled, integrated robotic blasting cells is higher, the long-term cost savings derived from increased operational uptime, reduction in material waste, and consistently superior cleaning quality are expected to drive rapid adoption among large industrial players focused on maximizing overall equipment effectiveness (OEE).

- AI-driven Predictive Maintenance: Analyzing machine telemetry (pressure, temperature, vibration) to forecast component failure, significantly reducing unscheduled downtime.

- Automated Blasting Trajectory: Utilizing machine vision and robotics to achieve precise, repeatable, and optimized cleaning paths, minimizing manual intervention.

- Real-Time Parameter Optimization: Algorithms dynamically adjust blasting pressure and pellet flow based on sensor feedback regarding surface contamination and substrate sensitivity.

- Enhanced Data Logging and Compliance: Automated generation of detailed operational reports for auditing and regulatory compliance (GEO factor).

- Reduced Consumption Efficiency: Optimizing dry ice usage through smart flow control, lowering operational expenditure.

DRO & Impact Forces Of Dry Ice Pellet Blasting Machine Market

The Dry Ice Pellet Blasting Machine Market is fundamentally shaped by a synergistic set of Drivers, Restraints, and Opportunities (DRO), underpinned by powerful impact forces that dictate industrial cleaning procurement decisions. A primary driver is the accelerating stringency of environmental regulations worldwide, particularly concerning VOC emissions and wastewater discharge associated with traditional chemical cleaning. Dry ice blasting provides a zero-waste, solvent-free alternative that directly addresses these compliance pressures, making it an indispensable tool for environmentally conscious organizations. Additionally, the increasing focus on minimizing equipment downtime in 24/7 production environments drives adoption, as dry ice cleaning is non-abrasive and often allows for cleaning-in-place (CIP) without cooling down or disassembling machinery, leading to significant operational time savings. The perceived non-damaging nature of the process on delicate or complex substrates further amplifies its appeal across precision manufacturing sectors.

However, the market faces notable restraints that temper adoption rates, particularly the high initial capital investment required for purchasing high-quality blasting equipment, which can be prohibitive for small and medium-sized enterprises (SMEs). Furthermore, the reliance on a consistent and cost-effective supply chain for dry ice pellets, which requires specialized storage and logistics, presents a continuous operational challenge, especially in geographically remote areas or regions lacking developed industrial gas infrastructure. The requirement for specialized operator training to maximize efficiency and minimize risk, coupled with inherent safety concerns related to high-pressure air and CO2 asphyxiation hazards in confined spaces, also contributes to market friction, demanding rigorous adherence to safety protocols.

The opportunities within this market are substantial, centered on technological advancements and market diversification. Opportunities include the development of next-generation micro-blasting systems capable of cleaning micron-level contamination in electronics and medical device manufacturing. Furthermore, the expansion of the service-based model (rentals and contract cleaning) allows potential users to mitigate the high upfront cost of ownership, thereby widening market access. The strongest impact forces shaping the market involve the Total Cost of Ownership (TCO) evaluation, where the benefits of reduced labor costs, minimal secondary waste disposal costs, and extended equipment lifespan often outweigh the high initial machine price. Technological obsolescence of older, manual cleaning methods and the growing industrial commitment to ESG (Environmental, Social, and Governance) criteria also exert significant positive pressure on market growth.

The impact forces are fundamentally categorized into supply-side constraints, centered on the cost and logistics of CO2 supply, and demand-side pressure, driven by mandates for operational efficiency and sustainability. The ability of manufacturers to innovate through integrated dry ice production units or highly efficient pellet usage systems directly addresses the supply-side risks. Simultaneously, the growing demand from specialized sectors, such as mold remediation and historical preservation, offers high-margin niche opportunities. Navigating these constraints while capitalizing on the shift toward sustainable industrial practices is crucial for market participants aiming to capture long-term value.

- Drivers: Strict global environmental regulations; reduced equipment downtime; non-abrasive cleaning preserves asset integrity; enhanced worker safety compared to chemical alternatives; high cleaning efficacy across diverse contaminants.

- Restraints: High initial capital expenditure for machinery; dependence on reliable dry ice supply chain; potential safety hazards (CO2 monitoring required); limited awareness in developing industrial sectors; high operational noise levels in certain older models.

- Opportunity: Expansion into niche cleaning sectors (e.g., aerospace composites, semiconductor manufacturing); adoption of automated and robotic blasting systems (AI integration); growth of contract cleaning and rental services; technological advances leading to portable and quieter machines; integration with in-house dry ice manufacturing units.

- Impact Forces: ESG commitments and corporate sustainability mandates; Total Cost of Ownership (TCO) favorable comparison against traditional methods; accelerated adoption in advanced manufacturing hubs; energy efficiency standards for industrial equipment; global macroeconomic stability influencing industrial capital spending.

Segmentation Analysis

The Dry Ice Pellet Blasting Machine Market is meticulously segmented based on product type, operational pressure, application industry, and regional geography, allowing for precise market analysis and strategic targeting. Segmentation by product type typically differentiates between standalone blasting units, integrated systems that include dry ice production, and robotic/automated blasting cells. The operational pressure segmentation—low, medium, and high pressure—is critical as it dictates the suitability of the machine for various substrate sensitivities and contamination types. Medium-pressure systems dominate, offering versatility for general industrial maintenance and cleaning tasks. Understanding these segment dynamics is essential for market players to tailor product development and distribution strategies to meet the specific demands of specialized end-user environments.

Application segmentation remains the most detailed categorization, reflecting the core demand drivers. Key industries include Automotive and Aerospace, relying on precision cleaning of molds, fixtures, and internal components; the Food and Beverage sector, which mandates hygienic, chemical-free sanitation; and Power Generation, where dry ice is ideal for cleaning electrical equipment without moisture risk. Regional segmentation highlights the disparities in market maturity and regulatory environments, with North America and Europe focused on high-specification, automated systems, while APAC drives volume growth through basic to medium-level industrial usage. This structured analysis confirms that market growth is increasingly shifting toward high-value, integrated solutions that offer superior efficiency and repeatability across all end-use segments.

- By Type:

- Standard Blasting Systems (Mobile/Portable)

- Automated/Robotic Blasting Cells

- Integrated Systems (Blaster with Pelleting Unit)

- Micro-Particle Blasting Units

- By Pressure Range:

- Low Pressure (Below 75 PSI)

- Medium Pressure (75 PSI – 200 PSI)

- High Pressure (Above 200 PSI)

- By End-Use Industry:

- Automotive

- Aerospace and Defense

- Food and Beverage

- Printing and Packaging

- Oil and Gas

- Power Generation (Electrical Maintenance)

- Pharmaceutical and Medical Devices

- General Manufacturing and Foundries

- Mold Remediation and Restoration

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Dry Ice Pellet Blasting Machine Market

The value chain for the Dry Ice Pellet Blasting Machine Market begins with the upstream suppliers responsible for raw materials, primarily high-grade stainless steel, specialized composite materials for nozzles, advanced pneumatics, and sophisticated control systems. Critical upstream dependency also lies in the industrial gas sector, specifically the supply of liquid CO2, which is the foundational consumable. Manufacturers must maintain robust relationships with metal fabrication specialists and industrial component suppliers to ensure the production of durable, high-performance machines capable of withstanding extreme pressure and cyclical use. Efficiency in this initial stage directly impacts the unit cost, quality, and long-term reliability of the final blasting equipment.

Midstream activities involve the design, assembly, and testing of the dry ice blasting machines. This includes R&D focused on optimizing energy efficiency (air consumption), enhancing pellet-feeding mechanisms to prevent clogging, and developing ergonomic designs for operator safety and ease of use. Distribution channels represent a critical node, often employing a dual strategy: direct sales to major industrial end-users (e.g., global automotive OEMs) seeking custom, integrated solutions, and indirect distribution through specialized industrial equipment dealers and rental agencies. These indirect channels are vital for penetrating smaller markets and supporting the growing contract cleaning service segment, offering localized support and maintenance expertise.

Downstream analysis focuses on the end-users and the after-sales services crucial for market sustainability. This includes technical support, mandated safety training, and the continuous supply of spare parts (especially nozzles and hoses, which are high-wear components). Crucially, the downstream relies heavily on the CO2 supply logistics, as the efficacy of the machine is dependent on the quality and availability of dry ice pellets, often necessitating partnerships between equipment manufacturers and industrial gas suppliers to offer a complete solution package to the customer. Successful companies often establish extensive global service networks to minimize customer downtime, thereby enhancing the product's overall value proposition and ensuring long-term customer loyalty.

Dry Ice Pellet Blasting Machine Market Potential Customers

The potential customer base for Dry Ice Pellet Blasting Machines is extensive and highly diversified, spanning nearly all sectors where cleaning, surface preparation, or decontamination is a critical maintenance activity. Primary end-users include major multinational corporations within the Automotive industry, particularly for cleaning tooling molds, paint booth equipment, and welding robots without incurring corrosive damage. Similarly, the Aerospace sector represents high-value customers, utilizing the non-abrasive nature of dry ice for cleaning sensitive composite structures, engine components, and avionics, where minimizing Foreign Object Debris (FOD) risk is paramount. These customers prioritize machine reliability, precision control, and documented cleaning efficacy.

Beyond heavy industry, the Food and Beverage sector constitutes a rapidly expanding customer segment, driven by strict mandates for microbiological cleanliness and the need to avoid water usage and chemical residue in processing environments. Dry ice blasting is applied to clean conveyor belts, mixing equipment, ovens, and packaging machinery rapidly and hygienically. Furthermore, the contract cleaning and environmental restoration services market segment represents a significant bulk purchaser of machinery, deploying portable units for diverse applications such as fire restoration, mold remediation in buildings, and general heavy equipment maintenance for third parties. These service providers require robust, highly mobile machines with excellent reliability under continuous use.

Emerging high-potential customers include pharmaceutical companies, where the technology is used for cleaning tablet presses and controlled environment rooms, leveraging its sterile, residue-free characteristics. Power generation facilities (nuclear, coal, gas) are crucial buyers, utilizing dry ice blasting for cleaning turbine blades, generators, and heat exchangers, as it avoids electrical short circuits associated with liquid cleaning methods. Ultimately, any industrial entity seeking to reduce labor costs, minimize production downtime, meet rigorous environmental compliance standards, and extend the functional lifespan of specialized assets is a prime target customer for dry ice pellet blasting machine manufacturers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 285.5 Million |

| Market Forecast in 2033 | USD 451.9 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Cold Jet, Kärcher (Kärcher North America), IceTech A/S, Aquila Technik, Wuxi Yongjie Chemical Equipment, CO2Blast, ZHENHENG, Phoenix Unlimited, Inc., Arctic Dolphin, Continental Carbonic Products, Inc., CryoClean, ASCO CARBON DIOXIDE LTD, Tomco Systems, Inc., P-BLAST, ICS (Industrial Cleaning Systems), COLDMAX, Blast It All, Ice-Clean, CryoSnow, Dry Ice Energy GmbH. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dry Ice Pellet Blasting Machine Market Key Technology Landscape

The technological landscape of the Dry Ice Pellet Blasting Machine Market is rapidly evolving, driven primarily by the need for increased efficiency, precision, and ease of integration into modern manufacturing environments. A key development is the advancement in pellet dosing and feeding mechanisms. Traditional systems struggled with inconsistent pellet flow, leading to variations in cleaning results. Modern machines utilize sophisticated rotary feeders and patented agitation systems that ensure a constant, uniform stream of dry ice, which is crucial for achieving consistent surface finishes and reducing overall dry ice consumption. Furthermore, multi-component nozzle designs are gaining traction, allowing operators to fine-tune the blast pattern and media mix, sometimes incorporating a small amount of abrasive material for hybrid blasting applications that require mild etching or heavy paint removal, expanding the scope of the technology beyond non-abrasive cleaning.

Another pivotal technological shift is the focus on portability and autonomous operation. High-performance, compact heat exchangers and advanced pneumatic components are enabling the development of smaller, lighter, and more energy-efficient portable units that maintain high cleaning power. These units are essential for contract cleaning services and maintenance teams operating in confined or remote locations, such as wind turbine maintenance or shipyard cleaning. Concurrently, the rise of Industry 4.0 dictates the integration of blasting machines into centralized operational networks. New systems feature embedded IoT sensors for real-time monitoring of parameters like blast pressure, air temperature, and pellet consumption. This connectivity facilitates remote diagnostics, predictive maintenance scheduling, and automated performance reporting, aligning the technology with smart factory standards.

Further innovation is concentrated on maximizing operator safety and reducing noise pollution. Next-generation machine designs incorporate sophisticated sound dampening technology and ergonomic features to comply with increasingly strict occupational health and safety standards in developed regions. Additionally, research into micro-blasting utilizes extremely fine dry ice particles, sometimes combined with CO2 snow, to clean delicate surfaces in semiconductor, optical, and high-precision instrument manufacturing. This technological specialization addresses cleaning requirements at a microscopic level, previously unattainable by standard pellet blasting. The convergence of AI for process control, robotics for automation, and material science for enhanced nozzle longevity is defining the competitive advantage for leading market players.

Regional Highlights

Regional dynamics are central to the Dry Ice Pellet Blasting Machine Market strategy, reflecting varying industrial maturity, regulatory frameworks, and capital expenditure tendencies across the globe. North America remains a highly lucrative market, characterized by mature manufacturing and aerospace sectors, high labor costs encouraging automation adoption, and widespread environmental legislation (particularly in states like California) promoting non-chemical cleaning alternatives. The region is a leader in adopting specialized, high-cost equipment for precision tasks, demanding superior performance and integrated data logging capabilities for regulatory compliance. The widespread availability of CO2 supply infrastructure further supports robust market growth in the United States and Canada.

Europe demonstrates high adoption rates, driven by stringent European Union (EU) directives regarding industrial emissions, worker safety, and waste minimization. Countries like Germany, known for their advanced automotive manufacturing (OEMs and suppliers) and precision engineering, heavily utilize dry ice blasting for mold cleaning and robotic maintenance. The regional market is highly competitive, emphasizing energy-efficient machines and noise-reduction features to meet strict occupational health standards. Furthermore, the strong prevalence of high-value aerospace and pharmaceutical manufacturing in Western Europe ensures sustained demand for non-destructive cleaning solutions.

Asia Pacific (APAC) is forecasted to be the fastest-growing region, propelled by accelerating industrialization, massive foreign direct investment in manufacturing hubs (China, India, Vietnam), and rising quality standards in export-oriented industries. Although the initial adoption might focus on more basic, cost-effective machines, the rapid expansion of the automotive and electronics sectors is generating significant demand for automated and robotic blasting cells. Increased awareness of global best practices, particularly concerning equipment longevity and maintenance efficiency, is converting manufacturers away from traditional, abrasive cleaning methods. The emerging markets of Latin America and the Middle East & Africa (MEA) are seeing localized growth primarily in infrastructure, mining, and the oil and gas industries, where dry ice blasting offers a safe method for cleaning hazardous or electrically sensitive equipment.

- North America (U.S., Canada, Mexico): Market leader in adoption of advanced, automated blasting systems; high regulatory emphasis on environmental compliance; strong demand from aerospace and automotive sectors.

- Europe (Germany, UK, France, Italy): High penetration due to stringent environmental and labor safety standards; focus on energy efficiency and low-noise machines; strong usage in pharmaceutical and precision manufacturing.

- Asia Pacific (China, India, Japan, South Korea): Fastest growth region driven by rapid industrial expansion; increasing adoption in automotive and electronics manufacturing; demand shift from manual to automated cleaning processes.

- Latin America (Brazil, Argentina): Emerging market focusing on mining, infrastructure, and heavy industrial maintenance; high price sensitivity impacting equipment purchase decisions.

- Middle East and Africa (MEA): Growth concentrated in the Oil & Gas, Power Generation, and Infrastructure sectors; need for specialized maintenance solutions in harsh operating environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dry Ice Pellet Blasting Machine Market.- Cold Jet

- Kärcher (Kärcher North America)

- IceTech A/S

- Aquila Technik

- Wuxi Yongjie Chemical Equipment

- CO2Blast

- ZHENHENG

- Phoenix Unlimited, Inc.

- Arctic Dolphin

- Continental Carbonic Products, Inc.

- CryoClean

- ASCO CARBON DIOXIDE LTD

- Tomco Systems, Inc.

- P-BLAST

- ICS (Industrial Cleaning Systems)

- COLDMAX

- Blast It All

- Ice-Clean

- CryoSnow

- Dry Ice Energy GmbH

Frequently Asked Questions

Analyze common user questions about the Dry Ice Pellet Blasting Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Dry Ice Pellet Blasting and how does it work?

Dry ice pellet blasting is a non-abrasive cleaning method utilizing compressed air to propel solid CO2 pellets (dry ice) at high velocity. Cleaning occurs through kinetic impact, thermal shock causing surface contaminants to shrink, and immediate sublimation of the CO2 upon impact, leaving no secondary residue or moisture. This process is highly effective for cleaning complex industrial machinery in place.

Is dry ice blasting environmentally friendly and safe for equipment?

Yes, dry ice blasting is highly environmentally friendly because it uses reclaimed CO2, produces zero secondary waste (no solvents, chemicals, or wastewater), and is non-toxic. It is safe for most equipment, including electrical components and delicate molds, because it is non-abrasive, non-conductive, and does not damage the substrate surface.

What are the primary applications of dry ice blasting machines?

The primary applications span various sectors, including cleaning injection molds in the Automotive and Rubber industries, sanitizing equipment in Food and Beverage processing, removing contaminants from electric motors and turbines in Power Generation, and performing delicate surface preparation in Aerospace and Pharmaceutical manufacturing.

What factors restrain the growth of the Dry Ice Pellet Blasting Market?

The main restraints are the substantial upfront capital expenditure required for purchasing professional-grade blasting equipment and the logistical dependence on a consistent, reliable, and cost-effective supply chain for dry ice pellets, which requires specialized handling and storage infrastructure.

How is AI impacting the future of dry ice blasting technology?

AI is primarily driving automation, enabling robotic blasting cells that use machine vision to optimize cleaning trajectories and adjust operational parameters (pressure, flow rate) in real-time. This integration enhances efficiency, reduces material consumption, and provides precise, verifiable data for quality control and predictive maintenance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager