Dry Storage Cabinets Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443348 | Date : Feb, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Dry Storage Cabinets Market Size

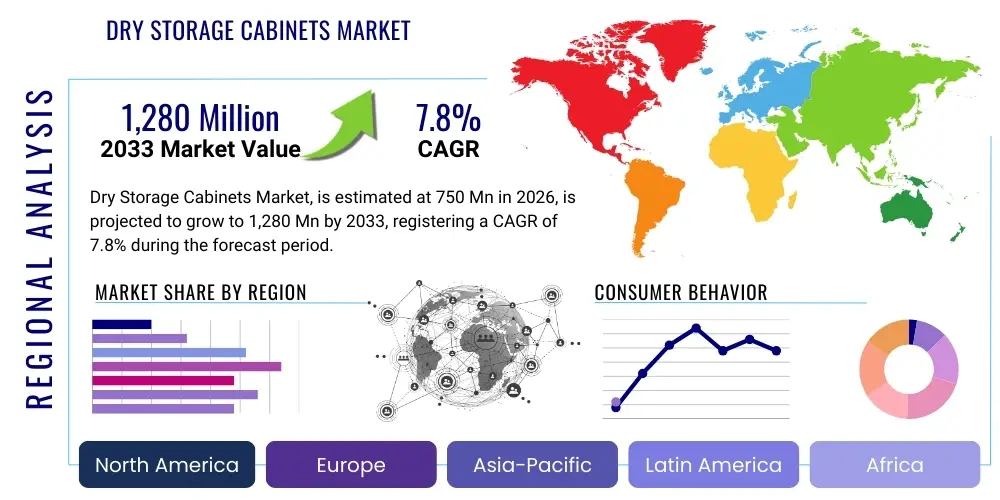

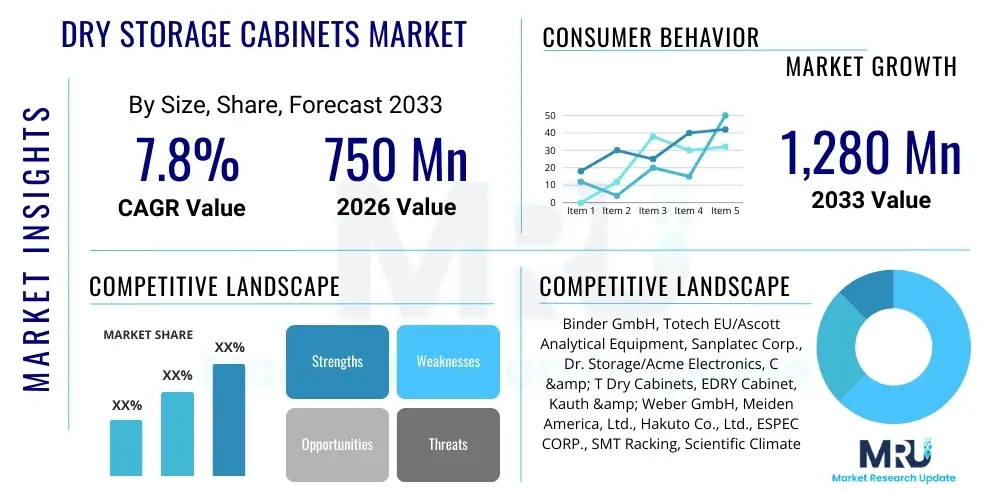

The Dry Storage Cabinets Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at $750 Million in 2026 and is projected to reach $1,280 Million by the end of the forecast period in 2033.

Dry Storage Cabinets Market introduction

The Dry Storage Cabinets Market encompasses highly specialized environmental control equipment designed to maintain ultra-low humidity levels, typically below 10% Relative Humidity (RH), for the preservation and protection of moisture-sensitive materials. These cabinets operate primarily using desiccant drying technologies, often utilizing specialized materials like zeolite or silica gel, coupled with sophisticated electronic control systems to ensure precise and stable internal atmospheric conditions. The fundamental objective is to prevent moisture absorption, which can lead to material degradation, corrosion, and catastrophic failure in high-value components, particularly in the electronics and specialized manufacturing sectors. The market growth is inherently tied to the increasing complexity and miniaturization of electronic components, demanding stricter environmental control throughout the manufacturing, storage, and assembly processes.

The primary application areas for dry storage cabinets are extensive, spanning Surface Mount Technology (SMT) manufacturing, where components like semiconductor devices, printed circuit boards (PCBs), and specialized adhesives must be stored per IPC/JEDEC standards to prevent moisture-induced damage during reflow soldering. Furthermore, these cabinets are indispensable in advanced research and development laboratories, aerospace and defense manufacturing, optical component storage, and pharmaceutical packaging lines. The benefits of deploying these systems are multifaceted, including extended shelf life of materials, mitigation of rework costs, improved product reliability, and compliance with stringent international quality standards. Modern dry storage solutions often incorporate features such as nitrogen purging capabilities for oxygen-sensitive materials, advanced data logging, and remote monitoring, transforming them from passive storage units into active environmental management systems.

The market is predominantly driven by the rapid expansion of the 5G infrastructure rollout, the burgeoning electric vehicle (EV) market, and increasing investment in advanced manufacturing techniques globally, particularly across the Asia-Pacific region. As electronic devices become smaller and more complex, their susceptibility to environmental moisture increases exponentially, making precise humidity control a mandatory requirement rather than an optional safeguard. The continuous pressure on manufacturers to minimize defects and maximize yields in high-volume production environments solidifies the essential role of dry storage cabinets in the modern industrial landscape. This sustained demand from critical high-tech industries ensures robust market expansion over the forecast period.

Dry Storage Cabinets Market Executive Summary

The Dry Storage Cabinets Market is experiencing significant upward momentum, driven by macro business trends emphasizing quality assurance, supply chain resilience, and technological integration across high-precision manufacturing industries. Key business trends include the shift toward decentralized manufacturing footprints, requiring standardized humidity control equipment across multiple global sites, and the growing adoption of smart factory principles (Industry 4.0), which mandates cabinets capable of real-time data communication and integration with Manufacturing Execution Systems (MES). Furthermore, the increasing use of Moisture Sensitive Devices (MSDs) in consumer electronics, automotive components, and medical devices directly correlates with higher investment in reliable, ultra-low humidity storage solutions. The competitive landscape is characterized by innovation in desiccant technology and electronic control precision, favoring providers who offer customizable, scalable, and energy-efficient solutions.

Regionally, the Asia Pacific (APAC) dominates the market due to its overwhelming concentration of global electronics manufacturing, specifically SMT operations in China, Taiwan, South Korea, and Japan. This region exhibits the highest demand volume, particularly for large-capacity, high-throughput cabinets used in mass production lines. North America and Europe, while possessing lower manufacturing volumes compared to APAC, represent critical markets due to high adoption rates of advanced, highly automated, and specialized dry storage cabinets used in high-value sectors such as defense, aerospace, pharmaceuticals, and specialized R&D. These regions prioritize sophisticated features like nitrogen backup, advanced environmental monitoring, and compliance validation. Emerging markets in Latin America and the Middle East are beginning to show substantial growth as local governments invest in building domestic high-tech industrial capabilities, generating new demand for foundational equipment like dry storage systems.

Segment trends reveal a strong preference for ultra-low humidity (ULH) cabinets capable of maintaining less than 5% RH, driven by the extremely sensitive nature of advanced semiconductor packaging and microelectronics. The technology segment is moving rapidly toward integrated IoT capabilities, allowing for predictive maintenance and streamlined auditing processes, which are critical for regulated industries. Application-wise, the electronics manufacturing segment remains the largest consumer, but significant growth is anticipated in the pharmaceutical and bioscience sectors, where precise atmospheric control is essential for storing reagents, active pharmaceutical ingredients (APIs), and specialized biological samples that degrade rapidly under ambient humidity. This convergence of demand for precision, automation, and regulatory compliance is shaping future product development strategies.

AI Impact Analysis on Dry Storage Cabinets Market

Users frequently inquire about how AI can enhance the reliability and efficiency of dry storage cabinets, specifically focusing on predictive maintenance, optimal energy consumption, and compliance automation. Common concerns revolve around whether AI-driven systems can anticipate potential desiccant saturation or component failure before critical moisture excursions occur, thereby preventing damage to high-value stored materials. There is a strong expectation that AI will move these systems beyond reactive control toward proactive environmental management, optimizing drying cycle timing based on usage patterns, external climate data, and real-time inventory sensitivity. This necessitates the development of algorithms that can process massive datasets concerning temperature, humidity fluctuations, door openings, and energy usage to provide actionable insights for facility managers and quality assurance teams, ultimately minimizing operational variance and ensuring uninterrupted compliance with stringent industry standards like IPC/JEDEC J-STD-033.

- AI-driven Predictive Maintenance: Utilizing machine learning models to analyze sensor data from desiccant rotors, dehumidifiers, and control electronics to predict component failure or performance degradation, scheduling maintenance proactively before moisture limits are breached.

- Optimized Energy Management: Implementation of AI algorithms to adjust drying cycles and regeneration schedules based on internal inventory load and ambient environmental conditions, minimizing electricity consumption while maintaining required RH levels.

- Automated Compliance Reporting: AI tools process continuous data logs, automatically flagging anomalies, generating audit-ready reports, and ensuring instantaneous adherence checks against predefined regulatory standards.

- Smart Inventory Placement: AI analyzes the Moisture Sensitive Level (MSL) of stored components and suggests optimal cabinet placement or configuration to maximize drying efficiency and minimize handling time.

- Usage Pattern Analysis: Machine learning interprets door opening frequencies and duration, adjusting the system recovery rate instantaneously to stabilize internal conditions faster after human interaction.

DRO & Impact Forces Of Dry Storage Cabinets Market

The Dry Storage Cabinets market is propelled by multiple converging forces, primarily the escalating demand for miniaturized and moisture-sensitive components across high-tech manufacturing sectors, coupled with increasingly strict international quality standards mandating controlled storage environments. The key drivers include the global push towards Industry 4.0, which necessitates integrated and data-logging capable storage solutions, and the fundamental growth of industries like automotive electronics (ADAS, infotainment), telecommunications (5G devices), and sophisticated medical instruments, all of which rely on high-reliability electronic assemblies. These drivers create a compelling need for storage infrastructure that guarantees component integrity, directly mitigating risks associated with reflow defects and subsequent field failures. The inherent benefits in yield improvement and cost reduction associated with proper dry storage provide a strong, quantifiable economic incentive for adoption across the supply chain.

However, the market faces significant restraints that temper overall growth, notably the high initial capital expenditure associated with purchasing advanced, high-precision dry storage cabinets, especially those with ultra-low humidity capabilities and integrated monitoring systems. Smaller manufacturers or those in price-sensitive markets often rely on less effective, passive storage methods or cheaper alternatives, limiting widespread penetration. Furthermore, the operational challenges related to integrating these systems into existing Manufacturing Execution Systems (MES) and the requirement for specialized training for maintenance staff can act as barriers to immediate adoption. The physical footprint of large-capacity cabinets in space-constrained facilities also presents a practical challenge in high-density urban industrial areas.

Opportunities for market expansion are substantial, particularly in developing customized and modular dry storage solutions that cater to specific niche requirements, such as explosive or cleanroom-compatible cabinets, or integrated handling systems that minimize human contact. The growing focus on environmental sustainability presents an opportunity for manufacturers to develop highly energy-efficient desiccant regeneration technologies that reduce operational costs. Furthermore, geographical expansion into emerging industrial hubs in Southeast Asia and Latin America, coupled with the rising demand from non-traditional applications like high-end food processing and museum conservation, provides new avenues for revenue generation. The primary impact forces—precision manufacturing demand and regulatory pressure—are sufficiently robust to ensure positive market growth, outweighing the current cost and integration restraints, positioning the market for sustained innovation and expansion.

Segmentation Analysis

The Dry Storage Cabinets Market segmentation provides a granular view of diverse product offerings based on technological capabilities, humidity control levels, and end-user requirements. The market is primarily segmented by Type (based on RH capacity), by Technology (desiccant type and control mechanism), and by Application (end-use industry). This structural division helps in understanding specific demand patterns, such as the increasing shift toward ultra-low humidity cabinets necessary for handling advanced semiconductor packaging (e.g., QFN, BGA components) where moisture sensitivity is paramount. The technology segmentation highlights the competitive advantage held by manufacturers developing energy-efficient, closed-loop desiccant regeneration systems, offering greater stability and lower long-term operational costs compared to nitrogen-purged or basic ambient dry boxes. Analyzing these segments is crucial for strategic market positioning and product development focused on specific high-growth sectors like automotive electronics and specialized pharmaceuticals.

- By Type:

- Standard Dry Storage Cabinets (10% RH to 20% RH)

- Ultra-Low Humidity (ULH) Cabinets (< 10% RH, often < 5% RH)

- Nitrogen Purge Cabinets

- Heated Dry Storage Cabinets

- By Technology:

- Desiccant Drying Technology (e.g., Zeolite, Silica Gel)

- Nitrogen Purging Systems

- Electronic Control Systems (PID, Fuzzy Logic Controllers)

- Integrated IoT/Data Logging Systems

- By Application:

- Electronics Manufacturing (SMT Assembly, Semiconductor Fabrication)

- Aerospace and Defense

- Pharmaceutical and Biotechnology

- Optical Components and Lenses

- Research and Development Laboratories

- By Volume/Capacity:

- Small (Under 300 Liters)

- Medium (300 Liters to 800 Liters)

- Large (Over 800 Liters)

- By Sales Channel:

- Direct Sales

- Distributors and Resellers

Value Chain Analysis For Dry Storage Cabinets Market

The value chain for the Dry Storage Cabinets market begins with the upstream segment, which involves the sourcing and processing of core raw materials and specialized components critical for the cabinet's function. This includes high-grade sheet metal (steel or aluminum) for structural integrity, advanced polymers for seals and windows, sophisticated electronic components such as humidity and temperature sensors (often high-accuracy relative humidity sensors like capacitive or resistive types), PID control boards, and, most crucially, specialized desiccant materials (e.g., Zeolite, which offers excellent regeneration properties and low dew points) or nitrogen gas suppliers for purge systems. Efficiency and quality control in this upstream stage are paramount, as the precision of the sensors and the regenerative efficiency of the desiccant directly determine the cabinet's performance and long-term stability. Strategic relationships with reliable, specialized component manufacturers are vital for sustaining quality output.

The middle segment of the value chain involves the manufacturing, assembly, and integration processes. This includes precision welding and fabrication of the cabinet housing, insulation installation, integration of the drying unit (desiccant rotor or chamber), and meticulous calibration of the electronic control system. Manufacturers must invest heavily in R&D to optimize airflow dynamics within the cabinet, ensuring uniform humidity distribution across all shelves, which is a major performance differentiator. Testing and quality assurance procedures, often involving prolonged run-in periods and calibration against NIST-traceable standards, are essential before product release. Value addition at this stage is achieved through superior design, modularity, energy efficiency enhancements, and integration of smart features like remote data monitoring capabilities.

The downstream segment focuses on distribution, sales, installation, and post-sale support. Distribution channels are varied, involving both direct sales to major multinational corporations with complex, bespoke requirements, and indirect sales through specialized industrial equipment distributors and regional resellers who possess deep local knowledge of specific industry compliance needs (e.g., SMT standards in APAC). Post-sales services, including regular calibration, desiccant replacement, software updates for integrated IoT systems, and prompt technical support, constitute a significant portion of the value proposition. The effectiveness of the distribution channel and the quality of the service network directly influence customer satisfaction and market reach, especially in geographically dispersed high-tech manufacturing areas.

Dry Storage Cabinets Market Potential Customers

Potential customers, or end-users/buyers, of dry storage cabinets are concentrated in industries that mandate precise environmental control to prevent material degradation, maintain component reliability, and comply with strict quality standards. The primary consumer base originates from the electronics manufacturing sector, particularly companies involved in Surface Mount Technology (SMT) assembly and semiconductor fabrication. These firms utilize cabinets extensively for storing Moisture Sensitive Devices (MSDs) such as integrated circuits, microchips, printed circuit boards, and specialized solder pastes, adhering strictly to IPC/JEDEC J-STD-033 standards to mitigate risks of popcorn effects and delamination during reflow soldering. The financial impact of component failure in these high-volume operations makes dry storage an essential, non-negotiable capital investment.

Beyond electronics, significant demand stems from the aerospace and defense industries, where the reliability of electronic and composite materials stored over extended periods is crucial for mission-critical applications. These sectors require cabinets offering highly verifiable data logging, robust construction, and often compliance with military specifications regarding storage and traceability. Furthermore, the pharmaceutical and biotechnology sector represents a growing customer segment, utilizing dry storage for preserving high-value, humidity-sensitive reagents, diagnostic test kits, and certain bulk Active Pharmaceutical Ingredients (APIs) where moisture contamination could compromise efficacy or stability. The demand here is driven by Good Manufacturing Practice (GMP) requirements and stringent regulatory oversight.

Additional potential customers include specialized laboratories (R&D, materials testing), manufacturers of high-end optical equipment (lenses, sensors, lasers) where even minor moisture contamination can cause irreparable fogging or corrosion, and specialized archival institutions, such as museums and libraries, preserving sensitive historical documents and artifacts. The purchasing decision for all these customer groups is rarely based solely on price; rather, it hinges on demonstrable performance (ultra-low RH stability), reliability (uptime and minimal maintenance), and the cabinet's ability to provide comprehensive, auditable environmental data logs that satisfy internal quality control measures and external regulatory bodies.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $750 Million |

| Market Forecast in 2033 | $1,280 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Binder GmbH, Totech EU/Ascott Analytical Equipment, Sanplatec Corp., Dr. Storage/Acme Electronics, C & T Dry Cabinets, EDRY Cabinet, Kauth & Weber GmbH, Meiden America, Ltd., Hakuto Co., Ltd., ESPEC CORP., SMT Racking, Scientific Climate Systems, Super Dry, Terra Universal, Inc., ULO Systems GmbH, Secador, Hanmi F&I Co., Ltd., Geesys Technologies, SMT Dry Box, GTE |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dry Storage Cabinets Market Key Technology Landscape

The technological landscape of the Dry Storage Cabinets market is characterized by advancements focused on achieving lower humidity levels with greater energy efficiency, higher stability, and enhanced connectivity. The core technology remains adsorption drying, predominantly utilizing specialized desiccant materials like zeolite, which possesses high moisture absorption capacity and efficient regeneration cycles. Current innovation centers on optimizing the desiccant rotor design and the regeneration process (often closed-loop systems), ensuring that the humidity recovery time after door opening is minimized, which is a critical performance indicator in high-throughput manufacturing environments. The integration of advanced Proportional-Integral-Derivative (PID) controllers and Fuzzy Logic algorithms allows cabinets to intelligently adapt their drying power based on internal and external environmental fluctuations, maintaining ultra-precise RH levels (e.g., < 1% RH in some specialized ultra-low models) essential for high-end microelectronics.

A major technological shift is the widespread adoption of IoT (Internet of Things) and connectivity features, transforming dry storage cabinets into smart assets within the Industry 4.0 ecosystem. Modern cabinets are equipped with built-in data logging capabilities, storing multi-year records of humidity, temperature, and door access events. Crucially, they facilitate remote monitoring via centralized dashboards or MES integration, allowing quality managers to track hundreds of cabinets across multiple global sites in real-time. This connectivity is vital for compliance auditing, as it provides an immutable record of environmental conditions, thereby confirming that sensitive materials were stored appropriately according to J-STD-033 or internal quality protocols. Furthermore, predictive analytics, often integrated through cloud-based platforms, utilizes this logged data to signal potential component wear or desiccant exhaustion before performance issues arise.

Another emerging technology involves specialized gas purging systems, particularly nitrogen purging, which are utilized in environments where not only moisture but also oxygen exposure must be minimized—such as for specialized chemical storage or highly sensitive optical components. These systems often work in conjunction with desiccant drying technology, offering a multi-layered approach to environmental control. Material science innovations are also playing a role, with manufacturers optimizing cabinet seal materials and insulation to minimize ambient air infiltration and reduce energy expenditure required for maintaining setpoint humidity. The focus on energy efficiency is becoming a major competitive factor, driven by corporate sustainability goals and the rising cost of industrial energy usage.

Regional Highlights

Regional dynamics significantly influence the Dry Storage Cabinets market, reflecting global manufacturing concentrations and technological adoption rates. Asia Pacific (APAC) dominates the market share due to its unparalleled position as the global hub for electronics manufacturing, including semiconductors, consumer devices, and automotive components. Countries such as China, Taiwan, and South Korea house massive SMT production lines that require thousands of large-capacity dry storage cabinets to manage the logistics of millions of moisture-sensitive devices (MSDs). The high volume of production and continuous investment in new fabrication facilities ensure sustained high demand across the forecast period. Furthermore, government initiatives supporting domestic advanced manufacturing in countries like India and Vietnam are contributing to regional expansion.

North America holds a substantial market position, characterized by high adoption of technologically advanced, specialized dry storage solutions. Demand in this region is driven heavily by the aerospace and defense sectors, highly regulated pharmaceutical and biotech industries, and advanced R&D institutions. Customers here prioritize cabinets with high precision, compliance features, detailed data logging, and integrated security measures, often opting for ultra-low humidity and nitrogen purging systems for specialized, high-value components. The robust defense industry expenditure and significant investment in cutting-edge research ensure a steady demand for premium-priced, high-performance units.

Europe represents a mature and stable market, emphasizing quality, energy efficiency, and compliance with stringent environmental and industrial regulations. Key demand comes from the automotive manufacturing sector, precision engineering, and the pharmaceutical industry, particularly in Germany, France, and the UK. European customers typically seek long-lasting, highly reliable cabinets that offer the lowest possible operational costs and possess certifications that validate their environmental control performance. The region is also a key center for innovation in specialized desiccant technology and electronic controls.

Latin America and the Middle East & Africa (MEA) currently hold smaller market shares but are projected to exhibit high growth rates. This growth is linked to the diversification of local economies, increasing foreign direct investment in manufacturing and assembly plants, and the establishment of local pharmaceutical production facilities. As these regions expand their high-tech industrial base, the foundational requirement for sophisticated environmental control equipment like dry storage cabinets will surge.

- Asia Pacific (APAC): Market leader due to concentration of SMT manufacturing; high demand for large-capacity, high-throughput cabinets; focus on cost-efficiency and volume.

- North America: Driven by aerospace, defense, R&D, and pharmaceutical compliance; preference for highly advanced, data-logging capable, ultra-low RH systems.

- Europe: Stable market with strong focus on quality, precision engineering, and energy efficiency; high regulatory standards drive demand for certified equipment.

- Latin America (LATAM): Emerging market growth driven by industrialization and rising electronics assembly activities; increasing need for basic and standard dry storage solutions.

- Middle East & Africa (MEA): Growth tied to diversification efforts, establishment of biotech/pharmaceutical centers, and specialized oil and gas electronics maintenance requirements.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dry Storage Cabinets Market.- Binder GmbH

- Totech EU/Ascott Analytical Equipment

- Sanplatec Corp.

- Dr. Storage/Acme Electronics

- C & T Dry Cabinets

- EDRY Cabinet

- Kauth & Weber GmbH

- Meiden America, Ltd.

- Hakuto Co., Ltd.

- ESPEC CORP.

- SMT Racking

- Scientific Climate Systems

- Super Dry

- Terra Universal, Inc.

- ULO Systems GmbH

- Secador

- Hanmi F&I Co., Ltd.

- Geesys Technologies

- SMT Dry Box

- GTE

Frequently Asked Questions

Analyze common user questions about the Dry Storage Cabinets market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of an ultra-low humidity (ULH) dry storage cabinet?

The primary function of a ULH dry storage cabinet is to maintain internal relative humidity levels consistently below 10% RH (often 5% RH or lower) to protect highly moisture-sensitive materials, such as semiconductor components (MSDs) and specialized optical sensors, from moisture absorption, preventing defects like component delamination during reflow soldering processes.

How is the growth of the Dry Storage Cabinets Market influenced by Industry 4.0?

Industry 4.0 accelerates market growth by driving the demand for smart dry storage solutions integrated with IoT connectivity. These advanced cabinets offer real-time data logging, remote monitoring, and automated compliance reporting, enabling seamless integration into Manufacturing Execution Systems (MES) for optimized, centralized environmental management.

What are the key technological differences between desiccant drying and nitrogen purging cabinets?

Desiccant drying cabinets use renewable chemical agents (like zeolite) to adsorb moisture from the air, maintaining low RH and requiring periodic regeneration. Nitrogen purging cabinets displace internal oxygen and moisture using inert nitrogen gas, achieving extremely low RH/oxygen levels, which is preferred for materials requiring both moisture and oxidation control.

Which geographical region represents the largest demand segment for dry storage cabinets?

The Asia Pacific (APAC) region currently holds the largest market share due to its overwhelming concentration of global electronics manufacturing, particularly Surface Mount Technology (SMT) and semiconductor fabrication, which necessitates large volumes of humidity control equipment to meet stringent quality standards like J-STD-033.

What are the typical end-user industries driving the market growth?

The market growth is primarily driven by the electronics manufacturing sector (SMT assembly), followed significantly by the aerospace and defense industry, pharmaceutical and biotechnology companies storing sensitive APIs and reagents, and specialized R&D laboratories requiring high-precision atmospheric control.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager